Dynamic Analysis by Laser Stimulation (DALS)

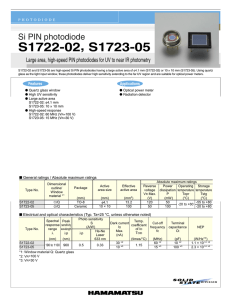

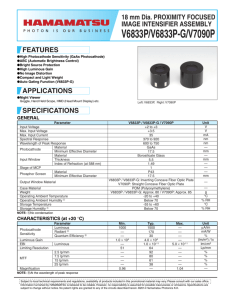

advertisement

New from Hamamatsu Dynamic Analysis by Laser Stimulation (DALS) With the recent miniaturization and high performance in LSIs, the failure mode itself has become more complex. Not only the analysis of current leakage failures in static mode, but also the one of functional failures in combination with LSI testers has become necessary. Dynamic Analysis by laser stimulation is a newly introduced method to localize functional failures in a LSI by observing its operating status (Pass/Fail) change. This document describes the optional function "Dynamic Analysis function kit (DA function kit)" to carry out such innovative analysis with uAMOS and PHEMOS. ■ Overview of Dynamic Analysis by Laser Stimulation Each device has a characteristic of the "drive voltage-operating frequency (Shmoo Plot)" which expresses the operating status (Pass/Fail). In case of a device having functional failures, it shows different characteristic compared to a good one (see the figure below). When driving a device under the conditions around the Pass/Fail boundary and irradiating it by 1.3 μm laser, the characteristics of the Shmoo Plot changes at a failure points (defective transistors, voids, etc.) due to the thermal effect by laser irradiation. That leads the change of Pass/Fail status of the device. By reading the status change as a signal and expressing it as an image, the location related to the functional status change can be identified. With the "DA function kit", localization of the root cause of functional failure can be done much quickly and easily. Concept of the analysis of a failed device by utilizing the "drive voltage – operating frequency" characteristics Analysis done by driving an LSI under conditions at the boundary * The Pass/Fail status changes as a reaction to the laser stimulation LSI tester Pass/Fail map corresponding to laser scan Image formation Pass/Fail status Failure location Status changes due to laser heat Change in status in reaction to the laser = failure location Analysis examples Analysis of an SRAM having insufficient voltage margin For a SRAM that becomes defective over 4 V at VDD, Fail ( ) ( ) Pass DALS analysis was carried out. The Pass/Fail changes was detected due to laser heat at three locations. Failure mechanism was further investigated with one signal. A change from Fail to Pass was indicated in a transistor of the timing circuit. A delay generated in the transistor switching turns the device into normal operation (Pass). Change from Fail to Pass Including the results of the investigations done on the other Fail ( two locations, the cause was defined as insufficient timing ( ) Pass margin between the sense amplifier signal and the word line signal. The problem was fixed by adjusting the timing of the sense amplifier signal slower and the word line signal faster. Data furnished by: Mr. Seigo Ito, Fujitsu Corporation Change from Fail to Pass due to a delay caused by laser. ) Dynamic Analysis function kit (A9771 series) In order to carry out Dynamic Analysis by Laser Stimulation, Dynamic Analysis function kit (A9771) shall be added on μAMOS or PHEMOS series. * In case of retrofitting this kit, modification of the system may be required. Features • Tester signal (Pass/Fail) input and imaging • External control of the scanner by tester signals (loop trigger) * Refer to the right figure for tester connections. NEW Full flexible scanning function • Multi Area Scan Laser scan area can be set up to 30 areas with necessary size, scan speed and direction, which makes measurement time much shorten compared to whole area scan. • Laser mask Laser mask area can be set up to 30 areas to skip scanning. Scan specification Tester I/F specification Three ports are prepared as tester signal inputs (Port shall be selected depending on analysis mode) Number Size*1 Tester signal Pass/Fail signal Position Tester trigger Timing trigger for data latch Scan direction*2 Loop trigger External control of the scanner with test loop trigger Pixel rate*2 * Inputting Pass/Fail signal into the tester signal connector is the minimum set-up to carry out dynamic analysis. Input conditions and trigger signal conditions Input voltage range ± 5 V (in analog mode) Trigger level 1.5 V (voltage level during trigger detection) Input impedance 50 Ω Scan area Laser mask Max. 30 Max. 30 16 to 512 (same in X and Y axis) Any position within the field of view. 0 ,90 ,180 ,270 Not available 128 to 128 000 μs/pixel Not available *1: In multiple of 16. *2: Each area can be set independently. Analysis examples Set up 3 scan areas and execute scanning only in these areas. Minimum trigger width Trigger width min. 100ns to max. 10ns *Trigger level can be set in 0.1V step within the range of +/- 4V. Input impedance can be changed to 4Ω. For more details, please contact your local sales written below. Detects DALS signal in each set area. Set up 3 scan areas and 1 laser masked area. Reference document [1] E.I. Cole Jr. et al., Resistive Interconnection Localization, ISTFA 2001, p.43-50 [2] M.R. Bruce et al., Soft Defect Localization (SDL) on ICs, ISTFA 2002, p.21-27 [3] F. Beaudoin et al., Laser Stimulation Applied to Dynamic IC Diagnostics, ISTFA2003, p.371-377 Laser scan skips the masked area. ★ PHEMOS is registered trademark of Hamamatsu Photonics K.K. ★ Product and software package names noted in this documentation are trademarks or registered trademarks of their respective manufacturers. • Information furnished by HAMAMATSU is believed to be reliable. However, no responsibility is assumed for possible inaccuracies or omissions. Specifications and external appearance are subject to change without notice. © 2009 Hamamatsu Photonics K.K. Web site www.hamamatsu.com HAMAMATSU PHOTONICS K.K., Systems Division 812 Joko-cho, Higashi-ku, Hamamatsu City, 431-3196, Japan, Telephone: (81)53-431-0124, Fax: (81)53-435-1574, E-mail:export@sys.hpk.co.jp U.S.A. and Canada: Hamamatsu Corporation: 360 Foothill Road, Bridgewater, N.J. 08807-0910, U.S.A., Telephone: (1) 908-231-0960, Fax: (1)908-231-0852, E-mail: usa@hamamatsu.com Germany: Hamamatsu Photonics Deutschland GmbH: Arzbergerstr. 10, D-82211 Herrsching am Ammersee, Germany, Telephone: (49)8152-375-0, Fax: (49)8152-2658,, E-mail: info@hamamatsu.de France: Hamamatsu Photonics France S.A.R.L.: 19, Rue du Saule Trapu, Parc du Moulin de Massy, 91882 Massy Cedex, France, Telephone: (33)1 69 53 71 00, Fax: (33)1 69 53 71 10, E-mail: infos@hamamatsu.fr United Kingdom: Hamamatsu Photonics UK Limited: 2 Howard Court, 10 Tewin Road, Welwyn Garden City, Hertfordshire, AL7 1BW, U.K., Telephone: (44) 1707-294888, Fax: (44) 1707-325777, E-mail: info@hamamatsu.co.uk North Europe: Hamamatsu Photonics Norden AB: Smidesvägen 12, SE-171-41 Solna, Sweden, Telephone: (46)8-509-031-00, Fax: (46)8-509-031-01, E-mail: info@hamamatsu.se Cat. No. SSMS0008E03 Italy: Hamamatsu Photonics Italia S.R.L.: Strada della Moia, 1/E 20020 Arese (Milano), Italy, Telephone: (39)02-935 81 733, Fax: (39)02-935 81 741, E-mail: info@hamamatsu.it SEP/2009HPK Created in Japan (PDF)