52A2965A 1 1 INTRODUCTION FOR ANALYTICAL OVERVIEW 3 2

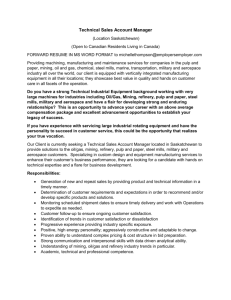

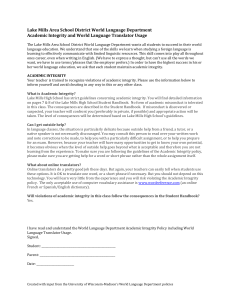

advertisement