Yarn Formation

advertisement

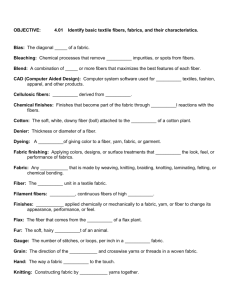

2/18/2010 OBJECTIVES What is a yarn? ´ What are the different types of yarns available? ´ How are yarns made? ´ How ´ Yarn Formation CHAPTER 7 YARN ´ A continuous strand of textile fibers, filaments, or material in a form suitable for knitting, weaving, or otherwise intertwining to form a textile material. FILAMENT YARNS Monofilament yarns – single filament by itself used as the yarn ´ Multifilament yarns – several filaments that make up the yarn – extruded at once (30 to several thousand) and twisted together BASED ON FIBER LENGTH Spun yarns: Made from short-staple fibers. ´ Regular or smooth Made filament yarns: y from long, smooth filament fibers. ´ Textured-bulk-filament yarns: Made from crimped filament fibers. ´ FILAMENT YARNS ´ Smooth-filament yarns: Regular or ´ Production: Used as produced or further ´ Uses: In I smooth, th lustrous l tr fabrics f bri orr where h r high conventional filament yarns. ´ treatments added (dye, finishes, texture, etc.) strength, compact yarns are needed. 1 2/18/2010 CHARACTERISTICS ´ ´ ´ ´ ´ More expensive than staple to produce; low production rate, number of holes in spinneret equal to number of fibers in yarn. Smooth with low or no twist, except crepe twist yarns. No p protrudingg ends Sheds soil Compact with little bulk, cover, or loft CHARACTERISTICS (CONT’D) Strength related to fiber strength and multi-filaments Fiber strength fully used Size based on denier system; related to number & size of filaments Characteristics related to number and size of filaments TYPES Fine fibers—soft & supple yarn Coarse fibers—stiff & abrasion resistant yarn Fibers as long as the yarn and the fabric from which they are removed YARNS Smooth-filament (mono or multi filament) ´ Tape yarns (fibrillated fibers/split films or slit films) ´ Network yarns—similar to tape yarns, but with ggreater bulk and comfort ((foamed p polymer) y ) Monofilament TEXTURING TYPES ´ Multifilament Bulky – sweaters, carpets Crimped - thermoplastic fibers – may be used for some stretch ´ Textured – mechanical, chemical and/or heat treatments used; spun or filament yarns ´ ´ False twist: Continuous process where yarns are twisted, heat set, uncoiled; widelyy used method. Knife Edge: Heated filaments drawn over an edge. ´ Stuffer box: Filaments stuffed into heated box; ´ increases volume 200-300%; widely used method. Air jet: Air tangles fiber; increases volume 50-150%; little or no increase in stretch. ´ Knit-deknit: Knit, heat set, unknit. ´ ´ 2 2/18/2010 TEXTURED TYPES BULK YARNS Bulky: From inherently bulky fibers; less stretch than stretch or textured yarns. ´ Stretch: High degree of potential stretch & rapid recovery; moderate bulk. ´ Loopy/Textured: Bulky yarns with comfort stretch. ´ ´ ´ Greater covering power or apparent volume compared to smooth filament yarn; also called bulk continuous filament (BCF) yarns. Characteristics « « « « « « HIGH BULK YARNS SPUN YARNS Part of tow is heat stretched. ´ Two parts combined, cut, and spun by con entional methods. conventional methods ´ Immersed in hot water; heat stretched fibers shrink; non-heat set fibers create bulk in yarn. ´ CHARACTERISTICS ´ ´ ´ ´ ´ ´ Fuzzy: Fiber ends protrude along length of yarn. Yarn strength related to cohesiveness of fibers and number of contact points along fiber. Low twist yarns separate easily with force; yarn strength not related to fiber strength. Likely to pill as fiber ends break off. More comfortable when in contact with skin (less area of yarn in contact with skin, the more comfortable and less clammy & confining it is). More likely to create problems with soiling. Continuous strand of fibers held together by some binding mechanism, made from short fibers. SPINNING PROCESS – COTTON SYSTEM ´ ´ Less smooth More permeable to air & liquids Less slippery More comfortable (may be more absorbent) Less static prone More bulk, cover, and elasticity ´ ´ ´ Opening: Loosens, cleans, blends fibers; removes dirt; helps determine yarn quality. Carding: Partially straightens fibers & forms into thin web; produces carded sliver. Drawing: Increases parallelism of fibers; combines carded slivers into a drawn sliver; continues blending for self-blended yarn, decreases sliver size (to a roving.) Combing: Select yarns of high quality fibers; removes short fibers & increases parallelism of fibers. 3 2/18/2010 COMPARE CARDED AND COMBED YARNS OTHER SYSTEMS ´ ´ ´ Woolen system: Wool fibers; soft, bulky, fuzzy yarns. Worsted system: Wool fibers; more even fiber distribution & more parallel; compact, smooth, strong yarns. yarns—shorter Flax system: Tow yarns shorter & less parallel fibers; line yarns: longer and more parallel fiber. SPINNING PROCESS (CONT’D) Roving: Reduces size of drawn sliver, increases fiber parallelism; adds small amount of twist. Repeated several times (blending often occurs here). ´ Inserting g yyarn twist: Several options p to reduce size & add full amount of twist; winds finished yarn on bobbins. ´ WOOLEN (TOP) AND WORSTED (BOTTOM) YARNS INSERTING YARN TWIST Ring or conventional: Series of operations. ´ Open end rotor: Eliminates roving & ring twisting (faster process, but weaker yarn). ´ Friction spinning: Combines rotor & air techniques; more even yarns; freer of lint, & loftier, but weaker. ´ 4 2/18/2010 ALTERNATE SPUN YARN PROCESSES Air jet: Similar to rotor, but twist formed by moving air; rougher & less elastic yarns than rotor spun yarns. ´ Direct: Similar to conventional; roving eliminated. eliminated ´ Compact: Variation of ring spinning that condenses the roving before final twist insertion; smoother & stronger yarn. ´ SPINNING FILAMENT TOW INTO SPUN YARNS ´ Tow-to-top (sliver system): Tow converted into staple by diagonal cutting (cut to desired length) or break stretch (stretched until fiber breaks at weakest point, uneven length) and formed into sliver; spun by conventional system. ´ Tow-to-yarn: Direct spinning system where fibers are broken at weakest point and spun into yarns in continuous process. TWIST ALTERNATE SPUN YARN PROCESSES Vortex: Twist develops as fibers swirl around spindle; eliminates shorter fibers. ´ Twistless: Eliminates twist; holds fibers g g soft, lustrous, together with starch or sizing; opaque fabric with good dyeability & durability. ´ Self-twist: Inexpensive way to ply 2 yarns of different twist (1S & 1Z) direction. ´ ENVIRONMENTAL IMPACT ´ ´ ´ ´ Hearing protection required. Opening steps create air-borne dust (controlled by vacuum heads or humidity levels). levels) Waste recycled whenever possible. Ring spinning often in low cost labor countries with related issues of social responsibility. TYPES OF YARN TWIST Spiral arrangement of fibers within a yarn. Direction: S or Z (Z is most common) ´ Amount of twist: Varies with length of fiber, yarn size, i & end d use; low, l napping, i g regular, g l high/voile, or crepe twist. ´ ´ 5 2/18/2010 LOW TWIST YARNS ´ Smooth and textured bulk filament yarns: very low twist. SPUN YARNS ´ Average Twist: Most common type of twist, neither low nor high, used for most end uses. SPUN YARNS ´ Crepe Twist: very high twist, produces lively, yarn SPUN YARNS ´ Napping Twist: Low twist, usually filling direction to facilitate brushing fibers to surface (napping); for flannelette, flannel, blankets, etc. SPUN YARNS ´ Voile Twist: high twist, used for voile YARN SIZE ´ Yarn number: Cotton, woolen, worsted systems are indirect systems; length per unit weight (finer yarns, higher numbers). ´ Denier: Direct system; weight per unit length (g/9,000 m)—finer yarns, lower numbers; denier used for yarns and fibers. ´ Tex system: Weight per unit length (g/1,000 m); finer yarns, lower numbers (decitex or dtex). 6 2/18/2010 YARN TYPES SINGLE, PLY, AND CORD YARNS ´ Simple: All parts are alike. ´ Single: Spun or filament. ´ Ply: Two or more singles; increases diameter, strength, (usually tr gth and d performance rf r ( ll spun yarns). r ) ´ Cord: Ply yarns are twisted together. Uses: Industrial products. ´ CORD (RIGHT), SINGLE (LEFT), AND PLY (BOTTOM) YARNS SEWING THREAD ´ ´ ´ ´ ´ FANCY, NOVELTY, OR SPECIALTY YARNS Yarn intended for stitching materials together by machine or hand process. Available in several sizes and structures: ply, corded, cable, braided, textured filament, smooth filament, monofilament, and core spun. L bi Lubricant or wax fi finish i h to ffacilitate ili sewing. i Many fibers used. Sized as denier, tex, count, yarn number, or ticket number. PARTS OF A NOVELTY YARN Single: 1 part ´ Complex: 2 or more parts ´ « Ground or foundation or core or effect component « Binder component « Fancy ´ Uses: Usually in filling only; adds interest; may add crease resistance to fabric; decreases durability; increases cost; fashion component. 7 2/18/2010 EXAMPLES OF NOVELTY YARNS TYPES ´ Slub or flake: Single, spun fancy thick-thin yarn. « « The twist can be varied at regular intervals. The thicker part can be twisted less than the thinner part. ´ Spiral or corkscrew: Two parts twisted together; differ in ´ Ratiné: Spiral effect with loops at intervals. Knot, spot, nub, or knop: Effect twisted many times in color, size, or texture. ´ one spot. TYPES FABRICS WITH NOVELTY YARNS Spike or snarl: Open loops at intervals. Loop, curl, or bouclé: Closed loops at intervals. ´ Metallic: Metal incorporated with yarn. ´ Chenille: Chenille Short Sh t pile il fibers fib held h ld in i place l by b two t binder bi d ´ ´ yarns twisted together. EFFECT PLY FOR SEVERAL KINDS OF FANCY YARNS FIBER BLENDS ´ Blend: Intimate mixture of different fibers (varied by ´ Mixture: One type of yarn used in one fabric place type, length, size, color, etc.) in one yarn. (i.e., warp) & another type used in another fabric place (i.e., filling). ´ Combination: Two unlike yarns twisted together to form a ply (simple or novelty yarn). 8 2/18/2010 REASONS FOR BLENDS Combine different fibers to get better combination of characteristics in product; achieve characteristics that are combinations of the fibers in the blend ´ Improve processing and uniformity ´ Obtain better hand, texture, and appearance ´ Economize ´ Obtain cross-dyeable effects ´ BLENDS ´ Blend levels: Related to end use and performance specifications. ´ Stage of blending: Earlier in processing, blend is more uniform. Light density fiber works to outer edge of yarn. ´ Other possibilities « « FIBER DISTRIBUTION IN YARNS COMPOSITE YARNS ´ ´ Regular in appearance with unlike components. Types: « « « « « YARN PERFORMANCE ´ Characteristics & performance measured to ensure consistent fabric and product quality and performance. « Size, Size twist, twist bulk, bulk evenness, evenness & appearance resistance to abrasion, & other performance aspects « Strength, Blended filament yarn: two unlike filaments blended together Fasciated yarns: filament & broken filament Covered: Yarn wraps around spandex/rubber. Core-spun: Fiber completely covers core of another fiber. Wrap spun: Staple fiber core wrapped with filament. Fasciated: Filament wrapped with staple fibers or filament yarn wrapped with filament fibers. Polymer with staple fibers; inexpensive. YARN QUALITY Thin spots assessed to minimize problems with processing, fabrication, and finishing. ´ Neps: Small knot of entangled fibers; assessed to minimize problems with dyeing and finishing. ´ Hairiness: Excessive fiber ends on yarn surface make the yyarn more sensitive to abrasion and pilling; assessed to minimize problems with fabrication and performance. ´ 9 2/18/2010 SUMMARY ´ ´ A yarn is a continuous strand of staple fibers, filament(s), or some other material that can be used to make a textile. The categories that yarns can fall into are: spun yarns, smooth filament yarns, or textured filament yarns. « « ´ ´ Filament yarns can be either monofilament or multifilament. They can also be made as tape or network yarns. Textured filament yarns can be created in a variety of ways and utilized for texture, bulk, stretch or comfort. Filament yarns are created through the extrusion process previously covered Spun yarns refer to staple length fibers. They go through a general process of cleaning, combing in various ways and stages, and twisting to form the yarn. « ´ ´ ´ ´ ´ Yarns can twist in a clockwise or counter-clockwise direction: z-twist or stwist. The z-twist is the most common. Yarns can have a low amount of twist or a high amount. This will affect what type of fabric and ultimately, what type of end-use the yarn is for. Yarns can be twisted into a certain type of grouping: single spun, ply yarn, cord or fancy yarn. yarn Yarns can be blended in a variety of ways and for different reasons. Quality must be monitored at every level. Spun yarns can go through more or less combing, which affects how strong and smooth the yarn is. If it goes through less combing it is called either combed (cotton process) or woolen (wool process); if it goes through more combing it is called carded (cotton process) or worsted (wool process). 10