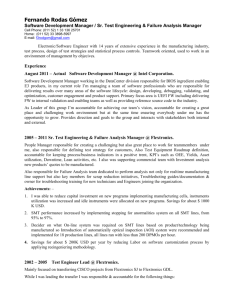

NEW - MIT

advertisement