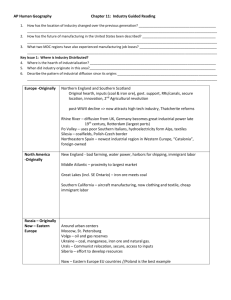

Center for Applied Textile Technology

advertisement