VINNAPAS® 5014 F and VINNAPAS® 7016 F: Self

advertisement

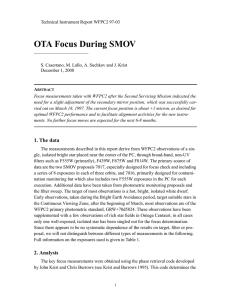

CREATING TOMORROW’S SOLUTIONS CONSTRucTION I Europe I SELF-LEVELING compounds VINNAPAS ® 5014 F and VINNAPAS ® 7016 F: DISPERSIBLE POLYMER POWDERS for self-leveling compounds Self-leveling compounds are subject to complex requirements. They must create smooth, void-free surfaces. Application should be fast and easy, combining a long open time with fast curing. Additionally, excellent technical performance must be accompanied by a VOC level that permits the formulation of end products which meet EMICODE EC1PLUS regulations. VINNAPAS® F dispersible polymer powders help to meet these demands by adding functionality to self-leveling compounds while reducing the number of additives you need. General Benefits VINNAPAS® polymer powders, generally polymeric that improve essential features of self-leveling compounds: •Increased adhesion to different substrates Product Features Flow Support VINNAPAS® ••• 5014 F VINNAPAS® 7016 F ••• •Improved compressive and flexural strength •Better abrasion resistance •Increased tensile strength and deformation capability •Enhanced flow and self-leveling properties •Defoaming properties •Stabilization against bleeding and sedimentation Product Data VINNAPAS® 5014 F Flexibility Hard Minimum film4 °C forming temperature Polymer base VAc-E Better Surfaces With Fewer Ingredients VINNAPAS® F Class polymer powders, specifically, act as binder and superplasticizer. This feature is particularly advantageous for pumpable compounds, where machine application cuts mixing time to a minimum. The required rheology can be adjusted by choosing the right F Class polymer powder; this will simplify handling and logistics. 7016 F Hard 7 °C VAc-E-MMA Eco-Labeling By using VINNAPAS® F products, you will meet the requirements of European eco-labels such as Blue Angel, EMICODE® EC1PLUS, etc. Compliance with such labels will be determined by the dosage level. VINNAPAS® 5014 F and VINNAPAS® 7016 F can be Differentiated by their Rheological Behavior •Different products and processing methods for floorings require different rheological behavior •Superplasticizer works instantly to lower risk of failure due to water over-dosage •High effectiveness of superplasticizer is ensured by patented manufacturing process Defoaming Stabilization Rheology Pumpability ••• Use in gypsum based SLC • Recommended Dosage* 1 – 1.5% ••• • ••• •• •Shear-thinning behavior •Similar rheology to MSF •High pumping capacity due to low pressure in the hose •Dilatant behavior •Very good flow and self-healing properties •Especially suitable for hand-applied SLC •• ••• 2 – 3% * Dosage expressed in terms of total formulation. Higher polymer contents can be achieved by admixing VINNAPAS® L class powders and VINNAPAS® 5010 N VINNAPAS® is a registered trademark of Wacker Chemie AG. CREATING TOMORROW’S SOLUTIONS VINNAPAS® 5014 F: Ideal for Pumping VINNAPAS® 5014 F has a low kinematic viscosity, similar to that of MSF (melamine sulfonate formaldehyde-based superplasticizers), and is beneficial for machineapplied, pumpable self leveling compounds. Its shear thinning rheology reduces pressure in the hose during pump-application and therefore increases the pumping capacity. The superplasticizer works instantly to reduce the tendency to sedimentation and bleeding. Compared to formulations with melamine sulfonates, products with VINNAPAS® 5014 F fulfill EMICODE® EC1PLUS requirements. VINNAPAS® 7016 F: Ideal for Application by Hand VINNAPAS® 7016 F displays casein-like rheological behavior as well as excellent self-healing and surface properties. The dilatant rheology supports application by hand. It imparts very good flow properties and is recommended not only for cementitious self-leveling compounds but also for self-leveling compounds based on calcium sulfate, where VINNAPAS® 7016 F acts as an excellent binder with superplasticizing properties. Go for the Optimum! 260 80 240 70 220 60 200 50 180 40 160 30 140 20 120 10 100 0 0.3% Casein + 1.7% VINNAPAS® 5011 L 2.0% VINNAPAS® 7016 F Kinematic viscosity (calculated): 0.1% PCE + 1.9% VINNAPAS® 5011 L 1.25% VINNAPAS® 5014 F + 0.75% VINNAPAS® 5011 L 341 mPa s 580 mPa s Time in sec 502 mPa s 276 mPa s Flow [mm] Time [sec] 7016 F Exhibits a Much Higher Kinematic Viscosity than 5014 F Through the Same Flow Diameter 90 Talk to our Experts! With VINNAPAS®, you profit from global experience and local expertise. Our experts in our Technical Centers worldwide will help you adapt formulations to your local raw materials, optimize and test products on state-of-the-art equipment in our laboratory – in accordance with local and international testing standards. You will also find a branch of the WACKER ACADEMY near the Technical Centers, unique training and competence centers that offer specialized seminars on relevant industry topics. Our seminars grant you access to a wealth of unique knowledge accumulated over 70 years of R&D and practical polymers’ expertise. Polymer and silicone chemistry have changed the construction industry worldwide. WACKER offers you this expertise in a unique way. Only WACKER is at the same time •A worldwide leader in polymeric binders for construction materials •One of the biggest silicone producers globally •Close to you with native expert staff •Able to offer individual technical assistance through our Technical Centers Our comprehensive portfolio, long experience and strong service will help you find the fitting solution for your specific application. Talk to us! Flow in mm The data presented in this information sheet are in accordance with the present state of our knowledge but do not absolve the user from carefully checking all supplies immediately on receipt. We reserve the right to alter product constants within the scope of technical progress or new developments. The recommendations made in this information sheet should be checked by preliminary trials because of conditions during processing over which we have no control, especially where other companies’ raw materials are also being used. The information provided by us does not absolve the user from the obligation of investigating the possibility of infringement of third parties’ rights and, if necessary, clarifying the position Recommendations for use do not constitute a warranty, either express or implied, of the fitness or suitability of the product for a particular purpose. 7057e/11.13 Wacker Chemie AG, Hanns-Seidel-Platz 4, 81737 München, Germany Infoline +49 89 6279-1741, Fax +49 89 6279-1770, info@wacker.com, www.wacker.com/vinnapas, www.wacker.com/construction