ASR's Partnership Paper

advertisement

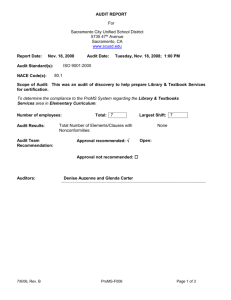

Volume 2, Issue 1 Special points of interest: • ASR now offers public training • ANSI/AIHA Z10 Released • Process Approach to Auditing & Expectations • ASR Provides New Service New Food Safety Management System Offers Opportunities to Global Food Supply Chain ASR’s Partnership Paper By Bill Grande, Food Think (www.FoodThink.com) As global markets for food and food products continue to grow the need for harmonization of international food safety standards is becoming an essential component for facilitating effective and efficient trade agreements and protocols between trade partners and regulatory bodies alike. After years of development, the International Organization for Standardization (ISO) issued its new food safety management system standard, ISO 22000:2005 last October. This new standard, first in the 22000 family, applies to any participating organization within the food industry; basically from farm inputs through final food product preparation, packaging and delivery to the ultimate user. This new international standard provides a framework for any food supply chain participant to demonstrate compliance with applicable statutory and regulatory food safety requirements across all food product realization activities, locations, and phases. By complying with this standard, an organization demonstrates that its food safety management system meets the requirements established by applicable regulatory bodies, as well as suppliers, customers, and other participants, while guarding against contamination that may enter food and food products at any link in the food chain. ISO 22000:2005 at a glance The new food safety management system leverages existing food safety programs – ISO ASR to Provide Additional Service American Systems Registrar has been invited to participate in the Control System Integrators Association (CSIA) certificated member program. This means that ASR will provide registration audits to the association’s best practices specification. A Control System Integrator is an Engineering firm that focuses on industrial control and information systems, manufacturing execution systems and plant automation. Integrators assist organizations with enhancing or developing the above systems. ASR can assist the CSIA member base in achieving and maintaining Certified Member status with thor- 9001:2000 and HACCP – to compliment either of these programs individually, or combine them into a “stand alone” program. Organizations that currently have ISO 9001:2000 and/ or HACCP certifications are in good position to adapt/adopt ISO 22000:2005 components and thereby provide additional assurance of food safety compliance to applicable regulatory bodies, their customers, and ultimately consumers of their food products. _________________________ ISO 22000:2005 consists of three sets of interdependent components (requirements): 1. Pre-requisite programs e.g. good manufacturing practices 2. HACCP principles 3. Management system ——————————–—— See Food Safety Management on pg. 2 ough, independent auditing that contributes to the improvement of business and customer satisfaction. The CSIA association is in its second decade of helping system integrators become better business people. CSIA’s trademarked Certified Member Program provides an industry-specific means for end users to identify areas of importance and minimize uncertainties in selecting a system integrator. This program also offers a framework for integrators to evaluate and continuously improve their own businesses. Inside this issue: Food Safety Management 1-2 ASR to Provide Additional Service 1 Process Approach to Auditing 2-5 ANSI/AIHA Z10 5 The Process Approach and Surveil- 5 lance Audit Requirements ASR Training 6 Page 2 A S R ’ S P AR T N E R S H I P P AP E R Food Safety Management Continued The major tenets of ISO 22000:2005 address: ο Interactive communication and documentation requirements ο System management i.e. management responsibilities and resource management ο Planning and realization of safe food products ο Validation, verification and im- provement of the food safety management system Opportunities offered by ISO 22000:2005 By adapting/adopting ISO 22000:2005 any organization can realize business success in three dimensions: 1. internal, namely measurable improvement in operational efficiencies 2. internal and external represented by global recognition of their food safety management system and reducing or potentially eliminating the need for multiple systems 3. external, namely measurable improvement in customer satisfaction reflected by sustained profitability and continued market growth opportunities ISO 22000 family includes: (1) ISO/TS22004, Food safety management systems – Guidance on the application of ISO 22000:2005; (2) ISO/CD TS 22003, Food safety management systems – Requirements for bodies providing audit and certification of food safety management systems; and (3) ISO/DIS 22005, Traceability in the feed and food chain – General principles and guidance for system design and development. To obtain a copy, contact ANSI at webstore@ansi.org Process Approach to Auditing and Expectations of Our Customers By Bart Solomon, ASR Technical Expert I am often asked the question “Do I have to do process auditing?” ASR has had many discussions concerning this topic. So I would like to analyze the requirements and try to reach a logical conclusion that adds value to your quality management system and sets out ASR’s expectations for your internal audit program. Let’s start by looking at what ISO 9001:2000 requires: “The organization shall conduct internal audits at planned intervals to determine whether the quality management system a) conforms to the planned arrange- ments, to the requirements of this International Standard and to the quality management system requirements established by the organization, and b) is effectively implemented and maintained. An audit program shall be planned, taking into consideration the status and importance of the processes and areas to be audited, as well as the results of previous audits.” So at least clause 8.2.2 does not explicitly require process auditing. However, this clause does require that we audit “whether the QMS conforms to planned arrangements”. Many of these planned arrangements are concerned with the management of the processes and the links between the processes as outlined in clauses 4.1 (a – f) and 8.2.3. In order to audit whether the system conforms to planned arrangements and whether the QMS is effectively maintained, we need to audit the management of the processes and the effectiveness of the processes. Let’s start by looking at the management of processes. See Process Approach on pg. 3 VOLUME 2, ISSUE 1 Page 3 Process Approach Continued Audit Turtle Diagram Step 2 Step 1 What resources are needed for the process? Who participates in the process? Step 3 Step 4 Step 5 Inputs Process Activities Outputs Step 7 Step 6 Are there monitors and measures that show effectiveness? How is the process implemented and controlled? Managing Processes A process can be described in several ways; procedures, work instructions and flowcharts. Many organizations have found turtle diagrams to be a very effective way to describe the management of their processes (see figure above). All processes have inputs, a set of activities to produce the outputs of the process, shown in Steps 3-5 of the turtle diagram. The inputs and outputs can include both tangible raw materials and components and intangible information. The management of the process is shown in the boxes at the corners of the turtle: Step 1 - Manpower/training/ competence - for each process the manpower requirements including the necessary training, competence and evaluation of competence should be defined; and a process owner should be identified so that someone has clear responsibility for the process. Step 2 - Infrastructure (machines, facilities) - the machines and facilities necessary for the process should be defined and managed, that is maintained and improved as needed; this also includes any software necessary for the process. Step 6 - Control Methods - methods for controlling the process include: Documentation -each process should have some minimal documentation, more important or difficult processes may require additional documentation. The documentation could include process flowcharts, procedures, work instructions and forms Set-up approval – some processes are controlled by approving the set-up of the process to established operating conditions Monitoring/inspection – some processes have instrumentation that monitors the process, others are monitored by in-process or product inspection activities Action if the process drifts - the control should include actions if the process deviates from what is planned – these tend to be short term actions which the Standard refers to as corrections (in clause 8.2.3) Step 7 - Metrics and reporting - the process should be monitored for its effectiveness and actions taken if the effectiveness is not adequate. This monitoring may be based on the control data collected in Step 6 which is evaluated over a longer period of time and used to determine if corrective or preventive action should be taken on the process to improve the process. These actions are not the process adjustments (corrections) in Step 6 but are actions taken to change the way the process is performed or controlled. Some organizations supplement the turtle diagram with a process flowchart since the turtle does not show the sequence of steps that make up the process. This management of the processes should provide the basis for our internal audit program. Let’s start with the planning of the audit program. Audit program planning The audit program should be planned and scheduled around the actual processes that make up the quality management system. We start with the processes that make up our quality management system and the interactions of these processes among each other. This information can come from your process map. The first step is to list the processes on the matrix below; we have found this matrix to be helpful in identifying which ISO 9001 requirements apply to which process. The second part of the audit program planning is to define the audit schedule. The important points to consider in defining the schedule are to make sure that • Entire quality management system is audited • Important processes are audited more frequently that less important processes See Process Approach on pg. 4 Page 4 A S R ’ S P AR T N E R S H I P P AP E R Process Approach Continued Process 4.1 4.2 5.1 5.2 5.3 5.4 5.5 5.6 6.1 Management Review/CI X X X X X X X X X 6.2 6.3 6.4 7.1 7.3 7.4 7.5 7.6 8.1 8.2 8.3 X Internal Audit Corrective action/preventive action Quote Order review & entry Scheduling Production Shipping Purchasing QA-inspection & test Calibration Facilities & maintenance Training & competence Document control Records control 7.2 8.4 8.5 X X X X X X X X X X X X X X X X X X X X X X X • Processes with key linkages are audited by the same audit team • Processes with key linkages are audited back-to-back so that the linkages can be audited The decisions concerning the importance of the processes and the process linkages can be discussed with top management to make sure their priorities are represented in the internal audit program. Next let’s discuss the auditing of the processes. Auditing processes Do your auditors use the same checklist each audit? Is the checklist based on the clause requirements in ISO 9001:2000? Do your auditors ask the same questions and look at the same things every time they audit? If your answers are yes, then consider refocusing the auditors on the process and most importantly on the performance of the process. The turtle diagram can help. We have found the turtle diagram a useful tool for auditing a process. The auditor starts with Step 1 and interviews the process owner to obtain a description of the process and discuss the resources necessary (Step 2). Then various participants in the process are interviewed to audit the inputs, activities and outputs of the process (Steps 3, 4 and 5). The control of the process (Step 6) is also audited with the process participants and the process owner. During these interviews the auditor should focus on the data from the process and explore any instances when the data does not appear to meet the needs of the next process in-line or the needs of the customer. See Process Approach on pg. 5 Audit Turtle Diagram Step 2 Step 1 What resources are needed for the process? Who participates in the process? Step 3 Step 4 Step 5 Inputs Process Activities Outputs A TURTLE DIAGRAM Step 7 Step 6 CAN HELP! Are there monitors and measures that show effectiveness? How is the process implemented and controlled? VOLUME 2, ISSUE 1 Page 5 Process Approach Continued Finally the performance of the process is reviewed with the process owner. Questions such as, • Have objectives for the process been established? What performance is expected? • How is the process performing at achieving those objectives? Review the data. • Are actions being taken to assure that the process achieves objectives? • What improvements to the process are necessary? • How are these improvements being implemented? The focus on the data from the process will assure that the questions vary from audit to audit, since the data will change. This will focus the auditor on the actual performance which will drive improvement of the process and the organization. Conclusion Refocusing the audit program and the auditors on the process(es) and the information/data coming from the process will rejuvenate the audit program and focus the internal audit program on improved performance. ANSI/AIHA Z10 Released ANSI/AIHA Z10, a co-sponsored standard from ANSI and the American Industrial Hygiene Association, has officially been released. This standard mirrors the Occupational Health and Safety (OHSAS) 18001 Standard that has been in existence since 1999. Many companies are already familiar with and registered to OHSAS 18001. Currently, there has been limited interest in the United States for the ANSI/AIHA Z10 version of Occupational Health and Safety as companies appear to be satisfied with the OHSAS 18001 and see little value in switching to the Z10 document. ASR will continue to monitor this standard and market, and keep you updated. ISO 9001:2000, The Process Approach & Surveillance Audit Requirements By Brad Bukowski, ASR Registration Manager We all know that at a Registration and/or a Re-Assessment Audit, auditors are required to review all elements of a Quality Management System as defined by the customer’s processes and the ISO 9001:2000 Standard, but what truly needs to be audited during a surveillance audit? There is obviously less time involved, so a comprehensive look at the whole system is not possible. However, as a Registrar, we want to give you a value-added audit that assists you with improving your business! So, what really has to be audited at each surveillance? The following areas MUST BE covered Annually: ∗ Management Review (5.6, 8.2.1, 8.2.3, 8.4, 8.5.1) ∗ Improvement Process (8.5.1, 8.2.3) ∗ Internal Audit (8.2.2, 8.2.3) ∗ Corrective Action (8.5.2, 8.2.3) ∗ Preventive Action (8.5.3, 8.2.3) If a company is on an annual surveillance schedule of 1.0 audit day, half the time could be spent auditing the above items. Remaining time would be spent reviewing other areas of the system. Areas could include Manufacturing or Service Processes, Design & Development, Non-Conforming Product, Measurement & Analysis, Purchasing and so forth. ASR’s goal is to provide the customer with a comprehensive audit whether it is a Registration, Re-Assessment or Surveillance Audit. We will do that by auditing those items that are required and then reviewing those parts of your system where we can truly add value and assist you with improvement of your business! ASR Public Training ASR is now offering Public Training Courses as an additional service to our customers. Our first course (ISO 9001:2000 Internal Auditing) on May 2-3, 2006 was a success. Auditing for Business Improvement is scheduled for September 12, 2006. Please contact us if you would like more information or would like to attend. Additional courses may be added in the fall or in early 2007. We will keep you posted! American Systems Registrar Corporate Office 5989 Tahoe Drive Suite 120 Grand Rapids, MI 49546 Phone: 888-891-9002 Fax: 616-942-6409 Email: info@ASRworldwide.com ASR NOW OFFERS PUBLIC TRAINING!