McGruer.

advertisement

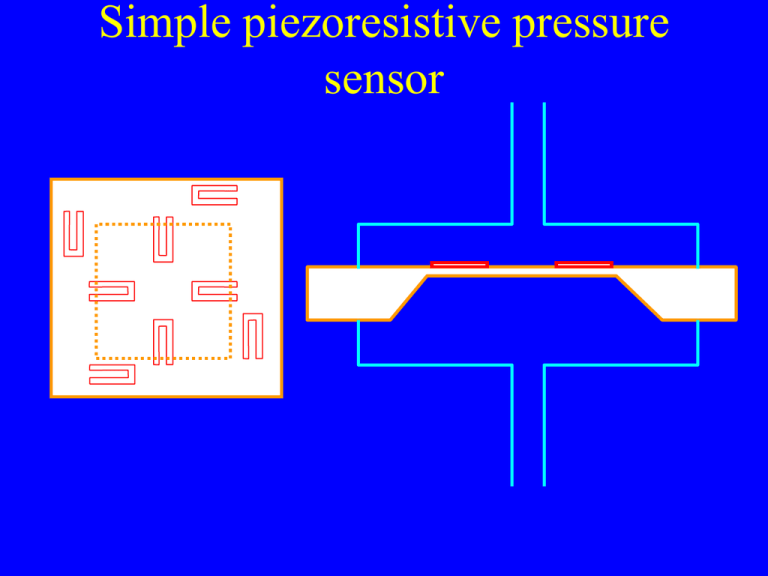

Simple piezoresistive pressure sensor Simple piezoresistive accelerometer Simple capacitive accelerometer C(x)=C(x(a)) Cap wafer • Cap wafer may be micromachined silicon, pyrex, … • Serves as over-range protection, and damping • Typically would have a bottom cap as well. Simple capacitive pressure sensor C(x)=C(x(P)) ADXL50 Accelerometer • +-50g • Polysilicon MEMS & BiCMOS • 3x3mm die • Integration of electronics! ADXL50 Sensing Mechanism • Balanced differential capacitor output • Under acceleration, capacitor plates move changing capacitance and hence output voltage • On-chip feedback circuit drives on-chip force-feedback to recenter capacitor plates (improved linearity). Analog Devices Polysilicon MEMS ADXL50 – block diagram • http://www.analog.com/en/mems-and-sensors/imems-accelerometers/products/index.html MEMS Gyroscope Chip Rotation induces Coriolis acceleration Proof Mass Sense Circuit Electrostatic Drive Circuit halteres J. Seeger, X. Jiang, and B. Boser Digital Output MEMS Gyroscope Chip J. Seeger, X. Jiang, and B. Boser Two-Axis Gyro, IMI(Integrated Micro Instruments Inc.)/ADI (fab) Single chip six-degree-of-freedom inertial measurement unit (uIMU) designed by IMI principals and fabricated by Sandia National Laboratories TI Digital Micromirror Device www.dlp.com NEU/ADI/Radant/MAT Microswitches http://www.radantmems.com/radantmems/switchoperation.html Surface Micromachined Post-Process Integration with CMOS 20-100 V Electrostatic Actuation ~100 Micron Size Gate Drain Beam Source Beam Drain Gate Source Gate SEM of NEU microswitch Landing ring Drain Source MEMS Seal ring Microbump Feedthrough Dielectric Package Substrate MAT Microswitch Contact End of Switch Contact Detail Packaged Plasma Source Top View Die in Hybrid Package Side View Fabrication PR Cr/Au/TiW Glass Wafer Expose/Dev. TiW etch Electroplate Gold PR strip TiW/Au/Cr etch spiral coil Bond to 10 mm diam. glass chamber interdigitated capacitor to vacuum system SEM of Interdigitated Capacitor Structure Spectrometer cross-section Surface Micromachined Spring System Electrostatic Actuator Plates 4/8/2015 Fabricated Microspectrometers 4/8/2015 Intensity vs. Wavelength 1.2 l =515 nm l = 575nm FWHM = 25nm FWHM = 30nm l =625nm RP = 21 RP = 20 FWHM = 39nm RP = 16 Intensity (arb. units) 1 0.8 0.6 0.4 0.2 0 450 500 550 600 Wavelength (nm) 650 700 750 Figure 1. Qualcomm Mirasol Display IMOD Structure Showing Light Reflecting off the Thin-film Stack and Mirror Interfering to Produce Color. Optical MEMS Vibration Sensors Uniform cantilever beam Cantilevered paddle Foster Miller - Diaphragm Cantilevered supported diaphragm Optically interrogated MEMS sensors 55 mm length cantilevered paddle after 7 hours of B.O.E. releasing and lifted up with a 1mm probe (~0.35mm thick, 2mm gap) Courtesy Connie Chang-Hasnain Courtesy Connie Chang-Hasnain Micromachining Ink Jet Nozzles Microtechnology group, TU Berlin Microfluidic Chips (UCLA, Fan) (Gruning) Gene chips, proteomics arrays. NEMS: TOWARD PHONON COUNTING: Quantum Limit of Heat Flow. Roukes Group Cal Tech Tito From Ashcroft and Mermin, Solid State Physics. Other: NSF-Funded NSEC, Center for High-Rate Nanomanufacturing (CHN): High-rate Directed Self-Assembly of Nanoelements Proof of Concept Testbed Nanotube Memory Device Nanotemplate: Layer of assembled nanostructures transferred to a wafer. Template is intended to be used for thousands of wafers. Partner: Nantero first to make memory devices using nanotubes Properties: nonvolatile, high speed at <3ns, lifetime (>1015 cycles), resistant to heat, cold, magnetism, vibration, and cosmic radiation. Switch Logic, 1996, Zavracky, Northeastern Inverter NOR Gate Simple Carbon Nanotube Switch Diameter: 1.2 nm Elastic Modulus: 1 TPa Electrostatic Gap: 2 nm Binding Energy to Substrate: 8.7x10-20 J/nm Length at which adhesion = restoring force: 16 nm Actuation Voltage at 16 nm = 2 V Resonant frequency at 16 nm = 25 GHz Electric Field = 109 V/m or 107 V/cm + Geom. (F-N tunneling at > 107 V/cm) Stored Mechanical Energy (1/2 k x2 ) = 4 x 10-19 J = 2.5 eV 4 x 10-19 = ½ CV2 gives C = 2 x 10-19 F << electrode capacitance! Much more energy stored in local electrodes than switch. NEMS Switch Fabrication: To be discussed. (a) Silicon chip with 500 nm of thermally grown oxide, 20 nm of tungsten, and PMMA. (b) Electron beam lithography was used to define features in the PMMA layer. An ICP etch was used to pattern the tungsten and etch down into the oxide. (c) A Cr/Au layer was evaporated and lifted off by removing the tungsten. (d) DEP was performed to assemble a small bundle of nanotubes traversing the trench between the two side electrodes. NEMS Switch Operation (a) Scanning electron micrograph of a switch. Atomic force microscopy scans before (b) and after (c) switch actuation. (d) Initial (solid lines), second (dashed lines), and third (dotted lines) I-V sweeps for the device seen in (a-c). This device had a vertical gap of 24 nm and a trench width of 195 nm. NEMS Switch Problems During Operation NEMS Switch Electro-Mechanical Model Carbon Nanotube for Adhesion Measurement Biological Nanomotor

![Sample_hold[1]](http://s2.studylib.net/store/data/005360237_1-66a09447be9ffd6ace4f3f67c2fef5c7-300x300.png)