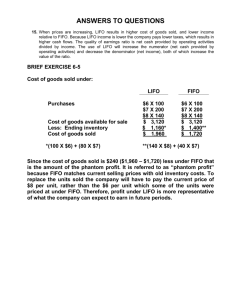

Document

advertisement

International Journal of the Information Systems for Logistics and Management (IJISLM), Vol. 1, No. 1, pp. 1-7 (2005) 1 Optimal Issuing Policy for Fish-Breeding Supply Center with Items Weibull Ameliorating Heung-Suk Hwang1*, Ho-Gyun Kim2 and Chun-Hyun Paik2 1*Department of Business Administration, Kainan University, No. 1 Kainan Rd., Lu-jhu, Taoyuan, 338, Taiwan 2Department of Information and Industrial Engineering, Dongeui University San 24, Gaya-dong, Pusanjin-gu, Pusan, 614-714, Korea ABSTRACT In conventional inventory models, the items are based on the assumptions that the values (or utility) of items in inventory remain constant over time, but in the most practical cases, it is not constant and changes increasing or decreasing over time. In this study, a special case of inventory model is studied for the items of which utilities are increasing over time. We develop ameliorating inventory models to find optimal issuing policy in fish-breeding supply center. The two issuing policies are considered, FIFO (first-in-first-out) and LIFO (last-in last-out), to find optimal issuing policy. We derived the equations of inventory levels for both issuing policies, FIFO and LIFO, and we developed two ameliorating inventory models to find the economic order quantity (EOQ) and the economic selling quantity (ESQ). We developed a computer program for this research and applied it in a fish-breeding supply center problem to show the effectiveness of the proposed models. From the sensitivity analysis, we can see that the ameliorating inventory effect affects the issuing policy, EOQ and ESQ of the fishbreeding supply center significantly. Keywords: ameliorating inventory, issuing polilcy, fish-breeding supply center management. 1. INTRODUCTION Most of the previous works on the supply chain inventory models have been based on the ideal assumption that the value of inventory items remains constant over time (Gupta, 1982; Lars and Tayfur, 1998; Nakamura et al., 1998). Only few studies dealt with deteriorating or perishable inventory models (Hwang and Hwang, 1982; Lin et al., 2000; Raafat and Eldin, 1991). In this paper, the term ameliorating inventory (or item) is introduced to represent the one whose utility (value or quantity) is increased over time. This amelioration phenomenon can often be observed in the areas such as cattle breeding, fish culture, and fund managing under the inflation, etc. The supply centers of these areas usually have a combined hierarchy structure consisting of a supply center and several retailers with ameliorating items. Our study is concerned on an ameliorating inventory model and optimal issuing policy for the fish-breeding supply center. There are several researches on supply chain inventory models (Garg, 1996; He, 1996; Leung et al., 2000; Ross, 1996), but most of these studies assumed unchanged utility during the storage period. However, due to the breeding ac- tivities the items in the fish-breeding supply center will ameliorate. Recently, these special inventory problems with ameliorating items are considered as an important area for inventory management in supply centers. There are several studies on ameliorating inventory models for supply centers in the literature. Hwang (1982, 1997, 1999) considered an inventory model for items with Weibul ameliorating and deteriorating. Sparker et al. (2000) developed a supply chain model to determine an optimal ordering policy for deteriorating items under inflation. Chung and Lin (2001) used a discounted cash flow approach to investigate deteriorating inventory problems. For the application of ameliorating inventory, Hwang (2004) studied a stochastic set-covering location problem for both ameliorating and deteriorating items. He determined the minimum number of supply center facilities via 0-1 programming. In ameliorating inventory system, the amount of items increase by ameliorating activities within a time period depends on the ameliorating rate of each items which are varied by the ages of items in storage. Thus, the inventory issuing policy is an important factor in ameliorating inventory modeling, but most of previous works 2 International Journal of the Information Systems for Logistics and Management (IJISLM), Vol. 1, No. 1 (2005) did not take into account of issuing polishes to consider the varying rate of ameliorating effect. In this study, we considered two issuing policies, LIFO and FIFO, to consider the varying rate of ameliorating items in storage of fish-breeding supply center. Fig. 1 shows an explanatory example for two-echelon hierarchy structure in which the items are in ameliorating state at the upper echelon, while the items are in deteriorating state at the lower echelon. This study is focused on the issuing policies in the upperechelon, supply center. Under the assumption that the time to amelioration of an item is distributed according to the Weibull distribution, we consider two different inventory models: the well-known economic order quantity-type (EOQ-type) model and the economic selling quantity (ESQ) model. While the former case is developed for the case of the inventory increment ratio (ameliorating rate) is less than the demand rate, while the latter is for the case that the ameliorating rate is greater than the demand rate. With the time varying rate of ameliorating, the amount of ameliorated items during a given time interval depends on the amount of on-hand inventory of which the ages of items in inventory are not same. Thus, it is reasonable to consider an appropriate issuing policy minimizing the inventory-related costs. In this study we consider the two issuing policies: FIFO and LIFO. We derive the equations of inventory levels for ameliorating items to find the minimizing inventory-related cost under each issuing policy, and also provide an efficient numerical method to solve the equations. The extensive computational experiments are performed to show the effectiveness of the developed models and the two issuing policies are compared in terms of inventory level. Notations: R: demand rate given in number of units/time, α, β: two parameters of Weibull amelioration, Co: ordering cost ($/unit), Ca: ameliorating cost ($/unit), Cp: purchasing cost ($/unit), Ps: selling price ($/unit), Ch: carrying cost ($/unit/time), Q: partial ordering size, S: partial selling amount, A(t): instantaneous ameliorating rate, TC: total cost/unit time. Assumptions: (1) Demand rate R is known and constant, (2) Units are available for satisfying demand after amelioration, (3) The ameliorated units are immediately added to inventory level, (4) Shortages are not allowed, (5) The number of units is treated as a continuous variable, (6) The time for an item to ameliorate follows a Weibull distribution of which probability density function, f(t), is given by f(t) = αβ t β - 1 e - α t β and the instantaneous amelioration rate is given by f (t) A(t) = ∞ = αβt β – 1, where α, β > 0. f (x)dx t 2.1 EOQ-type Model 2. MODEL DEVELOPMENT Throughout this paper, the time to amelioration of an item is assumed to be distributed according to the Weibull distribution which is one of the most commonly used distributions in the literature (Hwang and Hwang, 1982; Raafat and Eldin, 1991) because it can represent a variety of real-life situations simply by varying the values of two parameters of the distribution. The following notations and assumptions are used for model development: When the inventory increment rate by ameliorating activity is less than the demand rate, the inventory level decreases monotonically until the inventory level decreases to 0. Hence, the inventory behavior of this case is similar to that of the classical EOQ model except the amelioration phenomenon. This is the reason why we call our model EOQ-type one. We propose two EOQ-type models under different issuing policies LIFO and FIFO as followings. 2.1.1 Inventory level under LIFO issuing policy Fish-breeding Supply Center Retailer Retailer Upper-echelon Retailer Lower-echelon Fig. 1. Example of two-echelon hierarchy structure of supply chain We define the cycle time T by the duration from the replenishment epoch of items to the depletion epoch of the inventory consisting of replenished items, Io and the ameliorated items. We consider that during the time interval (t, t + ∆t) t < T, the instantaneous amelioration occurs according to the rate of A(t) and the demand occurs at a constant rate of R units. 3 H. S. Hwang et al.: Optimal Issuing Policy for Fish-Breeding Supply Center with Items Weibull Ameliorating Invt, Level Inv. Level R•T R•T I0 I0 Time 0 t T t+∆t Fig. 2. Inventory level of EOQ-type model under LIFO where 0 ≤ t ≤ T, and after some algebra, β I t = e αt – R t β e – α x dx + k , (1) From the boundary conditions at 0 and T, the value of constant k can be given by T k = I0 = R T of demand, R . ∆t1, during the time interval (t1, t1 + ∆t1) where t1 ≤ T, is satisfied from the amount ameliorated during (t(t1), t(t1) + ∆t1), as shown in Fig. 3. Note that the time t(t 1) indicates the epoch at which the items ameliorated up to t 1 are exhausted by the demands. Under FIFO Issuing policy, the amount of inventory ameliorated during (0, t(t1)) is exhausted by the demands occurred during (0, t1). This gives, R . ∆t1 = I0 . exp(−α (t1 − t) β) . ∆t and ∆t = R ⋅ exp ( – α(t 1 – t )β ) ∆t 1 I 0 (4) Let α (t1 − t) β = x (5) β e – α x dx . dt = h(x) . dx (6) where h (x ) = 1 / (α 1 / β ⋅ βx β – 1( I0 ⋅ exp ( – x ) – 1)) R Then the solution of equation (6) can be given by 0 x Thus, the inventory level at time t is given by β t1 then, differentiation of equation (5) and substitution of equation (4) into the result yields 0 where k is a constant value Time t(t1) t(t1) + = t1 Fig. 3. Inventory level of EOQ model under FIFO policy During this time interval the entire amount of ameliorated items is supplied for demands because the amount of ameliorated per unit time is less than the demand rate R. LIFO policy implies the ameliorated items do not enter the inventory as shown in Fig. 2. The inventory level at time t It can be derived as: dI = I t ⋅ A (t ) dt – Edt dI – I (αβ t β – 1) = – R , t dt 0 I t = e αt – R t 0 β e – α x dx + I 0 t (t 1) = (2) As a special case, if β = 1then the ameliorating rate becomes constant and the following is satisfied. R (1 – e α T ) and I = R (1 – e α (t – T ) ) I0 = α t α (3) 2.1.2 Inventory level under FIFO issuing policy The similar manner of the LIFO case can be applied to the FIFO one besides the fact that in this case, the amount h (y ) dy + K , (7) 0 where x = α(t1 − t) β , and h (x ) = 1 / (α 1 / β ⋅ βx β – 1( I0 ⋅ exp ( – x ) – 1)). R It is not easy to derive as closed-form solution of equation (7). An approximation method based on perturbation technique (Kevorkian and Cole, 1981) is used as follows: t(t1) ≅ f0 +αf1(t1) + α 2f2(t1) where, f = R t 1 0 I0 (8) 4 International Journal of the Information Systems for Logistics and Management (IJISLM), Vol. 1, No. 1 (2005) f 1(t 1) = R (t 1 – f 0)β + 1 (I 0 – R )(β + 1) f 2(t 1) = (t 1 – f 0)β R (I 0 + R )(t 1 – f 0)β + 1 R f 1(t 1) R βf 1(t 1) – – (I 0 – R ) 2(I 0 – R )(2β + 1) β +1 β +1 The boundary condition, at time t1 = 0, t = 0, and x = 0 gives k = 0. Since the inventory level at time t1 is the amount ameliorated during (t(t1), t1), the inventory level at time t1 is given by: t1 It1 = t (t 1) Z(T) T = Z(T) (0, β) I 0 exp ( – α(t 1 – y )β ) dy , where, t1 ≤ T (9) T+ T 2.1.3 Optimal cycle time Fig. 4. Graphical representation of T and Z(T) To illustrate the effect of amelioration on the inventory level, we have to consider the total cost function. To obtain an optimal cycle time T* minimizing the total cost per cycle time, we first have to find the total cost (TC) function which consists of ameliorating cost, holding cost, and ordering cost. With the inventory equations provided above, the total cost function can be obtained by TC = I 0( Letting T = Z(T), where, ∞ Z (T ) = 1 R Σ C0 k =0 Cp –Ca Ch C + ) + RC a + 0 T 2 T ( – α)k T k β + 3 k βT – 1 C h + ⋅ (C p – C a ) K! kβ + 1 2 The solution search procedure is then summarized as: ( – α)k T k β k = 0 (k β + 1)k ! ∞ = R (C p – C a ) Σ + C h ∞ ( – α)k T k β + 1 C R Σ + R C a + 0 (10) 2 k = 0 (k β + 1)k ! T An optimal cycle time T* can be obtained by letting dTC = 0 dT Fig. 4 shows a schematic diagram of the computer search method. Once T* is given, the optimal inventory level and total cost can be obtained by the equations (2), (9) and (10) respectively by this computer search method. k kβ –1 ∞ dTC = (C – C )R Σ ( – α) ⋅ k β ⋅ T p a dT (k β + 1)k ! k =0 + C h ∞ ( – α)k T k β C 0 R Σ – 2 =0 2 k =0 k! T (11) To solve the above equation, we adopt a numerical solution search method based on a graphical procedure after transforming the equation (11) into ∞ T = 1 R Σ C0 k =0 Step 1. Give a few values to T and find corresponding values of Z(T) from equation (10) for a particular value of α and β. Step 2. Plot these points for different values of α and β. Step 3. The points, where the line T = Z(T) cuts these curves, will give optimal values of T*. ( – α)k T k β + 3 k βT – 1 C h + ⋅ (C p – C a ) k! kβ + 1 2 (12) 2.2 ESQ Model When the inventory increment by amelioration is greater than the demand rate, the ameliorated items will be accumulated in the inventory system as time elapses. In this case the carrying cost per unit time would be increased as the surplus amount of inventory increases. Hence, at a proper point of time, it will be better to sell out this surplus amount of inventory So. Immediately after selling out this surplus, the inventory level will be dropped to I0 (base line of inventory level). An example 5 H. S. Hwang et al.: Optimal Issuing Policy for Fish-Breeding Supply Center with Items Weibull Ameliorating The amount of economic selling Inventory Level Z (T ) = It + S0 S0 It β (P s – C a ) I 0(e α T – 1) C0 β C – 1 (P s – C a ) – k T I 0αβT β + 3e α T 2 C0 I0 I0 + αβe α T t dt ∞ ( – α)k T (k + 1)β – 1 – C a) ⋅R ⋅T3 Σ C0 (k β + 1)k ! k =0 Time T k (k + 1)β – 1 β ∞ ( – α) T C – 1 α ⋅ β h ⋅ R ⋅ T 3e α T Σ 2 C0 (k β + 1)k ! k =0 T Fig. 5. Inventory cycle of ESQ model for the inventory cycle of ESQ model when the inventory increment by amelioration is decreasing is shown in Fig. 5. The initial inventory level (base-line inventory) I0 and the economic selling quantity So can be found by the equation (1). From the boundary condition IT = I0 + So, equation (1) yields T β I 0 + S 0 = e αT – R 0 1 β e αT – 1 e αx β t R e – αx β 0 dx + S 0 If the value of I0 is given, So is represented a function of cycle time T as follows: T β S 0 = e αT – R 0 β β e α x dx + I 0(e α T – 1) Let us now find the total cost per cycle time. Using ESQ model in which the selling cost is additionally included to the total cost, we can obtain the total cost TC by equation (13). TC = (P s – C a )R + I 0(e αT β Ps – C a C h – T 2 – 1) – Re C – C hI0 – 0 T αT β + k (k + 1)β – 1 β ∞ ( – α) T Ps – C a ⋅ R ⋅ e αT Σ C0 (k β + 1)k ! k =0 ∞ ( – α)k T k β C –1 h R Σ 2 C 0 k = 0 (k β + 1)k ! (14) 3. NUMERICAL EXAMPLES To illustrate the developed EOQ-type and ESQ models for ameliorating inventory, three examples are introduced for a fish-breeding supply center inventory problems. β e – α x dx + I 0 , and alternatively I0 = β (P s Example 1: Inventory level The inventory is depleted according to an issuing policy. Inventory levels at given times according to issuing policies are summarized in Table 1 under the identical cycle times, T = 4, and considered the Weibull ameliorating inventory with parameters, α = 0.3 and β = 1.4, and the results are depicted in Fig. 6. Note that the inventory level in case 1 decreases with a constant demand rate, R = 1000 units/unit time. In Table 1, we can see that the inventory levels needed for a cycle time, T are different by issuing policies. In case 1 (non-ameliorating) required amount of inventory level in fish-breeding supply centre is 4,000, while, in case 2 (FIFO issuing policy) it is 2,773 and in case Table 1. Comparison of inventory levels under LIFO and FIFO: ( – α)k T k β + 1 Σ k = 0 (k β + 1)k ! α = 0.3, β = 1.4, R = 1000 ∞ (13) Using dTC and the equation (14) given as following, dT we can find the optimal cycle time T* by the same method used for the case of EOQ-type model, Inventory level at time Issuing policy Case 1: Non-ameliorating Case 2: FIFO Case 3: LIFO 0 1 2 3 4 4,000 3,000 2,000 1,000 0 2,773 2,199 1,438 737 0 1,999 1,502 1,158 738 0 6 International Journal of the Information Systems for Logistics and Management (IJISLM), Vol. 1, No. 1 (2005) Inv. Level In Supply Center Z(T) α = 0.30 Z(T) = T α = 0.20 α = 0.15 Case 1. Non-Ameliorating Case 2. Amelisorating (FIFO) 4,000 2,773 α = 0.10 α = 0.05 Case 3. Ameliorating (LIFO) 1,999 4 9 14 20 27 Cycle Time, T* Fig. 7. Graphical representation for the EOQ-type model: β = 0.30 0 1 2 3 4 Time Fig. 6. Comparison of issuing policies (LIFO and FIFO) 3 (LIFO policy) it is only 1,999. In this case we can conclude that LIFO issuing policy better than FIFO policy. Example 2: EOQ-type model (T *, I *0, TC *) We consider the same fish culture company to sell raw fishes in a small sea village. The company periodically orders fishes when the tank is almost empty. The optimal values of cycle time, order quantity and corresponding total cost are obtained under various parameters of Weibull amelioration. The data needed are given as: R: 1,000 kg/day, Co: 300,000 /unit, Ca: 4,000 /unit, Ch: 400 /kg/day, Cp: 10,000 /kg Numerical results for the EOQ-type model under LIFO are summarized in Table 2 and the graphical representation of T and Z(T) with β = 0.30 is given as Fig. 7. Example 3: ESQ model ((T*, S*0, TC*) Table 3 and Fig. 8 show the results for the ESQ model under LIFO. Given β = 0.6 and other parameter Table 2. Sample results of EOQ-type model - Optimal Cycle Time, T * - Optimal Order Level, I *0 - Minimum Cost, TC * Description β = 0.10 β = 0.15 β = 0.20 β = 0.30 α = 0.05 α = 0.1 α = 0.2 α = 0.3 α = 0.4 3 2579.84 9661438 3 2579.84 9388672 3 2453.32 9129316 4 2945.28 8640190 4 3420.48 964625 4 3420.48 9376753 4 3246.75 9107472 9 4331.91 8598514 4 3584.23 9630564 6 5019.88 9320881 7 5478.88 9012989 20 7363.61 8411970 6 5262.66 9575801 9 7211.60 9201653. 14 10003.92 8809016 27 14689.99 8010052 8 6868.91 9532634 13 9926.00 9100634 21 13758.32 8633150 30 17655.00 7243463 values as following. The optimal values of cycle time, selling quantity, and total cost per cycle time are summarized in Table 3. The input data for ESQ model (example 3) are given as follows. R: 1,000 unit/day Co: 8,000 /unit Ca: 1,000 /kg, Ch: 100 /unit/time Cp: 8,000 /unit Ps: 10,000 /unit, In case of α = 0.6 and β = 0.6, the optimal economic selling quantity and the total cost per cycle time are given by; S*0 = 35,944, TC* = 7.61 × 106, T * = 12, I *0 = 30,000. From Fig. 8, we can find that the optimal cycle time in the ESQ model under LIFO does not become sensitive to the value of α as it increases. This example is the case that the amount of unit ameliorated is greater than the Table 3. Results for the ESQ model: β =0.6 T* 26 12 4 2 2 1 1 Description α = 0.5 α = 0.6 α = 0.7 α = 0.8 α = 0.9 α = 1.0 α = 1.2 S *0 845832 359444 80794 67551 83818 50043 67956 TC * 6.40 × 106 7.61 × 106 2.01 × 106 5.65 × 106 1.28 × 106 2.03 × 106 3.64 × 106 Z(T) α = 0.5 α = 0.6 α = 0.7 α = 0.8, 0.9 α = 1.0, 1.2 1 2 4 12 26 T, Cycle Time Fig. 8. Graphical representation of the ESQ model, β = 0.6 H. S. Hwang et al.: Optimal Issuing Policy for Fish-Breeding Supply Center with Items Weibull Ameliorating demand rate and the surplus amount of inventory is accumulated in fish-breeding supply center. 4. CONCLUSIONS In this paper, we have considered a special case of problem, the inventory issuing problem of a fish-breeding supply center for items with Weibull ameliorating that the utility in inventory items increase over time. We developed two supply chain inventory models, EOQ-type and ESQ model for items with Weibull amelioration. Since the inventory depletion policies of fish-breeding supply center are closely related to the ameliorating inventory, we have considered two issuing policies, LIFO and FIFO. The formulae for the inventory level and the total cost per cycle time have been obtained. Due to the non-closed forms of the solutions of the proposed models, we have solved by a computerized search technique and graphical method. Three numerical examples have been performed to illustrate and demonstrate the proposed models as: (1) computing the inventory levels by issuing policies and compared, (2) using the EOQ-type mode to find the optimal cycle time, T*, order point, I *0, and optimal cost per cycle, TC*), and (3) using the ESQ model to find optimal cycle time, T*, optimal selling quantity S*0, and related cycle time cost, TC*. For the further research we are to develop a more practical method to solve the optimal values for, T*, I *0, S*0, and TC*, related with ameliorating inventory management and develop GUI-type computer program for users. REFERENCES Chung, K. J. and Lin, S. P. (2001) Optimal inventory replenishment models for deteriorating items taking account of time discounting. International Journal of Computers and Operations Research, 28, 67-83. Garg, A. (1996) Product and Process Design Strategies for Effective Supply Chain, Stanford University, Ph.D. Dissertation. Gupta, N. K. (1982) Effect of lead time on inventory-a working result. International Journal of Operations Research 30(5), 477-481. 7 He, Q. M. (1996) The Value of Information Used in Inventory Replenishment (supply chain management). University of Waterloo, Ph.D. Dissertation. Hwang, H. and Hwang, H. S. (1982) Optimal issuing policy in production lot size system for items with Weibull deterioration. International Journal of Production Research, 20(1), 87-94. Hwang, H. S. (1997) A study on an inventory model for items with ameliorating and deteriorating. International Journal of Computers and Industrial Engineering, 33(3-4), 701-704. Hwang, H. S. (1999) Inventory models for both deteriorating and ameliorating items. International Journal of Computers and Industrial Engineering, 37, 257-260. Hwang, H. S. (2004) A stochastic set-covering location model for both deteriorating and ameliorating items. International Journal of Computers and Industrial Engineering, 46, 313-319. Kevorkian, J. and Cole, J. D. (1981) Perturbation Methods in Applied Mathematics. Springer-Verlag, New York. Lars, N. and Tayfur, A. (1998) Analysis of inventory systems with (r, Q)-policies and back-ordering. Proceedings of the 1998 IEEE International Conference on Systems, Management and Cybernetics 4, 3100-3105. Leung, L. C., Cheung, W. N. and Van, H. Y. (2000) A framework of a logistics E-commerce commodity network. IEEE Transactions on Systems, Management & Cybernetics Part A 30(4), 446-455. Lin, C. H., Tan, B. and Lee, W. C. (2000) An EOQ model for deteriorating items with time-varying demand and shortages. International Journal of Systems Science 31 (3), 391-400. Nakamura, M., Sakakibara, S. and Schroeder, R. (1998) Adoption on just-in-time manufacturing methods at US-and Japanese-owned plants-some empirical evidence. IEEE Transaction on Engineering Management, 45(3), 230-240. Raafat, F. and Eldin, H. (1991) An inventory model for deteriorating items. International Journal of Computers and Industrial Engineering, 20(1), 89-94. Ross, A. D. (1996) Logistics Planning within the Supply Chain: a Methodology and Solution Approaches. Indiana University, Ph.D. Dissertation. Sparker, B. R., Jamal, A. M. M. and Wang, S. (2000) Supply chain models for perishable products under inflation and perishable delay in payment. International Journal of Computers and Operations Research, 27, 59-75.