PDF - Gear Technology magazine

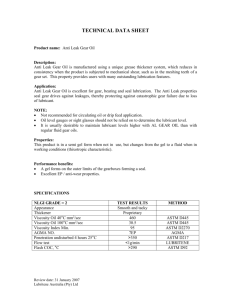

advertisement