AVIATION STOREKEEPER STUDY GUIDE

advertisement

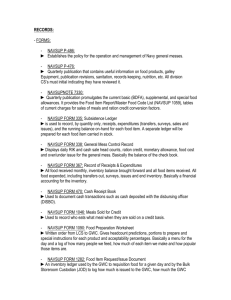

AVIATION STOREKEEPER STUDY GUIDE FSC GROUPS : 10 - Weapons 15 – ACFT & airframes structural components 16 – ACFT components 26 – Tires 28 – Engines 51 – Handtools 53 – Hardware & abrasives 59 – Electrical components 65 – Medical and dental supplies 67 – Photographic equipment 71 – Furnture 75 – Office supplies 79 – Cleaning equipment 81 – Containers 84 – Flight Deck Boots, flight clothing 91 – Fuels 99 – Miscellaneous SSIC’s Secnavinst 5210.11 1000 – Military personnel 2000 – Telecommunications 3000 – Operations 4000 – Logistics 5000 – General admin. 6000 – Medicine / Dentistry 8000 – Ordnance 9000 – Ships Designs / mat’l 10000 – General mat’l 11000 – Facilities / activities ashore 12000 – Civilian personnel 13000 – Aeronautical / Astronautical Mat’l Aircraft Inventory Record (AIR) OPNAV 4790/109 – Binder OPNAV 4790/110 – Ttile page / Sectional breakdown OPNAV 4790/111 – Equipment list OPNAV 4790/112 – Shortage list OPNAV 4790/104 – Certification & record of transfers Mode of Shipment Codes 1 F- MAC (Military Airlift Command) G- Service parcel post H – Air parcel post N – Logair Q – Air freight R – Air express S – Air charter T – Air freight forwarder Z- Military sealift command 2 – Gov’t watercraft (barge) 5 - UPS 6 - MOM 9 – Local delivery U - Quicktrans X – Bearer walk thru Record Type Codes 60 – Weapons 61 – RFI 62 – Deletion 63 – Non-RFI 64 – Technical directives 65 – Initial issue 66 – Servmart 67 – PEB Purpose Codes A – General issue (ASO) assets L – Pack-up kits W – Special pools program (SUPPO) assets MRIL Shipping Codes WW – Dispose of locally XX – Turn-in to nearest industrial NAS ( depot ) YY – Dispose of in accordance with local inst. ZZ – Requset turn-in instructions from item manager Advice Codes 2B – Do not sub 5A – Survey 5G – One for one exchange 5S – Remain in place (CRIPL) 5V – P/N for P/N 5D – In 53 – 5A/2B combo 5X – Stock replenishment 52 – 2B/5S combo Demand Codes R – Recurring demand N – Non recurring demand O – No demand 2 Media & status codes A – 100 % supply and shipment status to requisitioner by mailer prepared by DAAS B – 100 % supply and shipment status to requisitioner by autodin Service Designator Codes R – Pacific fleet operating units ( including ships ) V – Atlantic fleet operating units ( including ships ) N – Activities ashore ( NAS’s ) Shelf Life Condition Codes A – More than 6 months B – 3-6 months C – Less than 3 months Material Control Codes D – Field level repairables E – DLR designated for intensive management under IRAM H – Depot level repairables L – Items of local stock or items pending stock number M – Medium velocity demands consumables S – Slow demand velocity items ( consumables ) T – Terminalitems W – End use items X – Special program repairable items Z – Special program consumables Repair Capability Codes C1 – Full capability C3 – Limited capability A1 – test and check X1 – Repair not authorized X2 – Lack of equipment / tools / facilities X3 – Lack of technical skills 3 X4 – Lack of required test equipment X6 – Lack of technical data Z1 – Consumable material BCM Codes ( Beyond Capability of Maintenance ) 1 – Repair not authorized 2 – Lack of tools, equipment or facilities 3 – Lack of technical skills 4 – Lack of parts 5 – Fails test and check 6 – Lack of technical data 7 – Beyond authorized repair depth 8 – Administrative (EI, QDR ) 9 – Condemned Supply Condition Codes A – RFI material F – Whole NON-RFI material G – Incomplete NON-RFI material SM&R Codes P A G G D 6 (1) (2) (3) (4) (5) (6) (1) & (2) – source codes (2) & (4) - maintenance codes (5) – recoverability code (6) – service option code Source Codes : AO – assembled at “O” level AF – assem. at “I” level afloat AH – assem. at “I” level ashore AG – assem. at “I” level both afloat & ashore AD – assem. at “D” level XA – Order NHA XB – Obtain from salvage XC – Installatio, drawing or diagram that is identified by manufacturer’s P/N MO – Manufactured by “O” level MF - Manufactured by “I” level afloat MH – Manufactured by “I” level ashore MG – Manufactured by “I” level afloat & ashore 4 MD – Manufactured by “D” level COGS : This symbol consists of a two-character code that identifies the stores account and cognizant manager of an item. OI – Publications 1I – Forms 1R – Aviation, Aeronautical, Photographic, Meteorological consumable material 2R/7R – Aviation, Aeronautical, Photographic, Meteorological repairable material 2V – Aeronautical support equipment 4R – Catapult & arresting gear material repairable 4V – Aircraft engines 5R – Catapult arresting gear material repairable 6R – GSE with MCC of X 6V – Technical directives change kits 8R – Major aeronautical system and equipment 9C – Navy owned stock of defense construction material (S9C) 9D – Special clothing and textiles 9G – Navy owned stocks of defense general material (S9G) 9N – Navy owned stocks of defense electronic material (S9E) 9Q – Navy owned stocks 9Z – Navy owned stocks of defense industrial material (S9I) 9X – Bulk fuels, oils and solvents IMRL Reporting Codes Section 1 – Employment data – list of employment data used to create IMRL. Section 2 – Change list – List of all changes to activity’s IMRL. (additions, Deletions, or changes) Section 3 – Index – Rapid means of identifying and locating the position of an item in the body section (divided into six parts) 1 – Part number 2 – NIIN 3 – Nomenclature 4 – Avionics system name 5 – Avionics system number 6 – Line item number Section 4 - Main body – Lists of all items that are allowed for the applicable activity and shows the authorized allowance QTY for each item allowed. (each page presents identification data, description, land vessel (LV) code data, accountability & allowance data) Section 5 – Activity inventory record – lists all items that are on inventory at the Applicable activity on the date this section is prepared. (reissued on a monthly basis) provides identification data, management data, inventory status, authorized allowances & nonmenclature. 5 Preparation of IMRL’s - Prepared by cognizant SECA for each IMRL activity. SECA’s are responsible for printing and distributing. Issued on an annual basis or as required such AS/ACFT reconfiguration, mission changes, deckload variations, newly introduced equipment, etc. OPNAV FORM 4790/64 – IMRL transaction reporting (report gains, transfers & survey) NAVAIR FORM 13650/1 – IMRL revision request (correct discrepancies, request sermis, source data revision, report excess. Items O/H, amen se allowances) Compressed Gas Cylinder Color Codes CYLINDER COLOR CLASS OF MATERIAL ORANGE ----------------------------------------- Refrigerants BUFF----------------------------------------------- Industrial BROWN ------------------------------------------ Toxic Material BLUE ---------------------------------------------- Anesthetics GREEN -------------------------------------------- Oxidizing materials GRAY --------------------------------------------- Asphyxiating RED ------------------------------------------------ Firefighting protection BLACK -------------------------------------------- Combination of oxygen & other gases YELLOW ----------------------------------------- Flammable & combustible Material Forms DD Form 173/2 – Message form DD Form 200 – Report of survey DD Form 250 – Mat’l inspection & receiving report DD Form 1149 – Requisition & invoice / shipping document DD Form 1155 – Order for supplies and services DD Form 1342 – DOD property record DD Form 1348 (6 part) – DOD single line item requisition system doc (manual) DD Form 1348-1 – Single line item release / receipt document DD Form 1348-6 – Items with no NSN assigned DD Form 1384 – TCMD ( Transportation control & movement doc. ) DD Form 1387 – Shipment label ( red border PRI 01 / blue PRI 02 / no Border PRI 03 ) 6 DD Form 1896 – White indentaplate DD Form 1897 – Purple indentaplate NAVSUP Form 306 – Controlled equipment NAVSUP Form 1250-1 – Single line item consumption / requisition Document (manual) SF 44 – Purchase order invoice voucher SF 94 – Statement of witness SF 95 – Claim for damage or injury SF 364 – Report of descrepancy (ROD) SF 1103 – Gov’t bill of lading (GBL) NAVAIR 00-35-QH-2 – Flight clothing allowance list NAVAIRINST 13650.1 – IMRL (individual material readiness list) NAVCOMPT Form 2155 – REQ / Optar log NAVCOMPT Form 2156 – Optar document transmittal report NAVCOMPT Form 2157 – Budget optar report Publications NAVSUP P-284 – Storage & materials handling NAVSUP P-409 – Milstrip / milstrap desk guide NAVSUP P-437 – Milstrip / milstamp NAVSUP P-484 – Supply afloat field packaging procedures NAVSUP P-485 – Supply afloat – 26 appendixes 1 – Advice codes 2 – Status codes 3 – Distribution codes 4 – Document identifier 5 – Mode of shipment 6 – Project codes 7 – Routing identifier 8 – Suffix codes 9 – Logistic management codes 10 – Milstrip logistic / management codes 11 – Controlled equipage item list 12 – Planned 13 – Change notice and codes 14 – Signal codes NAVSUP P-485 – Supply Afloat (continued) 15 – Supply and transportation abbreviations and acronyms 16 – Media and status codes 17 – Type of hold codes 18 – Cogizance of Navy material 19 – Unit of issue 20 – Limited application directives 21 – Personal property transportation offices 22 – Navy airlift clearance authorities worldwide 7 23 – Air hour / day surface day shipped code 24 – Selected air terminal identifier codes 25 – Supply / financial reports (SFM) – snap II users 26 – Packaging and labeling guide for 2M repaired electronic component NAVSUP P-500 – Navy policies and standards for supply management NAVSUP P-504 – Preparation of freight for air shipment NAVSUP P-505 – Preparation of hazmat for air shipment NAVSUP P-545 – DLR requistioning, turn-in and carcass tracking guide NAVSUP P-560 – Navy supply acquisition regulation supplement (procuring mat’l for local purchase, BPA, imprest fund or purchase orders) NAVSUP P-567 – Volume 1 – Automated snap I supply procedures (inventory management) Volume 2 – Automated snap I supply procedures (financial management) For logistics management, inventory management and financial management NAVSUP P-600 – Naval logistics library NAVSUP P-2002 – Navy stock list of publications & forms NAVSUP P-2300 – Lists repairable assemblies under the cog of ASO NAVSUP P-2310 – Lists supporting repair parts NAVSUP P-2320 – SM&R codes NAVSUP P-2330 – Family group cross-reference NAVSUP P-4000 – Intro to federal supply catalog & related pubs (ML-N, CMCRL, MRIL, CHIL, LIRSH, ASG, IL, NICN/NIIN) NAVSUP P-4105 – (LIRSH) List of items requiring special handling NAVSUP P-4400 – (ASG) Afloat shopping guide NAVSUP P-4500 – (CHIL) Consolidated hazardous items list NAVSUP P-4998 – (CARGO) Consolidated afloat requistioning guide overseas NAVSUP PUB I – Volume II – Supply Ashore Volume V – Transportation of property NAVSO P-3006-1 – Financial management of resources operations procedures NAVSO P-3013-1 – Financial management of resources operations maintenance (opertaing forces) NAVSO P-3013-2 – Financial management of resources operations maintenance (shore activities) NAVCOMPT Manual – Volume 2 – Accounting classifications Volume 3 – Appropriation cost and property accouting (field) FASO INST 4000.2Q – ASO glossary of abbreviations FASO INST 4441.15 – OSI for ships and marine air groups (MAGS) Using the AVCAL process FASO INST 4441.16 – Aviation OSI for activities using the shorcal process NAVAIRINST 4423.11 – Assignment and application of SM&R codes NAVAIRINST 13650.1 – AMMRL program 8 NAVSUPINST 4200.85 – Shore and fleet small purchase and other simplified Purchase procedures NAVSUPINST 4235.3 – Fleet use of milstrip (Indoc milstrip) OPNAVINST 4110.2 – Hazardous material control and management OPNAVINST 4614.1 – UMMIPS (FADS) OPNAVINST 4790.2 – NAMP-6 Volumes ** Sponsored & directed by CNO** 1 – Concepts, objectives, policies, organizations and representatives 2 – “O” level maintenance 3 – “I” level maintenance 4 – “D” level maintenance 5 – Data processing requirements 6 – Maintenance data systems OPNAVINST 5100.23 – Hazardous material control OPNAVINST 5510.1 – Don information and personal security program regulation (security manual) SECNAVINST 5210.11 – SSIC’s SECNAVINST 5212.5 – Navy and Marine Corps disposition manual SECNAVINST 5215.1 – DON directives issuance system SECNAVINST 5216.5 – Navy correspondence manual SECNAVINST 5400.4 – MLSR NAVSUP manual – 4 Vols 1 – Intro to supply 2 – Supply ashore 4 – Retail clothing and commissary store 5 – Transportation of property Navcompt manual – 10 Vols 2 – Accounting classificationss (chapter 5 – UIC’s) 3 – Appropriation, cost and property 4 – Disbursing MLN – Management List Navy – Management data for all Navy Managed items (NIIN seq.) published by (DLSC) Defense Logistics Service Center, revisions quarterly, distribution (FMSO) MRIL – Master Repairable Items List – Catolog of selected Navy managed items C-MCRL – Consolidated Master Cross Reference List – 3 parts Part 1 – P/N and cage to NSN’s Part 2 – NSN’s to P/n’s and cage Part 3 – Cage and P/N to NSN’s H4/H8 – Contains name, address and cage code for each company that manufactures items for the federal government ICRL – Repair capability of each component repaired at the local IMA. Data Provided to ASO by the IMA’s, based on items processed, past Experience and SM&R codes. It is published by ASO. CRIPL – Consolidated Remain In Place List – Contains repairable components 9 that cannot be removed until receipt of a replacement item. (3 parts) Part 1 – NIIN sequence Part 2 – P/N sequence Part 3 – NIIN sequence within A/C type C AND P SECTIONS (CROSS REFERENCE AND PARTS LISTINGS) C0001 – Section Idex – List all titles of ASO pubs C0018 – Repairable assemblies model code table – lists various model codes & their respective NSN’s that are shown in the ASO P2300 & P2310 sections C0030 – Packaging data for ASO and NAVAIR repairable assemblies NAPI – NAVAL AERONAUTICAL PUBLICATIONS INDEX NA 00-500A – Equipment applicability list NA 00-500AV – Avionics change cross-reference NA 00-500B – Aircraft application list NA 00-500C – Directives application list NA 00-500M – Microfilm cartidge cross-reference NA 00-500P – Publications distribution index NA 00-500E – Support equipment cross-reference NA 01-700- Airborneweapons / stores, CONV / Nuclear, check lists / stores Reliability cards / manual NAVSUP P-2002 – Navy stock lists of Pubs and forms ALLOWANCE LISTS (ALs) – Contains material and equipment for the purposes indicated in each list. The AL is used as guides in establishing the IMRL. TABLE OF BASIC ALLOWANCES (TBAs) – Listings of equipment and material required for performance of specific missions. TECHNICAL DIRECTIVES (TDs) – 2 Types Formal Informal 3 ACTION CATEGORIES – Immediate, urgent, routine DOCUMENT IDENTIFIERS Overseas Shipment Domestic Shipment AO1 NSN AOA AO2 P/N AOB 10 AO3 AO4 AO5 NATO OTHER EXCEPTION AOC AOD AOE ADMINISTRATION STANDARD LETTER – SECNAVINST 5216.5 (NAVY CORRESP. MANUAL) Stationary – First page contains letterhead (name & address). Second page and succeeding pages are typed on plain white bond paper as same size and quality as letterhead paper. Copies – Made on copy machines or white carbon flimsy, the file copy is yellow carbon flimsy. MULTIPLE ADDRESS LETTER – Two or more activities. Each addressee must receive a letterhead copy with a signature. JOINT LETTER – Two or more commands wish to issue information that establishes an agreement of a matter that of which is mutual concern. MESSAGE – Quickest form of written communication. DD FORM 173/2 (Double Faced Format) CLASSIFIED MATERIAL CONTROL (OPNAVINST 5510.1 SECURITY MANUAL) CNO is responsible to SECNAV for all policies related to the security of all classified info within the Navy. Top Secret – Exceptionally grave damage to national security Secret – Serious damage Confidential – Identifiable damage Clearance – One of several types of personal investigations are complete. (final or interim) Final – Granted when all investigations requirements are met and are favorable Interim – Granted, not to exceed 6 months, when it is established that any delay would be Harmful to the national interest and a personal investigation request has been submitted. Access – Individual has a need to know up to a specific level. Marking Classified Mat’l Marked with appropriate classification at the top and bottom of each page. (All Capitals, largerthat type of text) Custodian Precautions Not removed without C.O. authority or an authorized representative. Stowage Procedures The combinations or key of a key of a container must be changed at the time of Receipt or not less than 12 months, and if any personnel transfer having previous knowledge. TRANSFERING CLASSIFIED MAT’L Only secret and lesser may be sent VIA mail 11 Registered Mail – Secret, NATO confidential and all confidential mailed To an FPO / APO address. Certified Mail – Confidential ( addressed to contractor facilities ) First Class Mail or Priority – Confidential ( addressed to DOD activities located in U.S. ) TURN-IN OF CLASSIFIED MAT’L – Hand delivered mat’l – obtained #1 copy of 1348-1 Shipped or mailed - #5 or #6 of 1348-1 OPTAR ( OPERATING TARGET ) Operating Target – Authorization of funds subject to administrative control Issued to a level below the responsibility center. Operating Budget – Annual budget and financial authority of an activity or command that contains the resources to perform that activity’s mission. FAADS ( DAO ) – Perform the official accounting and reporting for OPTARs Issued by **TYCOM** ( FAADCLANT & FAADCPAC ) Example : 1791804.602D 000 57025 A 060951 2D VO3369 0083051234BC (1) (2) (3) (4) (5) (6) (7) (8) (9) (1) (2) (3) (4) (5) (6) (7) (8) (9) – Appropriation ( 7 Characters ) – Subhead ( 4 Characters ) – Object class – Bureau control number ( UIC of the operating budget holder ) ( 5 Characters) – Suballotments ( Operating budget suffix ) ( 1 Character ) – UIC of authorized accounting activity ( UIC of requistioner ) ( 6 characters ) – Transaction – type code ( cite 2D ) ( 2 characters ) – Property accouting activity ( UIC of requisitioner ) ( 6 characters ) – Cost code ( consists of 2 zeros, followed by Julian date and serial number or requisition, followed by applicable fund code ) ( 12 characters ) NAVCOMPT FORM 2155 – REQUISITION OPTAR LOG Each activity will establish a requisition optar log ( NAVCOMPT FORM 2155 ) for each optar received. Optar grants are entered into the log and reduced by the value of chargeable requisitions ( unfilled orders ). All chargeable requisitions and purchase orders must be recorded. In addition, all 12 differences ( increase or decrease ) reported by the FAADC on the SFOEDL must be entered into the log and the optar balance adjusted. NAVCOMPT FORM 2156 Optar document transmittal report. All unfilled orders, cancellation documents and transaction listings ( SFOEDL / AUOL ) will be transmitted to FAADC ( DAO ) on a timely basis ( 16th and last day of the month ) NAVCOMPT FORM 2157 Budget optar report ( BOR ) when prepared, the BOR is submitted by hand, mail or message to FAADC, with a copy to the TYCOM and a copy to the wing, no later than the first workday of the month following the month to be reported. FUNDS OFC-01 – Flight operations ( Optar ) 7F, 7B OFC-50 – Aviation fleet maintenance ( AFM ) 2S, Y6 OFC-08 – IMRL outfitters 8X HOLDING FILES Optar holding files are established by fiscal year for each optar received to hold the appropriate accounting documents and listings pending transmittal to the FAADC. The contents of the holding files are as follows: File 1 – Unfilled order chargeable documents for transmittal. This file contains the accounting copy DD Form 1348 greeen copy. File 2 – Unfilled order cancellation documents / list for transmittal. This file contains lists of confirmed cancellations or copies of individual cancellation documents, advance downward price adjustments and administrative cancellations. All documents are entered in the optar log increasing the optar balance. SFOEDL Summary filled order / expenditure difference listing : Is forwarded monthly by the FAADC to individual optar holders for each optar held. The listing is a report of all filled orders with a difference of $100.00 or more. Optar holders accept and post to the requisition optar log all differences shown on the SFOEDL. All differences are listed by the fund code. After posting the differences, the optar holder reviews the listings and annotates transactions considered invalid with the appropriate rejection code. Rejection codes are listed in the NAVSO P-3013, paragraph 4108. 13 AUOL Aged unfilled order listing : Is forwarded monthly ( except for the first quarter of the current fiscal year ) by the FAADC to the individual optar holders for each optar held. The listing is distributed monthly for the 4th through the 15th month of the reporting period, and then quarterly for the 18th through the 33rd report month. The aged unfilled order listing lists all unfilledorders over 120 days old held in FAADC files that have not matched with related expenditure documents and have not been canelled. THRESHOLD Any charge under $100.00 can be charged to the optar holder without achieving a Match. MATERIAL RECEIPT – METHODS OF DELIVERY 1 – Direct delivery 2 – Freight 3 – Mail RECEIPT DOCUMENTATION ALL material and services received must be accompanied by a receipt document. Incoming material should be accompanied by one or several receipt documents depending on the method of purchase, supplier, type of delivery and government inspection requirements. Any document received with the material or service that contains enough information to process the receipt document. DD Form 1348 ( 6 part ) Generally used both as a requisition and a receipt document for most materials transferred between nonautomated ships. Issuing ship – white copy. Receiving activity – Hardback copy. DD Form 1348-6 Recommended for requistioning material that is not identified by a NSN. NAVSUP Form 1250-1 Used as a consumption document and as a requistion document for nonautomated ships. When the NAVSUP Form 1250-1 is submitted as a requisition to the parent tender, the white copy returned with material is processed as a receipt invoice. DD Form 1348-1 Single line item release / receipt document Receipts from shore activities and automated units are done either on a DD Form 1348-1 or an issue / receipt release document ( IRRD ). DD Form 1149 Rquisition and invoice / shipping document is normally used to requisition or receive specific materials or services such as repairs or rental equipment. When material or services are received on a DD Form 1149, a technical inspection by the ordering dept. is done, if required. 14 DD Form 1155 Order for supplies and services is used to purchase material from a commercial source. DD Form 250 Material inspection and receiving report is used to verify material inspection and acceptance for items received directly from a contractor. Standard Form 1103 Government bill of lading may be used to provide delivery instructions to a commercial carrier or to provide receipt documentation to the ordering activity. SHIPPING DISCREPANCIES Shipping discrepancies attributable to the responsibility of the activity ( including contractors, manufacturers or vendors ) are reported by the receiving activity on a report of discrepancy ( ROD ), Standard Form 364. RECEIPT DISCREPANCIES – 2 TYPES 1. Discrepancies such as overages, shortages, damages, incorrect or not – received material. 2. The second category includes material quality discrepancies. Material delivered in this category cannot be used for it’s intended purpose because it does not meet specified ( form, fit or function ) requirements. These discrepancies are caused by manufacturing or repair facility or, in some case, incorrect specifications. MATERIAL SURVEYS Procedure for determining the cause of gains, losses or damage to Navy property, establishing personal responsibility ( if any ), and documenting necessary inventory adjustments to stock records. When a loss or gain of material in the following categories is confirmed, a report of survey, DD Form 200, is prepared. MLSR Missing, lost, stolen and recovered reports, in addition to the procedures for preparing a survey; consult SECNAVINST 5400.4 with respect to the MLSR. A DD Form 200 and a MLSR report are required for losses of sensitive or claqssified items and for arms, ammunition and explosives. The approved DD Form 200, preliminary and causitive research findings and recommendations and all other documentation related to the surveyed material should be retained for 3 years. IMPREST FUND Simple and economical way of electing purchases not in excess of $500.00. The imprest fund method employs a cash fund from which payments are made at the time purchase transactions occur and to which reimbursements are made on a revolving basis. The amount of each imprest fund for shore activities is based on (1) estimated monthly payments not to exceed $10,000 (2) an amount of $500.00. For afloat activities, the imprest fund amount may not exceed $1,00.00 for ships with supply corps officers or $500.00 for ships without supply corps officers. Anyone with the exception of disbursing or fiscal office personnel may be appointed in writing as an imprest fund cashier by the 15 commanding officer. Both the imprest fund cashier and alternate must each have his or her safe and are the only persons authorized to have the combination for their respective safes. The combination of each safe must be changed every 6 months. SUPPLY SUPPORT CENTER Supply Responses Section ( SRS ) COMPONENT CONTROL SECTION (CCS) Requisition Control Unit (RCU) Technical Research Unit (TRU) Stock Locator Unit (SLU) Material Delivery Unit (MDU) Program Management Unit (PEB) Pre-Expended Bin Unit (PEB) Document Control Unit (DCU) LRCA Storage Unit (LRCA) Supply Screening Unit (SSU) Awaiting Parts Unit (AWP) SRS – Supply Response Section Single point of contact for processing customer requirements and providing Following-ups and status as required. RCU – Requisition Control Unit Receives all requests for mat’l req., prepares documentation maintains files and Registers and provides status. TRU – Technical Research Unit Verifies requisition data SLU – Stock Locator Unit Locating The Mat’L (MSSL) and other available locators MDU – Material Delivery Unit Picks-up and delivers mat’l PEB – Pre-Expended Bin Unit Contains high usage items, low cost, maintenance related consumable items PMU – Program Management Unit Processing & expediting all high priority req. (NMCS / PMCS) Work stoppage And exreps. CCS – Component Control Section Also known as (RMS) repairables management section accounts for all repairable Assets stored in LRCA as well as the IMA repair cycle. DCU – Document Control Unit Control of all NON-RFI components in the IMA repair cycle except rotable pool Components. Maintain files for repairable components in stages of repair cycle And for components awaiting turn-in from customers REPAIRABLE MANAGEMENT FILES Document Suspense File – DD 1348 white copy indicates that a demand for a repairable component Was made 16 Exchange Due File – DD 1348 yellow copy indicating that a defective retrograde is due from Customer Induction Return Due File – VIDS / MAF copy 2 indicates that a component has been inducted into repair cycle Completed Requisition File – Contains signed copies of LRCA issue documents certifying proof of Delivery Exrep File – DD Form 1348 outstanding requisitions representing outstanding repairables to be satisfied from AIMD. LCRA – Local Repair Cycle Asset Storage Unit Responsible for the receipt, stowage and issue of LRCA’s maintain records of stock, controls LCRA components in repair cycle SSU – Supply Screening Unit Responsible for processing all items received from AIMD after the repair cycle. SSU forwards RFI mat’l for stock or prepares retrograde mat’l for shipment to DOP. AWP – Awaiting Parts Unit - Receipt, stowage and control of all components in the AWP status returned from AIMD. - AWP levels should not exceed 15% of average monthly inductions. - Aged AWP assets ( over 60 days old ) should not exceed 5% of total AWP level. - 98% accuracy is established for effective AWP management. - IMA W/C has 24hrs to deliver component to AWP in case of nonavailability of part. - AWP validations conducted weekly. AMSU – Aeronautical Material Screening Unit ( component of AIMD ) - All components received for induction into AIMD must be determined if the component is in the check, test or repair capability of AIMD. - Vids copy 2 is signed as a receipt and returned to CCS ( the use of the ICRL is applied ) - Assignment workload requirements - PRI 01 – support of NMCS / PMCS and also assigned to activities within 30 days of development. - PRI 02 – Repair of critical LCRA & SE items. Also assigned to O-level maintenance work stoppage requirements. - PRI 03 – Repair of non-critical LRCA & SE items & repair or manufacture of mat’l for non-fixed allowance stock items. - PRI 04 – Process salvaged mat’l & non-aeronautical mat’l repair. Processing repairables – When repair capability does not exist items must be shipped to ( DSP ) designated support point or to an activity having repair capability. ( AIMD determination must be made within 24hrs, component is 17 shipped within 48hrs, may not exceed 3 days ) ICRL – Individual Component Repairable List Management tool that provides and activity with the ability to relate maintenance repair capability to an item. - Identifies fixed allowances NAVAIRINST 4790.18 – NAMP-6 volumes Policies and procedures for managing the ICRL is established - ICRL additions, deletions and changes are sent to ASO The master ICRL data file is established / published by ASO - Maintaining and using within IMA is shared by AIMD and supply AVIATION MATERIAL MANAGEMENT Repairables identified as – FLR’s – Field Level Reapirables : which are managed by ICP’s in the same manner as comsumables – normally disposed of when they cannot be repaired at the local level. DLR’s – Depot Level Repairables : can be economically repaired at depot Level maintenance. IRAM – Improved Repairables Asset Management program Two Subsets: (1) Management improvement iniatives applicable To all repairables. (2) Intensive repairable item management ( IRIM ) Of selected repairables. Objectives : To increase asset visibility and control increase Recovery rates, minimize that and improve Requirements determinations. STORAGE Storerooms should be arranged to permit : 1. Maximum storage capacity 2. Access to all stores 3. Orderly arrangement of stores 4. Security and safety of stores The material to be stored should be considered from four separate viewpoints: 1. Popularity 2. Similarity 18 3. Size 4. Characteristics Location Numbering : 324-112-123 32 – Building 4 – Floor 112 – Row 12 – Stack 3 – Level All keys padlocks must be ½, pin tumbler type, with dead bolt and must be either brass or bronze. All keyless padlocks must be the three-combination, manipulation resistant type. The custodian must not record the combination anywhere other than on the paper which is placed in a sealed envelope and turned into the accountable officer. The combination must not be disclosed to anyone. The sealed envelope is kept in the accountable officer’s safe. In selecting combination numbers, multiples of 5, simple acending or descending arithmetical series and personal data such as birthdays and serial numbers should be avoided. STACK HEIGHTS The heights of stacks below automatic sprinklers are as follows: A. When stack heights are 15 feet or lower, at least an 18-inch clearance must be maintained. B. When stack heights exceed 15 feet, at least a 36-inch clearance must be maintained. C. When hazardous commodities are involved, at least a 36-inch clearance must be maintained reguardless of stack height. Stack heights in buildings not protected by sprinklers must have at least a 36-inch clearance around joists, rafters, beams and roof trusses. Around light or heating fixtures, an 18-inch clearance must be maintained. HAZARDOUS MATERIAL INDENTIFICATION SYSTEM – HMIS Adequate safety to life and property NAVSUPINST 5100.27 – Implements new OSHA ( Occupational Safety & Health Admin. ) This expands on the CHIL Overall management responsibility is NAVSUPSYSCOM HMIS – Microfiche list produced by NAVSUPSYSCOM lists hazardous ingredients, use, protective clothing and emergency treatment. OPNAVINST 5090.1 – For disposal of hazardous mat’l OPNAVINST 5102.1 – Mishap ( chapter 3 & 4 ) NAVSUP P-485 – 19 Storage codes HAZMAT STOREROOMS Flammable – Located end of the ship or below full load water line, not adjacent to a magazine. ( Equipped with automatic fire alarms and CO2 systems ). Acid – Leakproof lead-lined box, chest or locker. 3/8 inch letters bearing ( acid bottle storage ) Must be kept in flammable liquid storerooms. TRANSPORTATION OF HAZMAT – DD Form 1387 – Military shipping label DD Form 1387-2 – Special handling data / certification label. PLANT ACCOUNT AND PROPERTY RECORDS Custody – Physical possession of mat’l and the assumption of responsibility against it’s improper usage and loss. Equipage – ( Afloat ) Noninstalled & relatively durable items. Controlled Equipage – ( Afloat ) Items require special management control because mat’l is essential for the protection life or is relatively valuable to personal use. Minor Property – Personal property acquired for immediate use & having a cost of less than $5,000 or more but having a useful life of less than 2 years. Plant Property – Navy-owned land, buildings and personal property of a capital nature located on shore. 4 classes : 1 – Land 2 – Buildings, stuctures & utilities 3 – Persoal property cost 5,000 or more, expected life 2 years or more. 4 – Industrial plant equipment costs $5,000 or more use for cutting, grinding etc. nothing less than $5,000. DD Form 1342 is used for reporting class 3 & 4 plant property. A separate form is prepared for each individual item. TYCOM – Physical inventories, surveys ( lost, missing, 20 unserviceable items ), periodic reports of consumption, deficiencies and excess all will be reported to TYCOM. CONTROLED EQUIPAGE RECORD : ( NAVSUP FORM 306 ) Original & one copy of each item in the custody of each department head. Department heads may duplicate custody records for any signature required items. Original – Maintained in space most convenient by Suppo. & when not in use must be kept in a locked file. Old Forms – Must be kept for up to 36 months even if original info was copied on to new custody from going by date of last entry. Designation of Forms – By commanding officer or TYCOM it must be indicated on top or bottom margin of each card. PHYSICAL INVENTORY OF CONTROLLED EQUIPAGE - Annually between 15 Februrary through 15 March - Other inventories which must be completed within 30 days after commencement date : 1. Commissioning, inactivation or reactivation of the ship. 2. Relief of head of dept., concerning that department. 3. Change of command , at descretion for relieving C.O. MILSTRIP - DATA BLOCKS FOR 1348 ( 6 PART ) Block A – Send to Block B – Requistioner Block C – Nomenclature Block D-F – Editing Data CC 1-3 – Document Identifier CC 4-6 – Routing Identifier CC 7 – Media and Status Code CC 8-20 – NSN CC 21-22 – SMIC CC 23-24 – Unit of Issue CC 25-29 – Quanity CC 30 – Service designator CC 31-35 – UIC of Requisitioner CC 36-39 – Julian Date CC 40-43 – Serial Number CC 44 – Demand Code CC 45-50 – Supplementary Address CC 51 – Signal Code CC 52-53 – Fund Code 21 CC 54 – Monitoring Activity CC 55-56 – COG CC 57-59 Project Code CC 60-61 – Priority Designator CC 62-64 – Required Delivery Date CC 65-66 – Advice Codes CC 71 – Supply Condition Code CC 73 – MCC UMMIPS Urgency of Need Designators ( UNDS ) Unabble to Perform Impaired Mission Operational Cap. ( FADS ) A B Force / Activity Designators Routine C I 1 4 11 II 2 5 12 III 3 6 13 IV 7 9 14 V 8 10 15 PRIORITY ISSUE GROUPS I – 01-03 II – 04-08 III – 09-15 FLIGHT PACKETS Inventory is done before and after each flight or at least weekly. The flight packet includes the following materials : DD FORM 1348 ( 6 part ) – Requistioning repair parts and other material for inplane servicing. SF 44 – Buying services and material from commercial sources. Lodging for officers. Lodging and food for enlisted personnel. 22 DD Form 1896 – Buying Jet Fuel and lubricantsfrom DOD activities. ( white ) DD Form 1897 – Buying AVGAS and lubricants from DOD activities. ( purple ) Miscellaneous Items – - Instructions for safeguarding and shipping damaged aircraft. - Instructions for procuring services and supplies. - SF 94 ( statement of witness ). - SF 95 ( claim for damage or injury ). - Indelible pencil or ball point pen and carbon paper. - Engineering investigation reports - VIDS / MAF ( OPNAV 4790 / 60 ) PROJECT CODES AK0 ( 796 ) – NMCS ( Non Mission Capable Supply ) AK7 ( 797 ) – PMCS ( Partial Mission Capable Supply ) AK1 – Work Stoppage ZC8 – Pool Critical YY9 – Miscellaneous AK5 – Low Priority Aeronautical Items ( Nuts, Bolts, Screws, etc. ) AP5 – Low Priority Non-Aeronautical Items ( Coveralls, Boots, etc. ) ZP7 – Broad Arrow ZA9 – High Time ZL9 – MAMS ZC5 – Test Bench Installment Items SUADPS DOCUMENT IDENTIFIERS XO5 – AVCAL / COSAL = Established or changed MRF record XO6 – AVCAL / COSAL = Established or changed NBR record XO8 – ADD / delete / change MRF record X10 – Establish NBR record X11 – Spot inventory X13 – Pre-determined inventory action X21 – Record demand and frequency X24 – Recorded pack-up data X31 – Repairable issue to supported unit X32 – Turn-in repairable from support unit X34 – Issue to end-used ship / receipt to end used ship X35 – Cash sales X37 – Off load or excess material X38 – OSO transfer to end used ashore X39 – MVO offload adjustment 23 X43 – Survey X50 – Fund allocation / withdrawal X51 – Establish / delete FMF data X70 – Receipt for aviation fuel X71 – Material receipt X72 – Receipt in process X73 – MVO receipts X76 – OPTAR adjustments X77 – MVO receipts adjustments X78 – MVO obligation adjustments X90 – File inquiry X91 – Surface MDS input X92 – Aviation MDS input NALCOLMIS CONVERSATION CODES PRODUCTION CONTROL N202 – Update / delete ICRL records N222 – ICRL N235 – Printout of ICRL in sequence selected by the user ASSET MANAGEMENT INQUIRIES N515 – IMRL part number inquiry N516 – IMRL requisition inquiry N517 – Calibration due date update ASSET MANAGEMENT REPORTS N520 – SE inventory sum report request N521 – IMRL report request N522 – SE subcustody report request N523 – IMRL cust / subcust report request MATERIAL REQUIREMENT PROCESSING N601 – Direct support material N602 – Indirect support material N603 – Pre-X bin / PACKUP material N604 – Material requirements update N607 – Material requirements approval N608 – Requisition reorder N609 – Supply system status update N610 – Local status update N611 – Requisition action initiation N612 – Requisition action aprv / update N613 – Receipt on board N614 – Generate duplicate DD1348-1 24 N615 – Proof of delivery N616 – Issue select N617 – End item BUNO / SERNO update N618 – Material turn-in N619 – Generate PEB / PACKUP requisition listing N652 – OFROB / PACKUP site replenishment REPAIRABLE STOCK MANAGEMENT N620 – AMSU induct discrepancy update N621 – DIFM return N622 – XFER to SUBCUST / PACKUP / SUSP N623 – Return from SUBCUST / PACKUP / SUSP N628 – Warehouse refusal N629 – Post serial number issue N630 – Customer refusal N631 – Alternate NIIN review clearing N632 – Generate inventory listing N633 – RFI inventory posting N634 – Inventory status monitoring N635 - IOU survey N636 – DIFM survey N637 – Lost in shipment survey N638 – Supply survey N639 – Matched set requisition clearing N641 – Inter-IMA customer service return AWAITING PARTS MANAGEMENT N644 – AWP component receipt N646 – AWP component release N648 – AWP repair parts transpose N649 – AWP component location update SUPPLY FILES MANAGEMENT N650 – NSN add N651 – NSN update / delete N653 – Alternate NIIN add N654 – Alternate NIIN update / delete N656 – FSCM P/N add N657 – FSCM P/N update/delete N659 – MRIL address add N660 – MRIL address update/delete N662 – Repairable stock data update N663 – SUBCUST repairable stock data update N664 – SUSP repairable stock data update N665 – Packup repairable stock data update N666 – FGC management data update 25 N667 – Repairable NIIN data update N685 – Pending due degree SUPPLY SUPPORT N668 – Requisition supply status inquiry N669 – Customer requisition inquiry N670 – RFI repairable stock status inquiry N671 – Due repairable stock status inquiry N672 – SUBCUST repairable stock status inquiry N673 – Suspense repairable stock status inquiry N674 – Packup repairable stock status inquiry N675 – DIFM repairable stock status inquiry N677 – Summary repairable stock status inquiry N678 – Transaction ledger inquiry N679 – Cross reference data inquiry N203 – P/N cross reference inquiry NAVSUP P-485 Volume II - Supply Appendices CONTENTS SUPPLY APPENDICES Appendix 1 Advice Codes Appendix 2 Status Codes Appendix 3 Distribution Codes Appendix 4 Document Identifier Codes Appendix 5 MILSTAMP Codes Appendix 6 Project Codes Appendix 7 Routing Identifier Codes Appendix 8 MILSTRIP Codes Appendix 9 Logistic Management Codes Appendix 10 MILSTRAP Codes Appendix 11 Country/International Organization Codes Appendix 12 Planned Requirement/Reservation Rejection Codes Appendix 13 Change Notice Codes Appendix 14 Special Material Identification Codes (SMIC) Appendix 15 SUADPS-RT Reports and Listings Appendix 16 Media and Status Codes Appendix 17 Management Codes Appendix 18 Cognizance of Navy Material Appendix 19 Unit of Issue Abbreviations and Conversion Table Appendix 20 Supply Directives Appendix 21 Personal Property Transportation Offices Appendix 22 Navy Airlift Clearance Authorities Worldwide Appendix 23 Acquisition Advice Codes (AAC) 26 Appendix 24 Weapon System Designator Codes Appendix 25 SFM Reports and Listings Appendix 26 Stock Action/Technical Information Codes Appendix 27 Type of Storage Codes Ch. 2 xv NAVSUP P-485 Volume II - Supply Appendices Appendix 28 MILSTRIP/MILSTRAP Formats Appendix 29 Electronic Information Systems Appendix 30 Fund Codes Appendix 31 Financial Inventory Report (FIR) Codes Appendix 32 SUADPS-RT Financial Reports Audit Appendix 33 Automatic Identification Technology Glossary Index xvi 27