Measurements Lab (620451):

advertisement

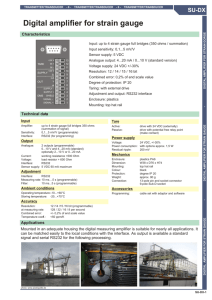

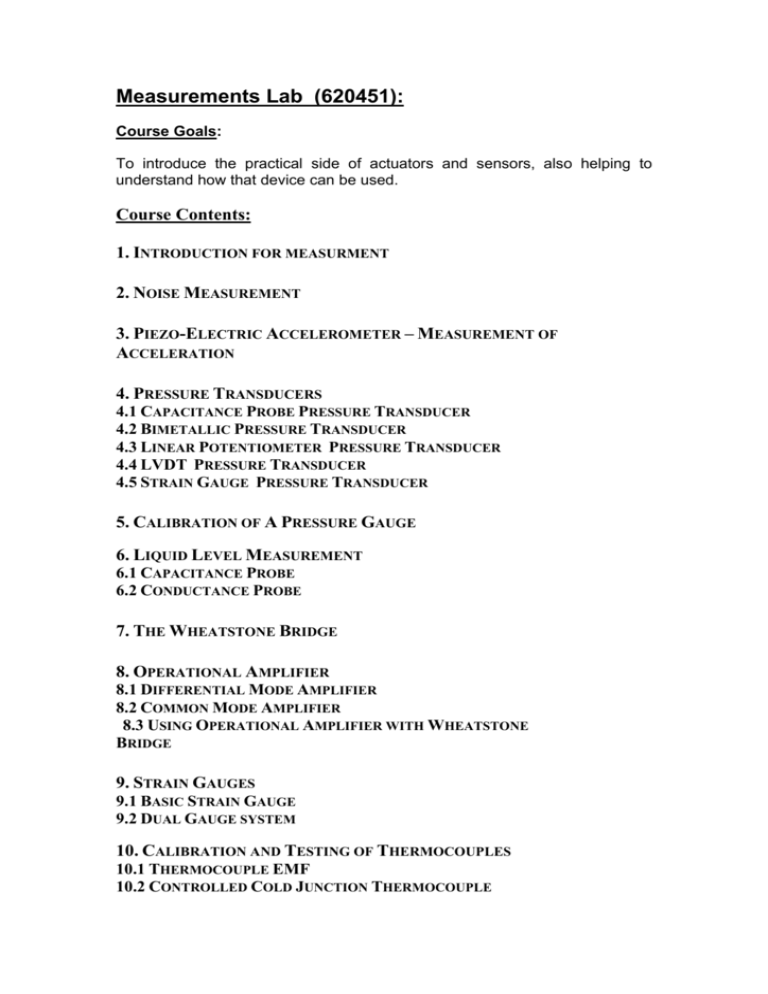

Measurements Lab (620451): Course Goals: To introduce the practical side of actuators and sensors, also helping to understand how that device can be used. Course Contents: 1. INTRODUCTION FOR MEASURMENT 2. NOISE MEASUREMENT 3. PIEZO-ELECTRIC ACCELEROMETER – MEASUREMENT OF ACCELERATION 4. PRESSURE TRANSDUCERS 4.1 CAPACITANCE PROBE PRESSURE TRANSDUCER 4.2 BIMETALLIC PRESSURE TRANSDUCER 4.3 LINEAR POTENTIOMETER PRESSURE TRANSDUCER 4.4 LVDT PRESSURE TRANSDUCER 4.5 STRAIN GAUGE PRESSURE TRANSDUCER 5. CALIBRATION OF A PRESSURE GAUGE 6. LIQUID LEVEL MEASUREMENT 6.1 CAPACITANCE PROBE 6.2 CONDUCTANCE PROBE 7. THE WHEATSTONE BRIDGE 8. OPERATIONAL AMPLIFIER 8.1 DIFFERENTIAL MODE AMPLIFIER 8.2 COMMON MODE AMPLIFIER 8.3 USING OPERATIONAL AMPLIFIER WITH WHEATSTONE BRIDGE 9. STRAIN GAUGES 9.1 BASIC STRAIN GAUGE 9.2 DUAL GAUGE SYSTEM 10. CALIBRATION AND TESTING OF THERMOCOUPLES 10.1 THERMOCOUPLE EMF 10.2 CONTROLLED COLD JUNCTION THERMOCOUPLE Internal Combustion Engines Lab (620546) Course Goals: To introduce the practical side of Internal Combustion Engines. Course Contents: 1. INTRODUCTION 1.1 SPARK IGNITION ENGINES (OTTO CYCLE) 1.2 COMPRESSION IGNITION ENGINES (DIESEL CYCLE) 1.3 KNOCKING (DETONATION) 1.4 BASIC TERMINOLOGY 2. MORSE TEST 3. WILLAN’S LINE TEST 4. FULL LOAD PERFORMANCE 5. HEAT BALANCE 6. SPARK IGNITION ENGINE – IGNITION LOOP 7. SPARK IGNITION ENGINE – MIXTURE LOOP 8. CO ANALYSIS 9. HALF LOAD PERFORMANCE – ENGINE BREATHING 10. FLASH AND FIRE POINTS Mechanical Eng Lab (640346): Course Goals: To introduce the practical side of Fluid Mechanics, Heat Transfer and Strength of Materials. Course Contents: Fluid Meters in Incompressible Flow. Impact of a Jet of Water. Heat Exchangers. Thermal Conductivity. Thermal Radiation & Natural Convection. Fatigue Test. Application of Mechanical Load Cell (Bending). Torsion Test. Tensile Test. Mechanical Vibration Lab(620476) : Course Goals: To introduce the equation of motion for some vibrating system. Course Contents: 1-Mass Spring System 2-Simple Pendulum 3-Compound pendulum 4-Bifilar suspension 5-Torsion oscillation of single rotor 6-Lateral vibrating of Abeam with one or more Bodies Attached 7-Forced Vibration with negligible Damping 8-Un damped Vibration 9-Damped transverse Vibrating 10-Pizo Electrometer – measurement of acceleration 11-Acceleration Experiment 12-Static and Dynamic Balancing 13-Whirling of Rotating Shafts 14-Frequency Response of Vibrating System 15-Torsion Oscillation of Two Rotors Gyroscope Strength and Properties of Material Lab(620366): Course Goals: To introduce the principles of strength and properties of material as a vehicle for engineer applications. Course Contents: ¾ Tensile Test. ¾ Compression Test ¾ Shear Test. ¾ Torsion Test ¾ Impact Test ¾ Fatigue Test. ¾ StrainGauge Measurement. ¾ Creep Test. ¾ Hardness Test. ¾ Application of Mechanical Load Cell. ¾ Corrosion Experiment. ¾ Examination of Material Microstructure. Automatic Control Lab (620457): Course Goals: To introduce the practical side of automatic control, including ON-OFF control, open loop control, closed loop control. Course Contents: 1. INTRODUCTION TO AUTOMATIC CONTROL 2. ADJUSTABLE BI-METALLIC STRIP THERMOSTAT 3. CAPILLARY BULB THERMOSTATIC CONTROLLER 4. ERROR OUTPUT IN THE POSITION CONTROL 5. CLOSED LOOP POSITION CONTROL 6. CLOSED LOOP SPEED CONTROL 7. OPERATIONAL AMPLIFIER AS AN ERROR DETECTOR 8. GAIN OF THE SYSTEM VS. SPEED CONTROL HEAT TRANSFER Lab (620446) Course Goals: To introduce the practical side of heat transfer, also to get a better understanding for the basic modes of heat transfer (Conduction, Convection and Radiation). Course Contents: 1. INTRODUCTION 2. MARCET BOILER EXPERIMENT. 3. THERMAL CONDUCTIVITY 4. NATURAL CONVECTION AND THERMAL RADIATION 5. FORCED CONVECTION 6. HEAT EXCHANGER (Parallel and Counter) 7. HEAT EXCHANGER (Flow Rate Variation) 8. FILMWISE AND DROPWISE CONDENSATION 9. AIR CONDITIONING (HEAT PUMP) 10. AIR CONDITIONING (AIR COOLER) Fluid Mechanics Lab(620336): Course Goals: To introduce the practical side of fluid mechanics. Course Contents: Introduction (Density, Surface Tension and Viscosity). Flow Measurements. Impact of Jet. Open Channel Flow (Sluice gate, Weirs, Hydraulic Jump and Manning Formula). Losses in pipes. Pressure Distribution about a Circular Cylinder. Drag Force Determination. Analysis of an Airfoil. Turbine and Pump Unit. Mechanical Drawing (620221): Course Goals: The main purpose of this course is to give the basics of Drawing Techniques through Mechanical Parts. Course Contents: 1- (2-D) drawing (Manual+ Mechanical Desktop) 2- (3-D)drawing(isometric and oblique for Manual+ Mechanical Desktop) 3- Screws (Manual+Mechanical Desktop) 4- Views(Manual+Mechanical Desktop) 5- Tolerance(Manual+Mechanical Desktop) 6- Options in Mechanical Desktop Engineering Workshop(620161): Course Goals: To teach the students to respect the technical work and discipline, also to gain hand and technical skills. Course Contents: Engineering materials principle Basic measuring instruments (Vernier caliper, micrometer, dial gauge, …etc.) Various manufacturing processes: − Forming processes (Forging, Bending and Shearing). − Metal cutting (Turning, Milling, Drilling, Reaming and Grinding). − Metal joining (Soldering, Welding: Electric, Arc welding, Gas welding and Spot welding. Mechanical fasteners: Screws, Bolts, Nuts and Rivets). − Sand Casting Safety regulations in workshop.