The Kinetics and Mechanism of a Reaction Catalyzed by Bacillus

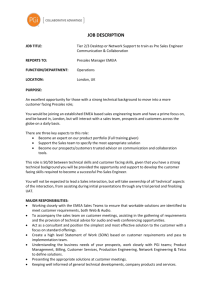

advertisement

JOURNALOF FERMENTATION ANDBIOENGINEERING Vol. 86, No. 3, 324-331. 1998 The Kinetics and Mechanism of a Reaction Catalyzed by Bacillus stearothermophilus Phosphoglucose Isomerase ARIEF WIDJAJA,’ MASAHIRO SHIROSHIMA,’ TAKASHI OKA,’ MASAHIRO YASUDA,’ HIROYASU KAZUTAKA MIYATAKE,2 HIROSHI NAKAJIMA,3 AND HARUO ISHIKAWA’* OGINO,’ Department of Chemical Engineering,’ Department of Applied Biological Chemistry,2 Osaka Prefecture University, 1-I Gakuen-cho, Sakai, Osaka 599-8531 and Basic Technology Department, Research and Development Center, Unitika Ltd., 23 Kozakura, Uji, Kyoto 611-0021,3 Japan Received 6 April 199WAccepted 18 June 1998 The initial rates of isomerization between glucose 6-phosphate and fructose Q-phosphate catalyzed by Bacillus stearothermophilus pbospboglucose isomerase (PGI) were measured in both the forward and reverse reactions. Although B. stearothermophilus PGI is a tetrameric enzyme, the reaction rate vs substrate concentration curves for both reactions exhibited Michaelis-Menten kinetic behavior. This was confirmed by the Hill plot which gave the Hill coefficient of 1.0 for both reactions. Based on the above experimental results and another experimental result that the number of substrate or product binding sites on the PGI molecule was 4, we propose a reaction scheme which is able to explain Michaelis-Menten kinetic behavior of this oligomeric enzyme, and determine the kinetic parameters. [Key words: kinetics, fructose 6-phosphate] mechanism, tetrameric enzyme, Materials from Unitika isomerase, glucose 6-phosphate, SDS-polyacrylamide gel electrophoresis was purchased from New England Biolabs, Inc. (Massachusetts, USA), and that for gel chromatography was from Serva Feinbiochemica GmbH. & Co. (Heidelberg, Germany). Monosodium salt of G6P and disodium salt of F6P were purchased from Sigma (St. Louis, MO, USA), ~-[l-l~C]glucose 6-phosphate from NEN (Tokyo), and glucose 6-phosphate dehydrogenase (G6PDH), NADP+, triethanolamine (TEA), MgC12, and other chemicals from Wako Pure Chemical Ind. Ltd. (Osaka). Solutions were made up in 0.1 M TEA buffer solutions containing 0.1 M HCl and adjusted to pH 8.0 using an aqueous KOH solution. Stability of B. stearothermophilus PGI To study the stability of B. stearothermophilus PGI, a solution containing 2.1 x 1O-5 mM PGI in 0.1 M TEA buffer (pH 8.0) was incubated at 30°C. After various incubation periods, 50,ul aliquots of the enzyme solution were taken and each was added to 2950~1 of a reaction mixture containing 8.40 mM F6P, 1.0 mM NADP+, 2.0U/ml G6PDH in 0.1 M TEA buffer (pH 8.0). The activity of the enzyme was measured by determining the rate of G6P formation by the reverse reaction at 30°C using the method described below. Gel chromatography and SDS-polyacrylamide gel electropboresis Gel chromatography experiments were performed using a Hiload 16/60 Superdex 200 p.g. gel filtration column which was equilibrated with 10 mM Tris-HCl buffer containing 150mM NaCl. Two ml of 1.32 x 10 4 mM PGI solution was loaded onto the column and was eluted at a rate of 1 ml/min at 4°C with the same buffer. As a standard, a mixture containing the marker proteins DNP-r.-alanine (molecular mass: 0.255 kDa), cytochrome C (12.3 kDa), myoglobin (17.8 kDa), chymotrypsinogen A (25 kDa), egg albumin (45 kDa), bovine serum albumin (67 kDa), rabbit muscle aldolase (160 kDa), bovine catalase (240 kDa), and horse spleen ferritin (450 kDa) was applied to the same column. SDS-polyacrylamide gel electrophoresis was performed Phosphoglucose isomerase (PGI: D-glucose 6-phosphate ketoisomerase; EC 5.3.1.9) is widely distributed in nature and catalyses the isomerization reaction between glucose 6-phosphate (G6P) and fructose 6-phosphate (F6P). PGI is physiologically very important as it is an enzyme of the glycolytic pathway. Furthermore, PGI plays an important role in the industrial production of fructose 1,6-diphosphate (FDP), which is expected to be useful for various medical applications, from glucose (1). Purification of PGI has been achieved from mesophilic sources, such as human erythrocyte (2, 3), spinach leaves (4), brewer’s yeast (5, 6), and rabbit muscle (7), as well as from thermophilic sources, such as Bacillus caldotenax (8) and Bacillus stearothermophilus (9). For analytical or industrial applications thermophilic PGI is suitable due to its high thermostability. There is some information available concerning the kinetics and mechanism of the reaction catalyzed by the mesophilic PGI, however almost none exists concerning the kinetics and mechanism of the reaction catalyzed by the thermophilic PGI. In the present work, the initial rates of both the forward and reverse reactions of the isomerization between G6P and F6P catalyzed by PGI of the thermophilic organism B. stearothermophilus at pH 8.0 and 30°C under various G6P or F6P concentration conditions, and the time courses of the increase in the G6P concentration produced by the reverse reaction were measured. Furthermore, experiments concerning the molecular mass of the enzyme and the number of substrate or product binding sites per molecule were performed. Based on these experimental results, we propose a reaction mechanism. MATERIALS phosphoglucose AND METHODS B. stearothermophilus PGI was obtained Ltd. (Osaka). The protein marker kit for * Corresponding author. 324 VOL. 86, 1998 REACTION MECHANISM OF B. STEAROTHERMOPHKUS at 10 mA for 4 h according to the method of Weber and Osborn (10) at a 7% gel concentration. As a standard, a mixture containing the marker proteins MBP-/3-galactosidase (175 kDa), MBP-paramyosin (83 kDa), glutamic dehydrogenase (62 kDa), aldolase (47.5 kDa) and triosephosphate isomerase (32.5 kDa), was used. The number of substrate or product binding sites on The number of substrate B. stearothermophilus PGI or product binding sites on PGI was measured by the dialysis equilibrium method (11). The experiments were carried out in a dialysis equilibrium apparatus consisting of two jacketed acrylic resin cells each with a working volume of 0.7 ml. Temperature-regulated water was circulated inside the jackets to maintain the temperature at 30°C. A Teflon-coated magnetic stirrer bar was placed in each of the cells to stir the liquid inside the cells. One of the compartments (compartment I) was filled with 0.1 M TEA buffer (pH 8.0) containing 52 PM PGI, while the other (compartment II) was filled with 0.1 M TEA buffer containing 0.15-10mM G6P which contained D-[l14C]-G6P. The ratio of the labeled G6P molar concentration to the total G6P molar concentration ranged from 0.00021 to 0.19 when the buffers containing labeled G6P were prepared. As in previous investigations, Visking Cellophane dialysis tubing was used as a membrane for separating the two compartments. Twenty-five ~1 of liquid sample was taken from each compartment for determination of the concentration of labeled G6P using a liquid scintillation counter (Wallac 1409 model, Pharmacia). In the present experiment, the total concentrations of D-[~-‘~C]-G~P and D-[~-‘~C]-F~P, and of G6P and F6P were measured because F6P was produced by the catalytic action of the enzyme. When equilibrium was attained between the solutions in the two compartments, the next run was carried out by replacing the solution in compartment II with fresh ligand (G6P) solution of a different concentration. A small amount of the enzyme solution was added to compartment I to compensate for the sample withdrawn for analysis. The time required to attain the equilibrium state was 4 d. The total concentration of ligands (G6P and F6P) bound to the enzyme was determined by the difference in concentrations between the two compartments. The initial rates of the forward reaction To obtain the initial rates of the forward reaction of the isomerization between G6P and F6P (the reaction in which G6P is the substrate and F6P is the product), the F6P concentrations were measured by the calorimetric method described by Roe (12). A 10 ml-volume vial, with a jacket in which temperature-regulated water at 30°C was circulated, was used as the reactor. Fiveml of a substrate solution containing 0.3-25 mM G6P in 0.1 M TEA buffer (pH 8.0) was stirred with a Teflon-coated magnetic stirrer bar. After the solution temperature reached 30°C 100/d of the enzyme solution (the final concentration was 1.97 x lo- 7 mM PGI) was added to the solution to initiate the reaction. At appropriate time intervals, liquid samples of 1 ml each were taken and mixed immediately with 4 ml of a 0.01 M HsP04 solution (pH 1.6) to stop the reaction. The analytical procedure was as follows: (i) 0.4 ml of ethanol containing 0.5% wt. resorcinol and 1Oml of 36% HCl were added to 5 ml of the sample solution, and the mixture was stirred vigorously. (ii) The mixture was heated in a water bath at 80°C for 8 min, and then cooled to 25°C. (iii) Using a Shimadzu UV-2100 spectrophotometer (Shimadzu Co. Ltd., Kyoto) PGJ 325 the absorbance was measured at 405 nm to determine the F6P concentration. To measure The initial rates of the reverse reaction the initial rates of the reverse reaction of the isomerization between G6P and F6P (the reaction in which F6P is the substrate and G6P is the product), the G6P formed was converted to a stoichiometrically equivalent amount of NADPH according to the following reaction: G6P+NADP+G= glucono-&lactone 6-phosphate +NADPH (1) Then, the formation of G6P was followed indirectly by measuring the absorbance change due to NADPH formation at 340nm (~~~=6220 M ~‘.crn~ ‘) using the Shimadzu UV-2100 spectrophotometer. The reactions were carried out at 30°C in total volume 3.0 ml of 0.1 M TEA buffer (pH 8.0) containing 0.05-7.0mM F6P, 2.0U/ml G6PDH, and 5.26~ 10 ’ 1.0 mM NADP+, mM PGI. Time courses of the increase in G6P concentration produced by the reverse reaction To measure the time courses of the G6P concentration produced by the reverse reaction, 100 ,nl of the enzyme solution (the final concentration was 5.26x lop6 mM PGI) was added to the reactor containing 2- 10mM F6P in 0.1 M TEA buffer (pH 8.0) to start the reaction. At appropriate time intervals, 200ml aliquots of liquid samples were taken and each was mixed promptly with 0.8 ml of HjPOd (pH 1.6) to stop the reaction. Then, to these solutions NADP+ and G6PDH were added (the final concentrations were 1 mM and 0.1 U/ml, respectively), and the concentrations of G6P produced were measured by following the absorbance change due to NADPH formation at 340 nm using the spectrophotometer. RESULTS AND DISCUSSEON Stability of B. stearothermophilus PGI Figure 1 shows the experimental results as a plot of the relative remaining activity vs the incubation period on a semilogarithmic scale. As shown in the figure, the experimental results were correlated well with a straight line generated by the linear regression method. The slope of the straight line gave the inactivation rate constant of the enzyme, kd=1.76x lop4 hh’, which was equivalent to a half-life of 164 d. This result assured us that the effect of enzyme inactivation on the isomerization reaction was negligible in all the reaction experiments because the measurements of the time courses of the G6P or F6P concentration were always completed within 90 min. However, 3.7% inactivation of PGI may have occurred during the dialysis equilibrium experiments where the longest experimental period was 12 d. We do not believe that this inactivation led to significant errors in the determination of the number of binding sites of the enzyme. Gel chromatography and SDS-polyacrylamide gel electrophoresis The experimental elution volumes of DNP-L-alanine, cytochrome C, myoglobin, chymotrypsinogen A, egg albumin, bovine serum albumin, rabbit muscle aldolase, bovine catalase, and horse spleen ferritin were 126.2, 98.0, 94.4, 91.8, 82.0, 75.4, 67.4, 65.8, and 44.0 ml, respectively. These experimental results are well described by the following equation: In m=17.7078-0.0842 I’,, (2) 326 WIDJAJA ET AL. J. FERMENT. BIOENG., kDa ._: 140.” d ” 0 1’ 100 ” 83 200 Time (d) FIG. 1. Stability of B. stearothermophilus PGI. The experimental relative remaining activity was plotted against the length of incubation period. A solution containing 2.1 x 10ds mM PGI (1.58 U/ml) in 0.1 M-TEA buffer (pH 8.0) was incubated at 30°C. After various incubation periods, 50 ,ul aliquots of the enzyme solution were taken and each was added to 2950~1 of a reaction mixture containing 8.4OmM F6P, l.OmM NADP+, 2.0U/ml G6PDH in 0.1 M TEA buffer (pH 8.0). The activity of the enzyme was measured by determining the rate of G6P formation by the reverse reaction at 30°C using the method described in the experimental section. 62 -- 47.5 32.5 where m and Vel represent the molecular mass [Da] and the elution volume [ml], respectively. In correlation analysis, the data for DNP-L-alanine and horse spleen ferritin were excluded because their molecular masses are too small and too large, respectively, compared with that of the enzyme PGI. When PGI was applied to the column, the elution volume was 66 ml. Therefore, the molecular mass of PGI was determined to be 189 kDa using Eq. 2. This value was in good agreement with the values reported by Unitika (200 kDa; Enzymes, p. 73, a brochure published by Unitika) and by Muramatsu and Nosoh (172 kDa) (9). The concentration of the enzyme PGI expressed throughout this paper was calculated based on the molecular mass of I89 kDa. Figure 2 shows the result of the SDS-polyacrylamide gel electrophoresis of B. steurothermophilus PGI. Only one band corresponding to a molecular mass of 50 kDa appeared. From this result and that of the molecular mass, we conclude that B. stearothermophilus PGI consists of four subunits of identical molecular mass. Takama and Nosoh (8) found that B. caldotenax PGI consists of four identical subunits based on the results of dansylation and cyanogen bromide cleavage of the enzyme. Furthermore, they found that it shares many common properties with B. stearothermophilus PGI. The experimental results obtained in the present work are in good agreement with their findings. The number of substrate or product binding sites of In order to clarify the mechanism of the isomeriPGI zation reaction between G6P and F6P, it is very important to know the number of substrate or product binding sites of B. stearothermophilus PGI. The number of binding sites on a protein for ligands (small molecules or ions) can be determined using the following equation (13, 14). [Fl@WW[Bl =Kd (3) Here, Kd represents the dissociation constant, [F] the concentration of free ligand, [B] the concentration of bound ligand per total protein concentration and n the number of binding sites. By plotting the experimental results as [B]/[F] vs [B], the number of binding sites and FIG. 2. SDS-polyacrylamide gel electrophoresis of B. sfearothertnophilus PGI. SDS-polyacrylamide gel electrophoresis was performed at 10 mA for 4 h at a 7% gel concentration. As a standard (lane 3) a mixture containing the marker proteins MBP+galactosidase (175 kDa), MBP-paramyosin (83 kDa), glutamic dehydrogenase (62 kDa), aldolase (47.5 kDa) and triosephosphate isomerase (32.5 kDa), was used. The single band (lanes 1 and 2) obtained corresponds to the molecular mass of 50 kDa. the dissociation constant can be obtained from the intercept of the abscissa and the slope of the straight line, respectively. This method is valid in principle when small molecules or ions bind to proteins without any catalytic action by the proteins after binding. However, several investigators (11, 15, 16) successfully used this method to determine the number of substrate or product binding sites of an enzyme. There are three possibilities concerning the number of the binding sites of the tetrameric enzyme PGI. First, there are four binding sites per molecule. In this case, the enzyme works as a tetrameric enzyme as it consists of four active units. Second, there are two binding sites, and the enzyme works as a dimer-like enzyme. Third, there is only one binding site so that the tetrameric PGI works as a monomer-like enzyme. The results of the dialysis equilibrium experiments are given in Table 1. The values of [B] and [F] calculated from the data are shown in Fig. 3 as a plot of [B]/[F] vs [B]. The largest experimental [B] value was 3.1. It is clear that the number of the binding sites on the enzyme is neither one nor two. The figure shows that the data points may be correlated by a straight line or a convex downward curve. The straight line which correlates the data points intersects the abscissa at a [B] value of about 3.4. However, a convex downward curve will intersect at a [B] value which is greater than 3.4. Because there is no possibility that the number of the binding sites is 3, it can be concluded that the number of the binding site on B. stearothermophilus PGI is four, that is, one binding site per subunit. REACTION MECHANISM OF B. STEAROTHERMOPHIL VOL. 86, 1998 TABLE 1. Run no. 1 2 3 4 5 6 Total amount of ligandsb in compartments 1 and 11 Wmol) 6.93 I.37 0.646 0.357 0.180 0.108 US PGI 327 Results of dialysis equilibrium experiments Total count in compartment 1 (dpm) 8.00X 104 6.98 x lo5 3.32 X 10’ 5.99 x 105 2.99 x 105 1.30x 106 Total count in compartment II (dpm) 7.75 x IO” 6.22 x lo5 2.85 X lo5 4.85% 105 2.37~ lo5 9.91 )r 105 Total concentration of ligandsb in compartment 1 (M) 5.03 x 10-j 1.03x10 J 4.97 x 10 4 2.82- 10 4 1.44* 10 ‘I 8.72~ 10m5 Total concentration of ligandsb in compartment Ii (M) 4.87:t 10 3 9.22,, 10 j 4.26:. 10 -I 2.28 ‘<10 4 1.14:. 10 4 6.68 10 5 a dpm=disintegrations per minute. b ligands=both the substrate G6P and the product F6P. Columns 3 and 4 show the total counts [dpm] for the labeled ligands in compartments 1 and II, respectively. Column 5 shows the total concentration of the free and bound ligands in compartment I. Column 6 shows the total concentration of the free ligands in compartment II. From the experimental results of Run no. 1, the values of [B] and [F] can be calculated as follows: as the working volume of each compartment was 0.7 ml, the total concentration of the ligands in compartment 1 is calculated as (8.00x 104/(8.00X 104+7.75X 104)X6.93)/0.7/1000=5.03x 10m3M The total concentration of the ligands in compartment 11, which is equal to [F], is calculated in the same way. The total concentration of ligands bound to the enzyme is given by the difference between the concentrations shown in columns 5 and 6. Using an enzyme concentration of 52 PM, [B] is calculated as: [B]=(5.03 x 10m~3-4.87 % 10m3)/52x IO- 6=3.1 For other runs, the values of [B] and [F] can be calculated in the same way. Initial reaction rates of the forward and reverse reactions Figure 4 shows the experimental forward reaction rates as a plot of the reaction rate v vs the G6P concentration [G6P], and Fig. 5 the experimental reverse reaction rates as a plot of -v vs the F6P concentration [F6P]. The lines in these figures are the theoretical ones and will be explained later. Both the figures show that the Iv I -[S] curves are hyperbolic, indicating that both the reactions exhibit Michaelis-Menten kinetic behavior. To check Michaelis-Menten kinetic behavior, the data shown in Figs. 4 and 5 were replotted as I v I /(v,,/ v I) vs [F6P] or [G6P] on a logarithmic scale in Figs. 6 and 7, respectively. In both figures, the data could be correlated well with a straight line. From the slopes of the straight lines, the Hill coefficients were determined to be 1.0 in both the cases. This demonstrates that the I v I -[S] curves of the forward and reverse reactions exhibit Michaelis-Menten kinetic behavior despite the fact that B. stearothermophifus PGI is a tetrameric enzyme, each of the subunits having one substrate or product binding site. Time courses of the increase in G6P concentration of the reverse reaction Figure 8 shows the time courses of the increase in the G6P concentration formed by the _r 6000 - E g 4000 - reverse reaction. As can be seen in the figure, the higher the initial concentration of F6P, the longer it takes to reach equilibrium. However, 90min was a sufficient period of time for the four initial F6P concentrations tested to reach equilibrium. The lines appearing in the figure are the theoretica values which will be explained later. Mechanism As shown above, B. stearothermophilus PGI is a tetrameric enzyme consisting of four subunits, each of which has one binding site for substrate or product. Furthermore, the Iv ~-[S] curves of the forward and reverse reactions of isomerization between G6P and F6P catalyzed by B. stearothermophilus PGI exhibited Michaelis-Menten kinetic behavior. This was confirmed by the Hill plots which give the Hill coefficient of 1.0 for both the reactions. The v- [S] curves of the reactions catalyzed by oligomerit enzymes usually exhibit sigmoidal behavior and sometimes exhibit Michaelis-Menten kinetic behavior. The sigmoidal behavior of the v- [S] curves of the reactions catalyzed by oligomeric enzymes was fully analyzed by Monod et al. (17) and Koshland et a/. ( 18). However, . 0 0 a E a 2000 - 0 0 ~‘~~I~,~~I~,*~‘~“’ 0 I 2 3 IBl (-) W[Fl vs [Bl. WPI 4 FIG. 3. Plot of [B]/[F] vs [B] to determine the number of binding sites of B. steurothermophilus PGI. The dialysis equilibrium experiments were carried out to determine the number of substrate or product binding sites on PGI. The values of [B] and [F] were calculated from the data shown in Table 1 and are shown as a plot of 0.01 FIG. 4. 0.02 0.03 (M) Initial rates of the forward reaction catalyzed by B. sfearothermophilus PGI. The initial rates of the forward reaction were measured at 30°C in 0.1 M TEA buffer (pH 8.0) containing 0.325 mM G6P and 1.97 x 10 -’ mM PGI. F6P concentration was determined by the calorimetric method described by Roe. The detailed procedure is described in the experimental section. The solid line was calculated using Eq. 6 and the kinetic parameters kl and KS listed in Table 2. 328 WIDJAJA ET AL. J. FERMENT.BIOENG., . 0 I I I 0.002 0.004 0.006 lF6PJ I 0.008 (M) FIG. 5. Initial rates of the reverse reaction catalyzed by B. sfeurothermophilus PGI. The initial rates of the reverse reaction were measured at 30°C in a total volume of 3.0ml of 0.1 M TEA buffer @H 8.0) containing 0.05-7.0 mM F6P, 1.OmM NADP c, 2.0 U/ml G6PDH, and 5.26 x lo-’ mM PGI. The formation of G6P was followed indirectly by measuring the absorbance change due to NADPH formation at 340nm (&s@=6220 Mm1.crn--‘) using a Shimadzu UV2100 spectrophotometer. The solid line was calculated using Eq. 7 and the kinetic parameters k, and KP listed in Table 2. Michaelis-Menten behavior of the reactions catalyzed by oligomeric enzymes has not yet been analyzed in full. Ishikawa et al. (19) studied the effects of the reaction schemes and the kinetic parameters on the co-operativity of the reaction catalyzed by a dimeric enzyme. For the reaction StiP catalyzed by a dimeric enzyme, the reaction schemes were considered on the basis of the KNF model (18). The rate equation for each of the possible schemes was derived on the basis of the combined steady-state and rapid-equilibrium assumptions. They found that even if interaction occurred between the distinct protomers or subunits, the sigmoidal rate behavior was not necessarily observed. On the other hand, the deviation of the V- [S] curve from the hyperbola associated with Michaelis-Menten kinetic behavior could be observed even if there was no interaction between the distinct protomers or subunits. Thus, they found that Michaelis-Menten kinetic behavior could be observed to occur even for a reaction catalyzed by an oligomeric 100 k 0.0001 0.00001 0.001 W’l 0.01 (MI FIG. 7. Hill plot of the initial rates of the reverse reaction catalyzed by B. stearothermophilus PGI. The data shown in Fig. 5 were replotted as 1v //(v,,/vi) vs [F6P]. The data in the region where O.l< /vl/(v,,1v I)< 10 were correlated by a straight line using the linear regression method. From the slope of the straight line, the Hill coefficient was determined to be 1.O. enzyme. Based on the above theoretical analysis, Ishikawa et al. (20) clarified the kinetics and mechanism of the ATP regeneration reaction catalyzed by B. stearothermophilus acetate kinase, which consists of four subunits but can be treated as a dimer-like enzyme because its functional unit consists of two subunits (21). The rate equation derived based on the Random Bi Bi mechanism and on the KNF model offered a good explanation of the experimental Iv 1- [S] curves in which the forward reaction exhibited Michaelis-Menten behavior while the reverse reaction exhibited sigmoidal behavior. We believe that this was the first investigation which clarified wholly the kinetics and mechanism of a reversible reaction catalyzed by an oligomeric enzyme. 0.008 , 1 I I 0.006 _j E ii; 0.004 Z 0.002 0 I 0 20 I I I 40 60 , I 80 , 100 Time (min) WPI Of) FIG. 6. Hill plot of the initial rates of the forward reaction catalyzed by B. stearothermophilus PGI. The data shown in Fig. 4 were replotted as v/(v,,,- v) vs [G6P]. The data in the region where 0.1< V/(Y,, -v)< 10 were correlated by a straight line using the linear regression method. From the slope of the straight line, the Hill coefficient was determined to be 1.O. FIG. 8. Time courses of the increase in G6P concentration. The time courses of the increase in G6P concentration produced by the reverse reaction were measured at 30°C in 0.1 M TEA buffer (pH 8.0) containing 5.26 X 10m6mM PGI. F6P concentrations were 2 mM (A), 3 mM ( n ), 5 mM (+) and 10 mM (0). At appropriate time intervals, 200 ~1 aliquots of the liquid samples were taken and each was mixed promptly with 0.8 ml of HXPOI (pH 1.6) to stop the reaction. Then, to these liquid samples NADP+ and G6PDH were added (the final concentrations were 1 mM and 0.1 U/ml, respectively), and the concentrations of G6P produced were measured spectrophotometrically by following the absorbance change due to NADPH formation at 340 nm. VOL. 86, 1998 REACTION In the present work, efforts were made to find a plausible reaction scheme that could explain MichaelisMenten kinetic behavior of the isomerization reaction between G6P and F6P catalyzed by B. stearothermophilus PGI, a tetrameric enzyme. According to Ishikawa et al. (19), the rate equations for the single substrate-single product/dimeric enzyme system reduced to the Michaelis-Menten rate equation under some special conditions if the reaction scheme did not include the reaction step between the complexes ESS and EPP. Therefore, a similar approach was adopted in this single substrate-single product/tetrameric enzyme system. Figure 9 shows a simplified scheme in which the reactions between the complexes ESS and EPP, ESSS and EPPP, and ESSSS and EPPPP are neglected. In the scheme, E represents a tetrameric enzyme consisting of four subunits, each of which has one binding site for S or P, and S and P are the substrate (G6P) and the product (F6P), respectively. ES and EP represent complexes in which one of the subunits is bound to S and to P, respectively. ESP represents a complex in which one of the subunits is bound to S and another one is bound to P. As in the case of the single substrate-single product/ dimeric enzyme system (19), further simplifications were introduced in order to reduce the number of kinetic constants to the same as or less than that of the experimentally obtainable kinetic parameters: The binding rates of the substrate to both the free enzyme and the enzyme complex, and the dissociation rates of the product from the enzyme complex are much faster than those of the reactions in which a change in the molecular structure of the substrate or the product occurs. Therefore the rapidequilibrium assumption was applied to steps l-20, and the steady state assumption was applied to steps 21-30 in the scheme shown in Fig. 9. The rate equation for the scheme can be derived by the method of King and Altman (22) or others. However, because of the number of reaction steps in the scheme proposed in the present work, the use of a computer program developed by the present authors, which is an advanced version of the previous program (23), is necessary. The rate equation derived was as follows. v= -d[S]/dt==d[P]/dt MECHANISM ESSS ESSSSFIG. 9. OF B. STEAROTHERMOPHILUS r-, ESSP N-% ESSSP A ESPP dh ESSPP +% PGI 329 EPPP ESPPP @+ EPPPP A scheme of the reaction catalyzed by B. stearothermophilus PGI. A simplified scheme was proposed to explain the isomerization reaction catalyzed by B. stearothemophilus PGI. E represents a tetrameric enzyme consisting of four subunits, each of which has one binding site for S or P, and S and P are the substrate (G6P) and product (F6P), respectively. ES and EP are the complexes in which one of the subunits is bound to S and to P, respectively. ESP is the complex in which one of the subunits is bound to S and another one is bound to P. Other symbols are defined in a similar manner. + indicates the steps to which the rapid-equilibrium assumption was applied, and - indicates the steps that the steady-state assumption was applied. stants as described by Segel (24). As the enzyme consists of four subunits, there are four sets of the intrinsic constants, that is, one for each of the four subunits. However, if the active sites are identical and completely independent of each other, the presence of a substrate or a product at one site will have no effect on the binding properties of the other sites (24). In this special case, it is sufficient to use only one set of the four intrinsic constants, kf, k,, KS and KP. The effective constants KTi-, o=l-lo), Kzj o=l-lo), kfj u=21-30) and ki u=21-30) were related to the intrinsic constants KS, KP, kf and k,, respectively, by a similar method to that reported by Segel (24), and the relationships obtained were substituted into Eq. 4 to give the following equation. v= -d[S]/dt=d[P]/dt (4&~f[~l-4~Pk[pI) = x [U +~s~~l~3~~~+~~~~I~3+~~sK~~~l~~1~~-t~~~~l+~s~~I~IIlElo (I +&lW+(I +&lP1)4+ I2KsK,lPllSl t lX&[P]*[S] t 1X~~p[P][S]2t6K~~;[P]z[S]2 t 4K$p[P])[s] t 4@p[P] [S]3- 1 (5) Equation 5 has only two rate constants kf and k, and two equilibrium constants KS and KP. However, it is noteworthy that the rate equation derived in the present work is quite different from that for a reversible reaction catalyzed by a monomeric enzyme (25). When [P]=O, Eq. 5 reduces to the Michaelis-Menten rate equation as given by: (4) In Eq. 4, there are 20 equilibrium constants Kj (j= l20) for steps l-20, and 20 rate constants consisting of 10 rate constants kfj U=21-30) for the forward reactions and 10 rate constants krj 0=21-30) for the reverse reaction of steps 21-30. The rate constants and the equilibrium constants used in Eq. 4 are the effective constants and can be related to the intrinsic rate and equilibrium con- v= -d[S]/dt= ;‘;p$l”s’l s Similarly, when [S]=O, the reduces to the Michaelis-Menten lows: rate equation rate equation 5 also as fol- (7) 330 J. FERMENT.BIOENG., WIDJAJA ET AL. TABLE 2. Kinetic parameters determined by using the data shown in Figs. 4 and 5 kr =8.46x UYs-l ~s=4.9Ox102M--’ k, =1.83x l@s-’ K,, =4.90x 10’ M-’ TABLE 3. The experimental equilibrium concentrations of G6P and the equilibrium concentration ratios obtained from the data in Fig. 8 The kinetic parameters were determined by fitting the experimental initial reaction rates shown in Figs. 4 and 5 to the rate equations given by Eqs. 6 and 7 using a non-linear regression procedure (the Pawell method). At equilibrium, ship. [PI,_ _- K&f Isle K&r Eq. 5 yields the following relation- (8) The intrinsic kinetic parameters kf, k,, KS and Kp were determined by fitting the experimental initial reaction rates shown in Figs. 4 and 5 to the rate equations given by Eqs. 6 and 7 using a non-linear regression procedure (the Pawell method). The parameters thus determined are listed in Table 2. Equation 8, which was derived from the rate equation for the proposed scheme, implies that the value of [PI,/ [S], must be constant irrespective of the initial concentrations of P (F6P) or S (G6P). Substitution of the experimental kinetic parameters listed in Table 2 into Eq. 8 gives the [P],/[S], value of 0.46. Table 3 lists the experimental [P],/[S], values which were directly calculated from the equilibrium concentrations of F6P and G6P determined from the time courses of [G6P] shown in Fig. 8. The [P],/[S], values were found to be constant at an average value of 0.45 irrespective of the initial F6P concentrations. Since this average value was in close agreement with the above value of 0.46, the reaction scheme proposed in the present work was demonstrated to offer an adequate explanation of Michaelis-Menten kinetic behavior of isomerization between G6P and F6P catalyzed by B. stearothermophilus PGI. The solid line in Fig. 4 shows the theoretical line calculated based on the rate equation Eq. 6, with the kinetic parameters listed in Table 2. The initial rate data in this figure were obtained using solutions containing only G6P as the substrate. Similarly, the solid line in Fig. 5 shows the theoretical line calculated based on Eq. 7 and is compared with the data obtained by using solutions containing only F6P as the substrate. Agreement between the theoretical lines and experimental data is satisfactory in both the figures. Using the kinetic parameters shown in Table 2, the theoretical values of the time courses of the increase in the G6P concentration formed by the reverse reaction were calculated based on Eq. 5 using the Runge-Kutta method. In Fig. 8, the theoretical values are shown as solid lines and are compared with the experimental time courses of the G6P concentration. All the data were obtained using solutions containing both G6P and F6P, though the solutions initially contained only F6P. The theoretical lines and experimental data are also in good agreement in this figure. From the above experimental results, we can conclude that despite the fact that B. stearothermophilus PGI is a tetrameric enzyme, its kinetic behavior can be explained by the Michaelis-Menten rate equation. In the present work, we clarified the kinetics and the mechanism of a single substrate-single product reaction wm lG@l, (mM) 10 5 3 2 (mM) 6.88 3.44 2.06 1.42 Experimental [FSP],/[GSP], (-) 0.454 0.454 0.457 0.415 av. 0.45 The experimental equilibrium concentration ratios were directly calculated from the equilibrium concentrations of F6P and G6P determined from the time courses of the increase in G6P concentration shown in Fig. 8. catalyzed by a tetrameric enzyme. To the best of our knowledge, the present study was the second investigation that wholly clarified the kinetics and mechanism of a reversible reaction catalyzed by an oligomeric enzyme. We believe that the present study contributes to the analysis of the kinetics and mechanism of reactions catalyzed by other oligomeric enzymes and the rational design of a reactor for the enzymatic production of FDP from glucose. NOMENCLATURE PI : concentration of bound substrates or ligands per total protein concentration, E : enzyme [Elo : initial enzyme concentration, M ES, ESS, ESSS, ESSSS, EP, EPP, EPPP, EPPPP, ESP, ESSP, ESSSP, ESPP, ESPPP, ESSPP : complexes of enzyme and one or more substrates (S) and/or products (P) Fl : concentration of free molecules or ligands, M kf : intrinsic rate constant of the forward reaction of the slow steps, s-l k, : effective rate constant for the forward reaction of slow step j Q=21-30), s-l k, : intrinsic rate constant of the reverse reaction of the slow steps, ssl kr, : effective rate constant for the reverse reaction of slow step j (j=21-30), s-r constant of rapid step j (j= K, : effective equilibrium l-20) (for example, Kl = [ES]/[E][S], K2= [EP]/ [EIPI, . ..A IV-’ kd : inactivation rate constant of enzyme, h-l : dissociation constant, M : intrinsic equilibrium constant of the product binds or dissociates, KS : intrinsic equilibrium constant of the substrate binds or dissociates, m : molecular mass, Da n : number of substrate or product enzyme, P : product (F6P) PI : concentration of product, M S : substrate (G6P) PI : concentration of substrate, M t : reaction time, s V : reaction rate, M. s-l VCI : elution volume, ml v,, : maximum reaction rate, M .s- I Kli KP the steps in which M-r the steps in which M-t binding sites of REACTION MECHANISM OF B. STEAROTHERMOPHILUS VOL. 86, 1998 ACKNOWLEDGMENTS This work was partially supported by a Grant-in-Aid for Developmental Scientific Research @lo. 06555250) from the Japanese Ministry of Education, Science, Sports and Culture. The authors express their thanks for its support. REFERENCES 1. Nakajima, H., Kondo, H., Tsurutani, R., Dombou, M., Tomioka, I., and Tomita, K.: Industrial application of adenosine 5’-triphosphate regeneration to synthesis of sugar phosphates, p. 111-120. 1n Mark, D., Bednarski, M. D., and Simon, E. S. (ed.), Enzymes in carbohydrate synthesis. Am. Chem. Sot., Washington, DC (1991). 2. Tsuboi, K.K., Fukunaga, K., and Cherrenka, C.H.: Phosphoglucose isomerase from human erythrocyte. J. Biol. Chem., 246, 7586-7594 (1971). 3. Tilley, B. E., Gracy, R. W., and Welch, S. G.: A point mutation increasing the stability of human phosphoglucose isomerase. J. Biol. Chem.. 249. 4571-4579 (1974). 4. Schnarrenberger, C. and Oeser, A.: Two isoenzymes of glucosephosphate isomerase from spinach leaves and their intracellular compartmentation. Eur. J. Biochem., 45, 77-82 (1974). 5. Kempe, T. D., Nakagawa, Y., and Noltmann, E. A.: Physical and chemical properties of yeast phosphoglucose isomerase isoenzymes. J. Biol. Chem.. 249. 4617-4624 (1974). 6. Lowe,. S. L. and Reithel, Fl J.: The subunit ‘structure of phosphoglucose isomerase from baker’s yeast. J. Biol. Chem., 250, 94-99 (1975). 7. Phillips, T. L., Talent, J. M., and Gracy, R. W.: Isolation of rabbit muscle glucosephosphate isomerase by a single-step substrate elution. Biochim. Biophys. Acta, 429, 624-628 (1976). 8. Takama, M. and Nosoh, Y.: Purification and some properties of 6-phosphoglucose isomerase from Bacillus caldotenax. J. Biochem., 87, 1821-1827 (1990). 9. Muramatsu, N. and Nosoh, Y.: Purification and characterization of glucose 6-phosphate isomerase from Bacillus stearothermophilus. Arch. Biochem. Biophys., 144, 245-252 (1971). 10. Weber, K. and Osbom, M.: The reliability of molecular weight determinations by dodecyl sulfate-polyacrylamide gel electrophoresis. J. Biol. Chem., 244, 4406-4412 (1969). 11. Myer, Y. P. and Schellman, J. A.: The interaction of ribonuclease with purine and pyrimidine phosphates. Biochim. Biophys. Acta, 55, 361-373 (1962). PGI 331 12. Roe, J. H.: A calorimetric method for the determination of fructose in blood and urine. J. Biol. Chem., 107, 15-22 (1934). 13. Scatchard, G.: The attractions of protein for small molecules and ions. Ann. N. Y. Acad. Sci., 51, 660-672 (1949). 14. Smith, E. L., Hill, R. L., Lehman, I. R., Leikowitz, R. J., Handler, P., and White, A.: Principles of Biochemistry: general aspect, 7th edn. McGraw-Hill Book Co., Singapore (1983). 15. Bruch, P., Schnackerz, K. D., Chirgwin, J. M., and Noltman, E. A.: Binding studies on rabbit-muscle phosphoglucose isomerase. Eur. J. Biochem., 36, 564-568 (1973). 16. Pettigrew, D. W., Yu, G. J., and Liu, Y.: Nucleotide regulation of Escherichia coli glycerol kinase. Biochem., 29, 86208627 (1990). 17. Monod, J., Wyman, J., and Cbangeux, J. P.: On the nature of allosteric transitions: a plausible model. J. Mol. Biol., 12, 88118 (1965). 18. Koshland, D. E., Jr., Nemethy, G., and Filmer, D.: Comparison of experimental binding data and theoretical models in proteins containing subunits. Biochem., 5, 365-385 (1966). 19. Ishikawa, H., Ogino, H., and Oshida, H.: Rates of reactions catalyzed by a dimeric enzyme. Effects of the reaction scheme and the kinetic parameters on co-operativity. Biochem. J., 280, 131-137 (1991). 20. Ishikawa, H., Shiroshima, M., Widjaja, A., Nakajima, H., and Tsurutani, R.: Kinetics and mechanism of acetate kinase from Bacillus stearothermophilus. J. Chem. Eng. Japan, 28, 517-524 (1995). 21. Nakajima, H., Suzuki, K., and Imahorl, K.: Subunit structure of acetate kinase from Bacillus stearothermophilus as studied by hybridization and cross-linking experiments. J. Biochem., 84, 1139-1146 (1978). 22. King, E. L. and Altman, C.: A schematic method of deriving the rate laws for enzyme-catalyzed reactions. J. Phys. Chem., 60, 1375-1378 (1956). 23. Ishikawa, H., Maeda, T., Hikita, H., and Miyatake, K.: The computerized derivation of rate equations for enzyme reactions on the basis of the pseudo-steady-state assumption and the rapid-equilibrium assumption. Biochem. J., 251, 175-181 (1988). 24. Segel, I. H.: Enzyme kinetics. Behavior and analysis of rapid equilibrium and steady-state enzyme systems, p. 346353. John Wiley & Sons Inc., New York (1975). 25. Segel, I. H.: Enzyme kinetics. Behavior and analysis of rapid equilibrium and steady-state enzyme systems, p. 29-34. John Wiley & Sons Inc., New York (1975).