Nucleation and Growth in a Eutectoid Steel

advertisement

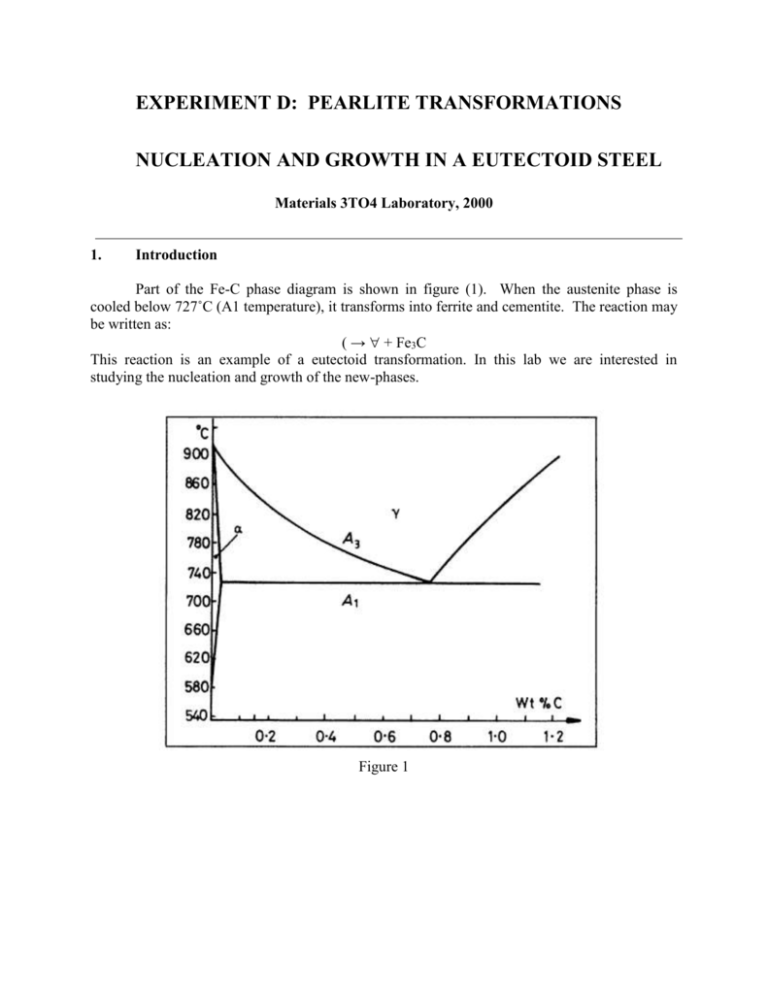

EXPERIMENT D: PEARLITE TRANSFORMATIONS NUCLEATION AND GROWTH IN A EUTECTOID STEEL Materials 3TO4 Laboratory, 2000 1. Introduction Part of the Fe-C phase diagram is shown in figure (1). When the austenite phase is cooled below 727˚C (A1 temperature), it transforms into ferrite and cementite. The reaction may be written as: → + Fe3C This reaction is an example of a eutectoid transformation. In this lab we are interested in studying the nucleation and growth of the new-phases. Figure 1 2 2. BACKGROUND 2.1 Pearlite Consider, the specific example of a steel containing 0.78 wt% C. When the temperature drops below 727˚C, the austenite phase is no longer stable with respect to ferrite and cementite. The new phases will nucleate on grain-boundaries. Consider the formation of a ferrite nucleus. The solubility of C in ferrite is less than 0.05 wt%. Consequently, carbon must diffuse out of the areas that form ferrite (i.e. the carbon is rejected from the ferrite). This will increase the carbon content of the surrounding areas leading to the nucleation of cementite. This then sets up the process of cooperative growth where carbon is partitioned away from the growing ferrite and into the growing cementite by diffusion in the austenite ahead of the reaction interphase. The resulting microstructure is shown in figure (2). The alternating layers of ferrite and cementite are collectively referred to as pearlite. The pearlite appears to grow into the adjoining grains as nodules as shown in figure 2b. Each nodule contains one or more colonies: a colony refers to adjacent ferrite and cementite sheets having the same orientation and growing in the same direction. In this lab we will study the kinetics of the → pearlite transformation. Figure 2a Figure 2b 3 2.2 The Avrami (JMAK) Equation Consider a Fe-0.78%C alloy that was cooled rapidly from 900ºC (austenite range) to 700ºC (+ cementite range). If we measured the pearlite volume fraction as a function of time, a sigmoidal curve is obtained (figure 3). The initial period where no pearlite is formed is referred to as the incubation period. It reflects the fact that diffusion is needed in order to form the nuclei. Following the incubation period, nucleation and growth occur rapidly, leading to an exponential increase in the pearlite fraction with time. Finally, impingement occurs and rate of transformation is reduced. Figure 3 In the late 1930's, Johnson, Mehl, Avrami and Kohnogorov modelled the transformation kinetics. The model is now commonly referred to as the INIAK or Johnson-Mehl model. We will derive the model for the simple case of a constant nucleation rate N (nucleus/sec/m 3) and a constant growth rate G (m/sec): The volume of a single new grain as a function of time is: V = 4/3 (G t)3. The total volume fraction of new phase is obtained by summing up (integrating) the volumes of all new grains within one m3: t 4 X total G 3 t 3 dn 0 3 where n is the number of grains. We can express n as a function of time; n = N t. Therefore: t 4 X total G 3 t 3 Ndt 0 3 The integration is straightforward because G and N are both assumed to be independent of time. One therefore obtains, 4 X total 3 4 G t N 3 The volume fraction is always between 0 and 1. If you examine the above expression, however, Xtotal as t . To understand the mistake that we have made consider a sample where 75% of the austenite has already transformed to pearlite. We assumed a constant nucleation rate of N nuclei per sec per m3. These nuclei can only form in the untransformed material (i.e. in austenite). If the total volume is 1 m3, the volume of austenite is (100% - 75%) or 25% of 1 m3. More generally, the volume of austenite is (1-X) * 1 m3. Our previous analysis ignored the correction factor of (1-X). To obtain the real volume fraction (X) form the total (extended) volume fraction we simply apply a correction of (1X): dX = (IX) dXtotal , Rearranging this expression we get: dX dX total 1 X integrate 1 ln X total 1 X exponentiate 1 exp( X total ) 1 X rearrange X = 1exp(Xtotal) substitute Xtotal 4 3 4 X 1 exp G Nt 3 Which is the JMAK equation. More generally, the equation is written as: X= 1exp (b tm) where b and m are constants. The exponent, m, is known as the Avrami or the JMAK exponent. Typical values of m are between 1 and 4. Try plotting X with b = 1 and m = 4 to convince yourself that this expression does indeed give a sigmoidal curve. 5 2.3 Isothermal Transformation (IT or TTT) Diagram The eutectoid transformation of steel is an extremely important practical reaction used by the steel industry to impart specific properties on steels. As such, it is of great importance to understand and be able to predict the speed with which this reaction will occur (if this reaction will occur at all). For example, if we want to produce a steel with the optimum hardness we would want to convert all of the austenite to martensite. Martensite may be formed by rapidly cooling a sample by quenching such that the above described pearlite reaction does not have time to occur. For us to know whether this is possible we must have a means of knowing the amount of pearlite transformation as a function of steel composition, temperature and time. This information is typically plotted as a time, temperature, transformation (TTT) diagram (figure 4). Figure 4 The first step in constructing a TTT diagram is plotting the transformed fraction as a function of time for different transformation temperatures. The information from the X-t plots is then condensed into a single TTT diagram as shown in figure 5. Note how each X-t diagram contributes one point to the TTT diagram. Typically, this point corresponds to the time needed to achieve a transformed fraction of 1% (start) or 99% (finish). Knowing the time spent at a given temperature one is able to predict the microstructure of the alloy. The TTT diagram has a "C" shape reflecting the fact that the kinetics are determined by two factors, namely, the driving force and the diffusion kinetics. Just below the A1 temperature, diffusion is fast, but the driving force is small. As a result, the transformation time is very long. At very low temperatures, the driving force is large, but now the diffusion coefficient is very small. Again, the transformation is very slow. There is an intermediate temperature range (nose of the C-curve) where the transformation is very fast because the driving force and the diffusion coefficient are both large. 6 Figure 5 2.4 Continuous Cooling (CCT) Diagrams The use of isothermal transformation (TTT) diagrams to predict the kinetics of the eutectoid transformation is relatively simple. In industrial practice, however, most heat treatments are far from being isothermal. Instead, most treatments involve the continuous cooling of a sample. In this case, the TTT diagram is not expected to predict the phase transformations accurately. To deal with this, a lot of time and effort has been put into the development of continuous cooling transformation (CCT) diagrams like the one shown in figure 6. To a first approximation the CCT diagram is just a TTT diagram shifted to lower temperatures and longer times. To a first approximation, this may be attributed to the fact that in a continuously cooled sample, fewer nuclei form initially compared with an isothermally transformed sample since few nuclei can form just below the A1 temperature. Finally, note that whereas the TTT diagram is interpreted by reading from left to right at constant temperature, the CCT diagram is read along the cooling curve going from top left to bottom right. A number of ways have been used to construct the CCT diagram. Experimentally, CCT diagrams may be determined from the Jominy end-quench test (figure7). In this test a bar of steel is austenitized for a period of time before being quickly removed from the furnace and placed in a rig which sprays water on the end of the sample. The sample then experiences different rates of cooling along its length. A CCT diagram may be roughly produced by plotting cooling curves corresponding to different positions along the sample length and observing the microstructure at these positions. 7 Figure 6 Figure 7 8 The Jominy test has a second, perhaps more common, use in determining the hardenability of a sample. The hardenability may be defined as the ability of a steel to harden by the formation of martensite on quenching. This must not be confused with the hardness of a sample. A sample which has a large hardenability is one which may be cooled relatively slowly and still produce a fully matensitic structure. In other words, such a material would be one that has its CCT start curve (X = 1%) shifted far to the right so that pearlite is not formed if the sample is quenched from above the Al temperature. In a Jominy test the cooling rate decreases along the length of the sample in a way that is well know. Therefore, it may be used to determine the hardenabiltiy of a given steel. This is normally determined by plotting the hardness of the sample as a function of the distance along the its length (top of figure 6). If the hardness of a fully martensitic sample is known, then the critical cooling rate may be determined from knowledge of the distance along the sample at which the hardness drops below this level. Finally, the Jominy test is frequently used by steel producers and heat treaters as a means of predicting the hardness profile across heat treated and quenched rods. Standard chats exist which allow the cooling rate along a Jominy sample to be related to the cooling rates within quenched rods. In this way the hardness data determined from the Jominy test may be used to predict the hardness profile across industrially heat treated bars of various diameters. 3. PROCEDURE This lab is made up of two separate experiments; isothermal transformation and continuous cooling transformation. 3.1 Isothermal Transformation For this portion of the lab we will use a 1070 plain carbon steel with the composition given below. C 0.72 Mn 0.76 S 0.02 max P 0.02 max Cu 0.01 max Si 0.24 Cr 0.06 The material is in the form of drawn rod approximately 20 mm in diameter with a hole drilled through it so that a wire can be threaded through for handling. The heat treatment will be performed using two salt baths. The one on the left is used to austenititze the sample while the second bath is used for the isothermal annealing treatment. The procedure is as follows: 9 Important: Extreme caution should be exercised when working with molten salts. An obvious concern is the high temperature. A second concern is the reactivity of the salt. Contact with the skin will result in severe burns. It is mandatory to wear a full face mask and heatresistant gloves when working around the salt baths. Keep water, dust and paper way from the bath as these will react with the salt. 1. When you arrive at the lab, the samples will be in the austentitizing bath at 900C. Each sample will have a wire attached. 2. When the one hour austenitizing period has passed, remove one sample from the first bath and place it quickly in the second salt bath. The transfer must be done very quickly so as to avoid cooling the sample below 700C. Also make sure the sample does not touch anything on its way into the salt pot. 3. Leave the sample in the salt bath at the transformation temperature for the required length of time, then quickly remove it and drop into the water bucket. 4. Repeat this procedure for each sample. The transformation times are: 100, 200, 300, 400, 600 seconds. 5. Once all the samples have been heat treated they must be mounted, polished and etched with 2% nital. It is very important that the polishing is done very well to ensure good results from the image analyzer. 6. 3.2 Use the image analysis system to determine the total area fraction of pearlite as well as the number and size distribution of the pearlite colonies for each specimen. Continuous Cooling - The Jominy Test In this test we will use an alloy produced by Atlas Steels. The alloy is designated as SPS, it is essentially a 1040 steel with Cr added to improve the hardenability. The chemistry of the alloy is as follows: C 0.72 Mn 0.76 S 0.02 max P 0.02 max Cu 0.01 max Si 0.24 Cr 0.06 The procedure is as follows: 1. The Jominy bars will be placed in an Inconel heat treat box filled with pitch coke. The coke is needed to minimize the decarburization of the steel. The box is then placed in a furnace at 900C for 1/2 hour. 10 2. Quench the sample in the Jominy tank. It should take no more than 5 seconds to transfer the sample from the furnace to the quench tank and begin quenching. When setting up the Jominy tank make sure that the height of the water jet is 6 cm. The water should be turned on immediately following the placement of the sample in the tank. 3. Leave the sample in the quench tank for at least 30 minutes. 4. Grind two parallel flats 180 apart and 0.015 inch deep. Avoid overheating the sample during grinding. Hardness testing is done by mounting the sample bar in a special jig which mount on the elevating screw of the Rockwell harness tester. The jig is calibrated in inches. 1. Measure at 1/16" intervals for the first inch. 2. Measure at 1/8" intervals for the second inch. 3. Measure at 1/4" for the remainder of the bar. 5. 4. LAB REPORT Please follow the following format: 1. One lab is to be handed per person two weeks after the second lab period. 2. The lab write up should include: a) Purpose: (Short, 3-4 sentences explaining what we are trying to do). b) Observations: Include: - a plot of the pearlite fraction as a function of time, - briefly described the microstructure observed on the microscope, - plot of the hardness as a function of distance, - include error bars for all plots. c) Discussion: Answer the questions given below: d) Sources of Error: (describe any sources of errors that may have influenced your results). 11 QUESTIONS FOR DISCUSSION A. Isothermal Transformation Experiment Al: From your X-t plot determine the values of B and m in the JMAK model. A2: If possible try to obtain a rough value of the growth rate (G) of the pearlite colonies. A3: Why is it necessary to use thin samples for this experiment? Can you see any advantages for using a salt bath rather than a normal furnace? A4: The addition of solutes (e.g. Mn, Cr, Si.... etc) will affect the shape and position of the Ccurve. Describe any two mechanisms by which the solutes are able to bring about such changes. B. Continuous Cooling Experiment B 1: From your plot of hardness vs. distance, estimate the minimum cooling rate necessary to obtain a fully martensitic structure. How can you increase the minimum cooling rate a) by changing the composition and b) without changing the composition of the steel. B2: Sometimes in the Jominy test, one initially observes an increasing hardness as one moves away from the quenched end. Under these circumstances, the maximum hardness does not coincide with the maximum cooling rate. Why? C. Other Questions Cl: Explain the differences between the TTT and CCT curves. Suppose you are concerned with the formation of martensite following welding. Which curve will you use to analyse the process? C2: How do you explain the sigmoidal shape of the X vs. t curve? Do you expect a plot of the recrystallized fraction vs. t to look the same? C3: Consider the precipitation of the -phase in Al. The overall reaction is: Al (supersaturated) (Al) + . A plot of the precipitate fraction as a function of time will show sigmoidal kinetics. In this case, however, the maximum precipitate fraction is a few percent (say 3%) and the physical impingement of the precipitates will not take place. How can we explain the levelling off of the curve? C4: How do you explain the "C" appearance of the TTT-diagram? Give an example of a phase transformation where C-Curve kinetics are not expected. Explain your example. 12 C5: The nucleation of pearlite is known to occur on grain-boundaries. What effect would a coarser grain size result in? Do you expect the austenitizing temperature to affect the Ccurve kinetics? How? C6: A heat treating company wishes to predict the hardness profile across a bar of SPS steel. The bar was austenitized for 1 hour at 900C. It was then quenched into water at a rate of 60 m/min. If the bar is 62.5 mm in diameter, plot the hardness profile using your experimentally determined data along with figure 8 below. How would the profile change if oil (faster cooling rate) was used instead of water? Figure 8 REFERENCES D.A. Porter and K. E. Easterling, Phase Transformations in Metals and Alloys, Chapman Hall, New York, 1992. (Pearlite, TTT, CCT). A.K. Sinha, Ferrous Physical Metallurgy, Butterworth, Stoneham, MA, 1989. (Pearlite, TTT, CCT). ASM Handbook, volume 9, p. 37 (Quantitative Metallography).