Transverse forces caused by acceleration and deceleration of the

advertisement

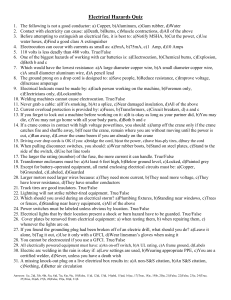

COMMENTS ABOUT THE DESIGN OF RUNWAY GIRDERS ACCORDNG TO NEW EN STANDARDS Helmuth Köber , Bogdan Ştefănescu & Şerban Dima Steel Structures Department Technical University of Civil Engineering Bucharest The present paper is intended to illustrate some particular aspects in using the new European standard EN 1993-6: 2007 (Eurocode 3: Design of steel structures – Part 6: Crane supporting structures) and the other involved Eurocodes regarding the design of runway beams for travelling cranes. References are also made to the Romanian and German design regulations in this matter. Two kind of simply supported runway girders were analyzed to show these particular aspects: - 9 meters span girders for two overhead travelling cranes, having each a hoist load of 20 tons; - 6 meters span girders for an underslung travelling crane, having a 5 tons hoist load. 2 Two overhead traveling cranes: - hoist load of 20tons HC2, S-class S4; - 16.5m crane girder span; - both traveling cranes are working together. 3 An underslung traveling crane: - hoist load of 5tons, HC4, S-class S7; - 6.0m girder span; - a single crane is working on the girder. 4 STAS 10101/2A2-78, Actions due to the exploitation process, Loads due to travelling cranes Eurocode 1, EN 1991-3: Actions on structures, Part3: Actions induced by cranes and machinery • Maximum vertical wheel load, Qr,max • Longitudinal forces caused by acceleration and deceleration of the crane, HL • Longitudinal buffer forces related to movements of the crane, HB,1 • Transverse forces caused by acceleration and deceleration of the hoist block, HT,3 • Transverse forces caused by skewing of the crane, HS 5 Groups of loads according to STAS 10101/0-78 Actions for Constructions. Classification of Actions. Groups of Actions ΣniPi + ΣniCi + ngΣniVi ni = 1,2 for vertical crane loads ni = 1,3 for horizontal crane loads ng = 1,0 for a single considered traveling crane ng = 0,9 for two considered traveling cranes Groups of loads according to EN 1990:2002 Basis of Structural Design respectively CR0 – 2005 Basis of Design. Basis of Structural Design for Construction γQ,1 = 1,5 1,35ΣGj + 1,5Q1 + 1,05ΣΨ0,iQi 6 Dynamic factors STAS 10101/2A -78 20tons traveling cranes (Hoisting Class HC2): Ψ = 1,3 – 0,1 = 1,2 for vertical crane loads (two traveling cranes acting together), Respectively Ψ = 1,3 (for a single considered traveling crane) α = 1,8 for horizontal crane loads 5tons traveling crane (Hoisting Class HC2): Ψ = 1,5 for vertical crane loads (for a single considered traveling crane) α = 2,2 for horizontal crane loads 7 Groups of loads considered as one characteristic crane action (extracted from EN 1991 – 3:2006 table 2.2) The self-weight of the crane Qc and the hoist load Qh are 8 amplified by different dynamic factors. The greatest value of the bending moment on the runway girder is generally obtained with group 1 of loads. For this group the self-weight of the crane Qc and the hoist load Qh are amplified by different dynamic factors (for Qc, respectively for Qh). Most of travelling cranes producers offer only the characteristic values for the relevant vertical wheel loads, where the influences of Qc and Qh are not separated. Following this, these producer’s values cannot be used for the procedure recommended by EN 1991 – 3:2006. 9 MAXIMUM VERTICAL WHEEL LOADS Poduri 20tf - Apăsări maxime pe roată 200 26,48% for two 20t cranes 5,07% for one 20t crane 160 120 Ψ = 1,2 80 φ2 = 1,12 ; φ1 = 1,0 40 0 (kN) STAS 10101 SR EN grup1 SR EN grup5 154.41 195.30 178.71 Pod 5tf - Apăsări maxime pe roată 75 γQ,1 = 1,5 ni = 1,2 60 45 Ψ = 1,5 φ2 = 1, 27 ; φ1 = 1,0 30 15 6,26% for one 5t crane 0 (kN) STAS 10101 SR EN grup1 SR EN10grup5 62.39 58.73 48.82 VALUES OF THE DYNAMIC FACTOR φ5 The proper choice of the values for the dynamic factor according to table 2.6 from EN could be argued. There is a lack of information for choosing a value between the limits given in that table (the limit between smoothly and sudden changes of the forces is not defined). 11 Longitudinal buffer forces related to movements of the crane Pod 20tf - Lovire pod în opritori 31.76 SR EN 1990 2,68 times bigger for the 20t crane 11.84 STAS 10101 0 6 12 18 24 30 36 (kN) Pod 5tf - Lovire pod în opritori 6.48 SR EN 1990 2,52 times bigger 2.57 STAS 10101 for the 5t crane 0.0 1.2 2.4 3.6 (kN) 4.8 12 6.0 7.2 Transverse forces caused by crab acceleration or deceleration EN 1991 – 3:2006 13 Transverse forces caused by crab acceleration or deceleration STAS 10101/2A -78 14 Transverse forces caused by crab acceleration or deceleration Poduri 20tf - Demarare/frânare cărucior 11% for variant 1 SR EN varianta1 12.78 78% for variant 2 SR EN varianta2 20.49 STAS 10101 11.50 0 4 8 12 16 20 24 (kN) Pod 5tf - Demarare/frânare cărucior SR EN varianta1 4.8 10% for variant 1 SR EN varianta2 5.01 12,6% for variant 2 STAS 10101 4.36 0 1 2 3 (kN) 4 515 6 CRANE TRANSVERSE SKEWING FORCES STAS 10101/2A -78 EN 1991 – 3:2006 The horizontal forces HS,i,j,k, caused by crane skewing, are acting as a single force (on a single crane wheel) on each runway beam according to EN 1991. In the appropriate Romanian and German code it is considered that the skewing of the crane generates a couple of forces on each runway girder. 16 Forces used for the design of the runway girders Two 20tons overhead traveling cranes A single 5tons underslung traveling crane 17 The vertical wheel loads generated by crane operations for lower hoisting classes (HC1 and HC2) were greater in the calculations according to the European standard [5], compared to those ones obtained with the Romanian code [1]. For higher hoisting classes (HC3 and HC4) bigger values were obtained for the loads given by the Romanian standard. RUNWAY GIRDERS CROSS-SECTIONS Two 20tons overhead traveling cranes acting together + 5,0% according to old Romanian code design 19 RUNWAY GIRDERS CROSS-SECTIONS A single 5tons underslung traveling crane + 5,0% according to old Romanian code design 20 Effective loaded length leff The limit between rigidly fixed and not rigidly fixed connection is not clearly established. ! 21 Local buckling checks of the web: A frequent loading state of the webs of runway beams is when they are simultaneously subjected to bending moment (My,Ed), shear force (Vz,Ed) and transversal force (FEd). European codes do not specify an interaction checking relation for this loading state and they do not make any reference to such a relation. The Romanian code provides such an interaction relation. 22 Checks against local web buckling for the 20tf traveling cranes runway girder: 23 Recommended partial safety factors values γMf for fatigue checks The fatigue check requires the use of the partial safety factors γMf given in table above, depending on concepts like “low and high failure consequence”, “damage tolerant”24and “safe life”, which are not clearly defined and delimited. The cross-sections designed according to the new European standards were checked according to the in charge Romanian codes in order to ensure an objective comparison (to avoid the influence of the different load estimation procedures) between the two sets of European and Romanian norms used for the design of runway girders. The results are presented in the tables below. General Conclusion Based on our calculations the checks according to the old Romanian code are one the safe side in a range of about 10% (excepting the fatigue limit state checks which had no influence on the designed crosssections). The European codes cover the different design situations more accurately. THANK YOU VERY MUCH FOR YOUR ATTENTION!!