career guide - Nicholls State University

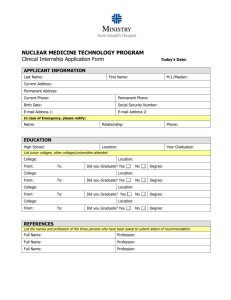

advertisement