THE DYNAMIC BEHAVIOR

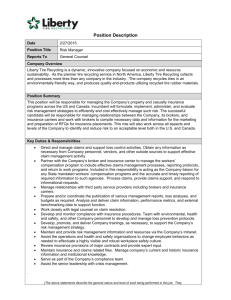

advertisement

Journal of Terramechanics, 1979, Vol. 16. No. 2, pp. 77 to 85. 0022-4898/79/0601-0077 $02.00/0 Pergamon Press Ltd. Printed in Great Britain. :c~ International Society for Terrain Vehicle Systems ON THE DYNAMIC BEHAVIOR AGRICULTURAL TIRES* OF L. LAIB~" Summary--The dynamic behavior of vehicles which are equipped with pneumatic tires depends, to a degree, on the properties of the tire. Therefore, road handling and comfort are also affected by tire characteristics. When the inflationpressure is reduced one obtains a softer "spring". The dynamic spring coefficient Cd~,,increases with increasing rolling speed. Damping coefficient k is related to the excitation frequency by a power function. This function shows a sharp negative slope for low velocities. These conclusions apply to the.tire types and test conditions described in this paper. THE TIREis the link between the road and the chassis of a vehicle. It has, therefore, an important role in the transmission of tractive and braking forces and it influences the ride and the road stability of the vehicle. In certain cases the tire (being a springdashpot system) influences the dynamic behavior of the vehicle significantly. The influence of the operational conditions on tire characteristics is not well known. Experiments show, for example, that vehicle velocity has a significant effect on these parameters, but there is a lack of available quantitative information concerning this subject. Safe road handling and ride comfort depend on the dynamic behavior of on-road vehicles, which is affected by the spring and dashpot characteristics of the tires. If one assumes that road handling stability is a function of the tire load and that acceleration is a measure of ride comfort then one can conclude that 10% stiffening of the tire would reduce stability and comfort by approximately the same amount. Effective damping by the tire is especially important for slow moving vehicles which do not have a suspension system (tractors, for example). These vehicles have unfavorable dynamic properties which is the result of inadequate tire damping over and beyond the lack of suspension [!]. Tire damping can be neglected for the accurate simulation of the dynamic behavior of fast moving vehicles which are equipped with a suspension system [2]. But if the shock absorbers fail, the ride dynamics will strongly depend on the damping characteristics of the tire. Next, I will discuss a method for the determination of the static spring characteristics of tractor tires and I will present tire spring characteristic curves. STATIC INVESTIGATION OF PNEUMATIC TIRES I performed tests to measure the static spring constant o f large tractor tires at various inflation pressures. The following tires were tested: )Translated by Zoltan J. Janosi. This paper appeared in its original form in the Proceedings of the Vlth International Conference of ISTVS. The present version is an improved translation (Editor). ~The University of Agricultural Sciences, College of Agricultural Engineering, God6116, Hungary. 77 78 L. LAIB 15-30; 14-34; 13-30: 13-28; 11-38. I appiied the following inflation pressures : 0.8; 1.0; 1.2 and 1.4 kp/cm2. I measured the deformation under increasing load (F). The deformation (j‘) is defined as the change of the height of the axle-line from the road surface. The spring constant is calculated from the above quantities: The test data are presented in Figs. i-5. Size d tire : 15-30 FIG. 1. FIG. 2. ON THE DYNAMIC BEHAVIOR OF AGRICULTURAL TIRES 79 It can be observed that the static spring coefficient is not constant. It increases with the load first, then, at increasing loads it remains constant or it may decrease slightly. At increasing travel speed (3-5 m/sec or l 1-18 km/hr) the spring constant changes to a small degree. DESCRIPTION AND ANALYSIS OF TESTS The purpose of the following tests was the determination of the dynamic spring coefficient Cdy . and that of damping coefficient k. The tests were performed for a number of excitation frequencies and travel velocities. In order to accomplish these tasks, I ran tests over road profiles which had been surveyed earlier. The tires were run over these profiles at various velocities and the excitation force and the tire Size of tire : 13-30 B = 13" 200O l o. ,," • [ ~.o~-1,~m 100o I,t,At/ /: o\~z/~ / 900 800 1500 DI • 14l,Scm ~ ?00 ~*¥' (~ 600 /,"/X 1000 5oo 40o 3o0 500 ~ - , 4 k p ~ _ pl- 1,2kp/c ~ pl.~O~/cn ,z '=--':- ~' 0 I to 2o 3o ,~o 50 so [ ?o [ ~o 9o I 2oo 1oo wo f Cmm] FIG. 3. ~'ze of tire: 13-28 p[*g • 1500 c ~p ,cmJ 9= 13u O" 5# I 2000 j~/' / ~.O8-~kp/c~ bn- 37,8 ~ " 1000 / 90O / #00 OI . 136,5cm ?O0 600 A 1000 $00 4OO X4~M o 10 20 30 4O 30O ~00 50 6O Fig. 4. 70 I I 80 90 I tOO tOOl[turn.7 L. LAIB Size of tire: 11-38 FIG. 5. deformation were measured. The evaluation of the raw test data was done in accordance with previously published methodology [2]. The tests were performed with 0.8, 1.4 and 2.0 kp/cm* inflation pressure. Both static and dynamic tire spring constant were computed C SIU,= c kp/cm?, f Cd.vn Where = c roll = Crolliady,, s F traction .I‘ ’ andadys is the absolute parameter of tire stiffening. The latter expresses the amplitude ratio of the forces and considers their relative phase angle too. (h-+4 where F1 is the exciting force and Ei is the force acting on the axle. One can also calculate the so-called loss factor: The damping coefficient of the tire may be obtained from the following expression: K = Cr,,,,x -!\/( ad,,, Q J ccm>. 1 -1- (12) kp ON THE DYNAMIC BEHAVIOR OF AGRICULTURAL TIRES 81 THE INFLUENCE OF VELOCITY ON TIRE STIFFNESS At increasing rolling velocity the spring coefficient tends to decrease for a while and then it increases (see Fig. 6). The decrease amounts to 10-20 ~/o for tires with bias ply construction. This is caused by the properties of the rubber and materials and also by a relief in stress at the tire-road interface which, in turn, is related to local relative motion or slip. 11-38 Biased ply tire c [kplcmT. 260 . . . . . . 240 .... t-k i i 220 200 . . . . ; . i : i ~ _ f 1/,otto jlt 16 o q 140 I2 i 4,t L FIG. 6 i 8L ,o 6. The initial spring coefficient is defined as C,,,t, which occurs at very low speed. As the speed increases, the stiffness of both radial and biased ply tires increases. This can be explained by the fact that the centrifugal force straightens the tire, the side walls become steeper and they exert more resistance against deformation. The degree of stiffening depends on the type of the tire construction. Biased ply tires allow more extensive changes in the diameter than radial ply tires because the chord angle can change slightly in a biased ply tire. LOSS FACTOR Loss factor " d " decreases as the velocity increases. An increase in the inflation pressure results in a somewhat smaller loss factor [see Figs. 7(a-c)]. In the medium velocity range the loss factor increases with frequency. When discussing these test results one must differentiate between rolling and static tires. When a tire is at rest and it is excited in the vertical direction then the "resistance of the tire" increases because of the flexing of the tire at the contact area. Further reasons for the increase are the compression of the tire walls and the shear deformation in the carcass structure. Thus the relation between the loss factor and the self-damping of the tire material is evident. When the tire rolls slowly, the deformations in the structure are similar to those obtained by varying vertical exciting forces, but the amplitudes are larger. For the tires examined, the loss factor was in the range o f d = 0,1-0.2. 82 L. LAIB 11-38 Biased ply tire O,25 P6 =0 8 kplcm ~ : ', 0,20 T:--v~.l;o , ,,c ! 0,15 -- 5 70 ,. o o,1o 0 .4 i 5 15 70 , 20 25 Generating frequency 310 ' to l~ /sec] FIG. 7 (a). t 1-3# : 0,25 &. ~oo; [ ;- Biased ply tire 1 1,4 t~lcn,,2 T ~ i O,2O o..............~ 2 i," ~ ' ! o ~, 0,15 o,io I : ! : L5 I0 4-- ~J 5 10 15 20 Generating FIG. 11-38 ~ o,251 1 ~ o,2o~ , 7 25 30 frequency D/se~ (b), Biased ply tire Y_ ~ ; ~ t I ^l I f t I f^ ( go o, t5 ,.40,lO ,, -]I" 11iLl 5 I0 L 1 15 20 25 Generating frequency 30 [llsec] Flc,. 7 (c). ON THE DYNAMIC BEHAVIOR OF AGRICULTURAL TIRES 83 PARAMETER OF STIFFENING The absolute values of ady n a r e plotted in Figs. 8(a-c). An increase in frequency results in the increase of this parameter when the tire is not rolling. It is noteworthy to point out that pertinent publications do not deal with the internal mechanism of the tire stiffening. Presumably, the reason for the stiffening can be explained by molecular processes which play an important role in the rubber material. Thus the degree of tire stiffening is directly proportional to its internal damping while the damping contributed by the rubber material is relatively insignificant. These effects can only be explained by molecular processes. DAMPING PROVIDED BY PNEUMATIC TIRES The tire is the only damping element for suspensionless vehicles (tractors). When plotting the damping coefficient k as a function of the excitation frequency 11-38 Biosed ply tire ,~,s,s ~1,,¢ I I I pc~"-o 8 kp/cM I I ,, [~/h] I ~.. 1,3 ~. ~ ....¢- ~0 : 5 ..--~ ~ " ~ - " - " ~ 0 O,9 - 5 I 10 15 20 25 30 FIG. 8 (a). I1-38 Biased ply #'re ,4 P/JI =I,~ kplcml 2 I vp,,,i I ,I ~= h3 ,I. __ w.O u~ t,2 1,I 1,(, o,9 5 lo 15 FIG. 8 (b). 20 25 30 ,~ 01s~3 84 L. LAIB ,-¢ 11-38 Biosed ply tire i 'S I j t ~3 ,. t ~ ~ f v [km/h:! I ii '. -. ~ 1, *o 5 10 15 20 25 30 FIG. 8 (C). (Fig. 9) one obtains values which depend on the velocity. A log-log plot will yield straight lines whose slope depends on the velocity. This is true for different tire constructions [2]. Thus, the damping coefficient may be represented empirically by means of an expression of the form k = Ao~B where the numerical values of A and B depend on the velocity of the rolling tire. 11-38 k [kpsJ" Biased ply tire -1 2'o Generating 0,8 kp/cm 2 ~ . ~ Pu" ]1,4 --.- [2, 0 - - I~-- FK;. 9. ~o frequency ~ / s e ~ ON THE DYNAMIC BEHAVIOR OF AGRICULTURAL TIRES 85 REFERENCES [l] L. LAILI,Study on the oscillation phenomena of tractors, and their influence on the tractive effort. Inaugural doctoral dissertation. God6116, Hungary, GATE (1977). [2] W. A. HAHN, uber das Feder-Dampfer-Verhalten von Luftreifen. Automobile fndustrie 18. 29-40 (1973).