45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit

2 - 5 August 2009, Denver, Colorado

AIAA 2009-5465

Controlling the rule of Coke Depositions of Hydrocarbon Fuels in

Channel to intensify Heat Transfer Under Supercritical Conditions

Weixing Zhou 1 , Wen Bao 2 , Yanjuan Duan 3 ,Jang Qin3

Harbin Institute of Technology, Harbin, People’s Republic of China,150001

As the temperature in chamber of scramjet engine would be very high, for the moment,

endothermic hydrocarbon fuels instead of the conventional aviation oils would be used in active

cooling. However, when endothermic hydrocarbon fuels were heated, it would be occurred coke

deposition on the in-wall of cooling channels. In this paper, the study is focused on the influence of

coke depositions on heat transfer by experiments and numerical calculations. Along with the time of

heating, the thickness of coke depositions in channel varied. At the beginning of heating, a few of

cokes are deposited on the in-wall of channels. Heat transfer is intensified as a result of the roughness

of coke. Then, the coke thickness increases, the efficiency of heat transfer gradually reduces. At this

time, other conditions were varied to control the rule of coke depositions in order to increase the

intensity of heat exchange. For example, the flux of fuels would be increased to overcome the clinging

force between cokes and channel wall,and so on.

Key Words: Coke depositions, Hydrocarbon fuels, Heat transfer, Supercritical Conditions

I. Introduction

II. Experimental system and methods

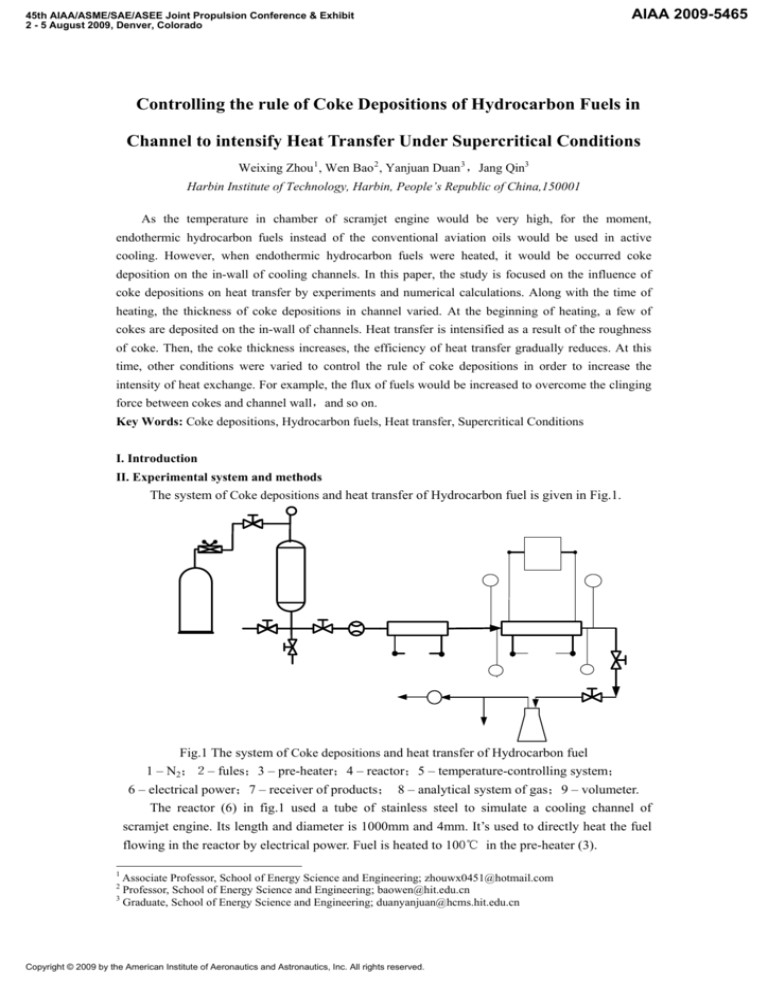

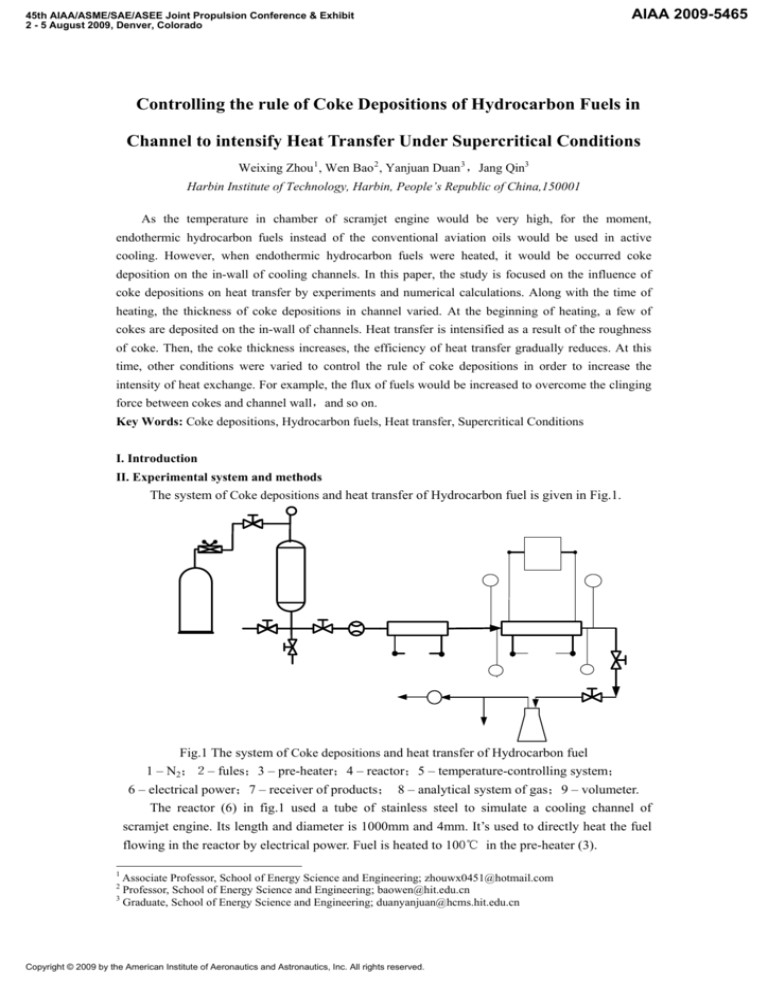

The system of Coke depositions and heat transfer of Hydrocarbon fuel is given in Fig.1.

Fig.1 The system of Coke depositions and heat transfer of Hydrocarbon fuel

1 – N2;2– fules;3 – pre-heater;4 – reactor;5 – temperature-controlling system;

6 – electrical power;7 – receiver of products; 8 – analytical system of gas;9 – volumeter.

The reactor (6) in fig.1 used a tube of stainless steel to simulate a cooling channel of

scramjet engine. Its length and diameter is 1000mm and 4mm. It’s used to directly heat the fuel

flowing in the reactor by electrical power. Fuel is heated to 100℃ in the pre-heater (3).

1

Associate Professor, School of Energy Science and Engineering; zhouwx0451@hotmail.com

Professor, School of Energy Science and Engineering; baowen@hit.edu.cn

3

Graduate, School of Energy Science and Engineering; duanyanjuan@hcms.hit.edu.cn

2

Copyright © 2009 by the American Institute of Aeronautics and Astronautics, Inc. All rights reserved.

III. Numerical model of the wall temperature

One dimension equation of tube reactor is following:

2

T λ ∂T

= qV

λ∂ 2 + ⋅

r ∂ r

∂r

(1)

then,heat source qv –heat density caused by electrical current, which heated the

3

tube wall, is named volume heat load (W/m ).

Fig.2 The partial sect of reactor

Thermal equilibrium on the outer-wall and the inner-wall of reactor:

qV ⋅ V = qS1 ⋅ S1 + q S 2 ⋅ S 2

(2)

Thermal density is given by equation (1) and (2):

q S 1 = qV ⋅

(R

− R12 ) R2

−

⋅ qS 2

R1

2 ⋅ R1

2

2

(3)

Thermal conductivity:

q S 1 = −λ ⋅

∂T

∂r

(4)

Then,

⎛R ⎞

⎛

⎞ 1

(R 2 − R12 )

R2

T1 = T2 − ⎜⎜ qV ⋅ 2 − R2 ⋅ q S 2 ⎟⎟ ⋅ ⋅ ln⎜⎜ 2 ⎟⎟ − qV ⋅ 2

2

4⋅λ

⎝

⎠ λ

⎝ R1 ⎠

(5)

Thermal equilibrium:

q s1 ⋅ 2πR1dx = m& ⋅ C p ⋅ dT f

(6)

Newton equation:

qs1 = α ⋅ (T1 − T f )

(7)

Then,

Nu = α ⋅ 2 R1 / λ

(8)

IV. Experimental result

Fig.3 is given the quantities of coke deposition on the in-wall of each segment of reactor.

Reactor is divided into 20 segments after 30min heating. The quantities of coke depositions is the

least in the middle of tube.

Fig.3 The quantities of coke deposition on the in-wall of each segment of reactor

It is illuminated the distribution of heat transfer coefficient on the in-wall of reactor in fig.4.

The intensity of heat transfer in the front of 200mm tube and in the back of reactor decreased along

with heating time. However, the heat transfer from 200mm to 900mm of the reactor increased. This

phenomena is illuminated that heat transfer is intensified as a result of the roughness of coke. Then, the

coke thickness increases, the efficiency of heat transfer gradually reduces.

Fig.4 The distribution of heat transfer coefficient on the in-wall of reactor

References

[1] Fu Quanjun, Yan Ke, Du Zonggang, Li Ning. Research progress of endothermic

hydrocarbon fuels. Journal of Rocket Propulsion2005.Vol.31.№5.

[2] Long Term Deposit Formation in Aviation Turbine Fuel at Elevated Temperature / Giovanetti

A.J., Szetela E.J. // AIAA – Paper , 1986, N0 – 526, 11p.

[3] Yanovskiy L.C.,Ivanov V.F., Galimov F.M., Sapgir G.B.: Coke Depositions in Aviation and Rocket

Engines. Kazan, 1999.Abak.

[4] Yanovskiy L.S., Martynenko S.I., Baykov A.V. Heat and Mass Transfer at Turbulent Flow of

Endothermic Hydrocarbon Fuels in Channels under Supercritical Pressure.ISABE-2005-1075.

[5] Wickhan D. T., Engel J.R., Karpuk M.E. Additives to Prevent Filamentous Coke Formation in

Endothermic Heat Exchangers Prepr Paf-Am Chen Soc, Div Pet Chem,2000,45(3).459-464.

[6] Gao Han, Li Zuguang, Li Gang, Zhu Wanliang, Lin Ruisen. BUILDING OF ENDOTHERMIC

FUEL COOLING SIMULATION SYSTEM. Journal of Propulsion Technology. 1999.

Vol.20.№5.

[7] Guo Yongsheng, He Long, Fang Wenjun, Lin Ruiseng. STUDY ON PYROLYSIS-CRACKING COKE OF

ENDOTHERMIC HYDROCARBON FUELS Journal of Fuel Chemistry and Technology. 2003.Vol.31.

№4.300-304.

[8] Zhu Yuhong, Yu Caixiang, Li Zimu. Formation of Coke in Thermal Cracking of Jet Fuel Under

Supercritical Conditions 2006,35(12):1151-1155.