March 2014 Horizon

T O S L E n g i n e e r i n g L i m i t e d

“ A n E n g i n e e r i n g S o l u t i o n s C o m p a n y ”

2014 March (Quarter 1) f o r t h e F u t u re B y S h a z a n A l i ( T O S L ’ s C E O )

I S O 9 0 0 1 C E R T I F I E D

I S O 1 4 0 0 1 C O M P L I A N T

S T O W C E R T I F I E D

See it...

Hear it...

Suspect it...

report it

If you have a concern about TOSL, but uncomfortable communicating it in person, report it anonymously by:

•

Calling the toll free hotline number:

1-800-872-2281 + 877-rpt-line or

•

Report it online at www.tosl.com

,

Username: toslltd; Password: reportit report it is our contracted independent third party hotline service available 24 hrs/ day, 7 days/week, 365 days/year.

M o t i v a t i o n a l Q u o t e s

“The best place to criticize is in front your own mirror.”

Unknown

“Discipline yourself so others won’t have to.”

Unknown

What’s inside

Security Fencing

Long Service Employee

GE Annual Meeting

TOSL Events Team Activities

HSSEQ Corner

Employees Spotlight

In January 2013, we started the process to create the TOSL Organization for the future. We envisaged that as we plan for the future that we needed to create an organization that is sustainable and, to achieve this sustainability, we needed to balance the social environmental and economic factors for both short and long term performance. We identified the need to build a strong foundation, ensure that we developed the necessary traction and then attend to the integration process. By doing the above we were of the view that we would have created a Sustainable

Pyramid and hence secured our future.

While all the factors mentioned above are important, we believe that the strategic direction is the foundation for the success and sustainability of the organization.

These are as follows :

•

Customer Relationship Management

•

Pricing Flexibility

•

Cost Management

•

Competency Gap Closure (Employee and Management)

•

Business Expansion and the Acquisition of New Business

It was clear in the assessment of the organization that we needed to instil certain beliefs into the psyche of the employees. Additionally, at TOSL we needed to balance the social, environmental and economic factors for both short and long term performance in 2014. This will allow us to achieve our current business goals and, at the same time, increase long term shareholder value. Sustainability means different things to different people. However, in essence, for us at TOSL, it must be concerned with meeting the needs of all of our stakeholders, today, without compromising the ability of future generations of TOSL’s people, …...

(Con’t on Pg. 2) i n a ro w !

As a continued sign of our initiatives and commitment in the area of Corporate Governance, on February 04

2014 we were awarded by The Energy Chamber of

Trinidad & Tobago, first place in the category of Corporate Governance for the second consecutive year.

This is a significant honour to all of us at TOSL for

TOSL’s Lisa Mohammed receives award from Derryck which we congratulate each and every member of our staff for their efforts in allowing us to win in this

Murray (President of the

Transparency Institute of category again.

Trinidad & Tobago).

(Photo Courtesy The Energy

Chamber of Trinidad & Tobago)

As a pioneer in the industry, over the last year we have undertaken new initiatives. These include:

♦

Development of new ventures such as Brownfield type projects and Green Technology;

♦

Redefining our HR Department with emphasis on strategic issues; and

♦ Increased emphasis on Corporate Governance,

Corporate Social Responsibility and Audit as we

continue to redefine the TOSL organization in

HSE Statistics

(as at 2014, March 31)

•

Man-Hours YTD: 207,541

2014 to include an Executive Director of Corporate

•

OSHA recordable: 0

Governance who is a member of the Caribbean

Corporate Governance Institute. • Loss Time Incidents (LTI): 1

We will continue to cut tracks to demonstrate our

“Continuing the drive to

Keep HSE alive” promise in this area.

Page 1

The Petrochemical & Process Engineering (PPE) Division has taken the initiative to venture into new product markets and have since acquired and commenced sales of a new line of High and Medium Security

Fencing, which is manufactured by HANGTONG WIRE MESH COMPANY of Anping County, China and marketed as a trademark product of the Sedco Group LLC.

The line of fencing provides superior protection against climbing and cutting.

The small mesh opening and strong wire construction resists hand and foot holds and common cutting tools.

It also prevents the insertion of leverage tools and the passing of objects such as weapons etc.

Strong wire and welded joints as well as the small openings make it very difficult to cut using conventional cutting tools.

Fencing components are currently available ex-stock. To request a quotation please contact Lennox Oudit at (868)

290-0099 or lennox.oudit@tosl.com

and sales@tosl.com

.

B u i l d i n g t h e T O S L O r g a n i z a t i o n … .

( C o n ’ t f r o m P g . 1 )

…..to meet their own needs.

We identified seven (7) distinguishing qualities as we travelled the journey to create a sustainable enterprise. These qualities were:

1. Deeply ingrained values

2. Strategic Positioning of the TOSL Organization

3. Top Management and Directors Support

4. System Alignment (Structures, Processes and Sustainability)

5. Metrics (Business Plans, Execution, Sales and GP Margins)

6. Holistic Integration (across the entire organization)

7. Stakeholder engagement

We viewed the functions of our Human Resource (HR) & Health, Safety, Security, Environment & Quality (HSSEQ) Division as strategic and crucial for us achieving our objective in 2014 and onwards. Within this framework, HR’s Role and

Support are important to provide our Human Capital for the sustainability of the company. To ensure this was achieved, we created the new position of Manager-HR & HSSEQ with the focus here identified as:

•

Leadership Development

•

Succession and Manpower Planning

•

Enhanced and Value Creating training and development

• Change Management

•

Collaboration and Teamwork

•

Talent Management

•

Diversity and Multi-Culturalism

•

Ethics and Governance

•

Creating and Inculcating Values

•

Health, Safety, Quality and Wellness

•

Workforce Engagement

TOSL also has committed itself to enhancing proper ethics and good Corporate Governance practice both at Board

Level and throughout the organization and to support this initiative, we have created the new position of Executive Director-Corporate Governance so that we have a clear focus on Governance Issues throughout the organization in order to improve our effectiveness and efficiency. In tandem with this, we have expanded the role of our Business Development Group to include Marketing and Customer Care, created new positions of General Managers and, additionally, we have established a new Project Management Office to centralize all our project efforts, across all Divisions.

We have laid the foundation in the last fifteen (15) months from January 2013. We have set the metrics for achieving our Vision, we have reorganized the Company in order to deliver exceptional results, and we shall continue to forge forward as we cut a new path for ourselves in the T&T landscape and on our journey to other shores.

Page 2

M r. G o o ko o l B o b b y D h o ra y

In this Horizon issue, we will be having a one-on-one discussion with another of our long

service employees, Mr. Gookool Bobby Dhoray , Superintendent Wire Rope.

1.) How many years have you worked at TOSL?

14 years

2.) Based on your experience with us, what do you think it takes to succeed at this company?

Commitment & hard work

3.) What suggestions for improvements do you have to make our workplace better?

Better Communication within Divisions

4.) What is most satisfying/ enjoyable about your job and working with TOSL?

Knowing that your customer is satisfied

5.) What has been your most memorable experience thus far with TOSL?

Winning our first internal cricket competition and having bragging rights thus far.

6.) What in your mind is the most significant change at TOSL when you compare the present to the days when you

had just started?

People & Culture

7.) How well do you think your training and development needs were assessed and met?

Thus far the training has been good. However the assessment document/ forms needs to be revisited.

8.) If you were retiring tomorrow, what one thing you would like to be remembered for and feel most proud of

accomplishing for TOSL?

Together, having set up a successful Department from nothing and now leading the way in the Rigging field.

9.) What are the first words that comes to mind when you think of TOSL?

Service & Quality

10.) Why have you chosen to stay with TOSL and not move to other jobs, as most people do these days?

Commitment to self and others.

The GE Oil and Gas 2014 Annual Meeting was held at the Palazzo dei Congressi in Florence Italy from February 2nd to February 5 th

, 2014. As a GE Channel Partner, TOSL was invited to attend and participate in the various activities designed to improve the partnership capabilities and strengths.

The objectives of the forum were as follows:-

• Meet with Channel Administrators to discuss TOSL’s Portfolio to include all products and services of the Measurement and Controls Group of GE

•

Participate in Focus groups designed for Channel Partner interaction and areas for GE improvement

• Understand GE’s mandate to grow the business in Oil and Gas via channel autonomy and acquisitions

•

View GE’s Metering and Analyzers portfolio as well as Subsea offerings

The visit entailed the formal opening by the renowned GE CEO Jeffrey Immelt; various Panel Discussions on GE’s endeavors and areas of operations with an intention to build on the success stories with a focus group arranged to have Channel Partners describe some of their concerns with GE; a plant tour to the Massa or Florence facilities where the Nuovo Pignone operations take place; and a visit to GE Oil and Gas Expo in Aberdeen, UK where Metering Technologies were on display.

At both exhibitions, the knowledge acquired was extensive both technically and commercially in that Italy had on display the

Mobile Reverse Osmosis Units, Bently Nevada Vibration; and in the UK the Masoneilan Valves, LCT Turbine Meters and Aurora TDLAS Analyzers were on display. The Florence conference entailed Industry Financial Experts from Statoil, Formula 1,

Shell, Mozambique and others who described initiatives in innovation that have enabled them to provide value adding services to increase revenue. Flowmetering and In Site Valve testing were demonstrated in the UK. There were also Inspection Technologies being demonstrated for which GE is interested in extending to TOSL and arrangements were subsequently made for a meeting with our CEO in Houston in March 2014.

The focus group comprised various companies who represent a mix of GE Technologies such as Valves and Bently or

Waukesha, and Valves or Bently and Measurement and Controls. It was suggested that amalgamation and… ( Con’t on Pg. 4)

Page 3

V i s i t t o G E ( C o n ’ t f r o m P g . 3 )

Left to Right: Shan G.

Jegatheeswaran-GE Global

Channel Strategy Leader,

Global Commercial Operations Leader and TOSL’s

Paul Samlalsingh, Manager -

Electrical, Instrumentation and Automation (EIA) Divi-

....conglomeration of the suite of products and services

would redound to the benefit of all stakeholders via

single source responsibility and a point of contact

within the stakeholders respective territories.

Moreover, in the past, representatives were referred to as

Independent Third Parties (ITP) and we are now called Channel

Partners as GE wants a more symbiotic relationship in growing sion at the Channel Forum in

Florence, Italy.

the business. The meeting and conference theme of

“Redefining what’s possible” was reiterated throughout as GE

continues to blaze an indelible trail of innovation.

We envisage that this enhanced partnership will augur well for augmenting the capabilities and offering our EIA Division in its aspiration of fulfilling our company’s vision as truly being the “Best in Class”. For further information contact us.

For the first Quarter of 2014 we had two events: Valentine’s Day Raffle and Carnival Competition.

For the Valentine’s Day Raffle participants took a chance to win one of two prizes; the first was a lovely bouquet of roses and a red velvet cake, and the second prize was a delicious black forest cake. A Grand Drawing took place where Daron

Rambarran of the PPE Division took the first prize while Lana Ramjass of Property Maintenance won the second prize.

Our 2014 Carnival Competition showcased the talent of our employees. The day brought us beautiful weather for this outdoor event. There were hot doubles (on the spot) and corn soup. The crowd was entertained with live performances by Mr. Lennox Saunders and

Mr. Ricky Gibson, as well as our very own, DJ Sly Fox (Dave

Banmally). There were two entrants to the Ole Mas Competition; the Electrical, Instrumentation &

Automation (EI&A) Division presented Crime Swatch, and a combination of Corporate Services and Finance brought you ‘Hercules’. The EI&A Division took home the 1 st

prize and holds on to the challenge trophy for another year. Don Edan also performed as

‘The Captain’ entertaining us with his original extempo calypso.

Look out for our upcoming events including the Easter Program and a Car

Rally & Treasure Hunt.

Page 4

Page 4

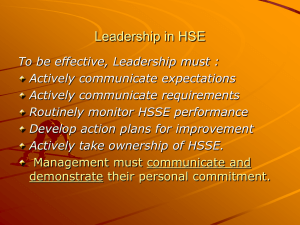

H S S E Q C o r n e r

As we have embarked upon 2014, below is the data for our 2013 HSE Performance which highlights the areas that we got right and the challenges that we met along the way, as well as highlight the 2014 HSE goal plan and

KPIs set for the organization.

From the statistics provided below, it can be seen that there was a loss time incident, 2 restricted duty incidents and several near misses in 2013. Our aim this year is zero accidents, incidents and near misses. That means ALL have a very significant role to play if this target is to be achieved.

2013 HSSE PERFORMANCE

IMPROVEMENTS IN HSSE

MANHOURS WORKED 2013

CORPORATE MANHOURS

CASUAL MANHOURS

NEAR MISS (NM)

DOC CARDS

UNSAFE CARDS (UC)

LOSS TIME INCIDENTS

TOTAL MANHOURS WORKED IN 2013

HSSE STATISTICAL DATA 2013

RESTRICTED DUTY INCIDENTS

592,192

274,802

866,994

1

2

4 (corporate)

16 (projects)

20

485

398 (corporate)

87 (projects)

322 (corporate)

33 (projects)

355

•

The Safety Officer

project assignment process

•

HSSE visibility throughout Divisions

•

Staff response to HSSE initiatives

• An increase in DOC, UC and NM reporting at the Project level

•

The JHA development process: a. These became more specific to task b. Improved involvement from executing team leads c. Improvement in communication process

•

Management support for HSSE at the senior level

•

Development of Strategic HSSE Plan for 2014

HSSE CHALLENGES

• Insufficient job planning

•

Absence of:

⇒ Supervisory / leadership skills (in some instances)

⇒ Disciplinary action for breach of HSSE protocols

⇒ Proper Communication

⇒ Incident Reporting

•

Disregard for HSSE protocols by senior level personnel

•

Overall ‘reactive style’ on Project Sites

• Long turnaround time for Corrective Action implementation

•

Competency gaps – HSSE & General

•

Poor response to in-house HSSE Training (in some cases)

•

Not enough HSSE ‘buy-in’ from all staff

•

Repeat hazards / Incidents such as ‘Dropped objects’, No JHA’s, Improper storage of PPE / HSSE Equipment.

( Con’t on Pg. 6)

Page 5

H S S E Q C o r n e r ( C o n ’ t f r o m P g . 5 )

2014 HSSE GOAL PLAN

2014 CORPORATE OBJECTIVES

E XISTING & N EW B USINESS E XPANSION

C USTOMER R ELATIONS M ANAGEMENT

C APABILITY G AP C LOSURE M ANAGE-

MENT & E MPLOYEE D EVELOPMENT

P ROCESS I MPROVEMENT

2014 HSSE KPI AREAS

HSSE P ERFORMANCE :

• 75% improvement in Monthly HSSE Statistical Data reporting

• 60% reduction in Loss Time Injury (LTI) Rate

• 50% improvement in Management HSSE Commitment

• 50% reduction of solid waste output company wide

HSSE C OMPETENCY

• 75% completion of approved Training Program

• 75% completion of approved HSE Communications Program

• 50% increased participation in DOC System

• Review HSSE Competency levels for 50% of operational personnel

R ISK M ANAGEMENT

• 75% completion of approved Audit and Inspection Program

• 100% JHA /RA Compliance

• 75% increase in NCR close out

• 50% improvement in Near Miss reporting

• 25% reduction in employee exposure to Health Hazards

S AFE S YSTEMS OF W ORK

• 50% increase in application of Management of Change (MOC) procedure

• 75% participation in new HSSE Programs

• Review at least 40% of Operating and Work Procedures to ensure adequate HSSE consideration

• 100% Development and distribution of HSSE handbook to staff

The HSSEQ Department thanks and encourages all employees for their continuous support towards improving HSSE.

Thank you!

On many occasions conflict arises between suppliers and their customers. When an organization has multiple customers who compete with each other there may be some challenges.

Establishing a relationship based on trust is critical to avoid or resolve conflict with a customer. A customer must know that confidential or proprietary information is safeguarded from competitors. A supplier should have procedures for protecting proprietary information, such as limiting access to drawings and restricting competitors’ access to a customer’s product.

Other than safeguarding proprietary or protected information there is an economic aspect to managing customer conflict. If the systems and resources required to resolve conflict with a demanding customer exceed the economic benefit of meeting the customer’s needs and resolving the conflict, it might appear to be more expedient to take no steps to resolve the conflict and let that customer go to a competitor. However, when making such decisions, the intangible impact should be considered.

A supplier needs to consider how the loss of that customer will affect business. Unhappy customers talk about their experience with many more people than do satisfied ones, and this needs to be considered when dealing with customers. In some industries, ceasing to do business with a customer might not have adverse effects, but in a small retail company which is heavily dependent on word of mouth for its reputation and future business, this solution could be disastrous.

When conflicts arise, high priority should be given to communicating with the customer in a calm manner, conducting root cause investigations and implementing corrective action. Results of corrective action should be fed back to the customer and response action should not be discontinued until both parties are satisfied that the conflict has been resolved. Customer Service Representatives should be trained to deal with the irate customers and also need to be given the authority to solve or resolve customer problems immediately. Passing problems along to others does not help relieve the customer’s concern.

Resolving conflict with a customer helps establish trust and promotes a long-term relationship. This is a competitive advantage in industries in which customers are reducing supply bases to deal with fewer suppliers. A supplier should develop a relationship with its customers and clearly understand their needs. When conflicts arise, the suppliers should try to understand the customer’s point of view and negotiate a resolution.

The biggest mistake a supplier can make is believing that the customer is unreasonable and not reacting to resolve the conflict or making a halfhearted attempt at conflict resolution. Many times, this lack of action is rooted in the supplier’s focus on optimizing the internal processes even if these processes do not serve the customer well. Conflict resolution is seldom possible in an environment in which the supplier tells the customer, “that’s the way we do it, take it or leave it.” Unfortunately, this scenario still is a common occurrence. The most important criteria for both multiple customer management and resolving conflict is excellent interpersonal relations. Hence, that means management’s commitment to training and support.

Reference: Okes D. & Westcott R. (2001) - The Certified Quality Manager Handbook 2 nd

Edition

Page 6

E m p l o y e e s S p o t l i g h t

We welcome the following persons to the TOSL Family:

January

♦ Raphael Hamilton (Tool Stores Attendant)

♦

Jans Ahing (Millwright)

♦

Reard Niamath (Senior Sales Representative)

March

♦

Leanna Maloney (Help Desk Administrator)

♦ Kenson Quash ( Senior Predictive Maintenance Technician)

♦

Julian Ferraz (Expediting Clerk)

February

♦ Luke Gittens (Manager-HR & HSSEQ)

♦ Russell Boodoo (Manager-Business Development)

♦ Sherlon Mohammed (Planner/Scheduler)

♦ Richard Charles (Mechanical Technician)

♦ Enzini Cambridge (Millwright)

♦ Garth Andrews (Millwright)

♦ Kevin Boodoo (Predictive Maintenance Technician)

This quarter we feature Jolly’s Coo-Coo Peau

Ingredients: Method:

- 1 ½ lbs seasoned boneless chicken, cut up - Heat oil in heavy pot or skillet.

or substitute with goat meat or beef - With heat on high, add the sugar and allow to caramelize until

- 1 onion, chopped

- 1 clove garlic, minced

- 1½ cups pigeon peas, soaked over-

almost burnt, stirring constantly. Add chicken/meat and stir until all

are covered with sugar.

- Reduce heat to medium, add onion and garlic, and stir for a minute.

night , or substitute with black-eyed peas - Drain the pigeon peas and add them to pot along with water &

- 2 lbs cornmeal (Promasa preferably)

- 3 cups water

- 3½ - 4 cups coconut milk

- 2 cups fresh Hubbard squash

- 2 carrots, chopped

- ¼ cup chopped parsley

- 4 pimento peppers

- 1 tsp. dried thyme

coconut milk. Reduce heat and simmer covered for 30 minutes.

- Add remaining ingredients (except cornmeal), stir until well mixed,

cover and cook until vegetables are tender, about 20 - 30 minutes.

Chicken should be cooked by this time, but meat may take longer.

- Pour in cornmeal whisking vigorously to prevent lumping. Stir well

and cook until mixture becomes stiff and smooth, moving away from

sides of pot.

- Generously butter a bowl/baking dish, add coo-coo mixture and

- 1 tbsp. chadon beni spread until the dish is evenly covered. Let set,

- 1 bunch scallions or green onions, chopped slice and serve.

- ¼ cup ketchup

- 3 tbsps. butter

NB . This dish goes well with callaloo and red beans.

This meal is a combination of coo-coo and pelau

- ½ - ¾ cups sugar (white/brown)

- 3 tbsps. oil

- 2 tbsps. cooking butter (optional)

without rice. It is a Grenadian dish that Jollys

grandmother made. Enjoy!

Births

♦ Syam Baliraj - Baby Girl

Our Vision : “To be the ‘best in class’ Engineering Company in Trinidad & Tobago and for us to be able to hold this position amongst other companies operating in a First World Environment.”

Our Cause : To develop people to be leaders in their community, homes & personal lives.

Our Culture is defined by : V alue Creation; E fficiency; Q uality; T eamwork; T echnological Improvement

VISIT OR CONTACT US AT:

Address: 8 - 10 Maharaj Avenue, Marabella, TRINIDAD, W.I.

INTERESTED IN RECEIVING A COPY OF OUR NEWSLETTER?

Send the following information to horizonteam@tosl.com :

Phone: (1-868) 657TOSL; 299 0360; 657 -7794

Fax: (1-868) 657-7502 (CEO & HR)

(1-868) 653-4188 (Metals)

(1-868) 652-9336 (Industrial Sales, Wire Rope, Inspection & Testing)

(1-868) 653-5404 (IT, HSSEQ, Audit, Finance, Business Development/Projects)

Name & Position

Company

Email address

Phone & Fax #

(1-868) 657-4621 (Upstream, Safety Sales, Petrochemicals & Process Engineering, Refractory, Valves, Scaffolding)

(1-868) 652-0856 (Electrical, Instrumentation & Automation)

(1-868) 653-0269

(1-868) 653-4187

(Predictive Maintenance, Pumps & Rotating Equip., Compressors, Engineering Sales)

(Inventory Management)

Page 7

Page 7