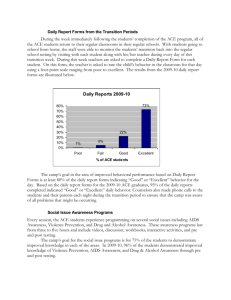

(ACE) Operating System Case Study

advertisement