Complements or Substitutes? Private Codes, State

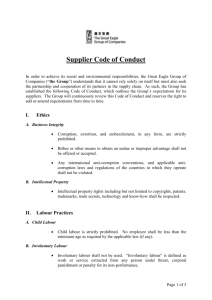

advertisement