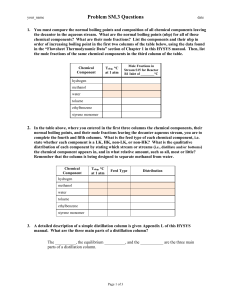

I_LPW_APED-I_RKM_2013

advertisement

Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) List of Laboratory Practical for APED-I During laboratory hours calculations for the following problems will be carried out manually as well as using software like Hysys and HTRI. Each student will be having different problem. Detail problem will be defined during semester. Each student has to carry out calculations for design for respective equipment manually and then they have to use this data and design and simulate using software. Sr. No. 1 List of experiment Software to be used Aspen.Hysys and SuperPro Designer 8 Introduction to Simulators and Building up of Process Flow Diagram (PFD) with Aspen.Hysys and SuperPro Designer Significance of thermodynamic fluid package in simulation and its selection for given problem. Some guidelines for selection of fluid package Simulation of short-cut distillation column – Determination of optimum operating temperature and pressure for distillation column Design and Simulation of distillation column – binary Design and Simulation of distillation column – Binary system with SuperPro Designer and Comparing results with Aspen.HYSYS Design and Simulation of distillation column – multicomponent Design and Simulation of packed absorption column Design of liquid-liquid extraction column 9 Sizing of Packed/Tray column using K G Tower 2 3 4 5 6 7 10 11 12 Dr R K Mewada -1- Aspen.Hysys Aspen.Hysys Aspen.Hysys SuperPRo Designer Aspen.Hysys Aspen.Hysys Calculation and other software like SuperPro Designer or SciLab can be used K G Tower is software for sizing of column Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) Experiment 1: Introduction to Simulators and Building up of Process Flow Diagram (PFD) with Aspen.Hysys and SuperPro Designer. Experiment 2: Objective: Significance of thermodynamic fluid package in simulation and its selection for given problem. Some guidelines for selection of fluid package. Algorithm or flow chart or decision making tree for selection of suitable fluid package for various types of components. Thermodynamic models are used to represent the phase equilibrium behavior and energy level of pure compound and mixture systems. In many cases, simulation results DO NOT reflect what is really happening in a plant. This is due to • Improperly selected thermodynamic models • Inadequate model parameters • Incorrect hypothetical components generation • Problems with plant data consistency Example: • A mixture of Ethane and Propane at 30 atm • The PR Equation of State most closely represents the true phase behavior of the system Aspen HYSYS contains over 30 thermodynamic models • Equations of State • Activity Coefficient Models • Vapor Pressure Models • Semi-Empirical Models • Specialty Models – Steam Tables – Amines Package – Clean Fuels Package – Glycol Package – OLI – Neotec Black Oil – Infochem Multiflash – etc. EQUATION OF STATE MODELS • Peng-Robinson (PR) – Most enhanced model in Aspen HYSYS – Largest applicability range in terms of T and P – Special treatments for some key components – Largest binary interaction parameter database • PRSV – Modified PR model -2- Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) – Better representation of vapor pressure of pure components and mixtures – Extends applicability of the original PR model to moderately non-ideal systems • SRK – Modified RK model – Can provide comparable results to PR in many cases, but with a lot less enhancement in Aspen HYSYS • PR-Twu • SRK-Twu • Twu-Sim-Tassone (TST) – Modified equations of state models for hydrocarbon systems-non ideal systems (used for glycol package) • Generalized Cubic Equation of State (GCEOS) – Provides a framework which allows users to define and implement their own generalized cubic equation of state including mixing rules and volume translation. • MBWR – Modified BWR model – Having 32 parameters, this model works extremely well with a number of pure components within specified T and P ranges • Lee-Kesler-Plocker – Also a modified BWR model – Can be used for non-polar substances and mixtures • BWRS – Modified BWR to handle multi components – Requires experimental data • Zudkevitch Joffee – Modified RK model with better prediction of VLE for hydrocarbon systems, and systems containing hydrogen • Kabadi-Danner – Modified SRK model with the enhancement to improve the VLE calculations for H2O-hydrocarbon systems, particularly in dilute regions • Sour PR/Sour SRK – Used for sour water systems containing H2S, CO2, and NH3 at low to moderate pressures. • Modified Antoine Model – Applicable for low pressure systems that behave ideally • Braun K10 Model – Strictly applicable to heavy hydrocarbon systems at low pressures • Esso K Model – Also strictly applicable to heavy hydrocarbon systems at low pressures -3- Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) • Chao-Seader model – Applicable to hydrocarbon systems in the range of T=0-500C, and P<10,000 kPa • Grayson-Streed model – An extension to the Chao-Seader model with special emphasis on H2 – Recommended for heavy hydrocarbon systems with high H2 content, such as hydrotreating units SPECIALTY MODELS • Glycol Package – For accurate representation of TEG circulation rates, purities of lean TEG, dew points and the water content of the gas stream used in natural gas dehydration process • Clean Fuels – For systems containing thiols and hydrocarbons • OLI – For electrolyte systems • Amines Models – For modeling sour system sweetening processes using amines (DEA, TEA, MEA, MDEA, DGA and DIPA) • Steam Table Models – ASME Steam – ASME 1967 Steam Tables – NBS Steam – NBS 1984 Steam Tables ASPEN HYSYS RECOMMENDATIONS FOR OIL AND GAS APPLICATIONS • Hydrocarbon systems – PR, SRK or any other EOS* • Hydrate inhibition – PR (special fit of BIP) • Natural gas dehydration with TEG – Glycol package • Sour gas sweetening with amines • Utility systems using H2O – Steam Table RECOMMENDED DESIGN TREE When faced with choosing a thermodynamic model, it is helpful to at least a logical procedure for deciding which model to try first. A decision tree is included in below figure. For non- polar fluids, an equation of state may suffice. For polar fluids , a fitted activity coefficient model is preferred , possibly in combination with the Hayden-O'Connell method or in combination with some other model. The property packages available in HYSYS allow you to predict properties of mixtures ranging from well defined light hydrocarbon systems to complex oil mixtures and highly non-ideal(non-electrolyte) chemical systems. HYSYS provides enhanced equation of state(PR and PRSV) for rigorous treatment of hydrocarbon systems; steam correlations for accurate steam property predictions; and activity coefficient models for chemical systems. All of these equations have their own inherent limitations and you are encouraged to become more familiar with the application of equation. -4- Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) TYPES OF SYSTEM RECOMMENDED PROPERTY METHOD TEG Dehydration Sour Water Cryogenic Gas Processing Air Separation Atm. Crude Towers PR PR, Sour PR PR,PRSV PR, PRSV PR, PR Optionws, GS (<10 mmHg), Braun K10, Esso K Lee Kesler Plocker PR, ZJ or GS Stream Package, CS or GS PR Activity Model, PRSV PRSV, NRTL PR Kabadi Danner Ethylene Towers High H2 Systems Reservoir Systems Hydrate Inhibition Chemical Systems HF Alkylation TEG Dehydratipon with Aromatics Hydrocarbon systems where H2O solubility in HC is important Systems with select gases and light HC -5- MBWR Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) The following diagrams show the process for choosing a property method. * See -6- Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) Guidelines for Choosing a Property Method for Polar Non-Electrolyte Systems -7- Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) Guidelines for Choosing an Activity Coefficient Property Method -8- Nirma University Institute of Technology Chemical Engineering Department Lab Manual for Advanced Process Equipment Design-I (M Tech – CPPD) Experiment 3: Simulation of short-cut distillation column – Determination of optimum operating temperature and pressure for distillation column Problem: Find out best possible operating temperature and pressure for separation of Vinyl chloride and Ethylene Dichloride. Experiment 4: Design and Simulation of distillation column – Binary system Problem: Design distillation column for separation of Vinyl chloride and Ethylene Dichloride based on best operating conditions data. Also carry out simulation to optimize operating parameters like reflux ratio, no. of stages, feed point location, condenser and reboiler duty, product purity etc. Experiment No. 5: Design and Simulation of distillation column – Binary system with SuperPro Designer and Comparing results with Aspen.HYSYS Problem: Carry out simulation to optimize operating parameters like reflux ratio, no. of stages, feed point location, condenser and reboiler duty, product purity etc using SuperPro Designer for the above case. Experiment No. 6: Design and Simulation of distillation column – multicomponent Problem: Proposed various sequence to separate mixture of C3-C5 alkanes. Feed composition is given in following table. Design any one column. Also carry out simulation to optimize operating parameters like reflux ratio, no. of stages, feed condition, condenser and reboiler duty, product purity etc. Experiment 7: Design and Simulation of packed absorption column Experiment 8: Design of liquid-liquid extraction column Experiment 9: Sizing of Packed/Tray column using K G Tower -9-