Example: Gauge Capability Analysis

advertisement

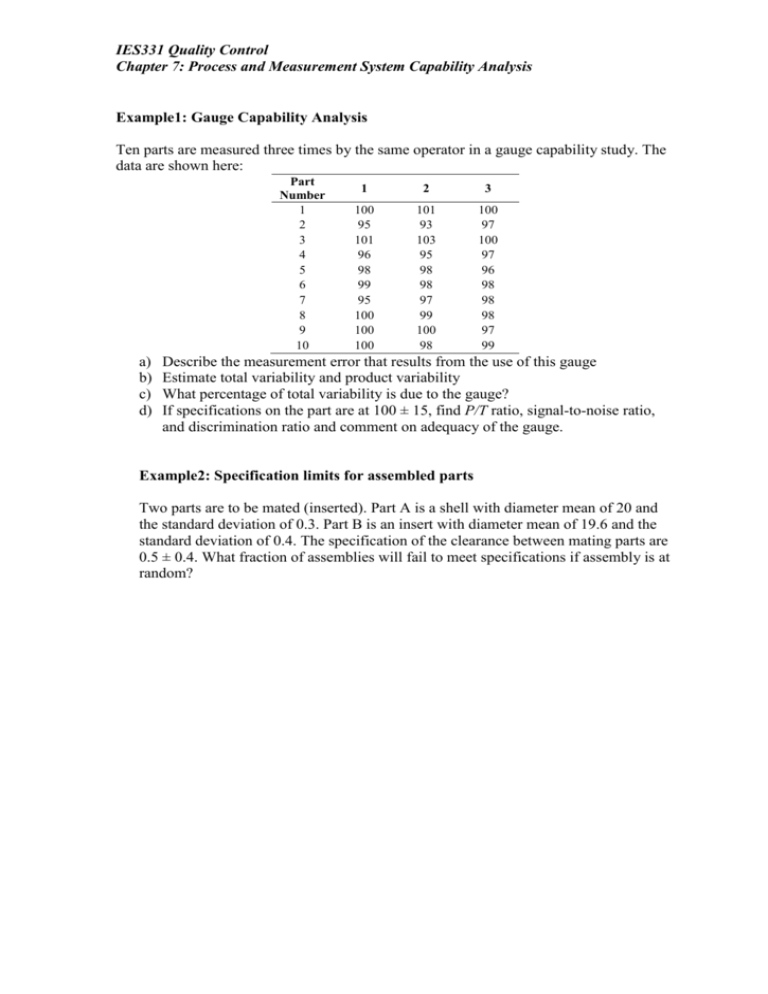

IES331 Quality Control Chapter 7: Process and Measurement System Capability Analysis Example1: Gauge Capability Analysis Ten parts are measured three times by the same operator in a gauge capability study. The data are shown here: Part Number 1 2 3 4 5 6 7 8 9 10 a) b) c) d) 1 2 3 100 95 101 96 98 99 95 100 100 100 101 93 103 95 98 98 97 99 100 98 100 97 100 97 96 98 98 98 97 99 Describe the measurement error that results from the use of this gauge Estimate total variability and product variability What percentage of total variability is due to the gauge? If specifications on the part are at 100 ± 15, find P/T ratio, signal-to-noise ratio, and discrimination ratio and comment on adequacy of the gauge. Example2: Specification limits for assembled parts Two parts are to be mated (inserted). Part A is a shell with diameter mean of 20 and the standard deviation of 0.3. Part B is an insert with diameter mean of 19.6 and the standard deviation of 0.4. The specification of the clearance between mating parts are 0.5 ± 0.4. What fraction of assemblies will fail to meet specifications if assembly is at random?