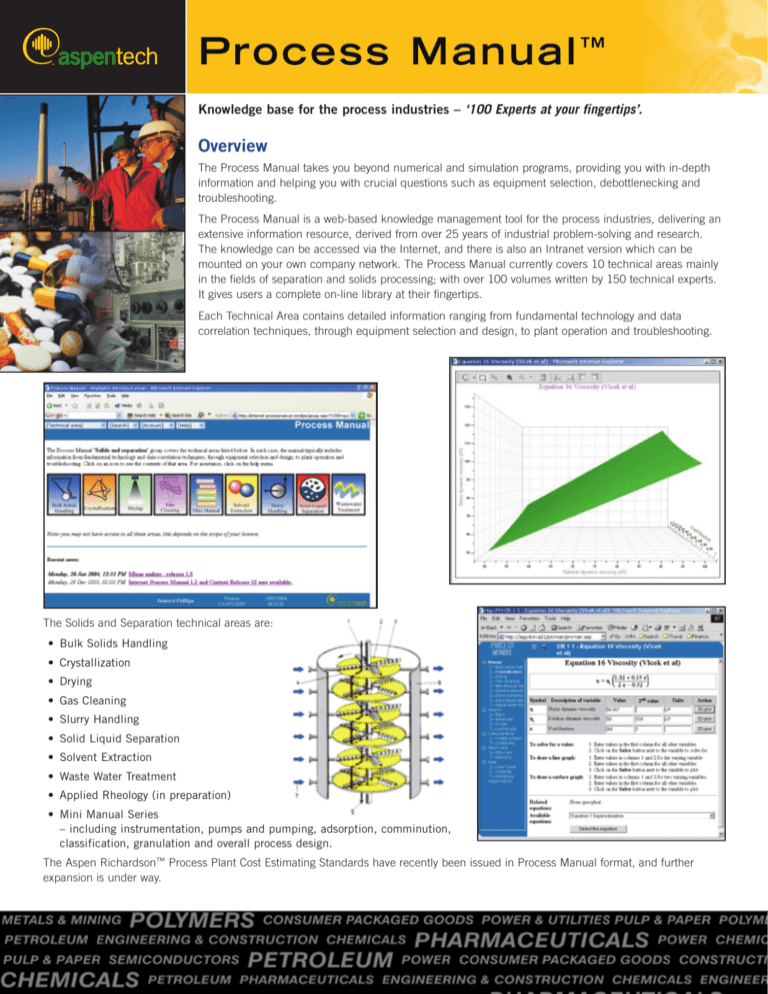

Process Manual ™

Knowledge base for the process industries – ‘100 Experts at your fingertips’.

Overview

The Process Manual takes you beyond numerical and simulation programs, providing you with in-depth

information and helping you with crucial questions such as equipment selection, debottlenecking and

troubleshooting.

The Process Manual is a web-based knowledge management tool for the process industries, delivering an

extensive information resource, derived from over 25 years of industrial problem-solving and research.

The knowledge can be accessed via the Internet, and there is also an Intranet version which can be

mounted on your own company network. The Process Manual currently covers 10 technical areas mainly

in the fields of separation and solids processing; with over 100 volumes written by 150 technical experts.

It gives users a complete on-line library at their fingertips.

Each Technical Area contains detailed information ranging from fundamental technology and data

correlation techniques, through equipment selection and design, to plant operation and troubleshooting.

The Solids and Separation technical areas are:

• Bulk Solids Handling

• Crystallization

• Drying

• Gas Cleaning

• Slurry Handling

• Solid Liquid Separation

• Solvent Extraction

• Waste Water Treatment

• Applied Rheology (in preparation)

• Mini Manual Series

– including instrumentation, pumps and pumping, adsorption, comminution,

classification, granulation and overall process design.

The Aspen Richardson™ Process Plant Cost Estimating Standards have recently been issued in Process Manual format, and further

expansion is under way.

Benefits

The Process Manual enables chemists, chemical engineers, plant operators,

engineering contractors or equipment supply companies to access valuable

chemical engineering knowledge using the standard web browser. If you ever find

yourself asking any of the following questions, the Process Manual could help you too.

• “I want to select process equipment but I need unbiased advice to give

confidence I’m making the right selection for my particular material”

• “I need to scale-up reliably and anticipate potential pitfalls”

• “I have a problem with production rate or product quality and need to know

how to solve it”

• “I need to increase throughput but want to know if I can squeeze it out of

my existing plant before I go for capital investment”

The Process Manual answers these questions by providing:

• A comprehensive, relevant and impartial source of knowledge, peer reviewed

and applied in industry for over 25 years

• In-depth information complementary to calculation and simulation programs,

giving the user the Why and How as well as the output

“Only after consulting Process Manual

and Process Tools for a gas cleaning

equipment selection problem did we

find that cyclones could be used where

they had previously been thought not

feasible. We saved over $ 1M a year

from recovering useful product, while

exceeding EPA air quality standards and

completely eliminating effluent

treatment requirements. The results

were above and beyond our expectations

both technically and economically.”

Jim Ryans

Eastman Chemical Co, Engineering

and Construction Division

• Rigorous theory which has been transformed into practical procedures for selection, design and performance improvement

• Easy access throughout your company, to all divisions, sites and countries

Features

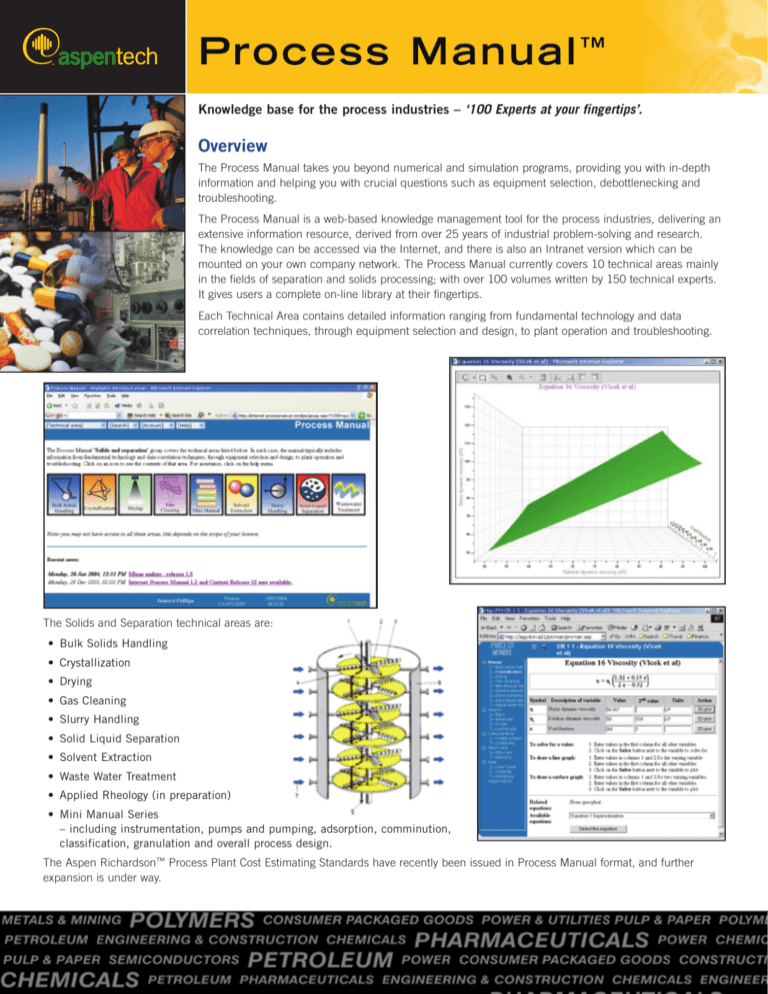

The Process Manual is powerful and user-friendly, requiring no specialized training. Key features include:

• Easy-to-use front end in standard web format

• Search tool for basic and advanced searching capabilities

• Live equations for key calculations performed on-line, including 2D/3D plots

• Links and contacts, allowing users to add cross-references to their own in-house documentation, files and personnel

• Links with calculation and simulation programs, including Process Tools™, Aspen Plus™, Batch Plus™ and HYSYS®

• Richardson WinRace Database™ searches and uses an electronic unit cost estimating database and estimating system

For more information on the Process Manual, please contact your local AspenTech sales office or visit

www.aspentech.com and www.processmanual.com.

worldwide headquarters

Aspen Technology, Inc.

Ten Canal Park

Cambridge, MA 02141-2201 USA

[phone] + 1 617 949 1000

[fax] + 1 617 949 1030

[world wide web] www.aspentech.com

[e-mail] info@aspentech.com

Copyright © 2004. AspenTech, Process Manual, Process Tools, Aspen Plus, Batch Plus, HYSYS and the aspen leaf logo are trademarks or registered trademarks of

Aspen Technology, Inc., Cambridge, Massachusetts USA. All rights reserved. All other brand and product names are trademarks or registered trademarks of their

respective companies. PB 187 04/16/04