Websol Energy Systems Ltd

advertisement

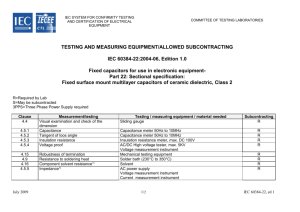

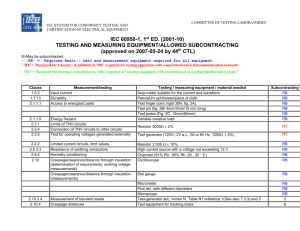

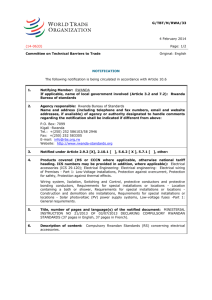

Power Plants with Webel Solar Modules Power Plants with Webel Solar Modules 17W Nautilus Water Pump imported fm Australia X 2 80Wp Solar Panel X 1 Charge controller X 1 Galvanised Steel Pole (3 meters) Amp and Voltage meter Total cost : USD 3800.00 (with maintenance) Performance: Iavg at 11.9 volt is 4.1 Amps (during day) Module: 12V; 80 Wp – 320 pcs Battery: 2V; 800 AHr – 120 pcs Inverter: 15KVA (1 stand by) -- 3 pcs Charge Controller Unit – 1 pc Plant Control Unit – 1 pc ACDB – 1 pc Installation date: Feb 2001 Examples of failures due to Hotspot Examples of failures due to poor contact 72,2°C 60 SP01 40 20 7,5°C (Thermographic Pictures of Modules) Requirements and relevant standards • Safety requirements (System and Operator) – – – – – DIN VDE 0126 IEC 60364-7-712 Ed.1.0 -> safety class II Accident prevention regulation Operator protection measures Lightning and over voltage protection system • Components and systems – Module: IEC 61215, 61646, 61730 etc. – Inverter: EN 50 178, EMC EN 61000-6-3 EN 61000-6-1 • CE marking – Low voltage directive – EMC directive • Grid connection – Grid utility connection regulations (e.g. cos etc.) Standards to be used in a PV Power plant • • • • • • • • -Accident prevention regulation - The EC-Directives – 89/336/EWG, EMC-Directive – 73/23/EWG und 93/68/EWG, Low Voltage directive IEC 60664 -Insulation coordination for equipment within lowvoltage Systems IEC60364-7-712 - Electrical installations of buildings – Requirements for special installations or locations – Solar Photovoltaic (PV) power supply systems EN 50110-1:2004 - Operation of electrical installations IEC 6000-3-2:2005 - Electromagnetic compatibility (EMC) – Limits for harmonic current emissions (equipment input current < = 16 A per phase) EN 50178: 1997 - Electronic equipment for use in power installations EN 61727: 1995 - Photovoltaic (PV) Systems – Characteristics of the utility interface Standards to be used in a PV Power plant • IEC 60364-4-41 - Low voltage electrical installations – Protection for safety-Protection against electric shock • IEC 60364-4-443 - Electrical installations of buildings, Part 4 – Protection for safety, Clause 443: Protection against over voltages of atmospheric origin or due to switching • IEC 60364-5-52:2001 Electrical installations of buildings – Selection and erection of electrical equipment – Wiring systems • IEC 60364-6 Draft Low voltage electrical installation Tests Standards to be used in a PV Power plant • IEC 64/1123/CD Draft Insulation coordination for equipment within low-voltage • Systems. Requirements for special installations or locations Photovoltaic power supply systems. • IEC/EN 61140:2002 - Protection against electric shock-Common aspects • Installation and equipment • PrEN 62305-1:2005 Draft Protection against lighting – Part 1: General principles • PrEN 62305-4:2005 Draft Protection against lighting – Part 4: Electrical and electronic systems within structures Project realisation Installation and project development • Receiving inspection specification for materials and equipments. • Monitoring and Quality Control by stages of assembly, technical documentation control (to avoid failures in the assembly). • Parameters measurement in partial stages of the installation work. • Partial freeing of installations according to the quality control by stages and technical areas like: Structure Assemblies Earth Wiring, Connections and Wires Modules Assembly Electrical Equipment. Security Systems, anti-thefts, … Result: Quality controlled assembly procedures Examples of failures Examples of failures After Project Completion Comparison of the PV installation with the specification The following should be checked in detail: •PV-module (type, performance date, certificates) •inverter (type, performance date, certificates) •cabling (type, cross section, data, laying) •connections and junction boxes •module support construction and mounting •general construction and orientation of the PV-generator (tilt angle, distances, shading). • check on suitability of installed components according to technical data and requirements on components After Project Completion Inspection on safety and functionality test The following should be checked in detail: • installation concept regarding the fulfilment of safety relevant requirements (protecting against hazard for persons and equipment) • visual inspection of the PV installation based on DIN VDE 0100/600 • function test of relevant protection units e.g. over/ under voltage monitoring, switches, measurement of insulation resistance of selected module strings Examples of failures Pictures of different failures After Project Completion Follow up inspections to ensure a safe and proper operation Yearly: Short inspection (visual inspection, spot check measurements, function tests, inspection on monitoring data (error messages, energy yield)) Every 3 years or as needed: Detailed inspection (visual inspection, spot check measurements, function tests, inspection on monitoring data (error messages, energy yield), insulation resistance measurements, string measurements) Result: Keep functionality and safety of total system according to the initial planning over the plant lifetime