50096-932 Rev B

advertisement

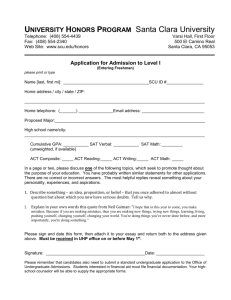

Product Bulletin For Distribution To: • International Distributors • International Management • U.S. Field Sales & Clinical Specialists • U.S. Technical & Field Service Date: January 16, 2013 rE: Advantage® Monitoring System Two industry standards for Endoscope reprocessors that are used in Europe are Health Technical Memorandum (HTM) 2030 for Washer-disinfectors and International Organization for Standards ISO 15883 for Washerdisinfectors. recently part 4 of ISO 15883 has been released which includes additional information on washerdisinfectors. These standards discuss the need for controls to monitor the operation of the machine to ensure that it successfully processes an endoscope. The monitoring system in the MEDIvATOrS’ Advantage Automated Endoscope reprocessor has been designed to meet or exceed the intent of these standards. The Advantage Independent Safety Control Unit (SCU) has been designed with a totally independent controller that monitors the condition of all the sensors, valves, and motors. When programmed to operate with a specific chemistry, that chemistry’s contact time, operating temperature and other related parameters are monitored. These conditions cannot be altered by the user. In the following pages we will review the industry standards named above and identify the specific areas related to a monitoring system. We will then describe the independent monitoring system (SCU) in the Advantage reprocessor that has been designed to meet these standards. Industry Standards ISO 15883-1:2006(E) states that “The washer-disinfector shall be fitted with means to verify and /or record the attainment of the specified process conditions (Section 5.11.1).” It further states “The nature and extent of monitoring shall be commensurate with the intended use of the load and the risk arising from not detecting a failure to attain the specified value for one or more critical process variables (section 5.11.2).” The ISO document also describes the need for a documented risk analysis in accordance with ISO 14971. ISO 15883-4:2008(E) states that “The temperature of the disinfectant solution throughout the disinfection stage shall be monitored to ensure that it remains within the limits specified by the manufacturer of the disinfectant and be compatible with the temperature limits for the devices(s) to be processed (Section 4.4.3).” It also states “The process monitoring of each operating cycle by the automatic controller shall include verification that the process conditions specified by the WD manufacturer as necessary and sufficient for disinfection to take place (e.g. disinfectant concentration, temperature and contact time) were attained (Section 4.4.4).” MEDIvATOrS Inc. Headquarters 14605 28th Avenue North Minneapolis, MN 55447-4822 USA Tel: +1.800.444.4729 Fax: +763.553.3387 1 MEDIvATOrS Bv Sourethweg 11 6422PC Heerlen The Netherlands Tel: +31.45.5.471.471 Fax: +31.45.5.429.695 www.medivators.com MEDIvATOrS Asia/Pacific Pte Ltd 1 A International Business Park #05-01 Singapore 609933 Tel: +65.6227.9698 Fax: +65.6225.6848 MEDIvATOrS Beijing representative Office room 708, 7th Floor Kaiheng Center, Block B No. 2 Chaoyangmennei Street Dongcheng District, Beijing China 100010 Tel: +8610.6567.8446 Fax: +8610.6567.8445 50096-932 Rev B Product Bulletin The SCU monitors the chemistry conditions using a critical step table. This table contains the required machine steps to insure a properly processed endoscope. It includes the required fluid volumes, temperatures, contact times, etc. to insure every step has been completed in a safe and efficacious manner. The SCU then monitors all of the sensors in the unit to assure that each critical step is completed. Only after all steps have been completed will the SCU allow the lid to be opened and the endoscope removed. If any step is skipped, or any sensor or time requirement missed, the SCU will lock the basin lid and alert the operator with a fault indicator on the control panel. The SCU will keep the lid locked until the operator responds to the condition and acknowledges the failed cycle. The SCU will then ensure that the machine shuts down in a safe manner (such as rinsing the basin if there was disinfectant present when the fault occurred). The SCU is an independent monitor, and a watchdog system has been incorporated between the SCU and the main computer. If communication is ever lost between the two computers, both of them will shut down and indicate an error. The risk management process used on the Advantage system is based on the ISO 14971 process. HTM 2030 contains similar wording related to the monitoring system for washer-disinfectors. In the Operational Management chapter, Section 10, “Washer Disinfectors for Thermo-labile Endoscopes,” the guideline specifies “The washer-disinfector should be equipped with means to provide independent monitoring of all critical cycle variables. This should include means to verify that all channels to be irrigated with cleaning solution are not blocked.” This requirement is repeated again in section 12, “Liquid Chemical Disinfectors”. In the Design Considerations chapter, Section 4, “Specification and Contract; General Design Considerations;” the guideline specifies, “The washer-disinfector should be fitted with means to verify and /or record the attainment of the specified process conditions. The nature and extent of the monitoring should be commensurate with the intended use of the load and the risk arising from the inadvertent use of an improperly cleaned or disinfected load.” The SCU provides a totally independent monitor of all critical cycle variables. All chemistry conditions, machine steps, and information from critical sensors, valves and motors are monitored, recorded, and verified. Should any critical process conditions not be attained, the SCU has an independent indicator which can notify the operator. 2 50096-932 Rev B Product Bulletin Redundant Sensors During the development of the Advantage system, an extensive risk analysis was performed based on the ISO 14971 risk process. As part of this process, any critical sensors that required independent verification by a second sensor were identified. In the case of the inlet flow meters, redundant sensors were incorporated with software checks to assure the same values are read. Additional Checks The development of the Advantage system included controls beyond the required checks and monitors listed above. Additional checks were incorporated in the software which monitor the operation of sensors, valves, and motors in conjunction with one another. As an example, the transition of pressure switches in the hydraulic lines is monitored to ensure they change as motors or valves change the fluid flow in the machine. With this capability, any unusual condition can be detected quickly, and the operator will be notified with the appropriate information so the problem can be resolved in a timely manner. Summary The Advantage system’s SCU provides the independent monitoring and verification required by all the industry standards currently being referenced in Europe. Using a risk analysis based on the ISO 14971 process, Medivators has designed the SCU to provide independent verification of critical sensors and software checks on that verification. To provide a next-generation level of constant feedback to the operator, the SCU performs multiple additional system checks and makes that information quickly available for troubleshooting, should a problem arise. If you have any questions related to this bulletin, please contact Medivators Technical Support at 1-800-444-4729. 3 50096-932 Rev B