MEMS Overview What is MEMS?

advertisement

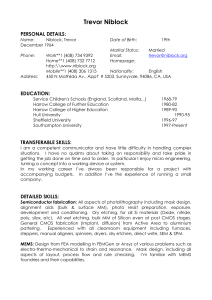

MEMS Overview SPEAKER • Andrew Mason, Asst. Professor in Electrical and Computer Engineering TOPIC • Overview of Micro-Electro-Mechanical Systems (MEMS) OUTLINE • Overview of MEMS & Microsystems Navid Yazdi • Micromachining & MEMS process technology Navid Yazdi • Micro-electro-mechanical devices & microsensors – – – – • Inertial sensors Pressure sensors Bio-sensors Shock sensors Navid Yazdi Navid Yazdi Andrew Mason Andrew Mason Integrated Microsystems Andrew Mason MEMS Overview, Prof. A. Mason Page 1 What is MEMS? • MEMS = MicroMicro-ElectoElecto-Mechanical Systems – creation of 33-dimensional structures using integrated circuits fabrication technologies and special micromachining processes – typically done on silicon or glass (SiO2) wafers • MEMS Devices and Structures – transducers • microsensors and microactuators – mechanically functional microstructures • microfluidics: microfluidics: valves, pumps, flow channels • microengines: microengines: gears, turbines, combustion engines • Integrated Microsystems – integrated circuitry and transducers combined to perform a task autonomously or with the aid of a host computer – MEMS components provide interface to nonnon-electrical world • sensors provide inputs from non-electronic events • actuators provide outputs to non-electronic events MEMS Overview, Prof. A. Mason Page 2 1 Why Use MEMS? • Motivation and Benefits – Small Size – Light Weight – Enhanced Performance & Reliability • high resolution devices • array of devices – Low Cost (from batch fabrication) • Applications – – – – – – – Automotive System Health Care Automated Manufacturing Instrumentation Environmental Monitoring & Control Consumer Products Aerospace • MEMSMEMS-based Microsystems – highly integrated systems – sensing – actuation – computation – control – communication MEMS Overview, Prof. A. Mason Page 3 Example MEMS-Based Microsystem “Micro Cluster” Environmental Monitoring Microinstrument (developed at UU-Mich in the 1990s, A. Mason, K. Wise, et. al.) Humidity Sensor Power Management - Power Management Accelerometer RF Transmitter Interface Chips Microcontroller - Communication 35mm Pressure Sensor Integrated Features - Control - Microcontroller - RF Transceiver - Sensing - Pressure - Humidity - Temperature - Vibration I/O Connector On/Off Switch 60mm - Packaging MEMS Overview, Prof. A. Mason Page 4 2 MEMS Fabrication Technologies • Applying Micromachining to create 3-D structures using 2-D processing 2-D IC fabrication technology 3-D structures micromachining • Micromachining Processes – – – – – – – bulk and surface micromachining isotropic etching anisotropic etching dissolved wafer process deep reactive ion etching anodic and fusion bonding micromolding MEMS Overview, Prof. A. Mason Page 5 Surface vs. Bulk Micromachining Bulk Micromachining: Backside etch Si Substrate Bulk Micromachining: Front-side Etch pit typically polysilicon Surface Micromachined Structure MEMS Overview, Prof. A. Mason Si Substrate Page 6 3 Isotropic Etching of Silicon • Isotropic etchant – etches in all directions – forms rounded pits in surface of wafer • Most common solution – HNA: Mixture of HF, HNO3, Acetic acid (CH3COOH) With agitation: Good reactant mass transport Without agitation MEMS Overview, Prof. A. Mason Page 7 Anisotropic Etching of Silicon • Anisotropic etchant – directional-dependant etch; based on crystal planes – forms flat-surface pits in surface of wafer • Common anisotropic etchants – EDP, KOH, TMAH (111) Surface orientation (100) Surface orientation 54.74° Silicon Anisotropic wet etching using EDP, KOH: (100) surface - Etch stop on (111) plane MEMS Overview, Prof. A. Mason Page 8 4 Anisotropic Etching: Convex vs. Concave Corners masking layer not attacked by Si etchant Concave corner Convex corner Top View Cantilever Beam (100) Masking layer (111) Buried etch stop layer (SiO2 in SOI wafers) Side View Silicon MEMS Overview, Prof. A. Mason Page 9 Anisotropic Etching of Silicon: Example bulk micromachined silicon proof mass MEMS Overview, Prof. A. Mason Page 10 5 Dissolved Wafer Process • Structure created by “diffusion masking layer” • heavily p-dope silicon (p++) • Dissolve bulk of silicon to release the p++ structure Released p++ structure P++ S ili con Dopant selective etch (e.g. EDP) Silicon K.D. Wise, K. Najafi, Univ of Michigan MEMS Overview, Prof. A. Mason Page 11 Dissolved Wafer Process Example • Shock Switch – weighted cantilever beam with contacts that close by acceleration (shock) • Fabrication Flow – create anchor, weight, support beam, and contact on Si – create cavity and contact on glass – bond wafers and then dissolve the Si wafer LPCVD layer deposition for beams Anodic bonding glass to silicon Dissolve silicon bulk and release structure MEMS Overview, Prof. A. Mason Page 12 6 Deep Reactive Ion Etching (DRIE) • Reactive Ion Etching = RIE – mechanical (ion) etching in plasma for chemical selectivity • Deep RIE – creates high aspect ratio patterns, narrow and deep Top view A A A-A cross section mask • Trench-Refill process Silicon – can fill the etched “trench” with another material MEMS Overview, Prof. A. Mason Page 13 Glass-Si Anodic Bonding • Bonding a glass wafer to a silicon wafer – both wafer can (and generally are) patterned with structures • Application – creating sealed cavities on a wafer surface • can be sealed in vacuum – hermetic packaging • Lead Transfer – need to bring the metal leads out of from sealed cavities Need sealing Metal Interconnect Silicon Glass MEMS Overview, Prof. A. Mason Page 14 7 Silicon-Silicon Fusion Bonding • Two silicon wafer with/without SiO2 can be bonded • Advantages: No thermal mismatch • Needs contamination free, smooth, and flat wafers (e.g. surface roughness ~5°A) • Process Flow – – – – – Clean wafers Make the surfaces hydrophilic (e.g. dip in Nitric Acid) Rinse-Dry Place the wafers together apply pressure H2 or N2 anneal at 800-1000°C MEMS Overview, Prof. A. Mason Page 15 Combined Bulk-Surface Process: Molding • • • • Etch silicon with high aspect ratio (e.g., DRIE) Refill partially with sacrificial layer (e.g. silicon oxide) Refill completely with structural layer (e.g. polysilicon) Example: U-Mich Precision Inertial Sensor Polysilicon Electrode with Damping Holes Polysilicon Electrode Nitride Standoff Air Gap Damping Holes Air Gap Silicon Proof Mass Air Gap Nitride Standoff Electrode Dimple Vertical Stiffener Vertical Stiffener Silicon Proof Mass N. Yazdi & K. Najafi, Transducers’97. MEMS Overview, Prof. A. Mason Page 16 8 Combined Bulk-Surface Process: Precision Inertial Sensors Dielectric Layer Metal Pads Metal Pad A A Silicon Proof mass Support Rim Damping Holes N. Yazdi , A. Salian & K. Najafi, MEMS’99. MEMS Overview, Prof. A. Mason Page 17 LIGA Process • • • • LIGA: Lithographie, Galvanoformung, Abformung Form high aspect ratio structures on top of wafer Uses molding and electroplating Synchrotron Radiation (X-Ray) used • Features – Aspect ratio: 100:1 – Gap: 0.25µm – Size: a few millimeters uses multiple polymethyl metharylate (PMMA) layers MEMS Overview, Prof. A. Mason Page 18 9 LIGA Process: Example Guckel, IEEE Proceedings, Aug. 1998. MEMS Overview, Prof. A. Mason Page 19 Monolithic Integration of MEMS and ICs Why Monolithic? Performance: - Reduce parasitics due to interconnecting devices - Reduce noise & crosstalk Size: - Reduce pin count - Reduce package volume Cost: - Integration with signal-processing better functionality - Reduce packaging cost - Self test & calibration at wafer level MEMS Overview, Prof. A. Mason Page 20 10 IC + MEMS Process Examples UC Berekely Integrated CMOS & surface micromachining technology • CMOS first and MEMS second • • CMOS circuit passivated using silicon nitride Tungsten interconnects for CMOS J. Bustillo, R. Howe, R. Muller, IEEE Proceedings Aug. 98 • Sandia Integrated CMOS & surface micromachining technology – MEMS first in recessed cavity – CMOS second after planarization J. Smith et. al., IEDM’95 MEMS Overview, Prof. A. Mason Page 21 MEMS Examples Neural Recording Probes • Monolithic Integration of Wafer-Dissolved Process and IC Technology OUTPUT LEADS P++ RIM INTERCONNECTING LEADS SIGNAL PROCESSING CIRCUITRY RECORDING/STIMULATING SITES - Neural probes with signal processing circuitry - P++ shanks - P++ rim and timed etch to protect Najafi, active circuitry Wise, JSSC-21 (6), May 1986 SUPPORTING SILICON SUBSTRATE MEMS Overview, Prof. A. Mason Page 22 11 Example: Capacitive Accelerometer Suspension Vertical accelerometer Suspension Anchor Mass Anchor Substrate Substrate Conductive Electrode (a) Cs Sense Capacitance (b) One of the sense Bidirectional capacitor elements Sense Fingers Anchors Mass Anchors Mass Mass Cs Lateral Suspensions accelerometer (a) Bidirectional Sense Fingers Substrate Suspensions (b) MEMS Overview, Prof. A. Mason Page 23 Example: Z-Axis Torsional Accelerometer Torque produced by the mass Anchor A' Support beam Anchor wm T T C Fixed Sense Fingers Inertial Element Support posts on glass A Glass Substrate Selvakumar, Najafi, JMEMS 1998. Anchor Torsional suspension Mass plate Sense fingers MEMS Overview, Prof. A. Mason Page 24 12 Capacitive Accelerometer 3-Axis Monolithic Surface Micromachined Accelerometer Analog Devices ADXL50 Sense & Feedback Interdigitated Fingers Proofmass Suspension Courtesy of Lemkin, Boser, Trasnducers’97. Courtesy of Kevin Chau, Analog Devices Inc. MEMS Overview, Prof. A. Mason Page 25 All-Silicon Micro-G Accelerometer Metal Pads Damping Holes Anchor Dielectric A Silicon Proofmass Top View Polysilicon Top/Bottom Polysilicon Electrode Stiffeners A Proofmass Suspension Beams A-A Cross-Sectional View Stiffened Polysilicon Electrode Proofmass Frame Stiffened Polysilicon Electrode Proofmass MEMS Overview, Prof. A. Mason Page 26 13 MEMS Gyroscopes GM & UM Ring Gyroscope Draper’s Tuning Fork Gyroscope Perforated masses (tines) Drive Combs Suspension Electrodes Ring structure MEMS Overview, Prof. A. Mason Page 27 Capacitive Pressure Sensors Consists of two components: • Fixed electrode • Flexible diaphragm forming a moving electrode • Sealed vacuum cavity between the two electrodes Diaphragm (Upper electrode) Lower electrode Silicon P++ Si Ti/Pt/Au Poly-Si Tab Contact SiO2/Si3N4/SiO2 External lead for Glass Substrate glass electrode A. Chavan, K.D. Wise, Transducers’97 MEMS Overview, Prof. A. Mason Page 28 14 Integrated Microsystems Architecture • Flexible Architectures – reconfigurable • new/different sensors can be added – sensor bus Power Management Chip Telemetry Humidity Sensor Accelerometer Transducer Array Pressure Transducer Array EPROM RAM Crystal SCI Temp Sensor SPI Wired I/O Port MCU Timer Analog Interface Analog Interface Bus Interface Bus Interface A/D Digital Interface Bus Interface Battery Capacitive Sensor Interface Chips Sensor Bus MEMS Overview, Prof. A. Mason Page 29 Microsystem Component: Interface Circuit • Generic capacitive sensor interface – sensor readout – sensor bus communication – programmable operation –useful for range of sensors Element Select Cf Digital Gain Control Charge Integrator Variable Gain Amp fs Sensor1 MUX Sensor2 Sample & Hold Temperature Sensor Sensor5 Programmable Reference Capacitor Sensor6 Self-Test DAC MUX Digital Control b2 b1 b0 Element Select Bus Interface Address Command Data Register Decoder Latch Self-Test Command Sensor Bus MEMS Overview, Prof. A. Mason Page 30 15 Microsystem Component: Shock switch • System wake-up switch – allows events to be captured while system is in sleep mode – useful for system-level power management – implements several shock thresholds Suspension B eam Silicon Anchor Support Altar Air Gap Cantilevered Mass Iner tial Mass Metal Pads & Interconnect Symm etric Contacts MEMS Overview, Prof. A. Mason Page 31 16