TECHNICAL INSTRUCTIONS

advertisement

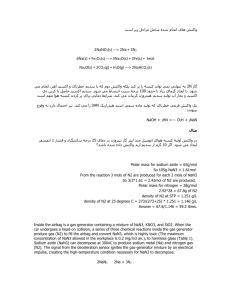

INSTRUCCIONES TECNICAS REEMPLAZO DEL INFLADOR EN COROLLA/AVENSIS Paso 1 1. DIAGRAMA DE LA OPERACION ·············································································· 3 2. IDENTIFICAR LOS VEHICULOS AFECTADOS ··························································· 4 3. PREPARACION ····································································································· 7 4. PROCEDIMIENTOS GENERALES DEL TRABAJO ······················································ 8 5. PRECAUCIONES DE AIRBAG REMOCION / INSTALACION ········································· 9 6. PRECAUCIONES PARA EL TRABAJO AL INTERIOR DE VEHÍCULOS ANTIGUOS ········· 11 7. PRECAUCIONES PARA REALIZAR EL TRABAJO ······················································ 12 8. COMPONENTES ···································································································· 14 Paso 2 9. VERIFICAR EL CÓDIGO DE BARRAS (Excepto Fabricados en TDB) ························· 16 10. VERIFICAR EL CÓDIGO DE BARRAS (Para los Fabricados en TDB) ······················· 17 VERIFICAR EL CÓDIGO DE BARRAS (AVENSIS) ··················································· 17 Paso 3 11. REMOVER PANEL DE INSTRUM/CONJUNTO AIRBAG PASAJERO (COROLLA) ······· 18 REMOVER PANEL DE INSTRUM/CONJUNTO AIRBAG PASAJERO (AVENSIS) ·········· 24 Paso 4 12. REEMPLAZO DEL INFLADOR (COROLLA) ··························································· 29 REEMPLAZO DEL INFLADOR (AVENSIS) ······························································ 37 Paso 5 13. REINSTALAR EL PANEL DE INSTRUMENTOS/CONJUNTO AIRBAG PASAJERO ······· 53 1 <<SAFETY PRECAUTIONS>> A. Be sure to observe the following precautions to prevent accidents and injuries. Park the vehicle and chock the wheels. If it is necessary to start the engine, perform the operation in a well ventilated area. Before removing and reinstalling heavy parts such as the engine, transmission an d differential using lifting equipment, check that there are no problems with the equipment. When working in a group of 2 or more, each person must work to ensure the safety of all team members. To prevent burns and other injuries, use extra caution when handling parts that are subject to high temperatures, as well as rotating, sliding, or vibrating parts. When lifting the vehicle using a jack, support it in the specified location using a rigid rack. When lifting the vehicle using a lift, lock the lift for safety. B. Also perform the following operation with care. Use of auto lift Make absolutely certain that there are no other workers and no tools, parts, or other objects within the movable range of the lift. Also, be sure to announce all lift operations out loud (such as “Raising the lift!” and “Lowering the lift!”) to alert other workers. When raising or lowering the lift to adjust the vehicle position, etc., pay attention to the positions of your arms, legs, and other body parts, and be extremely careful t o prevent them from being caught in the lift. Use of brake cleaner Use brake cleaner for appropriate purposes in accordance with instructions in the manual. Do not use brake cleaner to remove dirt or stains from work clothes, etc. It can catch on fire and cause serious burns. <Precautions> Do not use brake cleaner near flame or fire. Do not use large amounts of brake cleaner in a room where a fire is burning. Do not keep brake cleaner in a place subject to high temperatures exceeding 40° C , such as a place subject to direct sunlight or near fire. Do not put brake cleaner in fire. Edges When handling the edges of parts and panels, wear protective gloves or apply protective tape to the edges to prevent injuries to your hands and fingers. 2 1. DIAGRAMA DE LA OPERACION Compruebe si el vehículo esta dentro de No los número de VIN afectados. Si Verifique que el código de barras. No está involucrado a los trabajos de sustitución *Consulte el archivo 2. Está involucrado a los trabajo de sustitución Reemplace el inflador. *Consulte el archivo 3, 4, 5. Compruebe la luz de advertencia del airbag. * Consulte el archivo 5. Fin de los trabajos. ※ AVISO: El inflador es material peligroso (Hazmat). Le informaremos cómo desechar inflador original después de sustituirlo por uno nuevo. Por favor, mantenerlos en lugar seguro hasta que informamos el método de eliminación. 3 2. IDENTIFICAR LOS VEHICULOS AFECTADOS NUMERO DE IDENTIFICACION DE LOS VEHICULOS AFECTADOS VIN Range Model VIN Range WMI VDS Range 1NX BR#### Z000001 - ZPP4315 2T1 BR#### C000082 - C836386 9BR 53#### 8500004 - 8531416 BJ#### 2000003 - 4000825 BM#### 0001009 - 0049218 BR#### 0002007 - 3074259 BT#### 0015629 - 3203256 BW#### 0006951 - 3039985 BZ#### 0001801 - 3035691 EM#### 0001001 - 0009443 ER#### 0013935 - 0151722 EW#### 0008142 - 0060691 EX#### 3000005 - 3005199 EZ#### 0002150 - 0016837 KM#### 0009695 - 0025709 KR#### 0034118 - 2018046 KX#### 3005201 - 3013745 KZ#### 0017809 - 0035299 AHT 53#### 6500000 - 7513229 AHT 54#### 6500023 - 7513681 Model WMI VDS Range BM#### R000001 - R039410 BX#### R000001 - R005184 BZ#### R000001 - R027719 EM#### R001874 - R017653 EX#### R000304 - R005182 EZ#### R001512 - R027723 JM#### E001001 - E081129 JW#### E000540 - E028584 JX#### E000544 - E028611 JY#### E000533 - E007892 JZ#### E000533 - E077544 KM#### E000534 - E066931 KW#### E001004 - E028613 KX#### E001005 - E043887 KY#### E001007 - E007893 KZ#### E001001 - E062296 MHF 53#### 8000000 - 8008245 MR0 53#### 7000000 - 7058826 NMT COROLLA COROLLA JTD Model SB1 Frame type Frame No. 6000002 - 6002929 ZZE121 8000005 - 8009088 9501218 - 9501218 COROLLA ZZE122 6000000 - 7014562 5000010 - 9001709 4 NOTE: # indicates that various characters may occupy that position. As for the total number of affected vehicles shipped to your country, please refer to the attached VIN-list. 1. CHECK THE VEHICLE IDENTIFICATION NUMBER (a) Confirm that the VIN is within the range shown in the table above. HINT: The Vehicle Identification Number (VIN) is stamped on location A and B shown in the illustration. 5 AFFECTED VEHICLE IDENTIFICATION NUMBER Model AVENSIS WMI SB1 VIN Range VDS Range BH#### E000520 - E006844 BJ#### E000504 - E006854 BR#### E000501 - E081944 BW#### E000502 - E038315 BZ#### E000516 - E003486 DJ#### E000522 - E006853 DR#### E000505 - E069217 DW#### E000542 - E081611 DZ#### E000531 - E003466 EH#### E000521 - E000602 EJ#### E000538 - E006860 ER#### E000533 - E049464 EW#### E000503 - E075436 EZ#### E000604 - E003474 NOTE: # indicates that various characters may occupy that position. As for the total number of affected vehicles shipped to your country, please refer to the attached VIN -list. 2. CHECK THE VEHICLE IDENTIFICATION NUMBER (b) Confirm that the VIN is within the range shown in the table above. HINT: The Vehicle Identification Number (VIN) is stamped on location A and B shown in the illustration. 6 3. PREPARACION PARTES COROLLA Part Number 04000-44212 PARTES AVENSIS Part Number 04003-11105 - Part Description Kit del inflador del Air Bag Inflador Tuerca con autobloqueo Placa para determinar la posición Quantity 1 1 4 1 Others For LHD Single B Part Description Instrument Panel Airbag Inflator Kit Inflador Tuerca con autobloqueo Placa para determinar la posición Electro Tap Quantity 1 1 4 1 1 Others For LHD Dual E - Quantity 1 Others - Quantity - Others - Quantity - Others - - - SST Part Number 09950-50013 Name Set extractor C TOOLS&EQUIPMENT Part Number - Name Standard Hand Tools Torque Wrench Global TechStream (ITT3) Torx® Socket Wrench (T30) Moulding Remover Scan Tool SUPPLIES Name Protective Eyewear Work Gloves Protective Tape Marking Pen 7 4. PROCEDIMIENTOS GENERALES DEL TRABAJO 1. Remove the instrument panel sub-assy upper from the vehicle. 2. Replace the inflator inside the passenger airbag and install to the vehicle. 8 5. PRECAUCIONES DE AIRBAG REMOCION / INSTALACION If an airbag system is not handled with proper procedures and methods, it may be activated accidentally during work resulting in a life-threatening serious accident. Also if operation is wrong, the system may fail to be activated when needed. Be sure to perform proper work firmly and safely according to this instruction manual. 1. DISCONNECT THE BATTERY NEGATIVE TERMINAL (a) Always be sure to disconnect the negative terminal before performing work in order to prevent improper operation of an airbag. (b) Wait 90 seconds or more after disconnecting the negative terminal before performing any work due to the backup power supply equipped to the airbag system. 2. ELIMINATE STATIC ELECTRICITY (a) Before start of work, touch a metallic portion of the vehicle with a bare hand to discharge static electricity charged on your body. 3. DO NOT MEASURE RESISTANCE USING A CIRCUIT TESTER (a) Do not measure resistance of airbag components. Measuring current of a circuit tester may cause accidental activation. 9 4. HANDLE AN AIRBAG PROPERLY (a) Keep the deploying side facing upward except for when the inflator is replaced. Do not put anything on the airbag. CAUTION: Be sure to place parts properly. Otherwise a life-threatening serious accident may occur in case of accidental activation. (b) If an inflator is dropped accidentally, replace it with a NEW one. 10 6. PRECAUCIONES PARA EL TRABAJO AL INTERIOR DE VEHÍCULOS ANTIGUOS 1. PREVENT DAMAGE OF INTERIOR PARTS (a) Interior parts are brittle due to aging. Handle parts carefully. (b) Before attaching protective tape, check for aging of the part. 2. DISENGAGE CLIPS GENTLY (a) If pulled forcibly and locally, parts may be damaged or clips may drop off. (b) When it is possible to access the backside of a clip and push it from the behind, perform work from both frontside and backside to reduce the burden on the part as far as possible. 3. PLACE THE REMOVED PART PROPERLY (a) Keep the removed parts orderly to prevent damage. (b) For work on a removed part, lay a soft cloth under the part as needed in order to prevent damage of the design surface. 11 7. PRECAUCIONES PARA REALIZAR EL TRABAJO 1. PAY ATTENTION TO LIFTING UP OR JACKING UP A VEHICLE (a) Perform safe and secure work according to instructions in general description of a repair manual. (b) When operate a lifting or jacking device, make sure that all workers around the device including your self are safe and call to each other in order to prevent a trample accident. 2. WEAR PROTECTIVE EYEWEAR (a) Always wear protective eyewear in situations where gas or contaminations may fly such as fuel leakage prevention, carbon removal from a piston head, work on underbody parts etc. 3. DO NOT CLEAN CLOTHES WITH BRAKE CLEANER (a) Never spray brake cleaner on your clothes since it is easy to evaporate and flammable. A cigarette or a stove may cause a serious burn accident. 4. TAKE CARE NOT TO BURN YOURSELF (a) When the engine is hot, wear gloves etc. to protect yourself against burn injury. 12 5. PROTECT THE VEHICLE (a) In order not to contaminate or damage the vehicle, be sure to install the fender cover, the grill cover and the seat cover, and attach the masking tape etc. HINT: Some illustrations in the relevant instructions manual may not show the above-mentioned protective parts to make the target part easy and simple to recognize. 6. PAY ATTENTION TO HANDLING REPLACEMENT PARTS (a) The removed parts shall be marked or broken and stored in a replacement parts box etc. to avoid reassembling in error. (b) Check the replacement parts in final inspection. HINT: Illustrations are for work description only and not related to actual replacement parts. 7. DO NOT BREAK PARTS DURING WORK INSIDE ENGINE ROOM (a) Do not be absorbed in work and place your hand carelessly in the engine room resulting in breakage of parts. 8. CHECK THE ENGINE ROOM BEFORE STARTING THE ENGINE (a) Check if you have forgotten to attach any parts. (b) Check if you have forgotten to remove any tools, shop cloths, etc. 13 8. COMPONENTES COROLLA 14 COMPONENTES AVENSIS 15 9. VERIFICAR EL CÓDIGO DE BARRAS (Excepto Fabricados en TDB) 1. Escanear el código de barras en la etiqueta pegada en la carcasa del airbag. AVISO: La ubicación de la etiqueta varía dependiendo de las especificaciones. Hay dos etiquetas idénticas pegadas en las caras inferiores y laterales. Puede escanear una de las dos etiquetas. SUGERENCIA: Cuando el código de barras es escaneado con éxito, se produce sonido de confirmación . 2. Mira el resultado en la pantalla para determinar si procede o no es necesario la sustitución del inflador. RESULT (SCREEN) ACTION La sustitución del inflador es necesario.. Ir a REMOVER EL PANEL DE INSTRUMENTOS/CONJUNTO AIRBAG PASAJERO La sustitución del inflador no es necesario. Restaurar el vehículo y terminar el trabajo. 16 10. VERIFICAR EL CÓDIGO DE BARRAS (Para los Fabricados en TDB) 1. Escanear el código de barras en la etiqueta pegada en la carcasa del airbag. SUGERENCIA: Cuando el código de barras es escaneado con éxito, se produce sonido de confirmación. VERIFICAR EL CÓDIGO DE BARRAS (AVENSIS) 17 11. REMOVER EL PANEL DE INSTRUMENTOS/CONJUNTO AIRBAG PASAJERO EN COROLLA 1. DISCONNECT BATTERY NEGATIVE TERMINAL (a) Always be sure to disconnect the negative terminal before performing work in order to prevent improper operation of an airbag. (b) Wait 90 seconds or more after disconnecting the negative terminal before performing any work due to the backup power supply equipped to the airbag system. 2. PLACE FRONT WHEELS FACING STRAIGHT AHEAD 3. REMOVE HORN BUTTON ASSY NOTICE: If the airbag connector is disconnected with the ignition switch at ON or ACC, DTCs will be recorded. (a) Place the front wheels facing straight ahead. (b) Using a torx socket wrench (T30), loosen the 2 torxscrews until the groove along the screw circumference catches on the screw case. (c) Pull out the wheel pad from the horn button assy. (d) Disconnect the airbag connector and remove the horn button assy. 18 4. REMOVE STEERING WHEEL ASSY (a) Remove the steering wheel set nut. (b) Place matchmarks on the steering wheel and main shaft assembly. (c) Using SST, remove the steering wheel. SST 09950−50013 (09951−05010, 09952−05010, 09953−05020, 09954−05021) 5. REMOVE METER HOOD SUB−ASSY (a) Remove the clip. (b) Using a screwdriver, disengage the 3 clips and 4 claws, then remove the meter hood. HINT: Tape the screwdriver tip before use. 6. REMOVE COMBINATION METER ASSY (a) Remove the screw. (b) Disengage the 2 clips as shown in the illustration. (c) Disconnect the connector, then remove the combination meter. 19 7. REMOVE INSTRUMENT PANEL REGISTER ASSY NO.3 (a) Using a moulding remover, remove the instrument panel register No.3. HINT: Tape the moulding remover tip before use. 8. REMOVE INSTRUMENT PANEL REGISTER ASSY NO.1 9. REMOVE FRONT ASH RECEPTACLE BOX SUB−ASSY 10. REMOVE CONSOLE PANEL UPPER (a) M/T: (1) Remove the shift level knob. (b) Using a screwdriver, disengage the 6 claws. HINT: Tape the screwdriver tip before use. (c) Disconnect the connector, then remove the console upper panel. 11. REMOVE INSTRUMENT CLUSTER FINISH PANEL (a) Manual A/C: (1) Center the control lever. (2) Apply protective tape to the instrument cluster finish panel as shown in the illustration. 20 (3) Remove the control knob. (4) Remove the screw. (5) Using a screwdriver, disengage the 4 clips and 5 claws, then remove the instrument cluster finish panel. HINT: Tape the screwdriver tip before use. NOTICE: Do not pull the lid of auxiliarybox. (b) Auto A/C: (1) Using a screwdriver, disengage the 4 clips and 4 claws, then remove the instrument cluster finish panel. HINT: Tape the screwdriver tip before use. NOTICE: Do not pull the lid of auxiliarybox. (2) Disconnect the connectors. 12. REMOVE INSTRUMENT CLUSTER FINISH PANEL SUB−ASSY LOWER CENTER (a) Remove the 4 screws. 21 (b) Using a screwdriver, disengage the 8 clips, then remove the instrument cluster finish panel and radio turner opening cover. HINT: Tape the screwdriver tip before use. (c) Remove the instrument cluster finish panel from the radio turner opening cover. 13. REMOVE GLOVE COMPARTMENT DOOR ASSY (a) Remove the screw and glove compartment door stopper from the glove compartment door. (b) Deform the upper part of the glove compartment door to release the stoppers. (c) Pull the glove compartment door upward to remove it. 14. REMOVE FRONT PILLAR GARNISH RH (a) Disengage the 2 clips. (b) Pull the front pillar garnish RH upward to remove it. 15. REMOVE FRONT PILLAR GARNISH LH 16. SEPARATE PASSENGER AIRBAG CONNECTOR (a) Remove the connector cover from the lower instrument panel. NOTICE: When handling the airbag connector, take care not to damage the airbag wire harness. (b) Disconnect the front passenger airbag connector. 22 17. REMOVE INSTRUMENT PANEL SUB−ASSY UPPER (a) Remove the bolt and 2 screws. (b) Using a moulding remover, disengage the 6 clips. (c) Remove the instrument panel upper. 18. REMOVE INSTR PNL PASS L/DOOR AIR BAG ASSY (a) Remove the 2 bolts and 2 strings from the right and left brackets of the instrument panel passenger airbag assy. (b) Remove the 3 nuts and instr pnl l/door air bag assy from the instrument panel UPR. 23 11. REMOVER EL PANEL DE INSTRUMENTOS/CONJUNTO AIRBAG PASAJERO EN AVENSIS 1. DISCONNECT THE BATTERY NEGATIVE TERMINAL (a) Always be sure to disconnect the negative terminal before performing work in order to prevent improper operation of an airbag. (b) Wait 90 seconds or more after disconnecting the negative terminal before performing any work due to the backup power supply equipped to the airbag system. 2. REMOVE GLOVE COMPARTMENT DOOR ASSY (a) Remove the screw. (b) Deform the upper part of the glove compartment door assy to release the stoppers. (c) Pull the glove compartment door assy upward to remove it. 3. DISCONNECT PASSENGER AIRBAG CONNECTOR (a) Remove the passenger airbag connector clip. (b) Disconnect the passenger airbag connector. 24 4. REMOVE INSTRUMENT CLUSTER FINISH PANEL GARNISH NO.1 (a) Disengage the 2 clips and remove the instrument cluster finish panel garnish No.1. 5. REMOVE INSTRUMENT CLUSTER FINISH PANEL GARNISH NO.2 (a) Disengage the 5 clips and claw, and then remove the instrument cluster finish panel garnish No.2. (b) Disconnect the connectors. 6. REMOVE INSTRUMENT PANEL REGISTER ASSY CTR (a) Remove the 2 screws. (b) Disengage the 2 clips and remove the instrument panel register assy CTR, and then disconnect the connectors. 7. REMOVE STEERING COLUMN COVER LWR (a) Remove the 3 screws and steering column cover LWR. 25 8. REMOVE STEERING COLUMN COVER W/ INSTRUMENT CLUSTER FINISH PANEL ASSY (a) Disengage the 2 clips and remove the steering column cover w/ instrument cluster finish panel assy. 9. REMOVE COMBINATION METER ASSY (a) Remove the 2 screws and disengage the 2 clips. (b) Pull out the combination meter assy, and then disconnect the connectors. 10. REMOVE INSTRUMENT PANEL REGISTER ASSY NO.1 (a) Insert a clip remover between the center of the instrument panel register assy No.1 lower and the instrument panel sub–assy upper to disengage the 2 claws shown in the illustration. (b) Disengage the 2 claws and remove the instrument panel register assy No.1. 11. REMOVE INSTRUMENT PANEL REGISTER ASSY NO.2 26 12. REMOVE FRONT PILLAR GARNISH LH (a) Disengage the 2 clips, and remove the front pillar garnish LH. 13. REMOVE FRONT PILLAR GARNISH RH 14. REMOVE INSTRUMENT PANEL SUB–ASSY UPPER W/ INSTR PNL PASS L/DOOR AIRBAG ASSY (a) Remove the 2 screws and bolt. (b) Disengage the 2 clips and 3 claws. (c) Pull the instrument panel sub–assy upper w/ passenger airbag assy upper rearward to remove it. (d) Disconnect the connectors. 27 15. REMOVE INSTRUMENT PANEL PASSENGER AIRBAG ASSY (a) Remove the 2 screws. (b) Release the rear side wall of the airbag door from the hook by slightly deflecting it and roll the instrument panel passenger airbag assy forward. (c) Release the front side wall of the airbag door from the other hook and remove the instrument panel passenger airbag assy. 28 12. REEMPLAZO DEL INFLADOR EN COROLLA NOTICE: DO NOT allow foreign objects to enter into an airbag. Be sure to collect removed nuts. If foreign objects enter, they may fly off and cause a serious accident when the airbag is activated. 1. WEAR PROTECTIVE GEAR (a) Wear protective eyewear and work gloves throughout replacement work of an inflator from the beginning to the end. 2. WORK POSITION (a) For replacement work of an inflator, avoid standing directly in front of the parts. 29 3. LOOSEN THE SELF LOCKING NUTS NOTICE: If the stud bolt is pushed strongly with the 4 nuts removed, the folded bag assembly may drop off. If a bag assembly is dropped accidentally, replace it with a NEW one. (a) Loosen the 4 self locking nuts until each face becomes flush with the edge of the stud bolt. NOTICE: DO NOT use an air driven tool. 4. PUT A MARK ON THE SELF LOCKING NUTS (a) Put a mark on each of the 4 loosened self locking nuts to prevent accidental reuse. NOTICE: Be sure to put a mark in order not to mix old and NEW nuts in the later steps. 30 5. REMOVE THE INFLATOR (a) Push it down until the loosened nuts come into contact with the airbag case and release the stopper. 31 (b) In the same manner as shown on the previous page, remove the inflator while releasing the stopper. (c) Put a mark on the removed inflator and store it in a replacement part box etc. 32 6. INSERT A NEW INFLATOR (a) Release the stopper in the same manner as during removal. (b) Insert a NEW inflator into the airbag case. NOTICE: DO NOT mistake the insertion orientation of the inflator. 7. TIGHTEN THE SELF LOCKING NUTS (a) Confirm that a mark is put on each of the 4 old self locking nuts. (b) Remove the 2 old self locking nuts. (c) Put a mark on the removed self locking nuts and store it in a replacement part box etc. 33 (d) Install the position determining plate (additional part) with its flat aligned with the flat of the inflator. NOTICE: If the flats are not aligned, the position of the inflator may be misaligned, resulting in failure in normal deployment of the airbag. (e) Install temporarily 2 NEW self locking nuts by hand on the stud bolts to which the position determining plate was installed. (f) Remove the 2 remaining old self locking nuts and install temporarily 2 NEW self locking nuts by hand. (g) Put a mark on the removed self locking nuts and store it in a replacement part box etc. 34 (h) Push the inflator towards the position determining plate to eliminate any gap. NOTICE: If any gap exists, the aligned flats may move apart, resulting in failure in normal deployment of the airbag. (i) Tighten 4 NEW nuts evenly in several increments in the order shown in the illustration using a 10 mm socket driver while pushing the inflator. (You will encounter some resistance during tightening because these nuts are self locking nuts.) Torque: 3.9 N*m (40 kgf*cm, 35 in.*lbf) NOTICE: The tightening torque is low (3.9 N∙m). Use of an air ratchet wrench or tightening strongly with a T-handle wrench or a ratchet handle may cause deformation of the stud bolt. 35 8. INTERMEDIATE INSPECTION (a) Check that the inflator and the 4 self locking nuts are replaced and that the one of stopper plates is replaced with the position determining plate. (b) Check that the orientation of the inflator is correct. (The harness should face towards the position determining plate.) (c) Check that positions of the inflator and the position determining plate are correct. (The flats should be aligned and there should be no gap.) 36 12. REEMPLAZO DEL INFLADOR EN AVENSIS NOTICE: Once connected, the connector of an inflator cannot be disconnected. Never remove the seal and connect the connector until the inflator is placed in place. If the connector is connected accidentally, DO NOT disconnect forcibly. Prepare a NEW inflator again. 37 NOTICE: DO NOT allow foreign objects to enter into an airbag. Be sure to collect removed nuts. If foreign objects enter, they may fly off and cause a serious accident when the airbag is activated. 9. WEAR PROTECTIVE GEAR (b) Wear protective eyewear and work gloves throughout replacement work of an inflator from the beginning to the end. 10. WORK POSITION (b) For replacement work of an inflator, avoid standing directly in front of the parts. 38 11. CREATE A SHORT CIRCUIT BEFORE DISCONNECTION OF INFLATOR WIRE HARNESS HINT: The connector of an airbag inflator has a short-circuiting mechanism and eliminates voltage difference when disconnected. (1) In this work, however, it is necessary to cut the harness when removal of the inflator, and the circuit will be opened. Therefore create a new short circuit using an electro tap and cut the harness outside of the new short circuit in order to maintain short-circuiting. (2)(3) 39 (d) Cut open the corrugate tube on the yellow harness approx. 10 cm (4 in.) using nippers. NOTICE: DO NOT damage the internal wires. DO NOT use a knife or the like that tends to cause a mistake. (e) Cut off the portion of the electro tap (included in the kit) shown in the illustration. (f) Short-circuit the 2 wires using the electro tap. (1) Place one wire in the electro tap as shown in the figure. 40 (2) Fold and pinch the half of the electro tap where the wire is placed using pliers to lock firmly. NOTICE: Simultaneous work on the 2 wires tends to cause a mistake. Be sure to set the wire in the electro tap one by one. Lock the electro tap firmly using pliers. If locked by hand, the electro tap may unfasten. (3) Set the other wire in the electro tap and lock in a similar way. 41 12. CUT THE INFLATOR WIRES (a) Cut the 2 wires at the side of the electro tap opposite to the inflator. NOTICE: DO NOT mistake the cutting location. 42 13. PUT A MARK ON THE SELF LOCKING NUTS (b) Put a mark on each of the 4 self locking nuts to prevent accidental reuse. NOTICE: Be sure to put a mark in order not to mix old and NEW nuts in the later steps. 14. REMOVE STOPPER PLATE NOTICE: If the stud bolt is pushed strongly with the 4 nuts removed, the folded bag assembly may drop off. If a bag assembly is dropped accidentally, replace it with a NEW one. (b) Remove the 2 nuts on the yellow wire harness side. NOTICE: DO NOT use an air driven tool. (c) Remove the stopper plate. (1) Plate on the yellow wire harness side (the cut wire side): The stopper plate will be replaced with the position determining plate. 43 (d) Put a mark on the removed stopper plate and store it in a replacement part box etc. (e) Install the 2 old self locking nuts temporarily by hand so that the face of each nut becomes flush with the edge of the stud bolt. (f) Remove the 2 nuts on the red wire harness side. NOTICE: DO NOT use an air driven tool. (g) Remove the stopper plate. (1) Plate on the red wire harness side: The removed stopper plate will be reused. 44 (h) Install the 2 old self locking nuts temporarily by hand so that the face of each nut becomes flush with the edge of the stud bolt. 15. REMOVE THE INFLATOR (a) Push in the loosened nuts until they contact with the airbag case. 45 (b) Remove the inflator with the nuts pushed in. (c) Put a mark on the removed inflator and store it in a replacement part box etc. 16. INSERT A NEW INFLATOR (c) Insert a NEW inflator into the airbag case as shown in the illustration. NOTICE: DO NOT mistake the insertion orientation of the inflator. 17. FOLD THE SEAL NOTICE: DO NOT remove the seal until just before connecting the connector. (a) Fold the seal in order to prevent it from being caught under the position determining plate. 46 18. PLACE THE REUSED STOPPER PLATE (j) Confirm that a mark is put on each of the 4 old self locking nuts. (k) Remove the 2 old self locking nuts on the red wire harness side. (l) Put a mark on the removed self locking nuts and store it in a replacement part box etc. 47 (m) Place a stopper plate on the side where the harness is connected to the inflator (red wire). NOTICE: DO NOT route the harness between the plate and the inflator or the airbag case. (n) Install temporarily 2 new self locking nuts by hand on the stud bolts to which the reused stopper plate was placed. 48 19. TIGHTEN THE SELF LOCKING NUTS (a) Remove the 2 old self locking nuts on the yellow wire harness side. (b) Put a mark on the removed self locking nuts and store it in a replacement part box etc. (c) Install the position determining plate (additional part) with its flat aligned with the flat of the inflator. NOTICE: If the flats are not aligned, the position of the inflator may be misaligned, resulting in failure in normal deployment of the airbag. (d) Install temporarily 2 NEW self locking nuts by hand on the stud bolts to which the position determining plate was installed. 49 (e) Tighten 4 NEW nuts evenly in several increments in the order shown in the illustration using a 10 mm socket driver while pushing the inflator. (You will encounter some resistance during tightening because these nuts are self locking nuts.) Torque: 3.9 N*m (40 kgf*cm, 35 in.*lbf) NOTICE: The tightening torque is low (3.9 N∙m). Use of an air ratchet wrench or tightening strongly with a T-handle wrench or a ratchet handle may cause deformation of the stud bolt. 50 20. CONNECT THE CONNECTOR OF THE INFLATOR (a) Remove the seal of inflator. NOTICE: After removal of the seal, immediately connect the connector. D O NOT touch the terminal. (b) Insert the connector in the direction shown in the illustration. Push in the connector until the claw engages and a clicking sound is heard. (Push firmly because this engagement is tight.) NOTICE: If the direction of the connector is wrong, the terminal of the inflator may be bent. Clicking sound at engagement of the claw is low. Move your ear close to the connector. If the connector is inserted wrongly with its position 180 degrees turned, the claw will be tightly half-engaged though it will not be engaged fully. Be sure to check for correct orientation of the connector. 51 21. INTERMEDIATE INSPECTION (d) Check that the inflator and the 4 self locking nuts are replaced and that the one of stopper plates is replaced with the position determining plate. (e) Check that the orientation of the inflator is correct. (The yellow harness faces toward positioning plate.) (f) Check that the flats of the inflator and the position determining plate are aligned. 52 13. REINSTALAR EL PANEL DE INSTRUMENTOS/CONJUNTO AIRBAG PASAJERO Perform installation in the reverse order of removal. (Refer to COMPONENTS for the tightening torques.) Perform surely centering of the steering wheel and the spiral cable. Check the SRS warning light at the last. 1. CENTER SPIRAL CABLE (a) Check that the ignition switch is OFF. (b) Check that the battery negative terminal is disconnected. NOTICE: Do not start the operation for 90 seconds after removing the terminal. (c) Turn the cable counterclockwise by hand until it becomes harder to turn. HINT: The cable will rotate about 2.5 turns to either left or right of the center. (d) Then rotate the cable clockwise about 2.5 turns to align the marks. 2. INSPECT SRS WARNING LIGHT (a) Turn the ignition switch to ON, and check that the SRS warning light comes on. (b) Check that the SRS warning light goes out after approx. 6 seconds. HINT: When the ignition switch is at ON and the SRS warning light remains on or flashes, the airbag sensor assembly has detected a malfunction code. If, after approx. 6 second have elapsed, the SRS warning light sometimes lights up or the SRS warning light lights up even when the ignition switch is OFF, a short in the SRS warning light circuit can be considered likely. Proceed to ”SRS warning light circuit malfunction” . 53