Basic Skills for Chemistry CHEM

advertisement

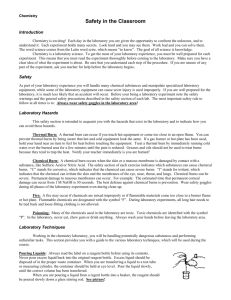

Basic Skills for Chemistry CHEM-1020 Experiment No. 8 The Laboratory Bunsen Burner: History, Operation and Safety (Revised 05/21/2015) Bunsen Burner History: The University of Heidelberg hired Robert Bunsen as a professor in 1852 and promised to build him a new chemistry laboratory. The city of Heidelberg had just installed coalgas* street lighting, so the university supplied the new laboratory building with this new illuminating gas. Illumination was one thing; a source of heat for chemical operations was something quite different. Previous laboratory heating devices left much to be desired regarding economy, simplicity and flame quality. Bunsen wanted a laboratory burner that would generate a clean flame and high temperatures. Bunsen suggested certain design principles to the university’s mechanic, Peter Desaga, who constructed prototype laboratory burner. The new design generated a hot, soot-free, non-luminous flame by mixing gas with air in a controlled fashion before combustion. Desaga placed slits for air at the bottom of a cylindrical burner, with the flame igniting at the top of the cylinder or barrel. Bunsen published a description and many of his colleagues soon adopted the burner design. Variations of the original design are still used worldwide in chemistry and biology laboratories. Bunsen Burner Design: The modern version in use today consists of a metal stand supporting a vertical metal tube in which methane, sometimes called natural gas (CH4) or bottled gas, a mixture of propane (C3H8) and butane (C4H10) mixes with air to produce a clean-burning, hot flame. The typical Bunsen burner has a weighted base with a gas inlet connector for a gas supply hose and a vertical tube or barrel rising from it. (See Figure 1) The gas inlet accepts flexible tubing that connects the burner to a gas supply nozzle and valve at the laboratory bench. Most academic laboratory benches are equipped with multiple gas nozzles connected to a central gas source. When the nozzle valve and burner valve are open, gas flows into the burner base through a small hole at the bottom of the barrel and upward through the barrel. Slots in the side of the tube bottom admit air into the gas stream via the Venturi effect. (In the Venturi effect, the pressure of a gas drops as it flows from a wide to a narrow channel. Air enters the burner through the air ports in response to this low pressure in the barrel.) The gas, now mixed with air, burns when ignited at the top of the tube. The amount of air, or rather oxygen, mixed with the gas stream affects the completeness of combustion. Less air yields an incomplete, cooler reaction. A gas stream well mixed with air provides a stoichiometric excess of oxygen and thus a complete and hotter reaction. The products of complete combustion, carbon dioxide and water vapor, both gases, leave no residue. During incomplete combustion, varying amounts of soot form because there is not enough oxygen to convert the carbon atoms in the fuel to carbon dioxide gas. Opening or closing the slot openings at the base of the barrel controls the airflow. *Coal gas, made by passing steam over burning coal, consists of toxic carbon monoxide (CO) and hydrogen (H2) gas. Coal gas leaks have caused many accidental deaths over the years. In the 1950s, coal gas was largely replaced in the US by nontoxic natural gas (principally methane) obtained from oil field wells. Figure 1 The Bunsen Burner and its Components With the bottom of the tube adjusted so enough air mixes with the gas before combustion, the flame burns hotter, appearing blue (non-luminous). With the air ports closed, the gas only mixes with air at the point of combustion, that is, only after it exits the tube at the top. This reduced mixing leads to an incomplete combustion reaction, producing a cooler but brighter yellow flame, often called the "safety flame". The yellow flame is luminous due to soot particles in the flame heated to incandescence. The yellow flame is dirty because it leaves a layer of carbon particles (soot) on whatever surface it contacts. Equation 1 illustrates incomplete combustion of methane that produces tiny carbon particles: CH4(g) + O2(g) → C(s) + 2H2O(g) (Equation 1) Admitting more air produces a hot, blue flame that can be nearly invisible under bright light conditions. The hottest part of the flame is just above the tip of the inner flame cone. Increasing the rate of fuel gas flow through the tube by opening the needle valve increases the size of the flame. However, unless the airflow is adjusted as well, the flame temperature will decrease because an increased amount of gas is mixed with the same amount of air, starving the flame of oxygen. Equation 2 illustrates the complete combustion of methane that produces more heat and no solid carbon residue. CH4(g) + 2O2(g) → CO2(g) + 2H2O(g) (Equation 2) Bunsen Burner Safety: The primary consideration when using a Bunsen burner is personal safety. Before you attempt to use a burner or other heating device, make sure your work area is free of loose papers and especially, flammable liquids of any kind. Be careful to ensure that your face, clothing and hair are not above or near the opening of the burner tube. Secure loose clothing such as wide sleeves. Long hair must be tied back and secured so it does not fall forward into the burner flame. Do not wear fluffy sweaters, loose sleeves or cuffs with lace or fake fur during any laboratory experiment. Fabrics with fuzzy surfaces are especially prone to accidental ignition. (In addition, always protect your clothing from chemical and hot water spills with a laboratory coat or plastic apron.) Be sure the burner gas valve is closed, not open, when you bring a match to the top of the burner chimney. If the burner gas valve is open and a large amount of gas flows from the burner before you light it, you will be unpleasantly surprised by a fireball instead of a small manageable flame. 2 Learn the operation of the gas supply valve mounted on your bench. Make sure you recognize the open and closed positions of the gas valve handle. With no hose attached, turn on the gas valve briefly to familiarize yourself with the smell of leaking gas. (Methane, propane, and butane, the gases commonly used in Bunsen burners are virtually odorless. The smell you detect is an odorant such as methanethiol, added by the gas supplier to warn of leaks.) Inspect the burner and hose. Check to make sure the hose is in good condition with no holes or sharp bends. Turn the burner upside down and familiarize yourself with the knurled knob at the bottom which operates the needle valve, regulating gas flow. Remember to turn the knob clockwise into the body of the burner to restrict the flow of gas. (When you place the burner back on the bench, you may be confused by the operation of this knob because it is now upside-down.) Familiarize yourself with the air ports which open and close when you rotate the burner chimney. The larger the air holes, the more air will enter and mix with the incoming gas. If the holes let in too much air relative to the amount of gas, the flame may “strike back” and burn at the bottom of the barrel. Strikeback can go unnoticed except for a scraping or whistling noise and is dangerous because the burner barrel gets very hot. Always use care when adjusting the air intake holes in case the barrel is hot. Burner Ignition: Attach the plastic or rubber supply hose securely to the burner gas inlet and to the bench gas supply nozzle. Close the needle valve completely by turning the valve handle clockwise up into the body of the burner. Then open it slightly by one-half turn to facilitate opening it later. Close the air holes at the bottom of the barrel completely and then open them slightly by a half turn. Open the bench gas valve completely. Never open the bench valve partially because opening it fully later can result in a sudden, unexpected increase in the burner flame size. (Check to be sure the gas valve at the bottom of the burner is closed, not open. If the valve is wide open before you light the burner, the gas will ignite as a fireball.) Hold a lit match just above the barrel. If the burner does not light immediately, open the needle valve further while keeping the lit match above the barrel. The burner should light with a yellow, smoky flame. Adjust the needle valve so the yellow flame is about 15 cm high. After lighting the burner, open the air holes until the flame is blue. A properly adjusted Bunsen flame will have two non-luminous blue cones, one inside the other. Warning: Burns are the most common laboratory accident. Temperatures in the burner flame can approach 1500 °C. After heating any object, be careful to let it cool before grasping it. Before you handle any part of the burner, touch it lightly to ensure it is not hot. The burner chimney, especially if the flame has struck back, can burn your skin badly. To extinguish a Bunsen burner flame, shut the bench gas supply valve, not the bottom burner valve. Let the burner cool before you handle it again. Before you attempt to light the burner again, shut its bottom gas valve and its air holes. Heating Techniques: The Bunsen burner can be used to heat of variety of laboratory equipment, including test tubes, crucibles, Erlenmeyer flasks, Florence flasks, beakers and wire loops. Test Tubes: To heat liquid in a test tube, hold the test tube with a wire test tube holder in your hand so the top of the burner flame contacts the side of the test tube just above the round bottom. Test tubes heated by a flame at the very bottom are more likely to “bump” and eject liquid from the test tube. Liquids in test tubes are best heated with a small blue flame, not the hottest flame possible. Never point the test tube toward your face or toward anyone else. 3 Crucibles: Porcelain crucibles, covered or uncovered, (See Figure 2) are used for high temperature experiments. Crucibles are heated by placing them in a clay triangle supported in an iron ring clamped to a ring stand (See Figure 3) with no wire gauze. For effective heating, use a hot, non-luminous flame with the inner cone just touching the bottom of the crucible. Figure 2 Porcelain Crucible and Cover Figure 3 Ring Stand and Accessories Flasks and Beakers: Beakers, Erlenmeyer flasks and Florence flasks should be placed on a wire gauze supported on the iron ring clamped to the ring stand. The hottest part of the flame, the tip of the inner cone, should just contact the wire gauze. Florence flasks tip over easily and must be secured at the neck with a flask or burette clamp. To adjust a flame, do not place your hand underneath any container of hot liquid. Use the burner hose to pull the burner from underneath the container, adjust the burner flame and push the burner back under the flask. 4 Wire Loops: Nichrome alloy wire loops mounted on a handle are used for flame testing of various metal solutions. The wire loop is cleaned by holding it in the hottest part of the flame, just above the blue inner cone until the wire no longer causes the flame to change color. Glassware Safety: Before you heat any piece of glassware, always inspect it, especially on the bottom for cracks or other defects. Cracks can cause a hot flask or test tube to break, creating a dangerous spill. Inform your instructor if you see defects in any glassware. Experimental 1. Lighting the Bunsen Burner: a) Before lighting your burner, refer to the detailed instructions on page 3. Close the air holes almost all the way to make the burner easier to light and to prevent strikeback or flashback (gas burning at the bottom of the tube). Close the needle gas valve, attach the burner hose to the bench gas outlet and open the bench valve completely. A partially closed bench valve will prevent the burner from operating properly. Open the needle valve slightly and bring a lit match to the burner top. If the gas does not light, open the needle valve further until you get a small yellow flame. Then open the needle valve until the flame is 10 to 15 cm long. Look carefully and you will see this flame is smoky (because there is insufficient air to burn all the carbon). On your data sheet, describe the appearance of the flame. b) Now open the air holes to allow air into the barrel gas stream. The flame will become progressively bluer and hotter as more air is admitted. The hottest part of the flame is just above the luminous inner cone. If you let in too much air, the flame may blow out or strike back and burn at the bottom near the air intake holes. Strikeback can go unnoticed except for a scraping or whistling sound and is hazardous because the burner barrel gets very hot. Always use care when adjusting the air intake holes in case the barrel is hot. On your data sheet, describe the appearance of the hot, blue flame. c) Try to induce strikeback by reducing the gas flow and opening the air holes completely. On the data sheet, describe the appearance of the flame. Is the flame noisier than before? d) To extinguish the burner, shut the bench gas supply valve. 2. Properties of the Burner Flame: a) With your metal tongs, hold a porcelain crucible in a hot, blue flame for about 15 s and observe what, if anything happens. b) Hold a corner of your wire gauze in a hot blue flame for 10 s and record your observations. c) Completely close off the air supply to the burner flame. Hold the same crucible in the "lazy" yellow flame for 15 s and observe what happens. d) Hold one corner of your wire gauze in the yellow flame for 10 s. Record your observations. Do not turn off the burner. Proceed to Experimental part 3. 5 3. Heating Laboratory Glassware with the Burner Flame: a) Adjust the gas flow so the yellow flame is about 10 cm high. Then open the air holes until the flame is blue. Inspect the bottom of a medium (15 cm long) test tube for cracks and fill it less than one fourth full of water. Grip the test tube with a wire test tube holder held in your hand. Without pointing the open end of the test tube at anyone, heat the bottom of the test tube with the flame until the water boils. Then move the test tube so the flame contacts the test tube slightly above the bottom. Observe the difference in the way the water boils. Extinguish the burner by shutting off the main gas valve. Pour the hot water into a sink and rinse the test tube with tap water to cool it. Test tubes are made of Pyrex® glass which withstands sudden temperature changes from boiling hot to cold. Pyrex heated in a flame without any water will shatter, however, if you put it in cold water. Any glass or porcelain article heated to redness or any temperature hotter than the boiling point of water must be allowed to cool in air before you put it in water or touch it with your fingers. b) Bring a ring stand and iron ring to your work area and clamp the iron ring about 20 cm above the ring stand base. Place a clay triangle and a porcelain crucible without its cover on the ring and place the burner under the clay triangle. Light the burner and adjust it so the inner cone of the hot, blue flame contacts the bottom of the crucible. Heat the crucible until either the clay triangle or the bottom of the crucible glows red-hot. When your instructor approves your placement and heating technique, extinguish the burner by shutting off the main gas valve. Allow the ring, clay triangle and crucible to cool to room temperature before you touch them again. (The hot crucible will break if you attempt to cool it with water.) c) When the iron ring has cooled, replace the clay triangle with a wire gauze square. Inspect a 500 mL Florence flask (Figure 4) for cracks and other defects, especially on its bottom. Place the Florence flask on the wire gauze and secure the neck with a flask or burette clamp to keep it from tipping over. Fill the Florence flask less than halfway with tap water. Light the burner and adjust it until you have a 10-cm high clean blue flame. Place the burner under the wire gauze square. The inner blue cone should just contact the wire gauze. If the flame extends around the edges of the wire gauze, use the hose to pull the burner toward you. Cut back the air and then the gas until you get a smaller, more manageable flame. Heat the water until it begins to boil and extinguish the burner by shutting off the main gas valve. Fill the Florence flask with cold water from a beaker to cool it and pour the water into the sink. Wait five minutes and use a pair of rubber hand protectors to disassemble the remainder of your apparatus. Cool the iron ring under a stream of water before you put it away. Figure 4 Florence flask 6 Basic Skills for Chemistry CHEM-1020 Experiment No. 8 The Laboratory Bunsen Burner: History, Operation and Safety Data Page 1. Lighting the Burner: a) Describe the appearance of the flame when you first ignite the burner. b) Describe the appearance of the burner flame after you open the air inlet holes. c) Describe the appearance and behavior of the flame after you reduce the flow of gas and open the air holes completely. 2. Properties of the Burner Flame: a) Observations on heating the porcelain crucible in the hot blue burner flame: b) Observations on heating the wire gauze in the hot blue burner flame: c) Observations on heating the crucible in the yellow burner flame: d) Observations on heating the wire gauze in the yellow burner flame: 7 Basic Skills for Chemistry CHEM-1020 Experiment No. 8 The Laboratory Bunsen Burner: History, Operation and Safety Data Page 3. Heating with the Bunsen Burner Flame: a) Describe how the water boiled when you heat the very bottom of the test tube containing water and then how it boiled when you heated slightly above the bottom of the test tube. b) Describe the appearance of the clay triangle and the crucible bottom after you have heated them with a hot blue burner flame for one minute. c) Describe the proper placement of the ring stand, Florence flask, clamp and Bunsen burner for boiling water in the Florence flask. 8 Basic Skills for Chemistry CHEM-1020 Experiment No. 8 The Laboratory Bunsen Burner: History, Operation and Safety Report 1. What causes burner "strikeback" and what does the term mean? (1 point) 2. Why is burner strikeback dangerous? (1 point) 3. Write the names and chemical formulas of the three gases commonly used to fuel Bunsen burners. (3 points) 4. What is meant by incomplete combustion of gas in a Bunsen burner flame? (2 points) 5. Why must you clamp the neck of a Florence flask when heating the flask on a ring stand? (1 point) 6. Describe the proper way to heat water or any liquid in a test tube. 9 (1 point) 7. What does the soot coating produced by a dirty burner flame consist of? (1 point) 8. When you heat the crucible and wire gauze with the blue, nonluminous burner flame, what two observations suggests that the flame is hot and clean-burning? (2 point) 9. When you heat the crucible and wire gauze with the yellow, luminous burner flame, what two observations suggest that the flame is cool and dirty? (2 point) 10. On a separate piece of plain white 8-1/2 by 11 inch paper, make a black ink sketch of the proper placement of the ring stand, Florence flask, clamp and Bunsen burner for boiling water in the Florence flask in a safe manner. Label each component of the sketch. Staple the paper to this report. (3 points) 11. Staple page 2 containing Figure 1 to this report. On Figure 1, next to each of the five labeled burner components, write a few words describing how each part functions and how you used each part to regulate the function of the burner. (3 points) 10