A brand new bag for the "Roll Your Own"

advertisement

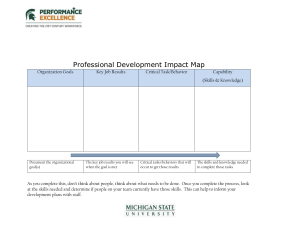

18 | packazine Customers & Markets Other Markets In 2001, Farmer’s Tobacco of Cynthiana, Packaging requirements After product sorting and check weigh- Inc. (Cynthiana, Kentucky), launched Farmer’s Tobacco had already decided ing, the filled tobacco bag is presented the Kentucky’s Best brand of whole- on two sizes (6 oz. and 16 oz.) of poly- to the Bosch B-500 sealer, which applies leaf tobacco cigarettes. Recently, the ethylene bags. The clear packaging film the final seal, after which the finished company saw an opportunity to expand was critical for success in the RYO mar- product is placed in secondary packag- this established brand with a product ket as research indicated that consumers ing for distribution. The weighing and line extension. As a result of higher tax like to view the product to inspect its sealing process is conducted by one rates on carton cigarettes, there has quality. A resealable closure was also operator, an important requirement from been increasing demand for “roll your important as it ensures freshness during Farmer’s Tobacco to keep labor costs own” (RYO) tobacco delivered in a bag use and storage. format. This represented a significant opportunity to expand the Kentucky’s Best brand into the RYO market. down and simplify operations. A key benefit the machine offers is the Packaging machinery solution precise placement of seals. Placing the A critical component of the operation was the band sealer from Doboy, a Having concentrated exclusively on Bosch Packaging Technology brand. The pre-made cigarettes in cartons, Farmer’s B-500 Continuous Band Sealer offered Tobacco required an entirely new industrial performance in a compact packaging solution to offer its tobacco in size, which was an ideal solution for the RYO format. A key requirement was a company attempting to upgrade its a resealable bag that would keep the operations and enter a niche market in a tobacco fresh during storage and use. An cost-effective manner. additional need was a flexible solution that would allow different bag sizes and future packaging line upgrades. 1 packazine | 19 A Brand New Bag: New packaging solution for the “Roll Your Own” market Farmer’s Tobacco breaks into the “roll your own” market with packaging solution seal too high up on the bag may cause length urethane time belts gripping the minute. This ensures that, if demand the seal to be ruined on initial opening bag to ensure consistent speed and bag rises, Farmer’s Tobacco could add two and inhibit resealable functionality, control. Heating and cooling bars provide weighing and filling stations, or even whereas placing it too low may cause consistent pressure throughout the seal- augment line capacity with an automated product bunching and affect quality. A ing process. infeed, and still continue sealing with the consistent, reproducible seal is an im- B-500. portant packaging feature, especially for With manual feeding into the sealer, the a newly launched product, as consumers B-500 currently runs 12–14 inches per For more information please contact: must be able to open and re-close the minute (6–8 bags per minute). However, Mark Larson package and access the product in a the machine is also designed for higher Phone +1 715 243 2255. convenient way. The B-500 accomplishes speed applications and can process mark.larson@bosch.com this seal with bag top control, with full linear speeds up to 750 inches per 1 Sealing bars ­produce 6 mm ­wide seals 2 Doboy B-500 Band Sealer 2