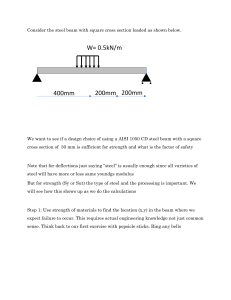

Mechanics of Materials: Shafts, Stress, and Bending Problems

advertisement

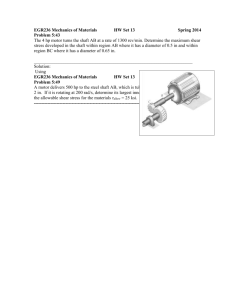

Mechanics of Materials Chapters 5 and 6 12/28/2009 by Shun-Fa Hwang 1/3 1. A steel tube having an outer diameter of 2.5 in. is used to transmit 350 hp when turning at 27 rev/min. Determine the inner diameter d of the tube to the nearest 1/8 in. if the allowable shear stress is allow 10 ksi. (1 hp=550 ft•lb/s)[15%] 2. The two solid steel shafts shown are coupled together using the meshed gears. Determine the angle of twist of end A of shaft AB when the torque T=45 N•m is applied. Take G=80 GPa. Shaft AB is free to rotate within bearings E and F, whereas shaft DC is fixed at D. Each shaft has a diameter of 20 mm. [20%] 2/3 3. The shaft is made from a solid steel section AB and a tubular portion made of steel and having a brass core. If it is fixed to a rigid support at A, and a torque of T= 50 lb•ft is applied to it at C, Determine the angle of twist that occurs at C and compute the maximum shear stress and maxiumu shear strain in the brass and steel. Take Gst 11.5(103 ) ksi, Gbr 5.6(103 ) ksi. [15%] 4. Draw the shear and moment diagrams for the beam. [15%] 5. 3/3 The aluminum machine part is subjected to a moment of M=75 N•m. (a) Determine the bending stress created at points B and C on the cross section. (b) Determine the maximum tensile and compressive bending stress in the part. [20%] 6. The beam has the rectangular cross section shown. If P=12kN, determine the absolute maximum bending stress in the beam. [15%]