Concreting SWMS - Lighthouse Construction & Developments

advertisement

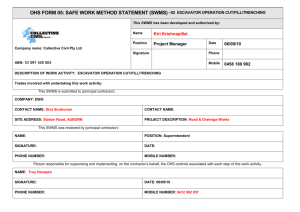

OHS FORM 005 SAFE WORK METHOD STATEMENT (SWMS) – also known as Job Safety Analysis (JSA) This SWMS has been developed and authorised by: Name: Company Name: Position: Date: ABN: Signature: Phone: Mobile: DESCRIPTION OF WORK ACTIVITY: Concrete Placement (General) Trades involved with undertaking this Work Activity: This SWMS is submitted to: (principle contractor) COMPANY: CONTACT NAME: PHONE NUMBER: SITE ADDRESS: PROJECT DESCRIPTION: This SWMS was review by: (principle contractor) NAME: POSITION: SIGNATURE: DATE: PHONE NUMBER: MOBILE NUMBER: Person responsible for OHS on the contractor’s behalf: NAME: POSITION: SIGNATURE: DATE: PHONE NUMBER: MOBILE NUMBER: Safe Work Method Statement (SWMS) Page 1 of 1 List plant, equipment and tools to be used eg. Electric generator List Hazardous Substances to be used or handled MSDS available? (Tick) eg. Unleaded petrol Hard Hat Safety Boots High-visy clothing Gloves Hearing Protection Safety Glasses 30+ Sunscreen Dust Masks Other (specify): Health Risks and Likelihood of Damage How LIKELY is it to be that bad? Note: If a hazard is rated 1, 2 or 3, action must be taken immediately. What damage could it cause? Death or permanent disability Long term illness or serious injury Medical attention or several days off work First Aid needed VERY LIKELY VERY UNLIKELY LIKELY UNLIKELY Could happen anytime Could happen sometimes Could happen, but only rarely Could happen, but probably never will 1 1 2 3 1 2 3 4 2 3 4 5 3 4 5 6 Safe Work Method Statement (SWMS) List PPE to be worn (Tick) List Hazards to consider (Tick) Fall from ladder Fall from heights Fall from scaffold Contact with electricity Falling objects Collapse Slips, trips and falls Manual handling Exposure to noise Struck by moving plant Inhalation of dust or fumes Cuts Other (specify): How to complete the following form 1. List the step-by-step sequence of tasks required to carry out the work activity from start to finish. 2. Listing of potential hazards associated with each step, and the related OHS risks. 3. Using the risk table, rating the identified risks. 4. List what controls you will implement to reduce the risks to the lowest possible level. 5. Rate the level of risk once those controls have been implemented (must be 4-6 before you can start work). 6. List the names or positions of the persons responsible for ensuring the controls are implemented. Page 2 of 2 1. 2. Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Entry to Site Entry to unsafe area Report to site office for site induction. Risk assessment of site conditions. Unloading Equipment Movement of site personnel, vehicles, plant & equipment Fall from vehicle Manual handling injuries, cuts, splinters & abrasions 3. Controls Implemented Setting out / up equipment Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Training of all employees Training employees in manual handling and team lifting Wear gloves (PPE) Being struck by equipment Crush hands Training employees in manual handling The use of P.P.E equipment such as gloves Team lifting Slips, trips & falls Unload equipment on a level clear area Trips & falls Ensure site is clear of any debris, obstructions. Define & barricade work area & fall areas 4. Drilling piers Hit by auger or bobcat excavator Only suitably trained personnel to work with plant Plant & equipment to be maintained, operator must be licensed Fall in holes Safe Work Method Statement (SWMS) The training and use of P.P.E equipment such as high visible vests, hard hats Personnel to be trained on relevant works. Site Induction Page 3 of 3 5. Placing Concrete in piers Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Run over by concrete pump or trucks Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Truck drivers to be made aware of site entry, driver to be aware of the whereabouts of the offsider Reverse siren to be in working order on concrete pumps & trucks. Relevant personnel to be in sight of driver at all times Pump operators to supply maintenance checklist & log books 6. Installing pegs for edge boards Back injury from using sledgehammer. All relevant personnel to be trained in the use and shown the correct procedure in using a sledgehammer. Missing target when using sledgehammer. Use P.P.E equipment Cuts, splinters and abrasions Training in manual handling and correct use of sledgehammer Arm & shoulder injuries Training in manual handling Keep hands and limbs out of rage Workers to keep others in sight Safe Work Method Statement (SWMS) Page 4 of 4 7. 8. Installation of formwork Benching / fill slab Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Back and shoulder injuries Injury from nail gun Hit by materials Hit by machines / plant Back and shoulder injury Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Training in manual handling Keep hands and limbs out of range. Workers to keep others in sight Training in the use of shovels and wheelbarrows. P.P.E equipment eye protection. Eye injury from dust Sunburn 9. 10. 11. 12. Laying of plastic Carrying steel Cutting and placing steel Set up of electrical leads Safe Work Method Statement (SWMS) Slips and Trips Back and shoulder injuries. Sun protection P.P.E equipment such as sunscreen hats and shirts. Clear waste materials from work area. Care taken when walking on plastic. Training provided in cutting and placing steel. Cuts and abrasions. Back and shoulder injuries. Training provided in cutting and placing steel. Cuts and abrasions from trips & slipping on steel. Care taken when stepping over formwork onto steel or plastic. Cuts from cut ends of steel. Wear gloves (PPE) Tripping over leads Training in the set up of electrical leads. Page 5 of 5 13. Grinder use Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Pieces of metal penetrating eyes P.P.E. equipment use – wear ear and eye protection Electrocution Training in correct use of grinder Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Electrical test & tagging. Register of all equipment 14. 15. 16. Use of Oxy Acetylene Tying Steel Installing bar chains Burns Wear Gloves Sparks hitting eyes High visibility vests to be removed prior to using Oxy Acetylene as the vests are highly flammable. Wear safety glasses (PPE) Explosion and Fire All Oxy Acetylene equipment to have flash back arrestors and have fire extinguishers accompanying them. Cuts and abrasions Wear gloves Penetrating wounds Bar caps to be installed on all exposed vertical bars. Back Injury Bend knees as placing chairs under reo bar All relevant personnel to be trained in manual handling Clear all waste materials Safe Work Method Statement (SWMS) Page 6 of 6 17. Set up of concrete pump Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Placing Concrete Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Concrete pump (boom line) not stable and tipping over Truck drivers / operators to be made aware of site entry, driver to be aware of the whereabouts of the offsider and site personnel. Machine failure Reverse siren to be in working order on concrete pump Set up of concrete pump (continued) 18. Controls Implemented Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Pump operators to supply maintenance checklist and log books Concrete pump to be set up in accordance with the Code of Practice. (concrete pumps are to be registered with WorkCover) Hit by concrete No persons to be standing in front of concrete hose Back injury from shovelling Relevant personnel shown correct posture for shovelling Concrete burns Avoid contact to skin, wash skin and clothing after. Sun burn, skin cancer, eye damage Safe Work Method Statement (SWMS) Sun protection P.P.E equipment such as sun cream, hats, shirts , sunglasses to be worn Page 7 of 7 19. Identify any potential hazards associated with each step – and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column. Run over by concrete pump or truck Controls Implemented Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work. Revised Risk Rating (1-6) Beak the job down into steps. List the steps in this column. Hazard Identification Initial Risk Rating (1-6) STEP Job Step Person Responsible Truck drivers to be made aware of site entry. Relevant personnel to be in sight of drivers at all times. Personnel to be trained in the use of hazardous substances e.g. cement. 20. THESE ARE STANDARD SWMS, THEY MUST BE MODIFIED TO SUIT YOUR WORKERS, YOUR EQUIPMENT AND YOUR SITE. Safe Work Method Statement (SWMS) Page 8 of 8 CHECKLIST OF ITEMS THAT MAY BE REQUIRED FOR THIS WORK ACTIVITY QUALIFICATIONS TRAINING Codes of Practice CODES OF PRACTICE OR AS/NZS STANDARDS TO BE COMPLIED WITH OHS Consultation OHS Induction Training for Construction Amenities for Construction Work Australian Standard AS 1012 Safe Work Method Statement (SWMS) Page 9 of 9 Declaration by contractors & workers: 1. I have been consulted and assited in the development of this SWMS. 2. I have been given the opportunity to comment on the content of this SWMS. 3. I have read and understand how I am to carry out the activities listed in this SWMS. 4. I have been supplied with the personal protective equipment identified on this SWMS and I have been given training in the safe use of this equipment. 5. I have read and understand the requirements set out in the mateial safety data sheets for the hazardous substances identified in this SWMS. NAME: Safe Work Method Statement (SWMS) SIGNATURE: DATE: Page 10 of 10