Painter SWMS - Lighthouse Construction & Developments

advertisement

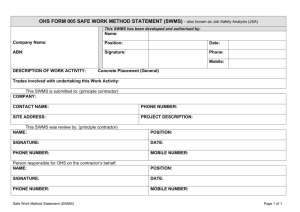

OHS FORM 005 SAFE WORK METHOD STATEMENT (SWMS) – also known as Job Safety Analysis (JSA) This SWMS has been developed and authorised by: Name: Company Name: Position: Date: ABN: Signature: Phone: Mobile: DESCRIPTION OF WORK ACTIVITY: Painter Trades involved with undertaking this Work Activity: This SWMS is submitted to: (principle contractor) COMPANY: CONTACT NAME: PHONE NUMBER: SITE ADDRESS: PROJECT DESCRIPTION: This SWMS was review by: (principle contractor) NAME: POSITION: SIGNATURE: DATE: PHONE NUMBER: MOBILE NUMBER: Person responsible for OHS on the contractor’s behalf: NAME: POSITION: SIGNATURE: DATE: PHONE NUMBER: MOBILE NUMBER: Safe Work Method Statement (SWMS) Page 1 of 7 List plant, equipment and tools to be used eg. Electric generator List Hazardous Substances to be used or handled MSDS available? (Tick) eg. Unleaded petrol Hard Hat Safety Boots High-visy clothing Gloves Hearing Protection Safety Glasses 30+ Sunscreen Dust Masks Other (specify): Health Risks and Likelihood of Damage How LIKELY is it to be that bad? Note: If a hazard is rated 1, 2 or 3, action must be taken immediately. What damage could it cause? Death or permanent disability Long term illness or serious injury Medical attention or several days off work First Aid needed VERY LIKELY VERY UNLIKELY LIKELY UNLIKELY Could happen anytime Could happen sometimes Could happen, but only rarely Could happen, but probably never will 1 1 2 3 1 2 3 4 2 3 4 5 3 4 5 6 Safe Work Method Statement (SWMS) List PPE to be worn (Tick) List Hazards to consider (Tick) Fall from ladder Fall from heights Fall from scaffold Contact with electricity Falling objects Collapse Slips, trips and falls Manual handling Exposure to noise Struck by moving plant Inhalation of dust or fumes Cuts Other (specify): How to complete the following form 1. List the step-by-step sequence of tasks required to carry out the work activity from start to finish. 2. Listing of potential hazards associated with each step, and the related OHS risks. 3. Using the risk table, rating the identified risks. 4. List what controls you will implement to reduce the risks to the lowest possible level. 5. Rate the level of risk once those controls have been implemented (must be 4-6 before you can start work). 6. List the names or positions of the persons responsible for ensuring the controls are implemented. Page 2 of 7 Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. 1. Arrival at site Hit by other vehicles or on site plant. Entry to unsafe areas. 2. Unloading of vehicle Back and shoulder injuries Slips, trips Site entry & set up equipment Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Report to site office for induction before entering or starting work on site, site and general induction of all employees. Park in specified area and appropriately. Risk assessment of job site and work areas including egress in buildings. Use team lifting techniques or mechanical means for manual handling. Training all employees in manual handling. Falls in open trenches Injuries from trips, slips and falls Hit by falling objects or hit by on site plant & equipment. Electrocution from overhead wires when carrying or setting up ladders. Slipping on wet areas. Back injuries. Unload vehicles in an area clear of traffic, plant & Equipment. Unload vehicle in clear level area. Determine clear access. Clear egress to be maintained to job site. Ensure trenches have been backfilled or barricading has been erected. Training in the use of P.P.E equipment such as hardhats, fluro vest etc. Check position of wires. Training in manual handling and the set up of ladders. Additional care taken in wet conditions or areas. Training in manual handling Safe Work Method Statement (SWMS) Page 3 of 7 3. 4. Sanding & Preparation Paint Application Internal Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Inhaling dust when sanding Cuts, splinters Slips, trips & falls Use PPE - dust masks when sanding. Training in the use of P.P.E equipment. Avoid sanding against the grain. Use P.P.E equipment such as gloves if required. Training in the set up & use of portable ladders. Ensure work area is clear of equipment & waste building materials. Ensure handrails, void & fall protection, are in place. Training in the use & set up of extension leads. Electrocution from electric sanders Back or shoulder injury when lifting paint Tins Electrical test & tagging of all equipment. Possible injury if lever slips Read material safety data sheets & manufactures recommendation prior to opening cans. Inhale fumes; contaminate skin, eye damage from splashing paint. Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Training in manual handling. Team lifting when required. Read MSDS data sheets all ventilation requirements are to be checked. Training in use of P.P.E equipment when required. Falls of ladders Trips over materials when rolling Skin damage or contamination Safe Work Method Statement (SWMS) Training in the use of portable ladders Ensure work area is clear Use P.P.E equipment such as protective clothing eg overalls or long sleeves. Page 4 of 7 5. Paint Application External Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Falls from ladders or scaffolds Training in the use of portable ladders & working from heights. Hit by falling materials Falls from lower roofs Hit by on site plant & equipment Ensure when working under others, safety head protection is worn. Ensure employees don’t either barricaded or warning signed areas. Ensure safety guardrails are erected. Use P.P.E equipment such as fluro vest. Set up only in safe clear areas. Sunburn Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Use P.P.E equipment such as sun cream, hats & protective clothing 6. THESE ARE STANDARD SWMS, THEY MUST BE MODIFIED TO SUIT YOUR WORKERS, YOUR EQUIPMENT AND YOUR SITE. Safe Work Method Statement (SWMS) Page 5 of 7 CHECKLIST OF ITEMS THAT MAY BE REQUIRED FOR THIS WORK ACTIVITY QUALIFICATIONS TRAINING Codes of Practice CODES OF PRACTICE OR AS/NZS STANDARDS TO BE COMPLIED WITH OHS Consultation OHS Induction Training for Construction Amenities for Construction Work Australian Standard AS 1580 Safe Work Method Statement (SWMS) Page 6 of 7 Declaration by contractors & workers: 1. I have been consulted and assited in the development of this SWMS. 2. I have been given the opportunity to comment on the content of this SWMS. 3. I have read and understand how I am to carry out the activities listed in this SWMS. 4. I have been supplied with the personal protective equipment identified on this SWMS and I have been given training in the safe use of this equipment. 5. I have read and understand the requirements set out in the mateial safety data sheets for the hazardous substances identified in this SWMS. NAME: Safe Work Method Statement (SWMS) SIGNATURE: DATE: Page 7 of 7