PIECING TOGETHER

THE INDIRECT

MATERIALS PUZZLE:

The Current Landscape of Indirect Material

Management Solutions

MARGINPOINT CORPORATION | 2 South Pointe Drive, Suite 220 | Lake Forest, CA 92630 | 888-229-3685 www.marginpoint.com

SHARE THIS EBOOK

Table of Contents

Introduction ................................................................................................................1

What to Look For in a Solution ..................................................................................2

Navigating the Solution Landscape ..........................................................................5

Enterprise Resource Planning (ERP) .............................................................5

Procurement and Sourcing System ................................................................6

Warehouse Management System (WMS) ......................................................6

Enterprise Asset Management (EAM) ............................................................7

Facilities Management System.......................................................................7

Industrial Vending Solution .............................................................................7

Custom or Home-Grown Solution ..................................................................8

Business Process Outsourcing (BPO) ...........................................................8

Conclusion .................................................................................................................9

SHARE THIS EBOOK

PIECING TOGETHER

THE INDIRECT

MATERIALS PUZZLE:

The Current Landscape of Indirect Material

Management Solutions

Introduction

50% of

indirect

materials

will remain

unused or

inactive

over a 12

month

period,

Industrial organizations such as manufacturers, construction firms and

utilities have an inherent cost in their business; indirect materials. Because

this is often perceived as a necessary cost of doing business, many

companies have ignored the indirect materials process which has created

significant inefficiencies and waste resulting in overspending, shortages

and high management costs. For example, 50% of indirect materials will

remain unused or inactive over a 12 month period. As an executive or

manager responsible for indirect material spend at your company or site,

you recognize the need to address these problems and get your indirect

materials in order. But where do you turn? What solutions are out there to

help you tackle this problem?

Traditional solutions that companies typically implement are lacking in one

key area or another. The variety and complexity of current market solutions

make it difficult to navigate and understand which option is best for your

organization. In this paper MarginPoint will help you survey each stage of

the indirect materials process. It will compare and contrast solutions that

you may be currently using or have considered in the past to highlight their

strengths and weaknesses. By auditing your process, you will begin to

understand the importance of indirect materials management and to

understand how to evaluate the landscape of solutions available to address

your indirect material management needs.

1

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

What to Look For in a Solution

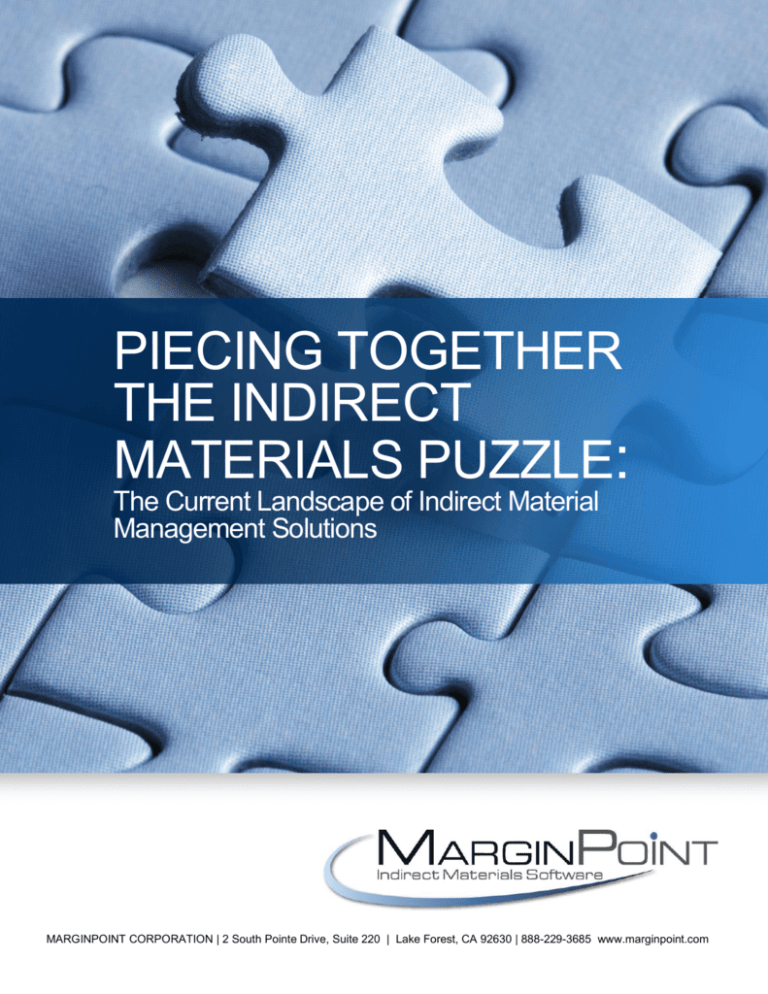

Before we get into a discussion of the various solutions that are out there,

let’s first spend some time analyzing what you should look for in an indirect

materials management solution. The figure below provides a framework for

the key indirect material business processes that need to be effectively

managed. They span the entire indirect material lifecycle from

replenishment to usage and disposal. Ideally, a comprehensive indirect

material management solution would help you address needs in each of

these categories.

FIGURE 1: FRAMEWORK FOR KEY INDIRECT MATERIAL BUSINESS PROCESSES

1. Use – This stage is focused on managing usage of indirect

materials throughout the enterprise. This is the heart of an effective

indirect materials management system and drives all other related

material processes. It entails controlling usage of materials to

reduce waste or unauthorized use and tracking usage at a detailed

level (including who, what, when, where and why for all

consumption activity) to improve accountability and to drive

improvement opportunities. In fact, companies that simply start

tracking material usage at the individual user level can reap as

much as a 10% reduction in usage. Without visibility to actual

usage details, all of the other indirect material processes would be

virtually impossible to effectively manage since those other

processes rely on inputs from the Use stage. It would also be

difficult to identify savings and process improvement opportunities

without visibility to why, when, where and by whom the indirect

material is being used. You can’t manage what you don’t measure!

2

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

2. Replenish – This is the stage in the indirect materials process

where required materials are procured. This is obviously an

important stage of the indirect materials process because it controls

what material enters your facilities. However, as mentioned above,

it is driven to a large extent by the information collected in the Use

stage to ensure that the right materials are replenished at the right

time and in the right quantities based on demand. The Replenish

stage includes the sourcing of material as well as the process of

procuring material from available suppliers as needed.

3. Stage – In this stage of the process, material is positioned at

appropriate places throughout a facility to be used as needed.

Material could be staged in a central crib location or at multiple

point-of-use locations throughout a facility. Like the Replenish

stage, the Stage process relies heavily on information from the Use

stage to help drive decisions on what to stock where and in what

quantities to make sure that the material required to keep the facility

running smoothly is available as needed. Also, this stage includes

the process for transferring/rebalancing stock levels among the

various stocking locations.

Companies

that simply

start tracking

material

usage at the 4.

individual user

level can reap

as much

as a 10%

reduction

in usage.

Dispose – This phase of the indirect material lifecycle is focused on

handling excess and obsolete material. In addition to managing the

replenishment, staging and usage of indirect material, an important

element of a comprehensive indirect material management solution

is the capability to deal with material which is no longer in demand.

This entails first identifying slow-moving items and then determining

how to effectively remove or dispose of such material. This is an

important yet often overlooked phase of the indirect material

lifecycle and can cause an unnecessary proliferation of material if

left unmanaged.

5. Control – Across all of the stages of the indirect material

lifecycle, the ideal indirect material management solution must

effectively control each of the processes with appropriate

transaction workflows and alerting to exception conditions as

they arise. The solution would ideally provide the capability to

establish normal operating parameters and performance targets

and then provide proactive alerts and allow corrective action if

actual performance deviates from the predefined plan.

6. Plan/Analyze – The ultimate objective of an indirect material

management solution is to meet the indirect material needs of an

3

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

enterprise at a lower cost. In order to achieve this objective,

organizations must be in a constant cycle of continuous

improvement – continuously adjusting how they manage their

indirect materials to wring cost out of the process while

maintaining high service levels. The ability to analyze past

performance is crucial for this process to yield results. Therefore,

the ideal indirect material management solution should have a

robust analytics capability that enables users to closely monitor

performance and identify opportunities for improvement. Going a

step further, a solution that could recommend process changes

and automatically implement them would provide an extremely

powerful capability to a company’s arsenal of material

management tools.

All of the above areas represent important components of a

comprehensive indirect material management solution that should be

considered when evaluating the various solution options.

The ideal indirect material management

solution should have a robust analytics

capability that enables users to closely

monitor performance and identify

opportunities for improvement.

4

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

☼

Navigating the Solution Landscape

Now that we have an idea of what we need our indirect material

management solution to do, let’s review some of the commonly available

solutions that are currently on the market and discuss some of the pros and

cons of each. The table below lists most of the commonly used solutions to

manage indirect materials.

Table 1: Solution Overview

Solution

Description

Enterprise Resource

Planning (ERP)

A company’s core system used to manage everything

from financials, HR, manufacturing, sales, distribution,

etc.

Procurement and

Sourcing System

Specialized systems that focus on streamlining a

company’s procure-to-pay process for all types of

procured materials and services

Warehouse Management

System (WMS)

Specialized inventory control system intended for

warehouses with high volumes of transactions

Enterprise Asset

Management (EAM)

Specialized system used to track and manage bigticket capital equipment (assets)

Facilities Management

System

Specialized system used to track and manage

facilities and facilities-related assets

Industrial Vending

Solution

Specialized inventory control solutions intended to

control and dispense industrial supplies at the pointof-use*

Custom or Home-Grown

Solution

This is a catch-all for any home-grown solutions

developed by companies for their own internal use

Business Process

Outsourcing (BPO)

As an alternative to figuring out how to manage their

indirect materials internally, some may choose to

outsource some or all of the indirect materials

management process to a third-party that specializes

in this type of service

Enterprise Resource Planning (ERP)

Most companies already have some sort of core ERP system to manage

financials and other core business processes such as purchasing,

manufacturing and sales. It’s entirely reasonable for companies to try to

leverage their existing ERP system to manage their indirect materials

processes. However, there are a few pitfalls to be aware of:

5

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

It would be

difficult to

continue to

adapt ERP

to meet the

evolving

needs of

your indirect

material

management

processes

1. ERP will not be able to control and track the issuance of material at

a sufficient level of detail to drive the Replenish, Stage and Dispose

indirect material processes. As a result, ERP won’t be able to

effectively help companies figure out what indirect material needs to

be purchased and when. It will continue to rely on external inputs

for such data

2. ERP systems will be strained to accommodate the dynamic nature

of the indirect material master where items are continuously being

added, removed and updated. This is much more than ERP was

intended to handle

3. ERP tends to be fairly rigid and expensive to adapt to changing

requirements. Companies spend hundreds of thousands of dollars

to implement their ERP systems to handle their existing processes.

Any subsequent changes or upgrades are fairly onerous

undertakings. Therefore, it would be difficult to continue to adapt

ERP to meet the evolving needs of your indirect material

management processes

Procurement and Sourcing System

Procurement and sourcing systems are focused on optimizing and

controlling the standard procure-to-pay process from the selection of goods

and suppliers to the placement of purchase orders, reconciling goods

receipt against invoices and payment processing. Similar to ERP,

procurement functionality is applicable to the Replenishment process of

indirect materials. However, these systems do not address the inventory

management requirements of an indirect materials management solution.

Warehouse Management System (WMS)

Warehouse management systems are specialized systems implemented to

control the movement and storage of material within a warehouse

environment. The focus of such solutions is the efficient storage and

access to materials. WMS solutions are well suited to high volume

warehouse operations with streamlined picking, put-away, shipping and

receiving processes. While WMS solutions would be able to provide some

measure of control and visibility to indirect material inventory, it would not

be able to:

1. Track the issuance and consumption of materials at a granular

enough level to provide insights to drive performance improvements

2. Address the upstream procurement processes or the downstream

disposal processes

3. Provide consumption control capabilities to proactively manage

indirect material usage

6

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

Only

5-10% of a

company’s

indirect

materials

spend flows

through a

vending

solution

Enterprise Asset Management (EAM)

Enterprise Asset Management systems are specialized systems designed

to ensure the most efficient utilization of a company’s big-ticket capital

equipment (assets). These systems can be found in manufacturing

facilities with expensive large-scale production machinery that needs to be

maintained in top condition for maximum uptime. They address indirect

materials to the extent that they are needed to support the uptime of the

assets that they manage. Therefore the perspective of such systems is to

ensure that the right parts and material are on-hand when needed to

support a variety of asset maintenance and repair activities. EAM solutions

are less concerned with the streamlining or optimization of indirect

materials.

Facilities Management System

Similar to EAM solutions, Facilities Management systems are specialized

systems designed to ensure the efficient utilization of facilities (plants,

offices, and warehouses) and facility-related assets. Also like EAM

solutions, facilities management solutions address indirect materials only to

the extent that they are required to support the primary mission of

maintaining facilities. Such solutions will typically provide for tracking and

replenishment of indirect material. However, such systems are not

concerned with the optimization of indirect materials usage.

Industrial Vending Solution

Industrial vending solutions are specialized inventory control solutions

intended to control and dispense industrial supplies at the point-of-use.

One of the key value propositions of this technology is the ability to position

material in a controlled manner within a vending unit in close proximity to

the locations where the material is required to support the various

operations. These solutions provide a strong measure of control over the

materials given the ability to restrict access and they provide a detailed

accounting of when, where and why the material is consumed. They also

provide for streamlined replenishment of materials based on usage.

The main issue with these solutions is their limited applicability. In simple

terms, only certain items can fit into a machine. As a result, only 5-10% of

a company’s indirect materials spend flows through a vending solution.

The remaining 90-95% falls outside of the scope of a vending solution and

requires an alternative management solution.

7

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

Custom or Home-Grown Solution

As they say, “necessity is the mother of inventory”, so of course another

available solution option to manage indirect materials is to develop a

custom solution tailored to meet the specific needs of the business. Such

solutions can run the gamut from simplistic (use of spreadsheets) to

sophisticated (custom developed web applications and interfaces) and

depending on the scope of the solution could address many of the

requirements for an indirect material management solution. However, with

a home grown solution comes:

1. High cost of ownership which will typically erode much of the value

that they were designed to create

2. A small army of IT folks to develop, manage and maintain complex

solutions

3. Internal cost and resource constraints will cause solutions to lag

behind the business requirements to the point where the business

needs have completely outgrown the solution

Business Process Outsourcing (BPO)

For companies that see indirect materials management as a non-core

capability, outsourcing may be seen as an attractive option. There is no

shortage of available outsourcing partners that have the resources and

expertise to effectively manage all aspects of the indirect material lifecycle.

Such an option can certainly make solid financial sense especially for

companies that do not have sufficient economies of scale to justify building

this capability internally. However, for companies with sufficient scale where

there is a large ROI or for companies that recognize the potential to turn

their indirect materials management capabilities into a source of

competitive advantage, outsourcing may not be the best option.

8

WHITEPAPER: PIECING TOGETHER THE INDIRECT MATERIALS PUZZLE

SHARE THIS EBOOK

Conclusion

The solutions outlined above attempt to address portions of the indirect

materials lifecycle. Clearly, some are more effective than others in

addressing the subset of indirect material business processes that are in

their respective sweet spots. What you may come to realize is that most of

solutions on the market today fall into one of three following categories:

1. They are intended to address a separate business problem from

indirect materials. They may have some indirect material

functionality to support their primary focus. However, indirect

materials management is secondary to their main objective.

2. They address a portion of the indirect materials management

challenge. They are effective for what they intend to accomplish but

are missing elements that you would need for a comprehensive

indirect materials management solution.

3. They may address a current short-term need but may not adapt well

as your business needs change and evolve.

There is no single well-established comprehensive solution for indirect

materials management. If you choose to leverage one or more of these

existing solutions to address your indirect materials, you should expect to

play the role of system integrator, in which you will have to figure out how to

piece together the various solution components into an overall integrated

solution. Even if you are successful, you will inevitably have to make a

number of compromises along the way that will reduce the overall benefit

that drove you to tackle this challenge in the first place.

As the indirect materials opportunity increases in visibility at the highest

levels of organizations, companies are pressing providers for better options.

As a result, more innovative solutions are coming to market. MarginPoint

recommends looking for a provider with significant domain expertise that

will address your indirect material management needs and integrate into

your existing systems to create a comprehensive solution. Companies will

see the tremendous value in taking an integrated and comprehensive

approach to indirect materials management and will not settle for putting

the indirect material management puzzle pieces on their own.

9

SHARE THIS EBOOK

About MarginPoint

MarginPoint is a leading provider of cloud-based indirect material

management solutions. We are uniquely focused on integrating the end-toend indirect material lifecycle to deliver the highest possible ROI for our

customers. Our software as a service (Saas) allows companies to deploy

without up front or significant IT investment. More than 400 companies rely

on MarginPoint to reduce their indirect material spending and streamline

their process.

MarginPoint

2 South Pointe Drive, Suite 220

Lake Forest, CA 92630

888-229-3685

Visit our website: www.marginpoint.com

Email: info@marginpoint.com

© 2013 MarginPoint Corporation. All rights reserved.