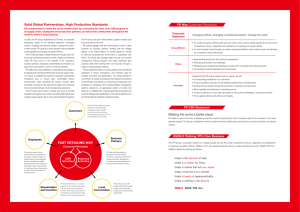

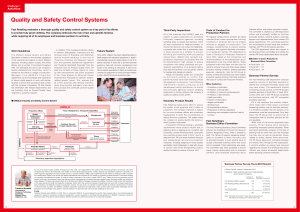

csr report 2014 - Fast Retailing

advertisement