SIMATIC System Assessment/Audit

advertisement

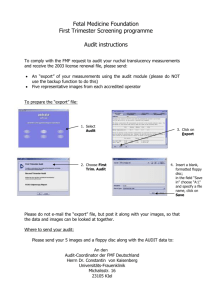

Industry Services SIMATIC System Assessment/Audit Technology-based services for a greater competitive edge Minimum downtime and the optimum use of staff and resources are key to ­sustainable success in industry. Siemens provides the basis for greater produc­ tivity, flexibility, and efficiency with ­technology-based services throughout the lifecycle of an industrial plant – ­reliably, globally, and around the clock. In-depth technology and product knowl­ edge as well as industry expertise within Siemens’ global network of experts ensure a considerable competitive edge. The challenge: optimum productivity through detailed knowledge of the plant’s condition The key requirements for a plant’s auto­ mation system are maximum productivity and cost-effectiveness for the plant over its entire lifecycle. As plants become increasingly complex and cost pressures rise, the SIMATIC automation systems’ availability and serviceability are becom­ ing more and more important for plant productivity. The smooth coordination between ­products, systems, and services requires detailed knowledge of the plant’s status. After all, this is the only way to ensure a practical design and implementation of system updates or lifecycle services. Answers for industry. SIMATIC System Assessment/Audit Assessment System Assessment Report Audit Status Audit LCS System Audit Status Report Lifecycle Services Conformance Report Extended System Check Basic System Check The solution: SIMATIC System Assessment/Audit As they age, many production plants must be adapted to new conditions, expanded, or upgraded for various rea­ sons. Such intervention into the original plant and automation concept affects all system components and can interrupt the production workflow through undefined system statuses. The causes of these ­disturbances include, for example, differ­ ent procedures used by external service providers or the lack of systematic main­ tenance on the automation system. A SIMATIC System Assessment/Audit brings complete transparency to the ­current status and serviceability of the SIMATIC automation system. Even if there are no problems, a system assess­ ment is recommended as it serves as the basis for future service strategies or lifecycle service agreements. The modular SIMATIC System Assess­ ment/Audit portfolio contains different versions, thereby enabling the operator to determine the system status when needed. A Basic System Check forms the founda­ tion for all performance modules. The “Assessment” module checks represen­ tative system components and, based on this, prepares a report with general recommendations for the system’s ­serviceability. Extended System Checks are used as a basis for reports in the “Audit Status” and “Audit LCS” modules. These checks result in a detailed system status report or pave the way for a system upgrade. Assessment This module delivers an analysis of the current system ­status. The goal is to discover vulnerabilities in the auto­ mation system’s serviceability and identify possible risks. The assessment results report provides an overview of the current system status and includes a report with general recommendations on ways to secure or restore serviceability, thereby also increasing system availability. The automation system is checked on the basis of ­representative system components, such as OS clients and OS servers. The selection is made in agreement with the customer. Audit Status A detailed system analysis for assessing the plant’s status forms the basis for: ◾◾ Making decisions on system expansions ◾◾ Developing service strategies ◾◾ Preparing hardware/software upgrades ◾◾ Minimizing the upgrade risk by analyzing and assessing the system configuration as well as up-to-date diagnostic data This module focuses on assessing the ◾◾ Serviceability ◾◾ Upgradeability/updateability ◾◾ System availability Audit LCS The results of the LCS audit are documented in a lifecycle conformance report, which, in particular, enables state­ ments to be made regarding the serviceability and upgradeability/updateability of the audited system. Modules of a long-term lifecycle service agreement: ◾◾ Service agreement management ◾◾ Industry Online Support and Technical Support (AVC) ◾◾ Inspection/maintenance [onsite/remote] ◾◾ Repairs [onsite/remote] ◾◾ On-call service ◾◾ Recovery time ◾◾ Information service ◾◾ Software updates ◾◾ Hardware and software upgrade ◾◾ Remote access to the PCS 7 control system (optional) SIMATIC System Assessment/Audit Assessment System Assessment Report Audit Status Audit LCS System Audit Status Report Lifecycle Services Conformance Report Extended System Check Basic System Check The goal is to prepare a short-term service agreement with a term of at least one year and the option of annual extensions SIMATIC System Assessment/Audit Assessment System Assessment Report Audit Status Audit LCS System Audit Status Report Lifecycle Services Conformance Report Extended System Check Basic System Check The goal is to analyze the plant, with complete ­identification of potential risks, and to determine the detailed system status SIMATIC System Assessment/Audit Assessment System Assessment Report Audit Status Audit LCS System Audit Status Report Lifecycle Services Conformance Report Extended System Check Basic System Check The goal is to prepare a long-term lifecycle service agreement with a term of 10 to 15 years Data collection Component list as well as project and diagnostic data The workflow: Ordinarily, the customer supplies the inventory data/component list and the project and diagnostic data. As an option, through a separate agreement, the data can also be collected by Siemens. As the next step, system specialists from Siemens review the project and diagnostic data (offsite), using reference ­documents and checklists. The functional obsolescence of the inventory data is also assessed. A system assessment report can be ­prepared after this review. Additional onsite analyses are required for both audit modules. Analysis and checks Diagnostic data, configuration (onsite/offsite) The Extended System Checks in the audit module result in a comprehensive system status report or lifecycle service confor­ mance report. Reporting and assessment Benefits: expert consulting for greater productivity In addition to the comprehensive over­ view of the status of their automation system, SIMATIC System Assessment/ Audit offers plant operators a wide range of benefits: ◾◾ Expert vulnerability and risk analysis with recommendations ◾◾ Avoidance or minimization of system risks related to serviceability and upgradeability ◾◾ Reduction of standstill and downtimes by ensuring serviceability ◾◾ Lifecycle information from the ­manufacturer about the status of the products used: –– Product lifecycle milestones –– Spare parts availability –– Successor components ◾◾ Proven basis for lifecycle service ­agreement For further information and support, please contact your local Siemens partner: www.siemens.com/services/partner Evaluation, summary, recommendations The information in this data sheet contains ­general descriptions of the technical options and features available and may not always apply in individual cases or may be changed as a result of continuing product development. Performance features are binding only if expressly agreed upon by contract. Siemens AG Industry Sector Customer Services Division Industry Automation Gleiwitzer Str. 555 90475 Nürnberg Germany All product designations may be trademarks or product names of Siemens AG or supplier ­companies whose use by third parties for their own purposes could violate the rights of the ­owners. Order No. E10001-T480-A279-X-7600 | Dispo No. 21638 | K-No. 20350 | Printed in Germany | TH 241-130505 | DB | 08131.0 © Siemens AG 2013 siemens.com/industry/lifecycle-services