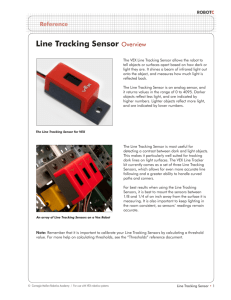

Line Follower

advertisement

Line Follower There are a number of methods which can be used to build a line following robot. In general there are three different types of line followers: 1. Single light sensor model 2. Two light sensor model 3. Three ligth sensor model Of these three models the most versatile, relatively reliable and easier to construct is the two light sensor model. It further can follow more easily black lines which go any direction. Where the single sensor models are either left or right turning favoring. Line Following Learning Resources Below are a number of PDF‘s with basic instructions on experimenting quickly with the various line following methods as described in more detail on the accompanying web pages. 3 Minute Line Follower Robot Single Sensor Line Follower Program Two Sensor Line Follower Program Light Sensor Calibration Placement of Light Sensors Where the light sensor is positioned makes a big diference in how well the robot follows an given line. In general placing the light sensor ahead of the wheels (motors) allows the robot to react more accurately to upcoming course (line) changes. You may want to experiment with the placement of the sensors and the distance between the sensor and the driving wheels. Experiment with placing the sensors behind the driving motors and observe the efects this has on the accuracy and fluency of the robot as it tries to follow the line. Two Sensor In this scenario, two light sensors are positioned so that thet are on either side of the black line the robot is intended to follow. By detecting which sensor changes from white to black, we know how to turn back toward and onto the line. This robot is therefore able to follow any line making any type of turns (left or right etc) There are 4 possible states which can occur: #1 L – Black R – White Robot needs to make a right turn to get back centered onto the line #2 Both White In this case the robot is perfectly centered above the black line and can drive straight forward, without corrective action. Both Black This is the case when the robot reaches an intersecting other black line. This is a special case and can be used to execute a special action. #4 L – White R – Black Robot needs to make a corrective action, in this case it needs to make a left turn to turn back onto the black line. This can be expressed using the following flow-chart: Note that in case of the Left and Right Sensor both detecting black, no action is determined. We could use it as a special condition, to for-example stop driving, or keep driving straigth and in effect ignoring the intersecting line. Program Example Things to note: 1. A Forever loop is used to repeatedly get sensor readings and apply the appropriate steering correction to the wheels, as fast as possible. The loop will repeat several times per second. 2. Inside the loop, we first set a logic variable to ‗false‘ which is used to control the outer loop, and is effeted when the special condition occurs where both the left and right sensor see black — corss an intersecting black line. 3. We repeatedly check the Left light sensor and then switch based it seeing more then 50% of light (none-black). 4. We then check the Right light sensor and switch based on it seeing more then 50% of light (none black) The turns are done by stopping one wheel and turning only the other wheel, using individual Motor blocks for each motor. This is more consistent and faster than using a single 2-motor Move block with steering because the rotation sensors don‘t interfere with the amount of steering. 5. When the special condition occurs where both the Right and Left sensor see black, a the Logic Varibale is set to True. whne this occures, the overall control loop is exited. Motor block duration is set to Unlimited because we just want to start moving that way then immediately loop back and check the sensor again to see if we need to change direction (Unlimited here means ―Go this way until I tell you otherwise‖). Advanced three Sensor model — PID control model Want to make your robot follow a line? At slower speeds, the process is pretty simple – if the sensors say it is going left, steer right and if going right, steer left. This process has its limitations though, mainly when the speed is increased . This is when a PID controller starts to shine. PID stands for Proportional, Integral, Derivative. A PID controller is a mathematically-based routine that processes sensor data and uses it to control the direction (and/ or speed) of a robot to keep it on course. Why does PID work better than our simple model described above? Let‘s talk about how robot acts (or behaves) as it follows a line to see why. Robot Behavior when following a line Let‘s say our robot has 3 sensors, Left, Center and Right. When the Center sensor sees the line, the robot is programmed to go straight. When the Left sensor sees the line, the robot is programmed to turn right. When the Right sensor sees the line, the robot is programmed to turn left. This will typically cause the robot the wobble back and forth over the line and if going too fast, it may lose control and stop following the line. This method only takes one behavior into consideration – is the robot centered over the line. To improve performance, we should also take into consideration 2 more behaviors – how rapidly is the robot moving from side to side and how long is it not centered over the line. These 3 behaviors are called Proportional, Integral and Derivative in terms of a PID controller.