Purification of Cholesterol An Oxidative Addition

advertisement

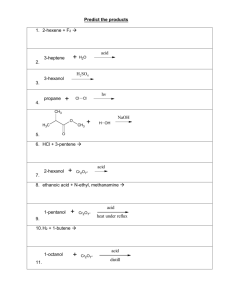

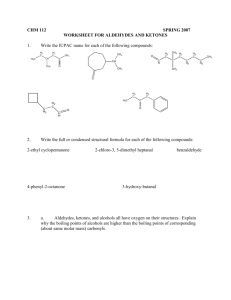

Page 1 of 5 Purification of Cholesterol An Oxidative Addition-Reductive Elimination Sequence From your lectures sessions in CHEM 2010 you have learned that elimination reactions may occur when alkyl halides are treated with strong base. With strong base, the mechanism is generally E2, as shown in the figure below. - OH H Br The orbitals of the atoms involved in the bond breaking sequence must be aligned in an ‘antiperiplanar’ arrangement to provide maximum orbital overlap in the transition state. This reaction is neither an oxidation nor reduction according to the convention of electron counting, since both an electropositive atom (H) and electronegative atom (Br) are lost. Another important type of elimination reaction is known as reductive elimination. In this reaction, a reducing agent (often powdered Zn metal) is used as the electron source. While the exact mechanism is not fully known, it can be envisioned mechanistically as shown in the following figure. Zn Br + Br ZnBr + + Br - ZnBr2 This reaction is considered an oxidation-reduction reaction, since the Zn metal is oxidized to Zn+2 and the dibromocyclohexane is reduced (two electronegative Br atoms are lost). In this experiment, you will use a reductive elimination reaction in the purification of crude cholesterol. Cholesterol is a steroidal compound present in animal cells. In spite of its bad reputation, cholesterol is vital for life. It is a structural component in cell walls and is also required for the formation the myelin sheath covering Updated 6/20/2005 Page 2 of 5 nerve bundles. It is also a precursor for other important steroidal hormones. Cholesterol isolated from natural sources is generally contaminated with ~3-5% related compounds. The structure of cholesterol and related impurities is shown in the following figure. H3C H3C CH3 CH3 H CH3 CH3 H CH3 H H HO H CH3 H CH3 H CH3 H HO 3β−cholestanol cholesterol H3C CH3 H3C CH3 H CH3 CH3 CH3 CH3 H CH3 CH3 H H H H HO HO 5,7-cholestadien-3β−ol 7-cholesten-3β−ol Because of steric constraints imposed by the steroid ring structure, only cholesterol reacts with bromine to form an insoluble diaxial dibromo compound, as shown below. Cholestanol does not react with bromine, whereas the two remaining impurities are dehydrogenated by bromine to form soluble dienes and trienes by a mechanism we will not consider here. H3C CH3 H CH3 CH3 CH3 H CH3 H CH3 H CH3 Br 2 H HO H3C CH3 H H Br HOAc HO H Br The dibromocompound has limited solubility in the reaction solvent and precipitates as a solid. It can be purified by solvent washing or crystallization techniques and separated Updated 6/20/2005 Page 3 of 5 from the impurities which remain soluble in the reaction solvent. Once the dibromo compound has been purified, it can be reacted with zinc to regenerate cholesterol free of the impurities. H3C CH3 H3C CH3 H CH3 H CH3 CH3 H CH3 H CH3 CH3 Zn H Br H H MTBE H HO HO Br ________________________________________________________________________ ! " % # $ " " " & ' ( Reagent cholesterol MTBE bromine acetic acid sodium acetate zinc 10% NaOH methanol formula C27H46O NaOH MW mp bp Density na Comments flammable toxic, corrosive 40 na Updated 6/20/2005 na na na 1.11 Corrosive Page 4 of 5 Procedure: Note: Ethers are common solvents used in many organic synthesis preparations. They have the general formula R-O-R’. Ethers dissolve many organic substrates, yet are unreactive with many reagents; these characteristics make them useful solvents. A common ether solvent is diethyl ether. It is commonly referred to simply as ‘ether’ and was often used as a general anesthetic prior to the development of improved substitutes. Its low boiling point (35oC) and its propensity to form explosive peroxides on standing are safety concerns. This procedure uses t-butyl methyl ether as the solvent. It has a higher boiling point than diethyl ether and is less prone to form unstable peroxides. This compound is generally known as MTBE and was added to certain gasoline blends to provide more complete combustion. However it dissolves in water to the extent of 4.8g MBTE per 100g water. Concerns about groundwater contamination from leaking gasoline storage tanks have led to a phase out of this use. A: Bromination of cholesterol 1. In a 50mL Erlenmeyer flask, dissolve approximately 1g (recorded to three decimal places) of crude cholesterol in 7mL t-butyl methyl ether (MTBE) by gentle warming on a hot plate (setting 4-5). 2. Using a graduated pipet, add 5mL of the bromine/sodium acetate reagent (this has been prepared from 9.0g bromine, 100mL acetic acid and 0.8g sodium acetate) to the Erlenmeyer flask in step 1. Record your observations over several minutes 3. After the reaction appears to stop, place the flask in an ice bath while stirring with a glass rod for approximately 10 minutes. 4. Collect the solids by Buchner filtration and wash with a cold solution prepared from 3mL MTBE and 7mL acetic acid. to remove the entrained mother liquors from the solid. 5. Wash the solids with cold methanol and suck dry for about 5 minutes. 6. Transfer the solids to a pre-weighed 50mL Erlenmeyer flask and record the weight of the dibromo compound. B: Reductive Elimination 7. Add 20mL MTBE to the dibromo compound in step 6 followed by 5mL of acetic acid. Swirl the contents to mix the solvents. 8. Add 0.2g Zn dust and continue swirling. Record your observations. 9. After swirling for 5-10 minutes, add water dropwise until any solids (other than the zinc) dissolve (no more than 0.5mL water should be necessary) 10. Decant the solution from the zinc into a small separatory funnel and add 20mL water. Shake and drain the water layer into a 150mL beaker. Add an additional 20mL water and repeat. 11. Add 20mL 10% NaOH solution to the separatory funnel, shake, settle, and drain the aqueous layer into the same 150mL beaker in step 10. 12. Add 20 mL saturated sodium chloride solution to the MTBE layer in the separatory funnel, shake, settle and drain. (The use of saturated salt solutions will lower the water content of the MTBE layer by drawing the water into the highly ionic salt solution-a process similar to osmosis) 13. Dry the MTBE layer with a small amount of magnesium sulfate; filter through a Chem-wipe tissue into a 50mL beaker to remove the hydrated magnesium sulfate. Updated 6/20/2005 Page 5 of 5 14. Add 10mL methanol and a boiling stone to the MTBE solution. Evaporate the solvent gently on a hot plate (use the snorkel hood!) until solids begin to form or the volume of the solution reaches ~5-10mL. 15. Remove the beaker from the hot plate and allow the contents to cool to room temperature. If no crystals have formed, scratch the surface of the beaker with a glass rod. Place the beaker (carefully-no spills now) into an ice bath for about 15 minutes. 16. Collect the crystals on a Buchner filter and wash with a small amount of cold methanol. Allow the crystals to air dry and record the mass. 17. Compare the melting point of your isolated material with that of the crude cholesterol starting material. 18. Obtain an IR of your isolated cholesterol. Include a “Data Summary Table” as part of your Data/Results Section. Here, the actual amount of reagents used should be specified. If the purity of a reagent is not known, assume 100%. Solvents are generally not necessary in this table. Note the use of ‘mmole’ in the table. It is generally more convenient to use milli moles, since the numbers are generally easier to manipulate. Your table should resemble the following. Compound MW purity cholesterol (crude) bromine zinc dibromocholesterol cholesterol (purified) 386.7 etc etc etc etc 95% etc etc etc etc wt used / recovered 1.00g etc etc etc etc Consider the following as part of your conclusion: • • • • • • “100% wt” 0.95g etc etc etc etc mmoles used / recovered 2.46 etc etc etc etc What is the underlying chemistry responsible for your observations in step 2 of the procedure? Why is cold methanol specified in step 5? What would be the effect if the methanol was at room temperature Occasionally a white solid is observed in steps 8-9 prior to the addition of water. What might be the identity of the white solid? What evidence (if any) do you have that the cholesterol isolated is more pure than the initial cholesterol? Are there any aspects of the procedure that are problematic? If you have suggestions for improvements, mention them as part of the conclusion. As part of your report, calculate the overall yield of purified cholesterol from crude cholesterol. This should be reported in your “Data/Results” section and reiterated in the Conclusion section. Updated 6/20/2005