Solubility of Ferrocene in Organic Solvents.

advertisement

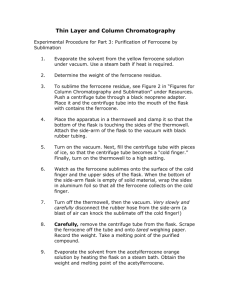

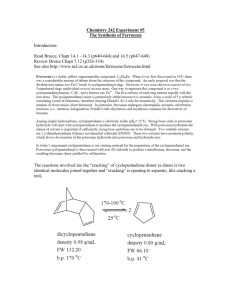

Solubility of Ferrocene in Organic Solvents Walter R. May SFA International, Inc. Houston, TX Of all metals with catalytic effects on the combustion of hydrocarbons, iron is one of the best. In the literature, iron reduces particulate matter in boiler and engine exhausts reaching as high as 50%.1 SFA International’s patented combustion catalyst technology involves the use of iron combined with magnesium.2 One of the requirements of a fuel additive is that metal compounds in the additive must be soluble in the fuel. Ferrocene contains 30% iron by weight and can be used as a source of iron in fuel additives. Ferrocene is sold as a fuel additive in liquid and solid forms. In solid form, it is available as “crumbs” and “caplets.” The advantage of using the solid form of ferrocene is that it is easy to ship and add to a fuel tank. Unfortunately, users of solid forms of ferrocene as a combustion catalyst have reported a wide range of results that are mostly negative.3 The purpose of this paper is to evaluate the chemistry of ferrocene and solubility in organic solvents to find the reasons for generally negative results with solid forms of ferrocene as a combustion catalyst. Ferrocene Sandwich compounds and ferrocene have been known since 1951 when Pauson and Kealy reacted cyclopentadienyl magnesium bromide Grignard Reagent with ferric chloride. They obtained a light orange powder of “remarkable stability.”4 It is stable to 400o without appreciable decomposition.5 Professor Mark M. Jones of Vanderbilt University (the author’s Ph.D. advisor) wrote extensively on ferrocene in his book Elementary Coordination Chemistry.6 1 Boiler Fuel Additives for Pollution Reduction and Energy Saving, Ed. R. C. Eliot, Noyes Data Corporation, Park Ridge, NJ, 1978. 2 See SFA’s web site at www.SFAInternational.com for more information. 3 Sources for this statement are personal and confidential conversations with several people who have had experience with using solid forms of ferrocene as a combustion catalyst. Results have been sporadic and overwhelmingly negative. 4 http://en.wikipedia.org/wiki/Ferrocene 5 Inorganic Reactions and Structure, Edwin S. Gould, Henry Holt and Company, New York, NY., 1955. 6 Elementary Coordination Chemistry, Mark M. Jones, Prentice-Hall, Inc., Englewood Cliffs, NJ, 1964. 1 According to the Handbook of Chemistry and Physics,7 ferrocene has a molecular weight of 186.04, 249o b.p. and 172.5o m.p. It is notable that there are no data regarding solubility of ferrocene in polar or non-polar solvents. Ferrocene is 30.02% iron by weight. Ferrocene - Dicyclopentadienyl Iron(0) Ferrocene as a Fuel Additive While ferrocene is made only in China at this time, there are a few importers of the product into the U.S. that hold Tier One testing and EPA Registration for on-road use. Most of these products are the solid form of ferrocene. The cost of Tier One registration testing is about $300,000 in an EPA acceptable laboratory. A number of companies have EPA registered re-branded products purchased from the holders of the original Tier One registration. Therefore, ferrocene has been very attractive as a lowcost on-road EPA Registered fuel catalyst with a minimum of problems shipping and applying solid forms. Metallic fuel additives can only be effective if dissolved at the molecular level in the fuel or, at a minimum, dispersed at sub-micrometer size levels. SFA’s FuelSpec® 116 and 117 products are oil-soluble iron carboxylates (salts of organic acids) that are completely soluble in aliphatic hydrocarbon fuels. SFA’s FuelSpec® 118 and 119 catalysts are based on an iron colloidal dispersion. FuelSpec® 118-1502 has a median particle size of 0.007 micrometers. To be an effective combustion catalyst, ferrocene must also be soluble in naphtha (gasoline) and Diesel fuels. The Wikipedia article states that ferrocene is “soluble in most organic solvents.” Siddiqi and Atakan8 studied the dynamic equilibrium between gas and liquid phases. They found ferrocene to be “only weakly soluble in these solvents” which included ethanol, toluene, hexane and 2,2,4-trimethylpentane (isooctane). With this minimal information, we undertook an investigation of the solubility characteristics of solid forms of ferrocene in organic solvents to find out if this is the cause of observed anomalies in performance of the product as a combustion catalyst. 7 8 Handbook of Chemistry and Physics, Ed. Robert C. Weast, CRC Press, Inc., Boca Raton, Florida, 1984-85. Siddiqi, A., Atakan, B., J. Chem. Eng. Data, 2006, 51 (3), pp. 1092-1096. 2 Solubility of Ferrocene in Organic Solvents A study was carried out at the University of North Texas on the “Solubility of Ferrocene in Organic Nonelectrolyte Solvents, Comparison of Observed versus Predicted Values Based upon Mobile Order Theory.”9 This paper includes experimental data on ferrocene in forty-six organic solvents compared with theoretical calculations for solubility based on mobile order theory. The solvents included a number of aliphatic compounds, aromatic compounds including benzene, toluene and xylene, alcohols, esters, ketones and organic sulfur compounds. The experimental data are presented in Table I. Solubility ranged from a high of 5.59% Fe for benzene to 0.09% for 1-Butanol. Xylene isomers had relative high solubility’s in the 3.5 to 4.0% range. Aliphatic solvents dropped off to the 1.0 to 1.5% ranges. Chlorinated hydrocarbons were high as well as carbon disulfide and pyridine. This indicates that solvents with higher levels of aromaticity were better solvents than non-polar aliphatic solvents. Oxygenated compounds were the poorest solvents. An examination of the structure of ferrocene (given on page two) indicates some aromaticity from the two sets of double bonded carbons in each cyclopentadienyl ring. However, those pi bonds are directed toward the strongly Lewis acid iron atom between the rings. The compound has weak aromatic character and a lack of non-polar areas commensurate with aliphatic properties. There are no polar areas for attraction to electron acceptors or donors. This eliminates oxygenated solvents. There is no reason to expect ferrocene to be especially soluble in any solvent, polar or non-polar. Ferrocene has no solubility in water and inorganic electrolyte solutions. SFA Solubility Results SFA recently undertook an evaluation of ferrocene solubility in a highly aromatic naphtha solvent and ultra low sulfur No. 2 (Diesel) fuel. We found a slow dissolution rate for ferrocene at 1% iron level (3.33% ferrocene) in heavy aromatic naphtha and an even slower dissolution rate in Diesel fuel. We were able to dissolve 2% iron (6.66% ferrocene) in heavy aromatic naphtha with vigorous mixing over about 3 days. We attribute this to the fact that aromatic fuels are better solvents for ferrocene than highly aliphatic fuels. Ferrocene was added to dyed off-road LED fuel at a 6.66% concentration to yield 2% iron in the solution. The product was vigorously shaken one time per day over a thirteen day period. The following time-dated photographs show the results. Figure 1 is a picture of the sample immediately following addition of the ferrocene to LED and 9 DeFina, K. M., Ezell, C., Acree, Jr., W. E., Physics and Chemistry of Liquids, 39, (6) Nov. 2001, Pages 699710. 3 vigorous shaking. Figure 2 shows un-dissolved ferrocene twelve days later. Figure 3 shows material clinging to the bottom of the bottle after it was inverted on the 13th day. Our work with ferrocene indicates that to dissolve the material in a solvent at percent levels, a highly aromatic solvent must be used. Vigorous agitation plus heating will help dissolution. It should be pointed out that iron is generally added to a fuel at 5 to 50 ppm whereas the samples evaluated in this study were at 1% and 2% or 10,000 and 20,000 ppm iron. Ferrocene would be expected to dissolve in aliphatic fuels at additive dosage levels with time and vigorous agitation. There are three things to consider with the use of solid forms of ferrocene as a fuel additive. 1. Because of low solubility and slow dissolution rates of ferrocene in typical LED aliphatic fuels, addition to a tank with minimal mixing is almost certain to result in poor results. Although ferrocene will dissolve with time in a static system due to thermal convection, localized concentration in the area of the solid material exceeding solubility limits will result in slowing or stopping dissolution of ferrocene in the fuel. Solid forms of ferrocene should never be put in fuel without thorough mixing which is generally not available in small contained tanks in vehicles and other equipment. 2. “Caplets” have a much smaller surface area to weight ratio than “crumbs” greatly reducing rate of dissolution. “Caplets” and large compressed forms of ferrocene should never be used and sales of these products should cease. 3. All ASTM No. 2 distilled fuels including LED fuels contain water that settles from the fuel and accumulates on the bottom of fuel tanks. Solid ferrocene has a higher density than fuel and, when added to a tank, immediately settles to the bottom of the tank in the water phase. Ferrocene is insoluble in water and this material will never dissolve. An eventual result can be plugging fuel filters. Ferrocene Solutions A limiting factor on the use of dissolved ferrocene as a fuel additive is the maximum concentration of iron that can be achieved in these solutions. The practical limit is 2% iron in highly aromatic solvents. To achieve 10 ppm iron in fuel with a 2% iron solution, a dosage rate of one part additive to 2,000 parts fuel by weight is required. SFA International has developed iron products with up to 9% iron in an oil soluble form and 18% iron in a colloidal dispersion for industrial applications. The resulting lower dosage rates yield much higher flexibility in application of the product and more 4 economically effective results. SFA discovered a synergistic combination of iron and magnesium that is a superior combustion catalyst to iron alone. In boiler and combustion turbine exhaust measurements, SFA’s iron-magnesium catalyst yields 90% reduction in particulate matter in exhausts10 compared with 50% expected from the literature.1 A study was carried out on a railroad locomotive using kerosene fuel with about 3,000 ppm sulfur that yielded 10% in switcher duty and 5% in road duty improvement with a ferrocene solution catalyst.11 SFA measured 12.0% fuel savings with the same fuel in 600 HP switch engine and 12.8% savings in a 1,500 HP road engine.12 It is estimated that SFA’s iron-magnesium catalyst yields 50% better fuel economy than iron alone. Conclusion Sporadic results from the use of ferrocene as a combustion catalyst can be explained by observations on the solubility of ferrocene in organic solvents. Our conclusion from this evaluation is that solid forms of ferrocene such as crumbs should be avoided. While crumbs can dissolve under ideal conditions, opportunities for the material to remain in solid form remain. Caplets with even poorer dissolution rates should be avoided and sales of these products should be stopped. Ferrocene can be used in combustion catalyst or fuel additive formulations when dissolved in a solvent so that it will disperse thoroughly into the fuel. There are better approaches to adding iron to a fuel exemplified by SFA’s higher concentration product line. Without mitigating circumstances such as EPA Registration requirements for onroad use, the user would be well advised to use SFA International’s much higher performing iron and magnesium combinations. Performance of a combustion catalyst containing iron (or iron plus magnesium) requires sufficient dosage. Optimum dosage levels are 10 ppm iron in compression-ignited reciprocating engines and 50 ppm iron in continuous firing equipment such as combustion turbines, boilers and process heaters. Lower dosage rates based on economic considerations are ill advised and will not produce desired results. 10 May, W and Hirs, E., “Catalyst for Improving the Combustion Efficiency of Petroleum Fuels in Diesel th Engines,” 11 Diesel Engine Emissions reduction Conference, August 21-25, 2005, Chicago, IL. 11 Note the 100% variation in the two measurements that could be attributed to mixing in the fuel. These types of observations are common with ferrocene based catalysts. 12 Verification Report was prepared by Greenhouse Gas Technology Center, Southern Research Institute, Research Triangle Park, NC, for EnviroFuels, Inc. The test was run on a St. Lawrence and Atlantic Railroad (Division of Genese & Wyoming) 3,000 HP EMD GP-40-3 locomotive. This test was run in 2005 in the state of Maine. Although an analysis of the fuel used in this test was not given in the report, it is estimated that the fuel was similar to that used in Lincoln and Plymouth Railroad tests with SFA’s iron-magnesium catalyst in new Hampshire in the same year. The complete test is available at www.envirofuelsllc.com. 5 Figure 1. Immediately following addition of ferrocene to off-road dyed Diesel fuel. 12-Apr-09. 6 Figure 2. Undissolved ferrocene after 12 days. 24-Apr-09 7 Figure 3. Undissolved ferrocene shown sticking to bottom of bottle. 25-Apr-09 8 Table I. Solubility of Ferrocene in Organic Non-Electrolyte Solvents Solvent n-Hexane n-Heptane n-Octane n-Nonane n-Decane n-Hexadecane Cyclohexane Methylcyclohexane Cyclooctane 2,2,4-Trimethylpentane t-Butylcyclohexane Benzene Toluene Ethylbenzene o-Xylene m-Xylene p-Xylene Dibutyl ether Methyl t-butyl ether 1,4-Dioxane Methanol Ethanol 1-Propanol 2-Propanol 1-Butanol 2-Butanol 2-Methyl-1-propanol 2-Methyl-2-propanol 1-Pentanol 2-Pentanol 3-Methyl-1-butanol 2-Methyl-2-butanol 1-Hexanol 2-Methyl-1-pentanol 4-Methyl-1-pentanol 1-Heptanol 1-Octanol 2-Ethyl-1-hexanol 1-Decanol 2-Ethyl-1-hexanol Solvent Mol. Wt. 86.178 100.205 114.232 128.259 142.286 226.448 98.189 113.224 109.192 114.232 154.297 78.114 92.141 106.168 106.168 106.168 106.168 130.232 88.151 88.108 32.043 46.070 60.097 60.097 74.124 74.124 74.124 74.124 88.151 88.151 88.151 88.151 102.178 102.178 102.178 116.205 130.232 130.232 158.286 130.232 Mole Fraction Solubility 0.022600 0.024890 0.027130 0.029010 0.030970 0.039630 0.033000 0.033720 0.046800 0.021790 0.036120 0.087586 0.083210 0.077030 0.080140 0.074360 0.077850 0.051070 0.041200 0.068300 0.003298 0.005976 0.008917 0.007078 0.001181 0.010270 0.009621 0.009215 0.013520 0.012630 0.012250 0.015540 0.017350 0.014260 0.013430 0.020500 0.022150 0.016670 0.027670 0.016670 % Sol. 4.75% 4.52% 4.34% 4.15% 4.01% 3.28% 6.07% 5.42% 7.72% 3.50% 4.32% 18.61% 15.49% 12.76% 13.24% 12.34% 12.89% 7.14% 8.31% 13.40% 1.88% 2.37% 2.71% 2.16% 0.30% 2.54% 2.38% 2.28% 2.81% 2.63% 2.55% 3.22% 3.11% 2.57% 2.42% 3.24% 3.13% 2.36% 3.24% 2.36% % Fe 1.43% 1.36% 1.30% 1.25% 1.20% 0.98% 1.82% 1.63% 2.32% 1.05% 1.30% 5.59% 4.65% 3.83% 3.98% 3.70% 3.87% 2.14% 2.50% 4.02% 0.57% 0.71% 0.81% 0.65% 0.09% 0.76% 0.71% 0.68% 0.84% 0.79% 0.77% 0.97% 0.94% 0.77% 0.73% 0.97% 0.94% 0.71% 0.97% 0.71% Table I Continued Solvent 1-Decanol Cyclopentanol Butyl acetate Ethyl acetate Methyl acetate 2,3-Dichloroethane 1-Chlorobutane 1-Chlorooctane Tetrachloromethane 2-Propanone Acetonitrile Dimethyl sulfoxide Carbon disulfide Pyridine Solvent Mol. Wt. 158.286 86.135 116.162 88.108 74.081 98.960 92.569 148.677 153.823 95.550 41.050 78.130 76.140 79.100 Mole Fraction Solubility 0.027670 0.017740 0.055800 0.043000 0.032580 0.077350 0.059620 0.060620 0.06920 0.02400 0.00756 0.01410 0.06690 0.07048 % Sol. 3.24% 3.75% 8.65% 8.67% 7.80% 13.61% 11.30% 7.47% 8.25% 4.57% 3.34% 3.29% 14.91% 15.13% % Fe 0.97% 1.13% 2.60% 2.60% 2.34% 4.09% 3.39% 2.24% 2.48% 1.37% 1.00% 0.99% 4.48% 4.54%