Synthesis of Ferrocene

advertisement

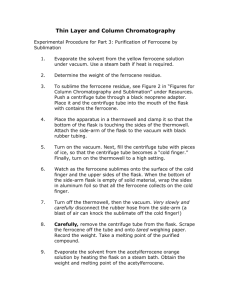

CH242L S2008 Jenkins PCC-Sylvania Experiment #6 Synthesis of Ferrocene Prior reading: Bruice, Chapter 14: Aromaticity, p.640-649, Bruice, Ch 7:Dienes, p.301-334 Introduction Ferrocene is a stable, yellow organometallic compound, C10H10Fe. When it was first discovered in 1951 there was a considerable amount of debate about the structure of this compound. An early proposal was that the divalent iron makes two Fe-C bonds to cyclopentadienyl rings. However, it was soon shown to consist of two 5-membered rings sandwiched around an iron atom. One way to represent this compound is as a two cyclopentadienylanions, C5H5-, and a ferrous ion, Fe2+. The five carbons of each ring interact equally with the iron atom. The cyclopentadienyl anion is particularly stable because it is aromatic: it has a cycle of 5 p orbitals containing a total of 6 electrons, therefore obeying Hückel's 4n+2 rule for aromaticity. This structure explains a number of observations about ferrocene. In particular, ferrocene undergoes electrophilic aromatic substitution reactions (i.e., nitration, halogenation, Friedel Crafts alkylations and acylations) common for derivatives of benzene. Among simple hydrocarbons, cyclopentadiene is relatively acidic (pKa= 15.5). Strong bases such as potassium hydroxide will react with cyclopentadiene to produce the cyclopentadienide ion. The choice of solvent is important if sufficiently strong base solutions with potassium hydroxide the are to be obtained. Two suitable solvents are 1,2dimethoxyethane (Glyme) and dimethyl sulfoxide (DMSO). These two solvents have moderate polarity, which favors dissociation of the potassium hydroxide into potassium and hydroxide ions. In today’s experiment cyclopentadiene is our starting material for the preparation of the cyclopentadienyl ion. Potassium cyclopentadienyl is then reacted with iron (II) chloride to produce a metallocene, ferrocene, and the resulting ferrocene slurry purified by sublimation. The reactions involved are the “cracking” of cyclopentadiene dimer (a dimer is two identical molecules joined together). CH242L S2008 Jenkins PCC-Sylvania Cyclopentadiene can be synthesized from dicyclopentadiene (the Diels-Alder self adduct) by "cracking" it, which just means heating it above the boiling point of cyclopentadiene. Because the Diels-Alder reaction is a reversible one and at equilibrium, the cyclopentadiene is removed by boiling and the equilibrium is driven to the right. This reaction is followed by the removal of an acidic hydrogen to make a stable aromatic ring that happens to have a negative charge. Finally, Iron (II) is brought in and we have all the pieces to make our ionic ferrocene molecule. Experimental Procedure There are two parts to this experiment: cracking of dicyclopentadiene to obtain fresh cyclopentadiene followed by the preparation of ferrocene. In your notebook, write the balanced chemical reaction that shows what is happening in this distillation apparatus as one of your prelab balanced equations. You will obtain freshly distilled cyclopentadiene from the still in the fume hood. This will be used to prepare the ferrocene. Cracking of Dicyclopentadiene. The cracking apparatus is a simple fractional distillation set-up. Freshly prepared cyclopentadiene is necessary to accomplish this synthesis. A source of dicyclopentadiene will be available in one of the hoods in the laboratory. Set up the apparatus for cracking the dicylopentadiene (this should already be in fume hood). CH242L S2008 Jenkins PCC-Sylvania The bulb of the thermometer in the 5-mL flask should extend into the mineral oil. The heater controller should be set to "5." In about 10 min the sand bath and reaction flask will be equilibrated to about 250 °C, and the heater control should be turned back to a setting of "34" before proceeding. At this point, you may start adding the dicyclopentadiene dropwise. The 1,3-cyclopentadiene will be formed very rapidly and will begin to reach the thermometer in the distillation head within 2-3 min Continue adding the dimer dropwise from the addition funnel (1 drop every 5-10 s) once you are collecting 1,3-cyclopentadiene in the receiving flask. Add the dimer slowly enough so the volume in the hot round-bottomed flask does not change appreciably. The condenser should be cool and the receiving flask should be submerged in ice since 1,3-cyclopentadiene is low boiling and volatile. It has a pungent, characteristic odor. Collect enough 1,3cyclopentadiene (34 mL) to perform the assigned reactions The dimer cracks slowly on heating and the monomer begins to distill steadily in the 40 42C range. Synthesis of Ferrocene CAUTION: KOH is extremely corrosive and highly hygroscopic. Wear Gloves. 6 M HCl is also corrosive. Be careful when handling. Reaction 1. Grind 0.750 g of KOH in a mortar with a pestle as rapidly as possible. 2. Quickly transfer the finely ground powder to a small round bottom flask equipped with a magnetic stir bar and add 1.3 mL of 1,2-dimethoxyethane (Glyme). The chromatography column funnel may be very useful for this transfer. 3. Cap the flask with a good septum, then pass nitrogen through the solution for about 1 minute. This is done by connecting a tank of nitrogen via a rubber tube to a 22-gauge needle and adjusting the nitrogen flow to a few milliliters per minute. When the flow rate has been correctly set, insert an empty syringe needle through the septum as an outlet for the pressure, then insert the nitrogen needle through the septum into the solution. 4. Remove the needles after a minute (any longer is a waste of nitrogen), shake the flask to dislodge any solid stuck to the bottom, then turn on the stir bar. Don’t forget to turn off the nitrogen flow if no one else is waiting to use it. 5. To a separate 10 mL vial, add 0.350 g of finely powdered green iron (II) chloride tetrahydrate and 1.5 mL of dimethyl sulfoxide (DMSO). 6. Cap this vial with a good septum, insert an empty syringe needle to bleed off excess pressure, then insert the nitrogen inlet needle. 7. After one minute remove both needles (don’t forget to turn off the nitrogen flow if no one else is waiting to use it), and shake the vial vigorously to dissolve all the iron chloride. Some GENTLE warming may be necessary. Use the warmth of your hands first before reaching for a heating mantle. 8. Using an accurate syringe, add 0.300 mL of the freshly distilled cyclopentadiene directly to the mixture of KOH in Glyme. Do not grasp the body of the syringe (what was the boiling point of cyclopentadiene again?). 9. Stir the flask vigorously. The solution should turn brown because of the formation of potassium cyclopendadienide salt. CH242L S2008 Jenkins PCC-Sylvania 10. After waiting five minutes for the anion to form, pierce the septum with an empty needle to relieve pressure and then inject the iron (II) chloride solution in six 0.25 mL portions over a ten minute period with a separate needle. Continue stirring. If the bar becomes immobile, remove both needles and shake the flask rabidly. 11. After all the iron (II) chloride has been added, rinse the reaction tube with 0.25 mL more of DMSO and add this to your reaction. Continue stirring for 15 minutes to complete the reaction. Isolation 12. Prepare a mixture of 5.0 g of ice and 4.5 mL of 6 M HCl in a 30 or 50 mL beaker. 13. To isolate the ferrocene, pour the dark reaction slurry (heterogeneous mix of liquid and solid) into the beaker with the ice and HCl. 14. Stir the mixture thoroughly to neutralize any leftover KOH (check with pH paper and add more HCl if necessary). 15. Filter the orange crystals and wash the crystals with two 1 mL portions of cold water. 16. Continue to draw air through the funnel to air dry for an additional five minutes, then dry the crystals further between the folds of a piece of filter paper. 17. Weigh the crude product and set aside a small amount to do a crude product mp. 18. Purification will take place by sublimation. Sublimation is the process of going right from a solid phase to a gas phase, as dry ice (frozen carbon dioxide) does. A material sublimes when the local pressure is below the substance’s triple point. Add the crude product to a 25-mL filter flask equipped with a neoprene fliter adapter (Pluro stopper) and a 15 mL centrifuge tube that is pushed to within 5 mm of the bottom of the flask. 19. Place a rubber bulb over the side arm of the flask, add ice to the centrifuge tube, and then gently heat the flask on the sand bath to sublime the product. 20. Tilting and rolling the filter flask in the hot sand will help sublime the ferrocene onto the centrifuge tube. Be sure to occasionally remove the bulb on the side arm so pressure does not build up too much. 21. When sublimation is complete, cool the filter flask, remove the ice water from the centrifuge tube, and replace it with room temperature water (to prevent condensation from forming on the tube). 22. Transfer the pure ferrocene to a tared stoppered vial, determine the mass, and calculate the percent yield. Characterization 23. Determine the mp of the final product as well as the crude product. Since ferrocene sublimes, you will have to do this in a sealed capillary tube. 24. Obtain a KBr pellet IR of your product. 25. Save your ferrocene for a later experiment (acetylation of ferrocene) in an airtight jar. Clean Up 26. the filtrate should be slightly acidic. Neutralize with sodium carbonate, dilute with tap water, and then flush it down the drain. Place any unused cyclopentadiene in the recovered cyclopentadiene container in the hood. CH242L S2008 Jenkins PCC-Sylvania 27. Add 0.4 mL of concentrated nitric acid to the sublimation flask to clean the residue. Next week, neutralize with sodium bicarbonate and flush that down the drain. Questions 1. Cyclopentadiene dimer cracks slowly to give monomeric cyclopentadiene, but on standing, even at room temperature, the monomer reverts to the dimer. Explain why. I want more of an explanation than “The reaction is reversible.” 2. It is observed that the addition of hydrogen bonding (protic) solvents like water or alcohol to DMSO solutions of potassium hydroxide sharply reduce the effective base strength. Explain why. http://www.ncl.ox.ac.uk/mom/ferrocene/ferrocene.html http://courses.cm.utexas.edu/archive/Fall2001/CH431/expt_5.pdf http://www.usm.maine.edu/~tracy/chy374/chy374labs/PrepFerrocene.pdf CH242L S2008 Jenkins PCC-Sylvania CH 242 Student Name Maazouz Date Grading Guidelines for Synthesis Lab Check List Description of Grading Criteria Name, Date, Experiment Title 2 Purpose 3 Table of Physical Properties Chemical structures Appropriate entries (see handout) Table format (neatness Organization Outline/Procedure Neatness (done before lab) Waste Disposal Procedure 8 8 3 Experimental Set-up Sloppiness: spilling, breaking, handling of chemicals, etc. Proper use of hood for ventilation 7 Experiment completed 5 Observation and Data (completeness) Yield: show all calculations % yield Spectral Data: Quality, Interpretation of Quality 12 Discussion/Analysis of ALL Data m.p, IR, purification methods…. Conclusion of experimental Data 16 Questions (2 questions @ 3pts each) 6 Overall organization, readability, completeness 4 Total for Lab Report Comments: Percent (%) 4 8 7 7 100% = 20 points Yours