AXIS_SERVO_DRIVE

SERCOS and Analog Motion Configuration and Startup

Catalog Numbers 1756-HYD02, 1756-M02AE, 1756-M02AS, 1756-M03SE, 1756-

M08SE, 1756-M16SE, 1768-M04SE, 2094-SE02F-M00-S0, 2094-SE02F-M00-S1

User Manual

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/ ) describes some important differences between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

Allen-Bradley, Rockwell Automation, RSLogix 5000, Rockwell Software, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

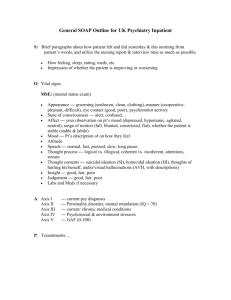

Introduction

Before You Begin

What You Need

Preface

Preface

Use this manual to configure a motion application and to start up your motion solution using Logix5000 motion modules.

Topic

Configuration and Start-up Scenarios

Help for Selecting Drives and Motors

Page

This manual is a redesigned manual from publication LOGIX-UM002. A companion manual is available called the Coordinate System User Manual, publication MOTION -UM002.

This manual is designed to give you the quickest and easiest approach to a

SERCOS or Analog control solution. If you have any comments or suggestions, please see Documentation Feedback on the back cover of this manual.

You need the following to set up either a SERCOS or Analog motion system:

SERCOS

• Logix L6 x or Logix L7 x controller

• SERCOS interface drive (6000,6200,2000, Ultra3000)

• SERCOS interface module

• Kinetix 6000 drive/actuators pair

• RSLogix 5000 programming software

Analog

• Logix L6 x controller

• Analog interface module

• Analog interface drive, Ultra3000

• Kinetix 6000 drive/actuators pair

• RSLogix 5000 programming software

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 3

Preface

Configuration and Start-up

Scenarios

Program First

1 - Program Virtual

2 - Configure

3 - Wire

Refer in Installation Instructions.

1 - Modify Program

If you program in Virtual first, you need to modify your program from using virtual axes to real axis.

The following are three example scenarios of how you can get a motion solution up and running.

TIP Programming Virtual first is the safest method to begin with because you are separating the motion programming from the hardware.

Configure First

1 - Configure

Wire First

1 - Wire

Refer in Installation Instructions.

2 - Program 2 - Configure

3 - Wire

Refer in Installation Instructions.

4 - Commission

3 - Commission

4 - Program

4 - Commission

4 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Preface

Description of the Modules

This table describes the Logix5000 motion modules.

Motion Module

1756-M03SE

Description

Use a SERCOS interface module to connect the controller to SERCOS interface drives.

1756-M08SE

1756-M16SE

1768-M04SE

2094-SE02F-M00-S0, 2094-

SE02F-M00-S1

1756-M02AE

• The SERCOS interface module lets you control digital drives by using high-speed, real time, serial communication.

• SERCOS is the IEC 61491 Serial Real-time Communication System protocol over a fiber optic network.

• The module uses a fiber optic network for all the wiring between the drives and the module.

Kinetix 6200 control modules use SERCOS interface to communicate with the Logix controller and EtherNet/

IP to access the safety configuration tool.

The 1756-M02AE module is a two-axis servo module for drives/actuators that need a ±10V velocity or torque reference. Use the 1756-M02AE module when your equipment has quadrature encoder feedback.

1756-HYD02

The module also has the following:

• Home limit switch inputs

• Drive fault inputs

• Drive enable outputs

• 5V or 24V position registration inputs

• 250

µ s position and velocity loop updates

The 1756-HYD02 module is a two-axis servo module for hydraulic actuators that need a ±10V velocity reference. Use the 1756-HYD02 module when your equipment has magnostrictive linear transducer (LDT) feedback.

The module is similar to the 1756-M02AE module with these exceptions:

1756-M02AS

• Feed Forward adjust in addition to single-step Auto Tune.

• Gain ratio between extend direction and retract direction to accommodate hydraulic cylinder dynamics.

• Intelligent transducer noise detection filtering in hardware and firmware replaces programmable IIR filtering.

The 1756-M02AS module is a two-axis servo module for drives/actuators that need a ±10V velocity or torque reference input. Use the 1756-M02AS module when your equipment has Serial Synchronous Input

(SSI) position feedback.

The module is similar to the 1756-M02AE module with these exceptions:

• Gain ratio between extend direction and retract direction to accommodate hydraulic cylinder dynamics.

• Intelligent transducer noise detection filtering in hardware and firmware replaces programmable IIR filtering.

• SSI interface consisting of Differential Clock output and Data return signals replaces the differential encoder interface.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 5

Preface

Help for Selecting Drives and

Motors

The Motion Analyzer utility helps you select the appropriate Rockwell

Automation drives and motors based upon your load characteristics and typical motion application cycles.

You can access and download the program at: http://www.ab.com/motion/software/analyzer_download.html

The Motion Analyzer guides you through wizard-like screens to collect information specific to your application. After you enter the information, for example, the load inertia, gear box ratio, feedback device, and brake requirements, the Motion Analyzer generates an easy-to-read list of recommended motors, drives, and other support equipment.

Where to Find Sample Projects

Use the RSLogix 5000 software Start Page (ALT+F9) to find the sample projects.

6

Additional Resources

The Rockwell Automation sample project’s default location is:

C:\RSLogix 5000\Projects\Samples\ENU\v18\Rockwell Automation

There is a PDF file named Vendor Sample Projects on the Start Page that explains how to work with the sample projects. Free sample code is available at: http:// samplecode.rockwellautomation.com/ .

These documents contain additional information concerning related Rockwell

Automation products. You can view or download publications at http:// literature.rockwellautomation.com

. To order paper copies of technical

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Preface documentation, contact your local Rockwell Automation distributor or sales representative.

Resource

Motion Coordinate System User Manual, publication MOTION-UM002.

Logix5000 Controller Motion Instructions

Reference Manual, publication MOTION-RM002.

Logix5000 Controllers Quick Start, publication

1756-QS001.

Logix5000 Controllers Common Procedures, publication 1756-PM001.

Description

Provides details on how to create and configure a coordinated motion system.

Provides a programmer with details about motion instructions for a Logix-based controller.

Describes how to get started programming and maintaining Logix5000 controllers.

Provides detailed and comprehensive information about how to program a Logix5000 controller.

Provides a programmer with details about general instructions for a Logix-based controller.

Provides a programmer with details about process and drives instructions for a Logix-based controller.

Logix5000 Controllers General Instructions

Reference Manual, publication 1756-RM003.

Logix5000 Controllers Advanced Process Control and Drives Instructions Reference Manual, publication 1756-RM006.

PhaseManager User Manual, publication LOGIX-

UM001.

ControlLogix System User Manual, publication

1756-UM001.

Describes how to set up and program a Logix5000 controller to use equipment phases.

Describes the necessary tasks to install, configure, program, and operate a ControlLogix system.

CompactLogix Controllers User Manual, publication 1768-UM001.

Describes the necessary tasks to install, configure, program, and operate a CompactLogix system.

Analog Encoder (AE) Servo Module Installation

Instructions, publication 1756-IN047.

ControlLogix SERCOS interface Module

Installation Instructions, publication 1756-IN572.

Provides installation instructions for the Analog

Encoder (AE) Servo Module, catalog number

1756-M02AE.

Provides installation instructions for the

ControlLogix SERCOS interface modules, catalog number 1756-M03SE, 1756-M08SE, 1756-

M16SE, 1756-M08SEG.

CompactLogix SERCOS interface Module

Installation Instructions, publication 1768-IN005.

Provides installation instructions for the

CompactLogix SERCOS interface Module, catalog number 1768-M04SE.

Ultra3000 Digital Servo Drives Installation

Manual, publication 2098-IN003.

Ultra3000 Digital Servo Drives Integration

Manual, publication 2098-IN005.

Provides the mounting, wiring, and connecting procedures for the Ultra3000 drives and standard

Rockwell Automation/Allen-Bradley motors recommended for use with the Ultra3000 drives.

Provides powerup procedures, system integration, and troubleshooting tables for the

Ultra3000 digital servo drives.

Kinetix 7000 High Power Servo Drive User

Manual, publication 2099-UM001.

Kinetix 6000 Integrated Axis Modules and Axis

Modules Installation Instructions, publication

2094-IN001.

Provides details on how to plan for, mount, install, configure, and troubleshoot the Kinetix

7000 High Power Servo drive.

Provides installation instructions for the Kinetix

6000 Integrated Axis Module and Axis Module series B drive components.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 7

Preface

Resource Description

Kinetix 6000 Multi-axis Servo Drives User Manual, publication 2094-UM001.

Provides detailed installation instructions for mounting, wiring, and troubleshooting your

Kinetix 6000 drive, and system integration for your drive/motor combination with a Logix controller.

Kinetix 6200 and Kinetix 6500 Safe Speed

Monitoring Multi-axis Servo Drives Safety

Reference Manual, publication 2094-RM001.

Kinetix 6200 and Kinetix 6500 Safe Torque-off

Multi-axis Servo Drives Safety Reference Manual, publication 2094-RM002.

Information on wiring, configuring, and troubleshooting the safety functions of your

Kinetix 6200 and Kinetix 6500 drives.

8720MC High Performance Drives Installation

Manual, publication 8720MC-IN001.

Provides the mounting, wiring, and connecting procedures for the 8720MC and standard

Rockwell Automation/Allen-Bradley motors recommended for use with the 8720MC drive.

8720MC High Performance Drives Integration

Manual, publication 8720MC-IN002.

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1.

Product Certifications website, www.ab.com

.

http://

This manual provides the startup, configuration, and troubleshooting procedures for the 8720MC drive.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity, certificates, and other certification details.

8 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Preface

Summary of Changes

Configure SERCOS Motion

Configure Analog Motion

Table of Contents

Preface

Chapter 1

Add a SERCOS Motion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Modify Properties for a SERCOS Motion Module . . . . . . . . . . . . . . . . . . 31

Set the Data Rate and Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Modify Properties for a SERCOS Interface Drive . . . . . . . . . . . . . . . . . . . 33

Set the Course Update Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set the Homing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 2

Modify Properties for Analog Modules . . . . . . . . . . . . . . . . . . . . . . . . . 49

Modify Properties for Hydraulic Drives . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuring the Feedback Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 9

Table of Contents

Commission and Tune

Program

10

Set the Homing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 3

Configure the Fault Actions for an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Example: Uninhibit an Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Test an Axis with Motion Direct Commands . . . . . . . . . . . . . . . . . . . . . . . 76

Access Motion Direct Commands for a Group . . . . . . . . . . . . . . . . . . 76

Access the Motion Direct Commands for an Axis . . . . . . . . . . . . . . . 77

Motion Direct Command Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Motion Group Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Motion Direct Command Error Process. . . . . . . . . . . . . . . . . . . . . . . . 82

Motion Direct Command Verification . . . . . . . . . . . . . . . . . . . . . . . . . 83

Motion Direct Command Execution Error . . . . . . . . . . . . . . . . . . . . . 84

What If the Software Goes Offline or the Controller Changes Modes?

Can Two Workstations Give Motion Direct Commands? . . . . . . . 85

Chapter 4

Program a Velocity Profile and Jerk Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Use % of Time for the Easiest Programming of Jerk . . . . . . . . . . . . . . 89

Example Motion Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Download a Project and Run the Logic . . . . . . . . . . . . . . . . . . . . . . . . 102

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Table of Contents

Home an Axis

Axis Properties

Why does my axis accelerate when I stop it?. . . . . . . . . . . . . . . . . . . . 106

Why does my axis overshoot its target speed?. . . . . . . . . . . . . . . . . . . 108

Why is there a delay when I stop and then restart a jog? . . . . . . . . . 111

Why does my axis reverse direction when I stop and start it?. . . . . 113

Chapter 5

Appendix A

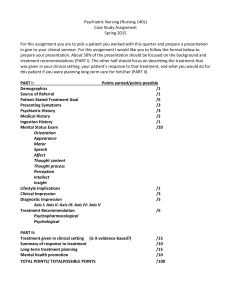

General Tab – AXIS_SERVO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

General Tab - AXIS_SERVO_DRIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Node with a Kinetix 6000 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

General Tab - AXIS_VIRTUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

MOTION_GROUP Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

General Tab – AXIS_GENERIC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Feedback Tab – (AXIS_SERVO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Drive/Motor Tab - (AXIS_SERVO_DRIVE) . . . . . . . . . . . . . . . . . . . . . 135

Motor Feedback Tab - AXIS_SERVO_DRIVE. . . . . . . . . . . . . . . . . . . . 140

Aux Feedback Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . 140

Homing Tab - AXIS_SERVO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Homing Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Homing Tab - AXIS_VIRTUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Hookup Tab - AXIS_SERVO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Hookup Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 11

Table of Contents

12

Test Command & Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Tune Tab - AXIS_SERVO, AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . 151

Torque/Force (AXIS_SERVO_DRIVE) . . . . . . . . . . . . . . . . . . . . . . 151

Torque (AXIS_SERVO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Dynamics Tab - AXIS_SERVO, AXIS_SERVO _DRIVE,

Maximum Acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Maximum Deceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Maximum Acceleration Jerk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Maximum Deceleration Jerk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Proportional (Position) Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Proportional (Velocity) Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Acceleration Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Gains Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Acceleration Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Proportional (Position) Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Proportional (Velocity) Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

This field is disabled for the 1756-M02AE module. . . . . . . . . . . . . . 169

Enable Low-pass Output Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Table of Contents

Low-pass Output Filter Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Output Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Enable Notch Filter Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Enable Low-pass Output Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Low-pass Output Filter Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Limits Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Peak Torque/Force Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Continuous Torque/Force Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Friction/Deadband Compensation and Backlash Compensation 182

Backlash Compensation Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Backlash Compensation and Reversal Offset . . . . . . . . . . . . . . . . . . . 183

Offset Tab - AXIS_SERVO_DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Backlash Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Backlash Compensation Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Backlash Compensation and Reversal Offset . . . . . . . . . . . . . . . . . . . 187

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 13

Table of Contents

Motion Axis Attributes

Wiring Diagrams

14

Fault Actions Tab - AXIS_SERVO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Fault Actions Tab - AXIS_SERVO_DRIVE. . . . . . . . . . . . . . . . . . . . . . . 191

Appendix B

Accessing an MSG Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Interpreting the Attribute Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Additional Error Code Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Appendix C

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Servo Loop Block Diagrams

1398-CFLAExx Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Pinouts for 1398-CFLAExx Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Ultra3000 to 1756-M02AE Interconnect diagram. . . . . . . . . . . . . . 284

2090-U3AE-D44xx Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Wiring from AB 842A Encoder without Reset to

Wiring for AB 842A Encoder with Remote Reset to

1756-HYD02 Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Temposonic GH Feedback Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Appendix D

Position Servo with Torque Servo Drive. . . . . . . . . . . . . . . . . . . . . . . 296

Position Servo with Velocity Servo Drive . . . . . . . . . . . . . . . . . . . . . . 297

Motor Dual Command Servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Auxiliary Dual Command Servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Dual Command Feedback Servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Index

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 15

Table of Contents

Notes:

16 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Summary of Changes

This manual contains new and updated information. Changes throughout this revision are marked by change bars, as shown in the margin.

New and Updated

Information

Item

Modify Properties for a SERCOS Interface Drive

Control multi-axis coordinated motion

Drive/Motor Tab - (AXIS_SERVO_DRIVE)

Aux Feedback Tab - AXIS_SERVO_DRIVE

Motor Feedback Tab - AXIS_SERVO_DRIVE

This table contains the changes made to this revision.

Description

Modify properties, such as the Bus Regulator, for a SERCOS interface drive, such as the

Integrated Drive Motor (IDM)

Configure the Drive/Motor tab for the Integrated Drive Motor (IDM).

Define a Master/Slave relationship between two motion axes and select which type of move instructions.

Define a Master/Slave relationship between a Master Axis and a Coordinate System.

Describes there is one MOTION_GROUP data type per controller.

Added field descriptions for the Calculate Position Parameters dialog box.

Added field description for Feedback Resolution.

Added field description for Feedback Resolution.

Added field description for the Output tab - AXIS_SERVO.

Page

Rockwell Automation Publication MOTION-UM100B-EN-P - November 2011 17

Summary of Changes

Notes:

18 Rockwell Automation Publication MOTION-UM100B-EN-P - November 2011

Chapter

1

Configure SERCOS Motion

Introduction

Use this chapter for procedures on how to set up SERCOS motion control.

Topic

Modify Properties for a SERCOS Motion Module

Set the Data Rate and Cycle Time

Modify Properties for a SERCOS Interface Drive

Page

Create a Controller Project

Follow these instructions to create a controller project.

1.

Open RSLogix 5000 software.

If the Start Page appears, close it.

2.

From the File menu, choose New.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 19

Chapter 1 Configure SERCOS Motion

The New Controller window appears

3.

Select a ControlLogix controller.

You can also select a CompactLogix controller.

20

For more information about the tasks to instal, configure, program, and operate a

CompactLogix system, see CompactLogix Controllers User Manual, publication

1768-UM001.

Configure the controller to match your project requirements.

You will need to determine the following:

• Type of Controller

• Software Revision

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

• Name of Project

• Chassis Type

• Controller Slot Location

• Project Location

4.

Click OK.

Setting Time Synchronization

Time Synchronization in ControlLogix is called CIP Sync. CIP Sync is a layer of functionality that Rockwell Automation has developed on top of the IEEE 1588

PTP protocol. CIP Sync lets you maintain accurate time synchronization of your automation solutions.

This setting establishes the module to participate in time synchronization. In systems with multiple processors, all controllers need to have time synchronization enabled if they are to use CST/PTP time. The 1756-EN x

T communication modules win the arbitration over any processor.

1.

In the Controller Organizer, right-click the controller and choose

Properties or double-click the controller.

2.

Click the Date/Time tab.

3.

Check Enable Time Synchronization.

4.

Click OK.

Without intervention, the Grandmaster is both PTP and CST master. You can use the settings on the Advanced Dialog box to let this module win the arbitration over other processors and communication modules in the chassis.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 21

Chapter 1 Configure SERCOS Motion

See the Integrated Architecture and CIP Sync Configuration Application

Technique, publication IA-AT003 for more information.

Add a SERCOS Motion Module

Follow these instruction to add a SERCOS motion module to your system

IMPORTANT For all motion modules, use the firmware revision that goes with the firmware revision of your controller. See the release notes for your controller’s firmware.

1.

.To add a module, right-click on the backplane and choose New Module.

2.

Select the module that you want to add and click OK.

3.

Name the module.

4.

Assign the slot for the module.

22

5.

Type a description, if desired.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Electronic Keying

Configure SERCOS Motion Chapter 1

6.

Choose a Keying option.

WARNING: When using motion modules, the electronic keying should be either ‘Exact Match‘ or ‘Compatible Keying‘.

WARNING: ‘Disable Keying‘ should never be used with motion modules.

The electronic keying feature automatically compares the expected module, as shown in the RSLogix 5000 I/O Configuration tree, to the physical module before I/O communication begins. You can use electronic keying to help prevent communication to a module that does not match the type and revision expected.

For each module in the I/O Configuration tree, the user-selected keying option determines if, and how, an electronic keying check is performed. Typically, three keying option are available.

• Exact Match

• Compatible Keying

• Disable Keying

You must carefully consider the benefits and implications of each keying option when selecting them. For some specific module types, fewer options are available.

Electronic keying is based on a set of attributes unique to each product revision.

When a Logix5000 controller begins communicating with a module, this set of keying attributes is considered.

Table 1 - Keying Attributes

Attribute

Vendor

Product Type

Product Code

Major Revision

Minor Revision

Description

The manufacturer of the module, for example, Rockwell Automation/

Allen-Bradley.

The general type of the module, for example, communication adapter,

AC drive, or digital I/O.

The specific type of module, generally represented by its catalog number, for example, the 1756-IB16I module.

A number that represents the functional capabilities and data exchange formats of the module. Typically, although not always, a later, (that is, higher), Major Revision supports at least all of the data formats supported by an earlier, that is lower, Major Revision of the same catalog number and, possibly, additional ones.

A number that indicates the module’s specific firmware revision. Minor

Revisions typically do not impact data compatibility, but may indicate performance or behavior improvement.

You can find revision information on the General tab of a module’s Properties dialog box.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 23

Chapter 1 Configure SERCOS Motion

24

Figure 1 - General Tab

IMPORTANT Changing electronic keying selections online may cause the I/O communication connection to the module to be disrupted and may result in a loss of data.

Exact Match

Exact Match keying requires all keying attributes, that is, Vendor, Product Type,

Product Code (catalog number), Major Revision, and Minor Revision, of the physical module and the module created in the software to match precisely in order to establish communication. If any attribute does not match precisely, I/O communication is not permitted with the module or with modules connected through it, as in the case of a communication module.

Use Exact Match keying when you need the system to verify that the module revisions in use are exactly as specified in the project, such as for use in highlyregulated industries. Exact Match keying is also necessary to enable Automatic

Firmware Update for the module via the Firmware Supervisor feature from a

Logix5000 controller.

EXAMPLE In the following scenario, Exact Match keying prevents I/O communication:

The module configuration is for a 1756-IB16D module with module revision

3.1. The physical module is a 1756-IB16D module with module revision 3.2. In this case, communication is prevented because the Minor Revision of the module does not match precisely.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 1

Communication is prevented.

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

IMPORTANT Changing electronic keying selections online may cause the I/O

Communication connection to the module to be disrupted and may result in a loss of data.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

Compatible Keying

Compatible Keying indicates that the module determines whether to accept or reject communication. Different module families, communication adapters, and module types implement the compatibility check differently based on the family capabilities and on prior knowledge of compatible products.

Compatible Keying is the default setting. Compatible Keying allows the physical module to accept the key of the module configured in the software, provided that the configured module is one the physical module is capable of emulating. The exact level of emulation required is product and revision specific.

With Compatible Keying, you can replace a module of a certain Major Revision with one of the same catalog number and the same or later, (that is higher), Major

Revision. In some cases, the selection makes it possible to use a replacement that is a different catalog number than the original. For example, you can replace a

1756-CNBR module with a 1756-CN2R module.

Release notes for individual modules indicate the specific compatibility details.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 25

Chapter 1 Configure SERCOS Motion

When a module is created, the module’s previous capabilities are emulated.

However, future capabilities are not known. Because of this, when a system is configured, we recommend that you configure your module using the earliest, that is, lowest, revision of the physical module that you believe will be used in the system. By doing this, you can avoid the case of a physical module rejecting the keying request because it is an earlier revision than the one configured in the software.

See the following examples.

EXAMPLE In the following scenario, Compatible Keying prevents I/O communication :

The module configuration is for a 1756-IB16D module with module revision

3.3. The physical module is a 1756-IB16D module with module revision 3.2. In this case, communication is prevented because the minor revision of the module is lower than expected and may not be compatible with 3.3.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 3

Communication is prevented.

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

26 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

EXAMPLE In the following scenario, Compatible Keying allows I/O communication :

The module configuration is for a 1756-IB16D module with module revision

2.1. The physical module is a 1756-IB16D module with module revision 3.2. In this case, communication is allowed because the major revision of the physical module is higher than expected and the module determines that it is compatible with the prior major revision.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 2

Minor Revision = 1

Communication is allowed.

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

IMPORTANT Changing electronic keying selections online may cause the I/O communication connection to the module to be disrupted and may result in a loss of data.

Disabled Keying

Disabled Keying indicates the keying attributes are not considered when attempting to communicate with a module. Other attributes, such as data size and format, are considered and must be acceptable before I/O communication is established. With Disabled Keying, I/O communication may occur with a module other than the type specified in the I/O Configuration tree with unpredictable results. We generally do not recommend using Disabled Keying.

ATTENTION: Be extremely cautious when using Disabled Keying; if used incorrectly, this option can lead to personal injury or death, property damage, or economic loss.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 27

Chapter 1 Configure SERCOS Motion

If you use Disabled Keying, you must take full responsibility for understanding whether the module being used can fulfill the functional requirements of the application.

EXAMPLE In the following scenario, Disable Keying prevents I/O communication :

The module configuration is for a 1756-IA16 digital input module. The physical module is a 1756-IF16 analog input module. In this case, communication is prevented because the analog module rejects the data formats that the digital module configuration requests .

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IA16

Major Revision = 3

Minor Revision = 1

Communication is prevented.

Physical Module

Vendor = Allen-Bradley

Product Type = Analog Input Module

Catalog Number = 1756-IF16

Major Revision = 3

Minor Revision = 2

28 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

EXAMPLE In the following scenario, Disable Keying allows I/O communication :

The module configuration is for a 1756-IA16 digital input module. The physical module is a 1756-IB16 digital input module. In this case, communication is allowed because the two digital modules share common data formats.

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IA16

Major Revision = 2

Minor Revision = 1

Communication is allowed.

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16

Major Revision = 3

Minor Revision = 2

IMPORTANT Changing electronic keying selections online may cause the I/O communication connection to the module to be disrupted and may result in a loss of data.

7.

Check Open Module Properties box, if you want the Properties dialog box to open automatically after you are done creating the new module.

If you do not check the box, you will need to either double-click the module in the Controller Organizer or right-click the module and choose

Properties.

8.

Click OK.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 29

Chapter 1 Configure SERCOS Motion

Add SERCOS Interface Drives

Add SERCOS interface drives to the I/O configuration of the controller.

IMPORTANT For all interface drives, use the firmware revision that goes with the firmware revision of your controller. See the release notes for your controller’s firmware.

1.

To add a module, right-click the SERCOS Network and choose New

Module.

2.

Select the module that you want to add and click OK.

3.

Name the module.

30

4.

Assign a slot for the module.

5.

Type a description, if desired.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

6.

Choose a Keying option.

WARNING: When using motion modules, the electronic keying should be either ‘Exact Match‘ or ‘Compatible Keying‘.

WARNING: ‘Disable Keying‘ should never be used with motion module.

See Electronic Keying on page 23

.

7.

Check Open Module Properties, if you want the Properties dialog box to open automatically after you are done creating the new module.

If you do not check the box, you will need to either double-click the module in the Controller Organizer or right-click the module and choose

Properties.

Modify Properties for a SERCOS

Motion Module

Follow these instructions to modify the module properties.

1.

Right-click the module you want to configure and choose Properties.

2.

Click the Connection Tab.

3.

Review the Major Fault on Controller function.

TIP By default this box is unchecked. If this box is checked, then a Major Fault is generated when the SERCOS ring attempts to phase up the first time. Leave this box unchecked until you execute the program the first time.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 31

Chapter 1 Configure SERCOS Motion

Set the Data Rate and Cycle Time

Next you need to set the data rate and cycle time for each SERCOS interface module in your project. The cycle time is how often the SERCOS ring is read.

The cycle time update rate is only applicable to a SERCOS application.

32

The data rate and the number of drives associated with the module will dictate your minimum cycle time.

For more information about configuring the Kinetix 6200 and Kinetix 6500 servo drive systems, see the Kinetix 6200 and Kinetix 6500 Modular Multi-axis

Servo Drive User Manual, publication 2094-UM002.

This table describes the cycle time in relation to the modules.

Table 2 - Cycle Times

Baud Rate of Drives

4 Mbps

Number of Drives on the Ring Type of Drives

Up to 2

Up to 4

Up to 8

9…16

Kinetix 2000

Kinetix 6000

Kinetix 6200

Kinetix 7000

Cycle Time

0.5 ms

1 ms

2 ms

No Support

8 Mbps

TIP The Ultra 3000 must be 1 or 2 ms SERCOS cycle time because the position loop update time minimum is 1 ms.

Up to 4 0.5 ms Kinetix 2000

Kinetix 6000

Kinetix 6200

Kinetix 7000

Up to 8

Up to 16

1 ms

2 ms

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

Modify Properties for a SERCOS

Interface Drive

Follow these instructions to modify drive properties.

1.

Right-click the drive that you want to configure and choose Properties.

2.

Click the Associated Axes tab.

3.

A ssociate an axis tag, of the type AXIS_SERVO_DRIVE, with nodes available on the module

.

IMPORTANT Click the New Tag button to open the New Tag dialog box to create an

AXIS_SERVO_DRIVE tag to associate with one of the nodes.

Note that this field is read-only while you are online.

4.

Click the ellipses button to access the Axis Properties dialog box for the associated axis.

Select a Bus Regulator

Use the Power tab to select a bus regulator for your drive modules.

1.

Click the Power tab.

2.

Select the catalog number that describes the bus regulator device used by the drive module. Depending upon the drive you have selected, one or more of the bus regulator IDs may be available.

IMPORTANT This tab does not apply to the 8720MC drive, the Ultra3000 SERCOS drive, or

Kinetix 6200 Integrated Drive Motor (IDM) drive. The only available selection in the Bus Regulator ID pull-down menu for these drives is <none>.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 33

Chapter 1 Configure SERCOS Motion

3.

If you are configuring a Kinetix 2000 230 volt drive, select either Singlephase or Three-phase as Drive input power.

IMPORTANT Input power only applies for the Kinetic 2000 230 volt drive family. The Input

Power field does not display in the dialog box for drive families other than the

Kinetic 2000 230 volt drive family.

4.

Define the additional bus capacitance that is required by the IDM Power

Interface Module (IPIM) and IDM modules. .

IMPORTANT This control is only valid when an axis is associated with the IDM module.

When an axis is initially associated to the IDM, this control displays the default value and is enabled.

If a valid value is set in the associated axis, and the axis is not associated to the IDM, this control is reset to the default value and cannot be changed until an axis is associated to the IDM .

34 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Add the Motion Group

Configure SERCOS Motion Chapter 1

Follow these instructions to add a motion group.

IMPORTANT Only one motion group can be created for each project.

1.

Right-click Motion Groups and choose New Motion Group.

2.

Type a name and description, if desired and click OK.

If you check Open Motion_Group Configuration, the Motion Group

Wizard appears. If not, you can access the Motion Group properties by right-clicking the group and choosing Properties.

Set the Course Update Period

The Course Update Period is how often the motion planner runs. When the motion planner runs, it interrupts most other tasks regardless of their priority.

The motion planner is the part of the controller that takes care of position and velocity information for the axes.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 35

Chapter 1 Configure SERCOS Motion

Motion Planner

Scans of Your Code,

System Overhead, and so on

0 ms 10 ms 20 ms 30 ms 40 ms

In this example, the Coarse Update Period = 10 ms. Every 10 ms the controller stops scanning your code and whatever else it is doing and runs the motion planner.

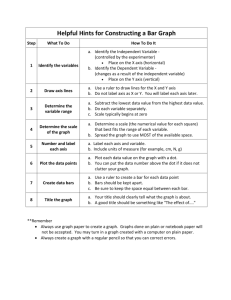

The Coarse Update Period is a trade-off between updating positions of your axes and scanning your code. Use these guidelines as a rough starting point.

Guideline

Number of Axes

Save Controller’s Time

Coarse Update Period and SERCOS modules

Coarse Update Period and Analog modules

Description

1756-L6 x controller 4 axes/ms

1756-L7 x controller8 axes/ms

Leave at least half the controller’s time for the scan of all your code.

If you have SERCOS interface motion modules, set the

Coarse Update Period to a multiple of the cycle time of the motion module.

Example: if the cycle time is 2 ms, set the Coarse Update

Period to 8 ms, 10 ms, 12ms, and so on.

If you have analog motion modules, set the Coarse Update

Period to:

• at least 3 times the servo update period of the motion module.

• a multiple of the servo update period of the motion module.

3.

Double-click the Motion Group in the Controller Organizer or the

Wizard appears.

36 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

4.

Set the Coarse Update Period.

Configure SERCOS Motion Chapter 1

5.

Set the Auto Tag Update

6.

Set the General Fault Type to Non Major Fault and click OK.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 37

Chapter 1 Configure SERCOS Motion

Add an Axis

Add an axis for each of your drives.

1.

Right-click Motion Group and choose New Axis.

If you use one of these motion modules then use the data type

AXIS_SERVO_DRIVE for the axis.

• 1756-M03SE

• 1756-M08SE

• 1756-M16SE

• 1768-M04SE

2.

Choose AXIS_SERVO_DRIVE.

If you want to use a virtual configuration (no hardware) then use the data type AXIS_VIRTUAL for the axis.

38 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Get Axis Information

Configure SERCOS Motion Chapter 1

You can get information about an axis in several ways.

• Use the Quick View pane to see the state and faults of an axis.

• Use a Get System Value (GSV) instruction or Set System Value (SSV) instruction to read or change the configuration at run-time.

• Use the tag of the axis for status and faults.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 39

Chapter 1 Configure SERCOS Motion

Configure an Axis

The following steps show how to set up the axis of a SERCOS interface drive.

The steps are may be different depending on the type of drive you are configuring.

1.

Right-click the axis and choose Properties.

2.

Click the General tab.

3.

Select the drive for the axis.

4.

Select the module name that you want to associate to the axis.

5.

Go to the Units tab and type the units and Average Velocity Timebase.

6.

Go to the Drive/Motor tab and select the Amplifier and related Motor

Catalog Numbers.

40

The following conditions apply for the Integrated Drive Motor (IDM):

• The Amplifier Catalog Number appears dimmed and cannot be edited when the axis is associated to an IDM.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

• The Motor Catalog Number is automatically set to the catalog number of the only valid motor available from the Motion Database for the IDM module when it is associated to the axis.

• The Catalog Number for the IDM appears dimmed and is read-only. It is automatically set tot he compatible motor from the motion database for each IDM.

• An IDM does not support Auxiliary Axis loop configurations. When the

Axis Configuration field on the General tab is set to Servo, the valid selections for Loop Configuration for the IDM are:

• Position Servo

• Dual Command Servo (does not use the Auxiliary Port)

• Velocity Servo

• Torque Servo

When the Axis Configuration field on the General tab is set to Feedback

Only, the valid selection for Loop Configuration for the IDM is Motor

Feedback Only.

• The following are real-time attributes for the IDM:

• Position Command

• Position Feedback

• Position Error

• Position Int. Error

• Velocity Command

• Velocity Feedback

• Velocity Error

• Velocity Int. Error

• Accel Command

• Accel Feedback

• Marker Distance

• Torque Command

• Torque Feedback

• Positive Dynamic Torque Limit

• Negative Dynamic Torque Limit

• Motor Capacity

• Drive Capacity

• Power Capacity

• Bus Regulator Capacity

• Motor Electrical Angle

• Torque Limit Source

• DC Bus Voltage

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 41

Chapter 1 Configure SERCOS Motion

7.

Select the Drive/Counts for the Conversion Constant.

8.

If you want to calculate the conversion constant yourself, just put in your values, if not, set the conversion between drive counts and units, and click

Calculate.

42

If this is a rotary axis, type the number of drive counts after which you want to unwind.

9.

After you click Calculate, this dialog box appears.

You can input different Position Units and click Calculate. You will see the new values.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure SERCOS Motion Chapter 1

If you want to keep the new calculated values, click Update and Close.

Set the Homing Sequence

For complete information about Homing modes, methods, and guidelines, see

Follow these instructions to set the homing sequence.

On the Homing tab, select the homing mode.

Enter the Position units.

10.

Select Sequence type.

Homing speeds appear dimmed depending on what Homing Mode and

Sequence Type you select.

11.

Set the homing speeds and click OK to apply the changes.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 43

Chapter 1 Configure SERCOS Motion

Notes:

44 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Introduction

Chapter

2

Configure Analog Motion

Use this chapter for step-by-step procedures on how to set up analog motion control.

Topic

Add an Analog Interface Module

Modify Properties for Analog Modules

Modify Properties for Hydraulic Drives

Page

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 45

Chapter 2 Configure Analog Motion

Create a Controller Project

Follow these instructions to create a controller project.

1.

Open RSLogix 5000 software.

If the Start Page appears, close it.

2.

From the File menu choose New.

The New Controller window appears.

3.

Configure the controller to match your project requirements.

You will need to determine the following:

• Type of Controller

• Software Revision

• Name of Project

• Chassis Type

• Controller Slot Location

• Project Location

4.

Click OK.

46 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Setting Time

Synchronization

Configure Analog Motion Chapter 2

Time Synchronization in ControlLogix is called CIP Sync. CIP Sync is a layer of functionality that Rockwell Automation has developed on top of the IEEE 1588

PTP protocol. CIP Sync lets you maintain accurate time synchronization of your automation solutions.

This setting establishes the module to participate in time synchronization. In systems with multiple processors, all controllers need to have time synchronization enabled if they are to use CST/PTP time. The 1756-EN x

T communication modules win the arbitration over any processor.

1.

In the Controller Organizer, right-click the controller and choose

Properties or double-click the controller.

2.

Click the Date/Time tab.

3.

Check Enable Time Synchronization.

4.

Click OK.

Without intervention, the Grandmaster is both PTP and CST master. You can use the settings on the Advanced Dialog box to let this module win the arbitration over other processors and communication modules in the chassis.

See the Integrated Architecture and CIP Sync Configuration Application

Technique, publication IA-AT003 for more information.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 47

Chapter 2 Configure Analog Motion

Add an Analog Interface

Module

Add interface modules to the I/O configuration of the controller.

IMPORTANT For all interface drives, use the firmware revision that goes with the firmware revision of your controller. See the release notes for your controller’s firmware.

1.

To add a module, right-click the backplane and choose New Module.

2.

Select the analog module that you want to add and click OK.

3.

Name the module.

48

4.

Assign a slot for the module.

5.

Type a description.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure Analog Motion Chapter 2

6.

Choose a Keying option.

WARNING: When using motion modules, the electronic keying should be either ‘Exact Match‘ or ‘Compatible Keying‘.

ATTENTION: ‘Disable Keying‘ should never be used with motion module.

7.

Check Open Module Properties if you want the Properties dialog box to open automatically after you are done creating the new module.

If you do not check the box, you will need to either double-click the module in the Controller Organizer or right-click the module and choose

Properties.

Modify Properties for Analog Modules

With an analog module, the main items that you need to configure from the

Module Properties dialog box are:

• create an associated axis.

• assign the axis to a motion group.

• select an external drive configuration.

Follow these instructions to modify the properties for an analog module.

1.

Double-click the 1756-M02AE module in the Controller Organizer.

The Module Properties dialog box appears.

2.

Click the Associated Axes tab.

3.

Click New Axis to create an axis that will be associated to this module.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 49

Chapter 2 Configure Analog Motion

Because you selected New Axis from the analog module dialog, the data type is defined. If you create the axis by right clicking on the Motion

Group, you will need to choose the correct axis type.

1.

Type a tag name for the Axis and click OK.

50

If you check Open AXIS_SERVO Configuration, the Axis Wizard appears and takes you through axis configuration used in motion planning.

2.

Click Browse to go to the Motion Group.

3.

If you have already created your Motion Group, associate the axis to your group. You can also do this by dragging the axis into the Motion Group in the Controller Organizer.

If you have not created a Motion Group, see Add the Motion Group

.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure Analog Motion Chapter 2

4.

Assign the axis to a Motion Group, select the unassigned axis, click Add, and OK.

5.

In the General tab, under Associated Module, select the module.

6.

Click Next until you access the Servo tab.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 51

Chapter 2 Configure Analog Motion

7.

Assign an External Drive Configuration and click OK.

TIP If you configure a torque drive then your drive must be able to be configured for torque. Hydraulic can only be selected if it’s a hydraulic module.

52 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Add an Hydraulic Module

Configure Analog Motion Chapter 2

Follow these instructions to add an hydraulic module, if desired.

IMPORTANT For all interface module, use the firmware revision that goes with the firmware revision of your controller. See the release notes for your controller’s firmware.

1.

To add a module, right-click the backplane and choose New Module.

2.

Select the module that you want to add and click OK.

3.

Name the module.

4.

Assign a slot for the module.

5.

Type a description, if desired

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 53

Chapter 2 Configure Analog Motion

6.

Choose a Keying option.

WARNING: When using motion modules the electronic keying should be either ‘Exact Match‘ or ‘Compatible Keying‘.

ATTENTION: ‘Disable Keying‘ should never be used with motion module.

7.

Check Open Module Properties, if you want the Properties dialog box to open automatically after you are done creating the new module.

If you do not check the box, you will need to either double-click the module in the Controller Organizer or right-click the module and choose

Properties.

Modify Properties for Hydraulic Drives

With a hydraulic drive, the main item that you need to configure is the feedback type.

Based on the length of the feedback, the Servo Update Period should be configured. This is unique for the 1756-HYD02 module. If the Servo Update

Period is not configured correctly, the axis will not work.

Follow these instructions to modify the properties for an analog drive.

1.

Double-click the 1756-HYD02 module in the Controller Organizer.

The Module Properties dialog box appears.

54 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

2.

Click the Associated Axis tab.

Configure Analog Motion Chapter 2

3.

Click New Axis to create a new axis that will be associated to this module.

Notice that the Data Type has been automatically filled in for you.

4.

Type a tag name for the axis and click OK.

If you check the Open AXIS_SERVO Configuration check box, the Axis

Wizard appears walks you through complete axis configuration used in

Motion Planning.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 55

Chapter 2 Configure Analog Motion

Servo Update Rate

Follow these instructions to set the Course Update Period that configures the

Motion Planner.

1.

Determine what your

should be based on the information presented in that section .

TIP A general guideline for the course rate is 4 axes/ms for a 1756-L6 x controller and 8 axes/ms for a 1756-L7 x controller.

2.

Go to the Associated Axis tab.

3.

Set the Servo Update Period.

Configuring the Feedback Type

1.

Double-click the axis and go to the Feedback tab.

Just changing the Feedback Type is not enough for a hydraulic axis. The rest of the feedback information must be configured.

56 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure Analog Motion Chapter 2

For example, the Calibration Constant is printed on the actual feedback device and may also be available in the documentation that comes with the hardware.

2.

Configure the Feedback type.

3.

Set the Calibration Constant and click Calculate.

This is the minimum servo update period for the configured feedback.

4.

You now have to manually update this value in the Associated Axis tab.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 57

Chapter 2 Configure Analog Motion

Add the Motion Group

Follow these instructions to add a motion group.

IMPORTANT Only one motion group can be created for each project.

1.

Right-click Motion Groups and choose New Motion Group.

2.

Type a name and description and click OK.

If you check Open Motion_Group Configuration, the Motion Group

Wizard appears. If not you can access the Motion Group properties by right-clicking the group and choosing Properties.

58 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Configure Analog Motion Chapter 2

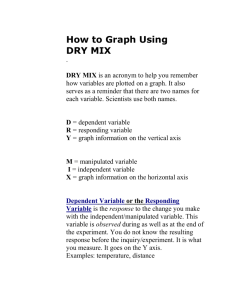

Course Update Period

The Course Update Period is how often the motion planner runs. When the motion planner runs, it interrupts most other tasks regardless of their priority.

The motion planner is the part of the controller that takes care of position and velocity information for the axes.

Motion Planner

Scans of Your Code, System

Overhead, and so on

0 ms 10 ms 20 ms 30 ms 40 ms

In this example, the Coarse Update Period = 10 ms. Every 10 ms the controller stops scanning your code and whatever else it is doing and runs the motion planner.

Follow these instructions to set the Course Update Period that configures the motion planner.

TIP A general guideline for the course rate is 4 axes/ms for a 1756-L6 x controller and 8 axes/ms for a 1756-L7 x controller.

1.

Select the Coarse Update Period and click Finish.

2.

Choose the Coarse Update Period.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 59

Chapter 2 Configure Analog Motion

Add an Axis

The Coarse Update Period is a trade-off between updating positions of your axes and scanning your code. Use these guidelines as a rough starting point.

Guideline

Number of Axes

Description

1756-L6 x controller 4

1756-L7 x controller 8 axes/ms

Leave at least half the controller’s time for the scan of all your code.

Save Controller’s Time

Coarse Update Period and SERCOS modules If you have SERCOS interface motion modules, set the Coarse Update

Period to a multiple of the cycle time of the motion module.

Example: if the cycle time is 2 ms, set the Coarse Update Period to 8 ms,

10 ms, 12ms, and so on.

Coarse Update Period and Analog modules If you have analog motion modules, set the Coarse Update Period to:

• at least 3 times the servo update period of the motion module.

• a multiple of the servo update period of the motion module.

Add an axis for each of your drives.

1.

Right-click Motion Group and choose New Axis.

If you use one of these motion modules then use the data type

AXIS_SERVO for the axis.

• 1756-M02AE

• 1756-HYD02

• 1756-M02AS

2.

Choose AXIS_SERVO.

If you want to use a virtual configuration (no hardware) then use the data type AXIS_VIRTUAL for the axis.

60 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Get Axis Information

Configure Analog Motion Chapter 2

You can get information about an axis in several ways.

• Use the Quick View pane to see the state and faults of an axis.

• Use a Get System Value (GSV) instruction or Set System Value (SSV) instruction to read or change the configuration at run-time.

• Use the tag of the axis for status and faults.

Configure an Axis

Follow these steps to set up the axis of an analog module.

1.

Right-click the axis and choose Properties.

2.

Click the General tab.

3.

Select the drive for the axis.

4.

Select the name that you gave to the drive for this axis.

5.

Set the units that you want to program in.

Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011 61

Chapter 2 Configure Analog Motion

6.

On the Conversion tab, select the Positioning Mode and enter the

Conversion Constant.

Set the Homing Sequence

For complete information about Homing modes, methods and guidelines, see

Follow these instructions to set the homing sequence.

1.

On the Homing tab, select the homing mode.

2.

Enter the Position units.

3.

Select a Sequence type.

Homing speeds appear dimmed depending on what Homing Mode and

Sequence Type you select.

4.

For all Sequence types except for Immediate, you need to select the Active

Home Sequence Group and the speeds.

62 Rockwell Automation Publication MOTION-UM001B-EN-P - November 2011

Chapter

3

Commission and Tune

Introduction

This chapter discusses how to commission an axis for a motion application.

Topic

Download a Project to a Controller

Test Axis Wiring and Direction

Configure the Fault Actions for an Axis

Set the Fault Action for an Axis

Test an Axis with Motion Direct Commands

What If the Software Goes Offline or the Controller Changes Modes?

Can Two Workstations Give Motion Direct Commands?

Page

Download a Project to a

Controller

Follow these steps to download your program to a controller.

1.

With the keyswitch, place the controller in program or remote program mode.

2.

From the Communications menu, choose Download.

3.

Confirm that you wish to complete the download procedure.

4.

Click Download.

5.

Once the download is complete, place the controller in Run/Test mode.

Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011 63

Chapter 3 Commission and Tune

Test Axis Wiring and

Direction

After the project file is downloaded, status and compiler messages appear in the status bar.

TIP When multiple workstations connect to the same controller using RSLogix

5000 software and invoke the Axis Wizard or Axis Properties dialog box, the firmware lets only the first workstation make any changes to axis attributes. The second workstation switches to a Read Only mode, indicated in the title bar, so that you may view the changes from that workstation, but not edit them.

If an axis in a motion group is open for edit, then any other workstation will only get read-only for any axis in that workstation. Even if it is not the axis that the first workstation is modifying.

Use the following procedure to check the wiring of each drive.

Test

Test marker

Test feedback

Test command and feedback

Description

Checks that the drive gets the marker pulse. You must manually move the axis for this test.

Checks the polarity of the feedback. You must manually move the axis for this test.

Checks the polarity of the drive.

ATTENTION: These tests make the axis move even with the controller in remote program mode.

• Before you do the tests, make sure no one is in the way of the axis.

• Do not change the polarity after you do the tests. Otherwise you may cause an axis-runaway condition.

1.

Download a program to the controller.

2.

Place controller in REM.

3.

Double-click the axis to open the Axis Properties.

64 Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011

4.

Click the Hookup tab.

Commission and Tune Chapter 3

Tune a SERCOS Axis

IMPORTANT Make sure to follow all the dialogs or the information derived from the test will not be saved to the axis configuration.

5.

Click Test Marker and follow the additional dialog box instructions.

6.

Click Test Feedback and follow the additional dialog box instructions.

7.

Click Test Command & Feedback and follow the additional dialog box instructions.

Use the Tune tab to tune an axis.

ATTENTION: When you tune an axis, it moves even with the controller in remote program mode. In that mode, your code is not in control of the axis.

ATTENTION: Before you tune an axis, make sure no one is in the way of the axis.

The default tuning procedure tunes the proportional gains. Typically, tune the proportional gains first and see how your equipment runs.

TIP Where tighter positioning is required, Integral gain, and feedforward constants can be selected. However, when used incorrectly can cause axis instability.

.

1.

Download a program to the controller.

2.

Place controller in REM.

3.

Double-click the axis.

Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011 65

Chapter 3 Commission and Tune

4.

Click the Tune tab.

Tune an Analog Axis

66

5.

Set the Travel Limit.

This is the limit of movement for the axis during the tuning procedure.

6.

Set the Speed.

This is the maximum speed for your equipment.

7.

Click Start Tuning.

8.

Accept the changes.

You must accept the changes or the data derived from the tune will not be saved as part of the axis configuration.

Use the Tune tab to tune an axis.

ATTENTION: When you tune an axis, it moves even with the controller in remote program mode. In that mode, your code is not in control of the axis.

ATTENTION: Before you tune an axis, make sure no one is in the way of the axis.

The default tuning procedure tunes the proportional gains. Typically, tune the proportional gains first and see how your equipment runs.

1.

Download a program to the controller.

2.

Place controller in REM.

3.

Select the axis.

4.

Right-click the axis and choose Properties.

Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011

5.

Click the Tune tab.

Commission and Tune Chapter 3

Troubleshoot Faults

6.

Set the Travel Limit.

Type the limit of movement for the axis during the tuning procedure.

7.

Set the Speed.

Type the maximum speed for your equipment.

8.

Click Start Tuning.

The controller has these types of motion faults.

Type

Instruction error

Fault

Description

Caused by a motion instruction:

• Instruction errors do not impact controller operation.

• Look at the error code in the motion control tag to see why an instruction has an error.

• Fix instruction errors to optimize execution time and make sure that your code is accurate.

Example

A Motion Axis Move (MAM) instruction with a parameter out of range

Caused by a problem with the servo loop:

• You choose whether or not motion faults give the controller major faults.

• Can shutdown the controller if you do not correct the fault condition.

• Loss of feedback

• Actual position exceeding an overtravel limit

Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011 67

Chapter 3 Commission and Tune

Manage Motion Faults

By default, the controller keeps running when there is a motion fault. As an option, you can have motion faults cause a major fault and shut down the controller.

1.

Choose a Non-Major Fault.

If you select Major Fault, then you should develop a Fault handler.

See Logix5000 Controllers Major, Minor, and I/O Faults Programming

Manual, publication 1756-PM014.

2.

Right-click Motion Group and choose Properties.

3.

Go to the Attribute tab.

4.

Select Non Major Fault.

5.

Place your programs into the Fault Handler so that when a fault occurs the program runs.

68 Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011

Commission and Tune Chapter 3

Configure the Fault Actions for an Axis

Use the fault actions to set how an axis responds to different types of faults. The type of faults depends on the type of axis and how you configure it.

If you want to Then choose

Shutdown the axis and let it coast to a stop Shutdown

Disable the axis and let the drive stop the axis using it's best available stopping method

Disable Drive

Leave the servo loop on and stop the axis at its Maximum Deceleration rate

Stop Motion

Write your own application code to handle the fault

Status Only

Description

Shutdown is the most severe action. Use it for faults that could endanger the machine or the operator if you do not remove power quickly and completely.

For this axis type

AXIS_SERVO

When the fault happens

• Axis servo action is disabled.

• The servo amplifier output is zeroed.

• The appropriate drive enable output is deactivated.

• The OK contact of the servo module opens. Use this to open the E-Stop string to the drive power supply.

• This impacts both axes associated with the analog motion, not just the axis with the fault.

AXIS_SERVO_DRIVE • Axis servo action and drive power structure are immediately disabled.

• The axis coasts to a stop unless you use some form of external braking.

When the fault happens For this axis type

AXIS_SERVO

AXIS_SERVO_DRIVE

• Planner decelerates axis motion to zero speed based on Maximum configured declaration using Trap Acc/Dec.

• Axis servo action is off.

• The servo amplifier output is zeroed.

• The appropriate drive enable output is deactivated.

• Planner decelerates axis motion to zero speed based on Maximum configured declaration using Trap Acc/Dec.

• If the axis does not stop in the Stopping Time, the servo action and the power structure are disabled.

Use this fault action for less severe faults. It is the gentlest way to stop. Once the axis stops, you must clear the fault before you can move the axis.

For this axis type

AXIS_SERVO

When the fault happens

The axis slows to a stop at the Maximum Deceleration Rate without disabling servo action or the servo module’s Drive Enable output.

AXIS_SERVO_DRIVE • Control of the drive’s servo loop is maintained.

• The axis slows to a stop at the Maximum Deceleration rate without disabling the drive.

Use this fault action only when the standard fault actions are not appropriate. With this fault action, you must write code to handle the motion faults. For Stop Motion or Status Only, the drive must stay enabled for the controller to continue to control the axis. Selecting Status Only only lets motion continue if the drive itself is still enabled and tracking the command reference.

Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011 69

Chapter 3 Commission and Tune

Set the Fault Action for an

Axis

Use the following steps to set the fault actions for an axis.

1.

Right-click on an axis choose Properties.

2.

Go to the Fault Actions tab.

3.

Set the desired attributes and click OK.

An analog axis will have fewer faults listed than a SERCOS axis.

70 Rockwell Automation Publication MOTION-UM001B-UM-P - November 2011

Inhibit an Axis

Commission and Tune Chapter 3

Follow these instructions to block the controller from using an axis.

When to Inhibit an Axis

IMPORTANT Inhibiting an axis will take down ALL axis on the motion module or ring.