High Quality Balance

advertisement

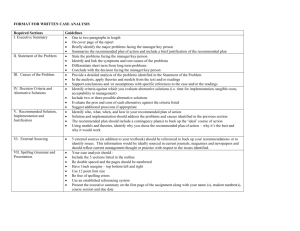

KomDrive facing heads with maximum speeds High Quality Balance HQB is the synonym for a technology developed by the KOMET GROUP for adjusting imbalance in flat action slides. This technology has already been used to achieve speeds which, in high-precision and high-speed applications, effectively doubles the possible fields of application. Facing slide tools are mainly used in special purpose machines, such as automatic rotary indexing machines and transfer lines for series production, and in combination with KOMET KomTronic® U-axes even in machining centres. Thanks to the High Quality Balance Technology from the KOMET GROUP used in KomDrive facing heads, speeds have already been achieved which, in highprecision and high-speed applications, effectively doubles the possible fields of application. Facing slides are tools that make flexible contour machining possible through radial cutting edge adjustment. Their field of application is mainly special purpose machines, such as automatic rotary indexing machines and transfer lines for series production, as well as in combination with KOMET KomTronic® U-axes even in machining centres. Adjusting the cutting edges however, involves adjusting the weights in the tool head, which in general causes imbalances. Round slides with eccentric adjustment, as usually found on the market, have good balance properties because of their kinematics. Disadvantage: All process strength must be absorbed by the drive chain. In addition, a change in the cutting edge positions changes the cutting parameters, such as clearance and rake angle, and as a consequence the stroke must be restricted. If you wish to use the NC technology to influence the chip control characteristics, then it is extremely difficult to calculate the position of the cutting edge. Up until now, in conventional flat action facing heads, balance compensation has only functioned statically via single-plane balance compensation, which is accomplished through a working slide and one or more adjusting slides rotating in opposite directions. This solution however causes wobble and moreover the required drive power is doubled by the counterrotating slides. With a long tradition At KOMET® there is a long tradition in the development and manufacture of these types of tools, which is reflected in the KomDrive family of products with its comprehensive standard catalogue range. A common feature is that all sliders are driven via large profile, diagonally cut gearing with a maximum overlay factor. Facing head lift can be controlled by positive stops. Sliding parts are made of nitriding steels nitrided over a long period to achieve good geometric precision with increased surface hardness and good sliding properties. The higher technical standard is based on many years of experience, careful development, design and precise production. The individual components are ground to fit each other and a special treatment of the moving parts produces favourable friction pairings. With a maximum backlash of 5 to 15 (10) µm - depending on the product range - the foundation has been laid for machining complex contours with the highest precision. Another feature of the KomDrive facing slides is the compact design of the slides and their integral design, providing high cutting efficiency without loss of precision and service life. Dynamic balance compensation With the new HQB technology, the balancing weights have been placed in front of the slide in one plane close to the centre of gravity for tool and slide. Thus, by using balancing weights in one plane, it is possible to achieve a close to multi-plane balance, which, due to the The radial cutting edge adjustment of the KOMET KomTronic® -U-axes makes flexible contour machining possible. design, can be realised irrespective of the stroke. In addition, the centrifugal forces are converted into reaction forces at coupling points so that the centrifugal forces of the compensator and the slide tool system in the drive chain do not simply add up. The result is a drive torque which is largely separated from the centrifugal force formula. Another not inconsiderable factor for the smooth running of these facing heads is their reduced overall length; approximately 30 to 40 %, depending on the overall size, which in turn means reduced weight. In practice, when used in KOMET® flataction facing heads, HQB technology means a considerable reduction in wobble; that is the rotational bending moment. Depending on the snapon tool, this can be as much as 50 to 90%, whereby even 100% and thus absolutely perfectly balanced systems were able to be realised. The clearest improvement was apparent in the significantly improved machining parameters for the ‚dynamic‘ balance compensation, i.e. the rotational speeds achievable. Currently, conventional values are being doubled. Machineside conditions, above all the available drive power, actually only have a limited effect. “To drive the rotational speeds even higher in future, the design of individual components in the tool heads, as regards their tensile strengths, such as the bearing strengths in the required size, must be developed and engineered further“, adds Dr.-Ing. Jürgen Fronius, responsible for the mechatronic business unit at KOMET®. KomDrive facing heads with HQB technology are being successfully used in high-speed and high-precision applications such as in machining journals or in boring con rods. They are at least as good as facing slide tools with eccentric adjustment, and may even be superior. With the new HQB technology, the balancing weights have been placed in front of the slide on a plane close to the centre of gravity for tool and slide. With its brands KOMET®, DIHART® and JEL®, the KOMET GROUP is a leading global manufacturer of precision tools for bore machining, reaming and threading. The group has been at the forefront of innovation in the sector for over 90 years - a tradition that began with the early indexable insert borers and continues today with their mechatronic tool systems. The company currently employs more than 1,600 staff in its 20 subsidiaries and is represented in around 50 countries.