cold formed sections 061103

advertisement

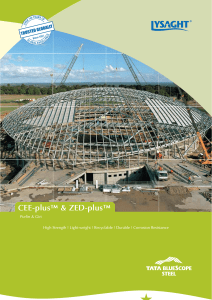

Cold Formed Sections CFS-2 Safe Load Tables • Many uses in the construction, general fabrication and home handyman fields • New steel sections enable more cost-effective use of materials and therefore less weight • Steel sections provide reliable performance, long life and freedom from warping, twisting, shrinking, rotting and damage from termites • Wide range of section shapes, sizes and thicknesses are available Introduction Angle Sections In addition to plain and lipped channels for which comprehensive load tables are provided, the BlueScope Lysaght’s cold formed steel sections range includes a number of new high strength angles. These angles have a variety of uses such as for bracing purposes and in the construction of gates, fences, handrails, frames and storage racks, as well as in many of the other applications listed below. Applications Some of the many uses for BlueScope Lysaght’s cold formed steel sections are: • Structural Building frames, floor joists, roof trusses, purlins and girts, gates, tank stands, stock pens, ladders, mullions and lintels, beams and columns, fences. • Mechanical Car trailers, boat trailers, truck and bus bodies, agricultural machinery, rolling stock, conveyor frames, crane frames, containers, pallets and storage racks. Adverse Conditions If it is intended to use BlueScope Lysaght’s cold formed steel sections in exposed situations within 1km of salt marine locations, or in severe industrial or unusually corrosive environments, please contact your nearest BlueScope Lysaght Office for specialised advice. Performance BlueScope Lysaght’s cold-formed steel sections will perform as specified if design, fabrication and fixing are in accordance with the Company’s recommendations. Specifications The information in this literature is correct at time of printing. However, specifications are subject to change without notice. 2 Notes to load tables Beam Length of bearing Support Notes to Load Tables 1 Load capacities are given for total uniformly distributed loads over simple spans in kilonewtons per metre (kN/m). To find load capacities for one or more concentrated loads (in kN), the values in tables should be multiplied by the factors in Table A. Where more than one load is carried, the above conversion factors apply to total of all loads shown in respective diagrams. Loads are assumed to be equal and equidistant. 2 Where the compression flange of a beam is braced against sidewise movement, the load capacity of the beam can be considerably greater, especially over long spans. Tables show load capacities for fully braced as well as unbraced beams. An example of a fully braced beam is a floor joist, where floor boards fully brace the upper (compression) flange. Similarly, roof sheeting fully braces purlins for downward loading, e.g. dead load or live load, but roof sheeting does not brace purlins for upward loads, e.g. a wind suction load, as the compression flange is then unbraced. An example of a completely unbraced beam would be one with load(s) hanging from it. However, loads carried by beams usually provide some bracing, and the load capacity can be found by interpolating between two extreme bracing conditions shown in the tables. 3 End bearing capacity depends upon the length of bearing (beam support). To determine the bearing capacity for any length of bearing from the tables, take the value for the first 10 mm and add the required number of 10 mm increment values to make up the total actual length of bearing. For instance, the end bearing capacity of a beam having a length of bearing of 50 mm is made up of first 10 mm plus 4 additional increments of 10 mm. End bearing capacity of a LC07630 for same length bearing is: First 10 mm = 8.50 kN + 4 incr. @ 0.27 kN = 1.08 kN Bearing capacity for 50 mm = 9.58 kN permissible capacity for the section is 11.10 kN. (The maximum permissible end bearing capacity corresponds to a length of bearing equal to the clear distance between flanges. Bearing length increase beyond that dimension, then, would not improve the end bearing capacity). Above applies only where section is supported by the flanges, i.e. not for bolted or welded webs. The maximum bearing capacity is given in the last column. This value must not be exceeded regardless of the length of bearing. If the length of bearing for the section in the above example was increased to say, 110 mm, the calculated bearing capacity would be 11.47 kN. This is, however, invalid as the maximum 4 Sections’ own mass is not considered in load tables. Table A Loading Condition Diagram Factor Single load at mid span 0.5 Two loads equally spaced 0.75 Three loads equally spaced 0.75 Four loads equally spaced 0.833 a Single load off centre Two loads b L a b L2 / 8ab L / 4a L 3 Plain Channels Plain Channels y B c t D x x Shear Centre Centroid R x O Table 1 Plain Channels 4 y 5 Lipped Channels Lipped Channels B R3.2 D Shear Centre L y Centroid X X t (BMT) X X O Table 2 Lipped Channels 6 y 7 Compound Plain Channels (Nested) Plain Channels (toe to toe) B Average Gap 2 D R X X t (BMT) y Table 4 Compound Plain Channels toe-to-toe 8 9 Compound Plain Channels (Nested) y L B (BMT) Plain Channels (back to back) D R X X y Table 3 Compound Plain Channels back-to-back 10 11 Compound Lipped Channel (Nested) Lipped Channel (toe to toe) B y D L R3.2 X X t y Table 5 Compound Lipped Channels (toe-to-toe) Table 6 Compound Lipped Channels (back-to-back) 12 13 Welding General Cold formed sections are suitable for all types of welding, such as spot welding, seam welding, projection welding, plug welding and arc welding, all of which are applicable to both uncoated and zinc coated sections. Fabricators generally prefer arc welding. A few typical examples of weld fillets are shown on page 15. Suitable electrode classification is E41 XX. Current should be adjusted to suit the steel thickness, but the heat input should be kept to a practicable minimum. Multiple weld beads should be avoided. Arc welding of zinc coated sections does not differ from that of uncoated sections, except that the electrode should be applied more slowly, making sure that the zinc coating evaporates ahead of the welding seam. Adequate ventilation should be provided. Compound Sections In making compound beam sections by welding two channels web-to-web or toe-totoe, the welds must be of structural quality; mere “stitching” is not satisfactory. Intermittent fillets as per the accompanying diagram and tables are recommended. (All dimensions in millimetres). Where concentrated forces are carried (cross-beams, partitions, etc.), the welds should be as for supports, with one short “miss” length each side of the weld length. For compound sections used as columns, the weld lengths given in the table can be halved, leaving the “miss” lengths as for beams. Intermittent Welds for Compound Sections Running Intermittent Weld At support Weld Depth D Miss Weld Miss Weld Miss COMPOUND BEAM Weld Weld top and bottom Lengths of Intermittent Welds for Compound Sections Depth of Section 'D' At Supports Running Intermittent Fillet Weld Miss Weld Miss Up to 40 45 20 20 40 61 - 80 90 40 40 70 41 - 60 70 81 - 110 120 161 - 210 220 111 - 160 211 - 260 180 260 30 60 30 50 50 100 90 60 120 130 80 180 110 70 150 The above information is given for users’ convenience as cold formed sections are supplied only in single lengths, i.e. not attached to each other in any way. 14 Welding Typical Welded Section Configurations 15 The sections are cold roll-formed from quality BlueScope Lysaght strip to ensure consistent dimensions and conformance to tolerances. BlueScope Lysaght’s cold formed steel channels and angles are available either zinc coated or uncoated in base metal thicknesses (BMT) of 1.0 mm, 1.6 mm, 2.5 mm and 3.0 mm depending on the section type. The materials used are zinc coated steel to AS 1397 – 2001 G300 – Z275 (300 MPa minimum yield stress, 275g/m2 minimum average coating mass) and uncoated steel to AS/NZS 1594-2002 HA300 (300 MPa minimum yield stress). This publication supersedes “Cold Formed Steel Channels and Angles – Load Capacity Tables and Welding Data” (Ref. No. CFS II – 1 April 1980). Performance is backed by BlueScope Lysaght with over 150 years experience in building products. Product Descriptions All descriptions, specifications, illustrations, drawings, data, dimensions and weights contained this catalogue, all technical literature and websites containing information from BlueScope Lysaght are approximations only. They are intended by BlueScope Lysaght to be a general description for information and identification purposes and do not create a sale by description. BlueScope Lysaght reserves the right at any time to: (a) supply Goods with such minor modifications from its drawings and specifications as it sees fit; and (b) alter specifications shown in its promotional literature to reflect changes made after the date of such publication. Disclaimer, warranties and limitation of liability This publication is intended to be an aid for all trades and professionals involved with specifying and installing Lysaght products and not to be a substitute for professional judgement. Terms and conditions of sale available at local BlueScope Lysaght sales offices. Except to the extent to which liability may not lawfully be excluded or limited, BlueScope Steel Limited will not be under or incur any liability to you for any direct or indirect loss or damage (including, without limitation, consequential loss or damage such as loss of profit or anticipated profit, loss of use, damage to goodwill and loss due to delay) however caused (including, without limitation, breach of contract, negligence and/or breach of statute), which you may suffer or incur in connection with this publication. © Copyright BlueScope Steel Limited 11 January 2010 For technical information, contact steeldirect@bluescopesteel.com or call 1800 641417 www.lysaght.com Please check the latest information which is always available on our website. lysaght is a registered trademark of BlueScope Steel Limited, ABN 16 000 011 058. The lysaght ® range of products is made by BlueScope Steel Limited trading as BlueScope Lysaght.