Norilsk Nickel

advertisement

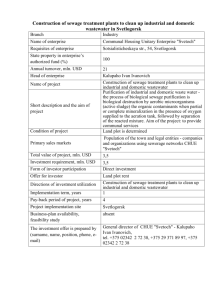

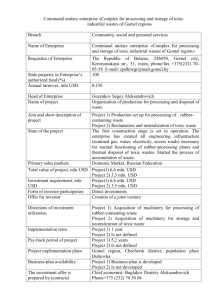

Investor Presentation VTB Capital RUSSIA CALLING! May 21-23, 2013 London Disclaimer The information contained herein has been prepared using information available to OJSC MMC Norilsk Nickel (“Norilsk Nickel” or “NN”) at the time of preparation of the presentation. External or other factors may have impacted on the business of Norilsk Nickel and the content of this presentation, since its preparation. In addition all relevant information about Norilsk Nickel may not be included in this presentation. No representation or warranty, expressed or implied, is made as to the accuracy, completeness or reliability of the information. Any forward looking information herein has been prepared on the basis of a number of assumptions which may prove to be incorrect. Forward looking statements, by the nature, involve risk and uncertainty and Norilsk Nickel cautions that actual results may differ materially from those expressed or implied in such statements. Reference should be made to the most recent Annual Report for a description of the major risk factors. This presentation should not be relied upon as a recommendation or forecast by Norilsk Nickel, which does not undertake an obligation to release any revision to these statements. This presentation does not constitute or form part of any advertisement of securities, any offer or invitation to sell or issue or any solicitation of any offer to purchase or subscribe for, any shares in Norilsk Nickel, nor shall it or any part of it nor the fact of its presentation or distribution form the basis of, or be relied on in connection with, any contract or investment decision. 1 Norilsk Nickel At a Glance Key highlights Key financials World leader in nickel and palladium with top 5 positions in platinum, cobalt, rhodium and a strong presence in copper US$ mln 2006 2007 2008 2009* 2010* 2011 2012 Revenue 11,923 17,119 13,980 8,542 12,775 14,122 12,065 EBITDA 7,736 10,253 5,807 4,198 7,209 7,239 4,932 Long-life, low-cost, vertically integrated producer margin (%) 65 60 42 49 56 51 41 Net income 5,965 5,276 -555 2,504 5,234 3,626 2,143 High-quality mineral base and production facilities in Russia margin (%) 50 31 nm 29 41 26 18 Net debt -1,388 4,064 4,445 1,685 -2,608 3,514 3,986 Solid financial standing and balance sheet supported by robust free cash flow Net debt/ EBITDA -0.2 0.4 0.8 0.4 -0.4 0.5 0.8 Committed to returning capital to shareholders Source: Note: Company data * Financial results of discontinued operations (OGK-3 and Stillwater) were deconsolidated for 2009-2010 Revenue mix from metal sales by products & destinations in 2012 Extensive worldwide operations Gold 2% Kola MMC Platinum 9% Harjavalta NN Corporate Headquarters NN Europe, UK NN Beijing NN USA NN Shanghai Palladium 16% NN Hong Kong Tati Nickel Nkomati Nickel Black Swan Lake Johnston Cawse Waterloo $ 11 bn Copper 26% Asia 25% Nickel 47% Chita Copper Project Overseas, Switzerland Mining operations Development projects Smelting/refining operations Headquarters and sales offices Europe 55% Polar Division $ 11 bn North America 11% Russia 9% Source: Norilsk Nickel 2 Unique Mineral Resource Base Norilsk Nickel possesses extensive mineral resources based on the deposits of the Norilsk industrial region, as well as the Kola peninsula, and international assets in Southern Africa and Australia Norilsk Nickel is one of the leading companies in the world in terms of quality and quantity of nickel sulphide ore resources The Talnakh ore deposit at Taimyr Peninsula has a unique geology with high grades of multiple metals At current level of production, Norilsk Nickel‘s average mine life exceeds 60 years Nickel (mln t) Copper (mln t) Palladium* (mln oz) Platinum* (mln oz) 5.96 (c. 12% of global) 8.06 56.59 15.02 Proven and probable Proven and probable Proven and probable Proven and probable 13.25 16.65 136.36 38.93 Measured and indicated Measured and indicated Measured and indicated Measured and indicated *Excludes international assets P&P Reserves of Nickel Ore* 8 M&I Resources by Geography Kola Peninsula 8% South Australia 13% 6.9 6.0 mln tonnes P&P Reserves by Geography 6 4 South Africa 17% 3.0 1.8 2 Polar Division 53% Australia 19% 1.1 0 Vale Source: Polar Division 47% Norilsk Nickel Companies reports Source: Note Xstrata** SMM BHP Billiton Africa 10% Kola Peninsula 23% Norilsk Nickel calculations, companies’ reports, data from 2012 Data for Norilsk Nickel Group includes 4.5 mln tonnes of nickel attributable to Polar Division Proven and Probable Reserves and additional Measured, Indicated and Inferred resources are stated on 100% consolidated basis *Peer group dating back to 2012 **Xstrata figure dates back to 2011 Botswana 9% 3 The Lowest Cash Cost Producer Norilsk Nickel benefits from a favourable cost position among large Nickel producers The only large Nickel producer with negative cash cost: costs are more than recovered through the sale of other metals produced -US$ 3.17 cash cost per lb of Nickel produced Vertical integration, rationalisation of existing assets, and selective development projects will contribute to maintain its position Cost Curve: Major Nickel Producers 8 Ni Price: 14,830$/tonne ($6.7/lb) 6 Cash Cost $/lb 4 2 0 MMC Norilsk Nickel Western Areas NL Cunico Resources N.V. Eramet SA -2 Vale S.A BHP Billiton Limited Cubaniquel Glencore International AG Xstrata plc Anglo American plc First Quantum Minerals Ltd Jinchuan Group Ltd. PT Vale Indonesia PT Aneka Tambang Tbk -4 0 100 Source: 200 300 400 500 600 Production 000 tonnes 700 800 900 AME, LME (Cash seller and settlement price 15/05/2013) 4 Solid Financial Position vs. Peers Strong financial performance compared to largest global diversified miners EBITDA Margin* BHP Billiton 42% Norilsk Nickel 41% Vale 37% Rio Tinto 31% Anglo America n 27% Xstrata 26% Source: Note: Net Leverage Ratio Interest Coverage BHP Billiton 35,5x Rio Tinto 23,0x BHP Billiton Norilsk Nickel Norilsk Nickel 20.8x Anglo American Xstrata 20,5x Rio Tinto Vale Anglo American 14,1x 9,6x Companies’ 2012 annual reports BHP Billiton financial year ended 30 June 2012 *Adjusted EBITDA for non-current or exceptional items Interest coverage is evaluated as a ratio of company/Group’s adjusted EBITDA to interest expenses Net leverage ratio is evaluated as a ratio of company/Group’s net indebtedness to adjusted EBITDA Vale Xstrata 0,7x 0.8x 1,0x 1,2x 1,5x 1,9x 5 Norilsk Nickel’s Shareholders Return1 Indexed Share Price Dynamic % 190 170 150 130 110 90 70 50 Dec-09 Mar-10 Jun-10 Sep-10 Dec-10 Mar-11 Norilsk Nickel Jun-11 Nickel Peers Sep-11 Dec-11 Mar-12 Jun-12 Sep-12 Diversified Mining Peers TSR1 2009 – 2012 50 30 48% 40% 18% 10 (10) (30) (50) (70) (90) 11% 15% 9% Average: -1% 11% (0) (27%) (17%) Average: -17% (37%) (27%) (51%) (77%) % (1) Total Shareholder Return includes (i) share price appreciation and (ii) cash dividends reinvested in security. Share buybacks are accounted for implicitly in share price appreciation. Norilsk Nickel – Market Positions by Production in 2012 Norilsk Nickel is world leader in nickel and palladium production with strong positions in platinum, copper, cobalt and rhodium 100% = 1,760 kt Nickel 100% = 6,653 koz Palladium 100% = 6,081 koz Platinum 3000 17% 300 39% 41% 3000 13% 2000 2000 200 7% 24% 21% 6% 15% 6% 100 4% 1000 1000 6% 5% 0 0 Copper 2000 100% = 16,720 kt 3% 100% = 703 koz Rhodium 10% 10% Cobalt 1 200 5% 4% 4% 2% 100 100% = 37,520 kt 13% 44% 6% 2% 0 300 1000 12% 11% 4% 4000 7% 7% 29% 14% 6% 6% 6% 6% 2000 13% 4% 0 0 0 7 Source: GFMS, Brook Hunt, CRU, companies’ results announcements, Norilsk Nickel Marketing Department, estimates from company reports Notes: 1 Cobalt metal Production Update & 2013 Outlook Nickel, ‘000 tonnes 297 295 Copper, ‘000 tonnes 300 275 - 285 14 364 11 360 - 366 5-6 237 234 230 – 235 366 363 352 355 – 360 2011 2012 2013F 2010 2 011 2 012 2013F 236 2010 2,806 139 102 2,722 2,704 2010 23 45 - 50 58 Platinum, ‘000 ounces Palladium, ‘000 ounces 233 378 67 62 2,861 389 2 011 Source: Company data 2,731 2,625 – 2,640 103 25 - 30 2,628 2 012 2,600 – 2,610 2013F 693 695 683 655 - 670 30 24 23 15 - 20 663 671 660 640 – 650 2010 2 011 2 012 2013F Russian operations Norilsk Nickel International Norilsk Nickel production outlook for 2013 8 Metal Markets Nickel Market in 2012 and Outlook for 2013-2014 Nickel supply and consumption, ‘000 t 1,761 1,433 1,501 1,617 1,614 Key potential drivers of Nickel market in 2013-2014: 1,844 1,680 1,769 Price upside risk: - Expected cuts of production, primarily NPI: at current prices around 40% of all nickel producers are below the water - Expected growth of high-quality nickel usage by 6% in 2013, mainly driven by +10% in stainless steel production - Appreciation of RMB against US Dollar and rising costs for energy, labor and transport to push high cost operations of NPI to $9-12/lb in the medium term 2010 2011 Production 2012 Consumption 2013E Nickel prices cut deep into cost curve - Indonesia’s taxes on raw materials exports and introduction of export ban starting from 2014 - Continuing growth in global consumption from non-stainless steel applications, namely non-ferrous alloys in aerospace sector C1 cash costs + royalty + sustaining capital ($/t Ni) - Strong track record of persistent delays and technical failures for new laterite HPAL projects and depleting sulphide deposits worldwide Price downside risk: - deterioration of macroeconomic environment - potential additions of new NPI capacities in China in the next 1-2 years with lower operating costs Cumulative production (kt Ni) - ramp-up of non-Chinese new big projects Source: Company’s estimates, Wood Mackenzie April Report 10 NPI: Key Swinging Factor in Nickel Market Equation NPI emerged as response to nickel price escalation in mid- NPI costs forward trends 2000s and is currently produced and consumed by China only NPI is high cost production due to significant energy intensity of process and transportation costs for ore sourced from Philippines and Indonesia and costs are expected to upward Key components of cash costs for BF – coking coal (58%), ore (15%), transportation (13%), for EAF – power (30%), ore (26%), coking coal (20%) and transportation (17%), for RKEF – power, ore, transportation (30% each) Source: Macquarie Capital Source: Macquarie Capital NPI production Majority of NPI producers’ break even costs range from 320 $17,000/t up to $20,000/t, but RKEF costs are ~$15,500/t 335 270 Brook Hunt estimates that at price level $18.3k/t Ni, production of 110kt of Ni in form of NPI is uneconomic and 168 cash burning Announced export taxes (25% in 2012, 50% in 2013) to be followed with export ban on nickel ore from Indonesia in 2014 (53% of Chinese ore import in 2011) provide efficient long-term floor to nickel price 2010 2011 2012E 2013F Source: Company estimates Source: Brook Hunt, VTB Capital, Macquarie Capital 11 Palladium Market Balance As of May 2013 no major supplies on the market from Russian state palladium reserves Global supply & demand balance -11% decline in Pd supply in 2012 due to South African unrests and mines put on care & maintenance +7% growth in demand for autocatalysts mainly due to North American and Chinese vehicle production increase in 2012 In recent years, supply was absorbed by strong emergence of investment demand. Net investments in 2012 resulted in 430koz. In recent 6 months Pd ETFs are up by 21%. In the long run, consumption growth rate should continue to exceed production growth rate and move palladium market into sustained deficit mln oz Millions ETF Pd holdings Palladium consumption by industry & regions 2,500 Autocats 67% 2,000 1,500 Other 1% Investment 6% 1,000 Other 18% China 16% 0,500 Apr-07 Apr-08 Other funds Apr-09 Apr-10 Deutsche Bank Apr-11 Julius Baer Apr-12 ZKB Apr-13 ETF Securities Electrical 15% North America 24% EU 23% Dental 6% Chemical 5% Japan 19% Source: Johnson Matthew, Renaissance Capital, Deutsche Bank, HSBC, Macquarie research, VTB capital, Bloomberg, Reuters 12 Palladium Demand: Consumption Palladium consumption is projected to grow driven by the auto industry (67% of gross palladium demand): Car sales are holding up well… continuing growth of palladium demand in autocats as EM and US car markets have favorable outlook China revives subsidies to buyers of small vehicles boosting its auto sector full implementation of Euro-V in light duty vehicles return to normal mode of operation by Japanese car industry post devastating earthquake in March 2011 end-user demand should continue to grow strongly over the medium term due to tighter emissions regulations growth of car market in China, mostly represented by gasoline-powered vehicles whose catalysts tend to be more palladium intensive (70% of all light vehicles production globally) … and car ownership in China is yet to catch up Car ownership per 1,000 people (units) continued growth of palladium content in diesel and heavy trucks engines Source: Norilsk Nickel Marketing Department, VTB Capital Research, Reuters 13 Copper Market Rising Supply and Uncertain Demand Supply surpassed demand by some 1% in 2012, due to new capacities and weaker physical demand Overall new capacities and ongoing projects may accelerate supply growth (2.3% increase in refined supply and a 3.6% growth in concentrate supply in 2012) As regards consumption growth, China remains structurally the key driver, while: IMF sees Chinese growth averaging 8.5% p/y in 20142017 Rising government spending on infrastructure may support consumption in economic hard landing Overall consumption of copper may remain uncertain in the short to medium term given economic uncertainties in western and large emerging markets In this context, a decrease in capacities surplus and price tendency will depend on the resilience of demand in weakened economies Copper Price Evolution (USD/t) $11,000 $10,000 $9,000 $8,000 $7,000 $6,000 $5,000 $4,000 $3,000 $2,000 Jan 07 Jan 08 Jan 09 Jan 10 Jan 11 Jan 12 Copper Consumption in 2012 Consumer goods 9% Machinery 13% Electronics 34% 20.2 mt Transport 13% Construction 31% Source: Norilsk Nickel 14 FY 2012 Financial Update Revenue and EBITDA Dynamics Revenue Revenue decreased by 15% in 2012 y-o-y due 14,122 12,775 825 649 12,065 to decrease in market prices of base and 1,004 precious metals produced by the Group: 8,542 $ mln 467 12,126 13,297 11,061 8,075 2009 2010 Metal sales 2011 2012 Average Ni LME price down by 23% Average Cu LME price down by 10% Average Pd LPPM price down by 12% Average Pt LPPM price down by 10% Other sales EBITDA & EBITDA margin 7,209 Metals sales volumes remained almost 7,239 80% 7 000 70% 5 000 4 000 $ mln 6 000 51% 4,198 56% 4,932 41% 49% 60% Ni sales went up by 1% 50% Cu sales decreased by 3% 40% Pt & Pd physical volume of sales decreased by 1% due to lower metal output 3 000 30% 2 000 20% 1 000 10% - unchanged y-o-y: EBITDA amounted to $4.9 billion with a healthy 0% 2009 2010 2011 2012 margin of 41% Source: Company data 16 EBITDA Analysis Adjusted EBITDA decreased by 32% y-o-y mostly due to substantial decrease in metal prices Adjusted EBITDA margin remained at healthy 41% Cost of metal sales increased by 2% y-o-y mostly due to: increasing expenses on consumables and spares growth of 3rd parties services Expenses on acquisition of raw materials and semis decreased by 23% y-o-y amounting to $918 mln Depreciation & amortisation charge amounted to US$789 mln (+4% y-o-y) Adjusted EBITDA bridge, $ mln 8000 7,239 7000 6000 179 5000 (2,236) 134 (195) (157) Cost of metal sales Cost of other sales 4,932 28 (64) 4000 3000 2000 1000 0 EBITDA 2011 Metal sales Other sales SG&A expenses D&A Other EBITDA 2012 Source: Company data 17 2012 Cash Costs Breakdown Cash costs before by-product credits remained flat at $5 billion y-o-y as a result of cost control measures, Consumables & Spares $1,309 mln lower expenses on raw materials and rouble 26% depreciation against US dollar Acquisition of raw materials & semis $918 mln Labour costs slightly increased by $ 24 mln (2%) y-oy driven mainly by inflation-related adjustments for salaries and wages Labor $1,488 mln 18% $ 5,040 mln Consumables and spares are up by 13% y-o-y ($ 152 mln) due to increased purchases for repairs and maintenance and relaunch of operations at Lake 30% Johnston Acquisition of raw materials & semis decreased by 23% y-o-y and amounted to $918 mln due to decrease in volumes and LME prices for metals 13% Cash costs of Russian operations and Harjavalta Other $109 mln 2% 3% 5% 4% 3d parties services $651 mln Transportation Utilities Taxes $156 mln $216 mln $193 mln continue to dominate in the cost structure accounting for 94% Source: Company data 18 Debt & Liquidity Position As of YE 2012 total debt amounted to US$ 5 bn with a US$ 1 The Highest Rating Among Peers bn cash pile Balanced debt portfolio comprising both bank and capital market instruments Strong liquidity reserve formed of available cash & cash equivalents and bank lines Comfortable Net debt/EBITDA remains below 1x Baa2 Cash & debt dynamics, US$ mln 5,405 5,317 Ba category Debt structure, US$ mln 5,317 5,141 5,141 5,023 2,400 2,497 2,741 2,526 2011 2012 5,023 3,986 3,632 Baa3 3,514 2,345 2,797 2,797 1,685 1,561 1,627 1,037 2,972 1,236 2009 2010 2011 2012 2009 2010 LT debt (2,608) Total debt Net debt Source: ST debt Cash & cash equivalents Company data 19 CAPEX CAPEX amounted to $2.7 billion in 2012 Hefty CF Generation Investments in mineral resource base of Polar Division and Kola MMC: 5,514 4,702 3,434 3,401 — mining of new sections of ore bodies; — increase of ore production; 2009 (1,061) 2010 2011 (1,728) (2,201) (2,713) САРЕХ OCF — replenishment of retired facilities; and 2012 2012 CAPEX Breakdown — implementation of new mining technologies Modernisation and upgrading of enrichment and Other investments $374 mln Intern. assets $37 mln 14% smelting facilities of Polar Division and Kola MMC Mineral resource base $558 mln 1% 21% Lowering of environmental footprint through cutting emissions Securing reliable energy and gas supplies Expenses on replacement of equipment $771 mln 28% 2% 6% $ 2,713 mln 6% 7% 15% Non-industrial facilities $394 mln Enrichment $48 mln Metallurgy $172 mln Utilities $172 mln Auxiliary facilities $186 mln Russian Operations: Investments in Production Ore extraction $558 mln Enrichment $48 mln $490 mln – key mines of Polar >$36 mln – expansion of Division Talnakh enrichment plant; $40 mln – Chita design project tailings storages and other $28 mln – Kola MMC projects of Polar Divison Smelting $172 mln $115 mln – upgrading Nadezhda Metallurgical Plant (construction of Severny-Gluboky $24 mln – modernisation of production lines to reduce SO2 emissions mine, etc) Replacement of equipment $771 mln $230 mln – non-core subsidiaries Non-Industrial Construction $394 mln Construction of nonindustrial assets, health $442 mln – Polar Division and recreational facilities, $99 mln – Kola MMC social programmes Energy and auxiliary facilities $358 mln Geological exploration, IT, R&D etc. $119 mln $158 mln – development >$84 mln – geological of Pelyatka gas field prospecting in Polar $131 mln – construction of railroad for Chita project Division & Zabaikalsk region >$30 mln – IT projects of Polar Division and Kola MMC Source: Company data 21 Strategic Priorities for 2013 Strategic Priorities Rebalanced value-centered group strategy in place by the end of 2013 Reinforcement of Management Team Throughout the organisation - adding highly experienced professionals to improve in key competence areas and create a globally competitive team Sharper Investment / Project Management Reassessment of investment portfolio and project assessment / management practices Balanced investment policy with the selective stage-gate approach to each project Rationalisation of Non-performing / Non-core assets Extraction of capital from non-core businesses and assets Business-minded approach to retained assets OPEX Savings Ongoing work, first results expected in 6 months Tighter Working Capital Management Ongoing work, first results expected in 6 months Greater Transparency New management reporting system and IT initiatives and Accountability Performance- and efficiency-centered culture Enhanced Corporate Governance Sustainability Management Key new appointments to the Board and Committees, including independent Chairman Taking the dialogue with investors to a new level Sharpened, KPI-driven approach to environmental and social programs 23 Focus on the Environmental Programmes Performance indicators for last 5 years* Compliance with Environmental Standards Reduction of pollutant emissions with priority to sulphur dioxide and solid particles Reduction of polluted wastewater discharges Arrangement of waste disposal sites Prevention of pollution from cargo shipping -21% Wastewater discharge -17% Pollutants discharged with wastewaters -15% -3% Overall waste generation Air pollutant emissions * Data is represented for 2007 – 2011 Environmental expenditures Focus on Sulphur Dioxide Reduction Maximising sulphur recovery by renovation of 2007 – 2012: $3,010 mln modern technologies Minimising the sources of sulphur containing gas by replacing obsolete process $ mln concentration capacities including implementation of 600 620 2011 2012 530 470 430 360 Total investments aimed at reducing sulphur dioxide emission will be approx. USD 2.5bn through 2018 2007 2008 2009 2010 24 Enhanced Governance and Shareholder Consensus “The settlement of a dispute between major shareholders should provide the company with a solid platform for further improvement of strategic, operational and corporate governance issues” Gareth Penny , Chairman of the new Board of Directors The new elected Board of Directors includes 4 independent non executive directors out of 13 members, including the Chairman of the Board Several changes in the Management Board including the CEO and the CFO Shareholders agree not to take any action with respect to specified fundamental matters without the agreement of each of them Composition of the Board Other 1 INEDs 4 Governance Structure General Meeting of Shareholders Interros 4 Audit Committee Strategy Committee Corporate Governance, Remuneration and Nomination Committee Budget Committee Board of Directors 13 members Management Board UC RUSAL 4 General Director (CEO) 25 A New Shareholder Structure From December 2012, Interros and UC Rusal have a signed agreement with Crispian Investment Limited Key Takeaways Crispian is to become a new significant shareholder of Norilsk Nickel by purchasing shares from Interros and UC Rusal Following redemption of all quasi-treasury shares (held by Norilsk Nickel), UC Rusal, Interros and Crispian will hold approximately 27.8%, 30.3% and 5.87% shares respectively Embedded mechanism limiting the risk of shareholder conflicts1 Guidelines for future dividend distribution Before the Agreement Post-Agreement and Cancellation of Treasuries Other 5% Interros 28% Treasury Shares 17% Crispian 6% Other 6% Interros 30% Free float 30% Free float 25% UC Rusal 25% UC RUSAL 28% 1 Crispian Investment Limited - an affiliate of Mr. Roman A. Abramovitch - would exercise certain voting rights in respect of shares held by each Interros and Rusal. It was agreed that the maximum number of shares would represent 7.5% of the Company issued share capital for each of Interos and RUSAL. 26 Sustainable Development Sustainability and Effective CSR Governance Rational water resource use CSR Governance Stakeholders engagement Managing land and enhancing biodiversity Keeping our staff safe and healthy Employing, developing and motivating staff Human rights and social partnership 28 Working For Benefit Of The Country Being a significant player in Russian economy A significant tax-payer: aggregate tax payments in 2011 amounted ca $3.4 bn A big employer: over 81,000 people work in Norilsk Nickel (96% in Russia). A major employer offering well-paid jobs for Norilsk, Monchegorsk, Zapolyarny and Nickel with the aggregate population over 285,000 people An owner and developer of infrastructural assets across the country: Arctic fleet, airlines, railroads A strategic partner of the Russian Federation in full scale projects of economic, social and environmental nature Company tax payments to region budgets, 2011 $1.5 bn 1% 2% 3% 7% in Russia’s GDP of Russia’s export of Russia’s industrial production in Russia’s non-ferrous metals industry Total tax payments, 2009-2011 > $0.3 bn 3.4 >30% 2.7 $ bn >30% The Company’s share 1.2 Krasnoyarsk region Murmansk region 2009 2010 2011 29 Tackling The Key Challenge Of SO2 Emissions In Polar Division implements a system of measures aimed at SO2 emissions at Polar Division reduction of SO2 emissions to Maximum Permissible Emissions 2,011 2004 – 2011: - 5% which includes: Concentrator in order to maximize sulphur percentage in final tailings without losses of valuable metals 1,955 Development of the concentration facilities of the Talnakh 1,939 1,950 1,920 ‘000 t 1,917 1,912 1,881 Modernization of pyrometallurgical processing facilities of the Nadezhda Metallurgical Plant and shutdown of the main facilities of the Nickel Plant situated in the immediate vicinity of the residential areas being a source of weak sulfureous 2004 2005 2006 2007 2008 2009 2010 2011 gas which is difficult to recycle In June 2012, MMC Norilsk Nickel signed contract with Techint S.p.A (Italy) to develop design documentation with simultaneous specification of technical parameters at pilot facilities and consequent construction of sulphur recycling and storage facilities with a total capacity of up to 950 thousand tons per annum. The total amount of CapEx for the project is USD1.7 bn 30 Corporate Social Programmes for Personnel Budget of social programmes exceeds $176 mln Annual compensation of travel and baggage expenses (>$85 mln) Corporate sport events ($1.4 mln) Vacation at health resorts ($54.5 mln) Corporate housing programmes Non-governmental pension programmes ($27.2 mln) Mass cultural events and festivals, international corporate tourism ($10.2 mln) * Data is represented for 2011 31 IR Contact Details Mikhail Borovikov Investor Relations Officer Elena Romanova Investor Relations Vera Timoshenko Investor Relations Tel: +7 495 786 83 20 Fax: +7 495 797 86 13 e-mail borovikovma@nornik.ru, romanovaev@nornik.ru, timoshenkovv@nornik.ru, ir@nornik.ru 11, Bolshaya Tatarskaya, Moscow, Russia, 115184 32