Fast Cycling Upgrades for Combined Cycle

Power Plants – Hot-start on the Fly

for Highest Operational Flexibility

Our solution

For SCC5-4000F single shaft combined

cycle power plants (see Fig. 1) Siemens

developed an innovative upgrade package

designed to significantly reduce the plant’s

hot-start times from currently 65 or more

minutes down to approx 40 minutes.

The significant improvement is based on

a parallel start-up of the gas turbine and

the steam turbine – the so- called hotstart on the fly.

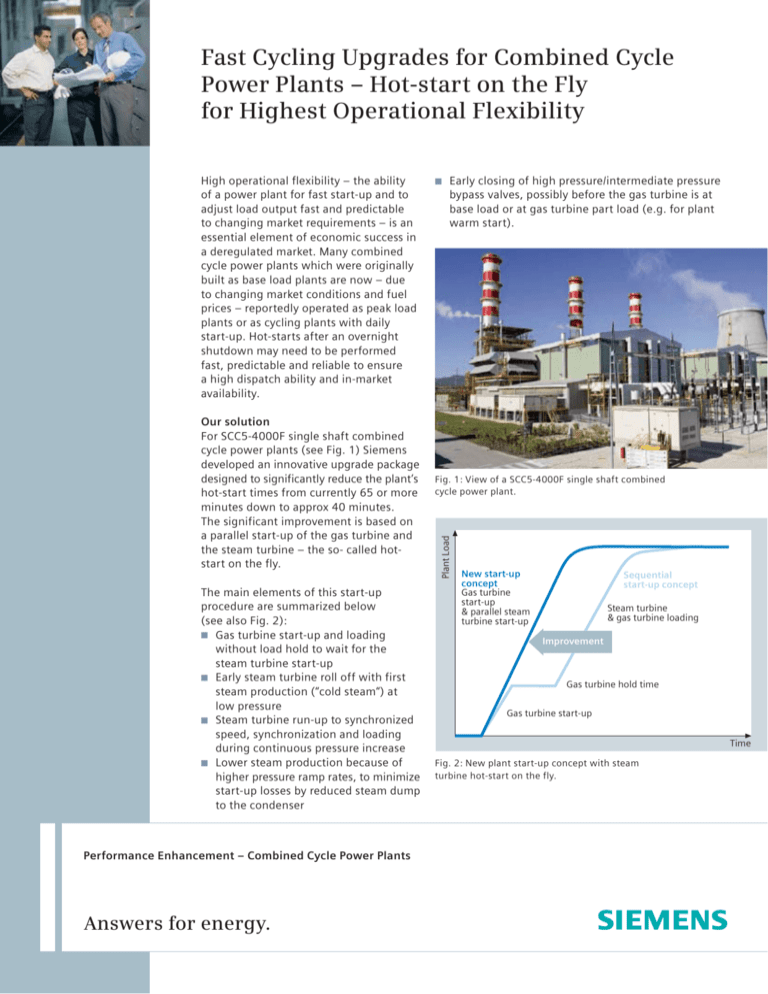

The main elements of this start-up

procedure are summarized below

(see also Fig. 2):

■ Gas turbine start-up and loading

without load hold to wait for the

steam turbine start-up

■ Early steam turbine roll off with first

steam production (“cold steam“) at

low pressure

■ Steam turbine run-up to synchronized

speed, synchronization and loading

during continuous pressure increase

■ Lower steam production because of

higher pressure ramp rates, to minimize

start-up losses by reduced steam dump

to the condenser

Performance Enhancement – Combined Cycle Power Plants

Answers for energy.

■

Early closing of high pressure/intermediate pressure

bypass valves, possibly before the gas turbine is at

base load or at gas turbine part load (e.g. for plant

warm start).

Fig. 1: View of a SCC5-4000F single shaft combined

cycle power plant.

Plant Load

High operational flexibility – the ability

of a power plant for fast start-up and to

adjust load output fast and predictable

to changing market requirements – is an

essential element of economic success in

a deregulated market. Many combined

cycle power plants which were originally

built as base load plants are now – due

to changing market conditions and fuel

prices – reportedly operated as peak load

plants or as cycling plants with daily

start-up. Hot-starts after an overnight

shutdown may need to be performed

fast, predictable and reliable to ensure

a high dispatch ability and in-market

availability.

Gas turbine

start-up

& parallel steam

turbine start-up

Steam turbine

& gas turbine loading

Gas turbine hold time

Gas turbine start-up

Time

Fig. 2: New plant start-up concept with steam

turbine hot-start on the fly.

Our concept includes:

■ Modified high pressure/hot reheat

steam temperature control and

modified unit controls

■ New high pressure and hot reheat

bypass control philosophy

■ Modifications in the steam turbine

controller and new balance of plant

system signals

■ Improved gas turbine control promoting

usage of maximal possible load ramps

over a wide operating range

■ Implementation of logic changes into

the plant’s digital control system

■ Stress and fatigue monitoring systems

for the steam turbine and the heat

recovery steam generator

■ Re-commissioning, testing and

verification

■ Operator training and documentation.

Fig. 3: Automated optimized start-up process.

Published by and copyright © 2009:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

www.siemens.com/energy

!"#"$

1)

Scope of supply

Siemens supplies an integral solution –

tailored to the specific situation and

configuration of the power plant.

2)

%

~ 25-40 min.

faster start-up

with steam

turbine

hot-start

on the fly.

&'(

)*+

&,*+

1) Typical expirience - may vary.

2) Illustration only - results may vary.

Fig. 4: Benefits of new plant start-up concept.

Customer benefits

With this solution for a hot-restart after an

overnight shutdown a total unit start-up

time below 40 minutes can be achieved –

from gas turbine ignition to full plant load.

In comparison: a hot-restart after an

overnight shutdown for a SCC5-4000F

combined cycle power plant may take

about 65 or more minutes depending on

the current plant configuration and the

age of the plant (see Fig. 4).

For more information please contact

your local Siemens sales representative.

Our automated start-up procedure can

help you to save fuel and gain a higher

efficiency during start-up which can result

in saving. In addition, the capability to

provide full MW loading in as little as

40 minutes opens up new revenue opportunities like utilizing hourly and seasonal

market arbitrage or peak shaving in a

deregulated market environment, which

need to be quantified plant-specifically.

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

Energy Service Division

Order No. E50001-G520-A204-V1-4A00

Printed in Germany

Dispo 34805, c4bs No. 7816

TH 258-090760 460326 DB 09092.0

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.