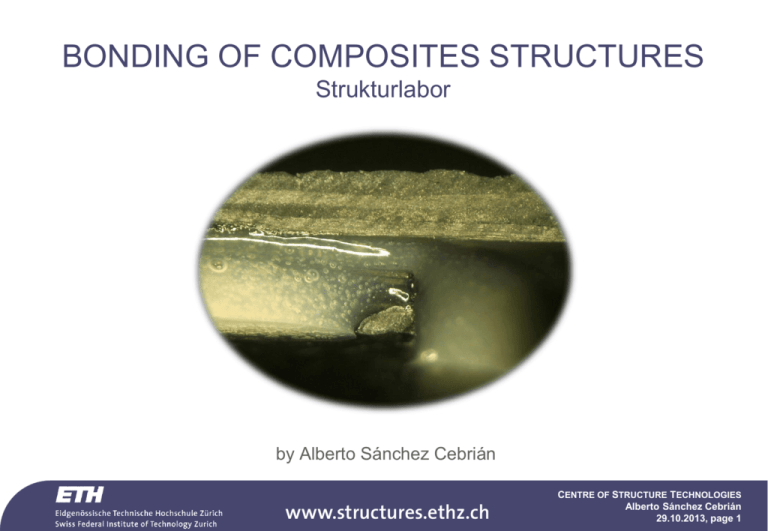

BONDING OF COMPOSITES STRUCTURES

advertisement

BONDING OF COMPOSITES STRUCTURES Strukturlabor by Alberto Sánchez Cebrián www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 1 Outline o State of the art • Types of joints • Riveting vs. adhesive • Types of adhesive o Materials • Adhesive • Composites o Influencing parameters • • • • • • • Design Surface treatment Manufacturing process Thickness of bondline Curing process Quality of the adherent Thickness of adherent o Failure modes o Quality control www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 2 Background Bolted Temporary Screw Riveting Pressure Permanent Welding Adhesive www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 3 Background Temporary Bolted Expensive Screw Expensive Riveting State of Art Pressure No plates Welding No CFRP Adhesive FUTURE? Permanent Riveting is commonly used due to simplicity and robustness www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 4 Background o Adhesive bonding Uniform load distribution Light weight & Cheap Less components Rigid, sealed & isolated unions Difficult to qualify Curing process required Load and temperature limits depend on adhesive, toxic material. Surface treatment needed www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 5 Background o Film adhesives –SoA- o Paste adhesives • Pressure needed • Do not require pressure • Typically all assembly is heated • Wider tolerances • Narrow tolerances • One or two part systems • One part system • More difficult to apply • Low void content • Sensitive to void content www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 6 Materials o Adhesive bonding is a permanent joint type. o Two elements can be observed: o Adherent: Material to be bonded. o Adhesive: Material used to bond adherents. o Stresses in a joint Opening In plane shear Out-of-plane shear www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 7 Materials: Adhesive o Main providers: • Henkel • 3m • Huntsman o Characteristics to observe in a paste adhesive: • Mixing ratio: Ratio of Epoxy and hardener to mix. Only in two paste adhesives. • Pot life: Time after mixing to get certain green strength. • Curing process: Temperature and time to carry out a complete curing process. * For aerospace more that 95% curing is required. • Mechanical performance in different materials and conditions. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 8 Materials: Composites Typical composite processing methods. • RTM: Resin is injected into a preform sealed inside of a mold. + Does not require the curing in an autoclave. - Processing is complex and expensive. • Prepreg: Layers of composite layers are layered up on an opened mold. + Quality and mechanical performance is typically higher - Curing is typically carried out in autoclave. • Wet lamination: Impregnation of the composite is hand made. + Cheap and simple - Quality is typically low. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 9 Materials: Composites Contact between mold and material: • Release film • Peel ply • Release agent www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 10 Influencing parameters o Design: A good design can improve allowable load. o Surface treatment: Cleaning of CFRP is critical. o Thickness of bondline: Best performance between 0.1-0.5 mm. o Manufacturing process of CFRP: The manufacturing process can mean another contamination source. o Curing process: Fast curing can produce degradation. o Quality of the adherent: Bad quality means an earlier delamination. o Thickness of adherent: Thinner adherent means bigger bending moment. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 11 Influencing parameters: Design Adhesive joints of CFRP have a non linear behavior. Despite they can be approached to a traditional model, the prediction is very complex due to the variability of the parameters such as: • Porosity and local disbonds. • Thickness variations. • Benefits from spews at the end of the joint. • Plastic – elastic behavior. • … Hart-Smith, L. J., Analysis and Design of Advanced Composite Bonded Joints, NASA CR-2218, 1974. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 12 Influencing parameters: Surface treatment 30 Shear strength [Mpa] RF: Release film 25 15 C: Cleaning with acetone, water and de-ionized water. Then oven drying for 60 minutes. 10 SXXX: Size of the sand paper 20 GB: grit blasting 5 WJ: Water-jet Pp: Peel ply 0 www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 13 Influencing parameters: Manufacturing process Shear stress [MPa] 30 25 20 15 10 5 0 Release film no cleaned Release film with Release agent no acetone cleaned www.structures.ethz.ch Release agent with acetone Peel ply CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 14 Influencing parameters: Surface treatment In previous research, it was proven that the surface treatment achieving higher shear strength and lower scattering with CFRP composites was: 1. Mechanical treatment: 1.1. Sanding P100 1.2. Sanding P150 2. Cleaning: 2.1: Acetone cleaning 2.2. Water cleaning 2.3. De-ionized water cleaning 2.4. Oven drying www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 15 Influencing parameters: Thickness of bondline o Effect of bondline and adherent thickness on SLS performance 26 Shear strength [MPa] 24 22 20 18 16 14 Adherents thickness 1 mm Adherents thickness 2 mm Co-curing 12 10 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 Bondline thickness [mm] www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 16 Influencing parameters: Curing process o Effect of fast curing in SLS performance Shear strength [MPa] 30 25 20 15 10 5 0 80 100 120 140 160 180 200 Temperature [°C] * A very thick bondline can produce a exothermal reaction. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 17 Influencing parameters: Quality of the adherent o Quality of the adherent can be assessed with the measure of the roughness that can detect fracture of fibers. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 18 Influencing parameters: Thickness of adherent o Adherent thickness influence on SLS performance by MTM 44-1 OoA CFRP prepreg. 26 Shear strength [MPa] 24 22 20 18 16 14 Adherents thickness 1 mm Adherents thickness 2 mm Co-curing 12 10 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 Bondline thickness [mm] www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 19 Failure modes Cohesive Adhesive Adherent Mixed www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 20 Failure modes I. Cohesive: Fracture in the middle of the adhesive surface. • Acetone cleaned samples tested in DCB www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 21 Failure modes II. Adhesive: Fracture between one adherent and adhesive. • Non treated sample tested in DCB. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 22 Failure modes III. Adherent: Fracture is located in one of the adherents. • Grit blasted sample tested for DCB. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 23 Failure modes IV.Mixed: Different modes can be observed. • Peel ply sample tested for DCB. www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 24 Quality control o One of the biggest drawbacks of paste adhesive is quality control. o Control of the adhesive: The assessment of a proper curing process is critical. For structural applications in aerospace 95% curing is required. In this context, Differential scanning calorimetry (DSC) is carried out to ensure that the process is complete. o Control of the joint: • Destructive testing is based in different mechanical testing. - Single lap shear - Wedge and double cantilever beam - Peel test - 3 or 4 point bending • Non destructive testing Some techniques can be used to detect voids, but its use for qualification is not standardized for paste adhesives. – Ultrasounds – X-Rays – … www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 25 Quality control: Control of the adhesive o Modeling the curing kinetics permit to predict the relation between degree of cure, temperature and time. 1.0 5 0.9 0.8 T2 = 211 °C 3 T1 = 28 °C 0.7 Degree of cure [-] Endothermic heat flow [mW] 4 2 1 Overall heat = 260.97 [J/g] 0 0.6 0.5 Experimental 80 °C Model 80 °C Experimental 100 °C Model 100 °C Experimental 120 °C Model 120 °C Experimental 140 °C Model 140 °C 0.4 0.3 -1 0.2 -2 0 50 100 150 200 250 300 Temperature [°C] 0.1 0.0 0 𝑑𝛼 = 𝑘 · (1 − 𝛼)𝑛 𝑑𝑡 with = Degree of cure [-] 5 10 15 20 25 30 Time [min] t = Time [s] k = Reaction rate [-] n = Reaction order [-] www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 26 Quality control: Control of the joint Single lap shear Fracture toughness (DCB) EN 2243-1 www.structures.ethz.ch ISO 15024 CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 27 Quality control: Control of the joint Peel test Bending tests: 3 or 4 point bending EN 2243-2 or ISO 4578 www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 28 Quality control: Control of the joint Void content [%] o Effect of fast curing in porosity levels of the paste adhesive. 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 80 100 120 140 160 180 200 Temperature [°C] www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 29 Quality control: Control of the joint o Effect of fast curing in size of voids of the paste adhesive. Void average diameter [μm] 600 500 400 300 200 100 0 80 100 120 140 160 180 200 Temperature [°C] www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 30 Quality control: Control of the joint o Effect of fast curing in SLS performance Shear strength [MPa] 30 25 20 15 10 5 0 80 100 120 140 160 180 200 Temperature [°C] www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 31 Questions?? www.structures.ethz.ch CENTRE OF STRUCTURE TECHNOLOGIES Alberto Sánchez Cebrián 29.10.2013, page 32