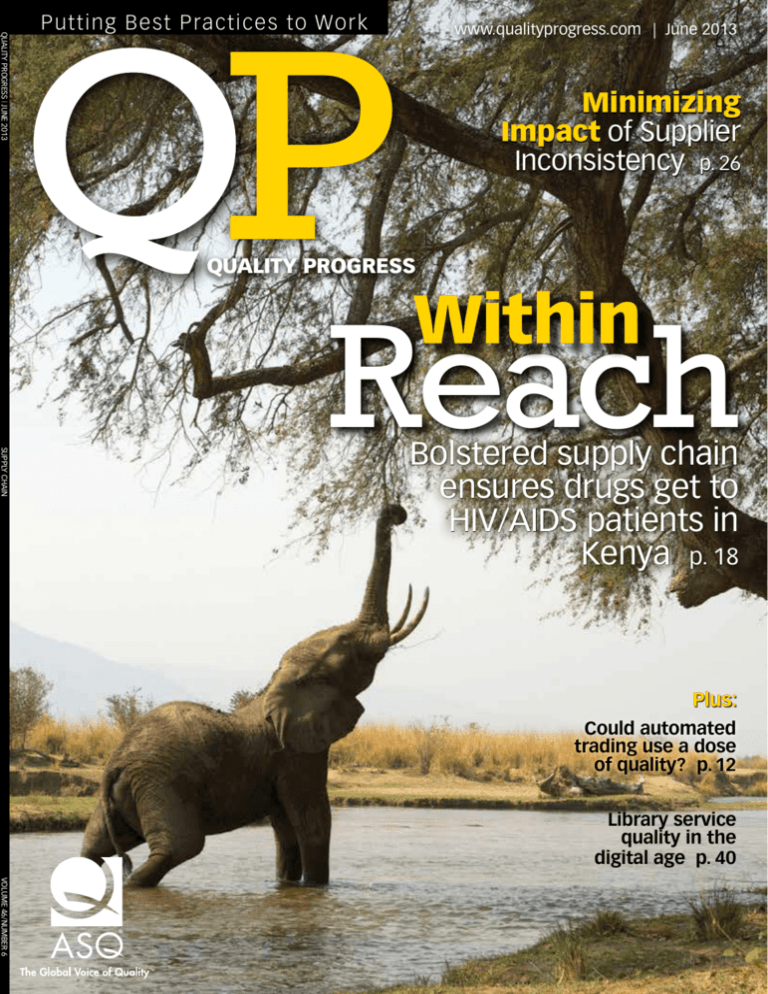

Quality Progress | June 2013

P

Putting Best Practices to Work

www.qualityprogress.com | June 2013

Minimizing

Impact of Supplier

Inconsistency p. 26

QUALITY PROGRESS

Within

Supply Chain

Reach

Bolstered supply chain

ensures drugs get to

HIV/AIDS patients in

Kenya p. 18

Plus:

Could automated

trading use a dose

of quality? p. 12

Library service

quality in the

digital age p. 40

Volume 46/Number 6

increase Your effectiveness With valuable

lean Six Sigma Training

Stand out From the Crowd With lean

Six Sigma Training and Certification

From villanova University – 100% online

Gain advanced expertise that can distinguish you and

increase your earning potential with a Master Certificate

in Six Sigma. Renowned Villanova University, ranked by

U.S. News & World Report as the #1 Regional University

in the North for nearly two decades, provides resumeboosting Lean Six Sigma training – 100% online.

Attain Prestigious lean Six Sigma Credentials online

As a leader in Lean Six Sigma education online,

Villanova enables you to earn must-have credentials

through innovative video-based e-learning technology.

Enjoy maximum mobile convenience with streaming

video, and downloadable MP3 and MP4 lectures as you

complete your Six Sigma master certificate online. Then

round out your credentials with certification in one of

these in-demand areas:

Six Sigma Green Belt

Lean Sensei

Lean Black Belt

Lean Master Black Belt

Act Now to Save $945 on a

3-Course Master Certificate!

800-341-7106 | www.VillanovaU.com/Efficiency

© 2011 All Rights Reserved. Made Available by University Alliance® – The Nation’s Leading Universities Online. SC: 198042zv1 | MCID: 14408

TrAdiTioN. ACAdeMiC exCelleNCe. oNliNe CoNveNieNCe.

^ĞůĞĐƚƚŚĞnterprise Quality &

PDM

NCMR

QMS Software

ISO/TS FMEA

ISO

Nonconforming

Quality

ISO 9000 PDM

Quality Software ISO 13485

NCM

QMS

Nonconforming Materials

TL 9001

CAPA

ISO

Quality Compliance Software Manufacturing

Quality Assurance

Product Data Management

Manufacturing

Supplier &

Materials

Quality Compliance

Process

Nonconformance

Discrete

Corrective Actions

Quality

Discrete ERP

Manufacturing

Quality Compliance

QMS Software

Discrete

Risk Assessment

Nonconforming Materials

ISO 9000

FMEA

ERP

ISO/TS

MRB

QMS Software

NCM

ISO 9000

Discrete

Calibration

ISO/TS 16949

ISO/TS

ISO 13485

FMEA

Supplier &

Materials

AS9100

Compliance

Corrective Actions

AS9100

TL 9001

Nonconforming

FMEA

Actions

Inspections Corrective

Manufacturing

Quality

ISO

ISO 9000 Quality Assurance

Risk Assessment

Calibration

Process

ISO/TS

ISO

Product Data

Management

ISO/TS 16949

ERP

ISO 13485

Receiving

Inspections

CAPA

Calibration

Quality

Quality Software

Process

Supplier

Quality Assurance

MRB

CAPA

PDM

ISO/TS

Supplier

TL 9001

Product Data Management

Materials

Inspections

Nonconformance

FMEA Quality Systems Software Receiving

Quality Management Software Supplier Rating

MES

CAPA QMS Software

Manufacturing

Product Data Management

Calibration

Quality

QMS

Process

Supplier

& Materials QMS QMS Software

Calibration

ISO/TS

QMS Software

Quality

FMEA

Manufacturing

ISO 13485

Rating

CAPA

ISO/TS

QMS

Calibration

ISO 13485

PDM

AS9100

Quality

Calibration

Quality Compliance QMS PDM Manufacturing

Receiving Nonconformance Quality Assurance

Materials

Compliance ERP

CAPA

ISO

Process

ISO 13485

ISO/TS

MRB

TL 9001

Process

...ǁŝƚŚƚŚĞŵŽst VALUE

: Integrated modules for Quality and FDA Compliance

Management:

CAPAͻŚange ManagementͻRisk Assessment ...and more!

Risk Management

in tŚĞQuality System

events

Flexible: Leading edgĞŇexible workŇow adapts to all business

processes, witŚŽƵt programming

: Integrates witŚ3rd party business systems

Scalable: Readily adapts to enterprise environments, and

deployments

Supplier Management: Collaborates witŚ^ƵƉƉůŝĞrs tŚrougŚ^ƵƉƉůŝer

Business Intelligence

in

decision-making witŚŚƵŶĚreds of conĮgurable cŚarts and reports

800-354-4476 ͻ info@etq.com

www.etq.com/quality

What’s Online in the

ASQ Knowledge Center?

CASE STUDY

Shortening Throughput Time of a Hospital’s

Billing Process

See how a Dutch hospital applied Lean Six Sigma

to shorten its billing process by one month. Key

tools used for the project included the Gantt chart

and critical path analysis.

BASICS

Learn About Quality—Root Cause Analysis

Brush up on the basics of root cause analysis and

see recommended resources for more information,

including a two-part introductory webcast, and case

studies and articles about successful applications,

and books and courses to continue your learning.

WEBcast

Patient Safety—Eliminating Harm System-wide

Learn how Henry Ford Healthcare System

achieved a 26 percent reduction in harm events

and a 12 percent reduction in mortality over a

three-year period through its No-Harm Campaign.

The approach involves every business unit and

all members of the workforce, and is integrated

into the organization’s strategy, culture, daily

operations, and educational mission.

Access this month’s featured content and more Web exclusives in the

ASQ Knowledge Center at asq.org/knowledge-center/featured.html.

training

CERTIFICATION

CONFERENCEs

MEMBERSHIP

PUBLICATIONS

Contents

Putting Best Practices to Work | June 2013 | www.qualityprogress.com

FEATURES

18

CASE STUDY

To All Corners of Kenya

Delivering medicine to Kenyans living with HIV/AIDS was much

improved through a project that used an ISO 9001 approach

to solidify the supply chain that handled the life-saving drugs.

by Tiffany Darabi

26

SUPPLY CHAIN

The Power of Prediction

Use quality and statistical methods to predict parts demand and adjust

to inconsistent supplier deliveries to stay one step ahead in servicing

customers.

by Gregory A. Kruger

34

STATISTICS

18

Partial View

Repeatability and reproducibility studies can help evaluate the parts of

a measurement system that may need improving.

by Víctor M. Aguirre-Torres and Maria Teresa López-Alvarez

40

SERVICE QUALITY

Getting a Good Read

Implementing quality management helped libraries learn to better serve

their patrons in the internet age.

by Todd Bruns and Rendong Bai

Only @

www.qualityprogress.com

• Keen on Kenya

Hear from Tiffany Darabi, author

of “To All Corners of Kenya,” p. 18,

discuss the project that strengthened

supply chain activities and helped

deliver HIV/AIDS drugs more efficiently

to patients throughout the nation.

• Volviendo a los Fundamentos

Back to Basics translated in Spanish.

• Ready Reference

Brush up on quality fundamentals,

including your vocabulary with our

handy glossary.

26

DEPARTMENTS

6

LogOn

8

Expert Answers

14

47

• Extolling the value of statistics.

• When an audit finding is refuted.

• Banking on customer satisfaction.

Quality Progress/ASQ

600 N. Plankinton Ave.

Milwaukee, WI 53203

Telephone

Fax

800-248-1946414-272-1734

414-272-8575

Keeping Current

Mr. Pareto Head

66

QP Toolbox

68

QP Reviews

Email

Follow protocol of first initial and full last

name followed by @asq.org (for example,

vellifson@asq.org).

Article Submissions

Quality Progress is a peer-reviewed publication with 85% of its feature articles written

by quality professionals. For information

about submitting an article, call Valerie

Ellifson at 800-248-1946 x7373, or email

manuscripts@asq.org.

COLUMNS

5

12

QUALITY PROGRESS

Mail

• A new plan for Toyota.

• ASQ World Conference wrap-up.

14

QP

Up Front

Motivating factors.

Perspectives

Fortifying automated trading with

ethics and quality.

50

Author Guidelines

47

Standards Outlook

50

Measure for Measure

52

Quality in the First Person

54

Career Corner

72

Back to Basics

Clarifying some confusion over

ISO 9001 conformance.

How environmental conditions

can impact tests and equipment.

Dealing with diabetes.

Understanding stakeholder

management.

Finding different perspectives

through DMAIC.

2013 Software showcase

& directory p. 56

To learn more about the manuscript review

process, helpful hints before submitting a

manuscript and QP’s 2013 editorial planner,

click on “Author Guidelines” at www.

qualityprogress.com under “Tools and

Resources."

Photocopying Authorization

Authorization to photocopy items for

internal or personal use or the internal or

personal use of specific clients is granted by

Quality Progress provided the fee of $1 per

copy is paid to ASQ or the Copyright Clearance Center, 222 Rosewood Drive, Danvers,

MA 01923, 978-750-8400. Copying for other

purposes requires the express permission

of Quality Progress. For permission, write

Quality Progress, PO Box 3005, Milwaukee,

WI 53201-3005, call 414-272-8575 x7406, fax

414-272-1734 or email reprints@asq.org.

Photocopies, Reprints

And Microform

Article photocopies are available from ASQ

at 800-248-1946. To purchase bulk reprints

(more than 100), contact Barbara Mitrovic at

ASQ, 800-248-1946. For microform, contact

ProQuest Information and Learning, 300 N.

Zeeb Road, Ann Arbor, MI 48106, 800-5210600 x2888, international 734-761-4700,

www.il.proquest.com.

Membership and Subscriptions

NEXT MONTH

- performance review

The plan-do-check-act method to improve

360˚ surveys.

- Reinventing excellence

How Corning stays on the cutting edge.

ASQ’s Vision: By making quality a global priority, an organizational imperative and

a personal ethic, the American Society for Quality becomes the community for everyone

who seeks quality technology, concepts or tools to improve themselves and their world.

Quality Progress (ISSN 0033-524X) is published monthly by the American Society for Quality, 600 N. Plankinton Ave., Milwaukee, WI 53203.

Editorial and advertising offices: 414-272-8575. Periodicals postage paid at Milwaukee, WI, and at additional mailing offices. Institutional

subscriptions are held in the name of a company, corporation, government agency or library. Requests for back issues must be prepaid and

are based on availability: ASQ members $15 per copy; nonmembers $23 per copy. Canadian GST #128717618, Canadian Publications Mail

Agreement #40030175. Canada Post: Return undeliverables to 2835 Kew Drive, Windsor, ON N8T 3B7. Prices are subject to change without

prior notification. © 2013 by ASQ. No claim for missing issues will be accepted after three months following the month of publication of the

issue for domestic addresses and six months for Canadian and international addresses.

Postmaster: Please send address changes to the American Society for Quality, PO Box 3005, Milwaukee, WI 53201-3005. Printed in USA.

4

QP • www.qualityprogress.com

For more than 60 years, ASQ has been the

worldwide provider of information and learning opportunities related to quality. In addition, ASQ membership offers information,

networking, certification and educational

opportunities to help quality professionals obtain practical solutions to the many

problems they face each day. Subscriptions

to Quality Progress are one of the many

benefits of ASQ membership. To join, call

800-248-1946 or see information and an

application on p. 33.

List Rentals

Orders for ASQ’s member and nonmember

buyer lists can be purchased by contacting

Michael Costantino at the Infogroup/Edith

Roman List Management Co., 845-731-2748

or fax 845-620-9035.

upfront

QP

QUALITY PROGRESS

Means to Motivate

Contribution proves to be key component

Executive Editor and

Associate Publisher

Seiche Sanders

Associate Editor

Mark Edmund

Assistant Editor

WHAt motivates people most in their work lives? Would it surprise you to learn

Amanda Hankel

it’s not money? Recent research reveals that people are motivated most by their ability

manuscript Coordinator

to make steady progress on meaningful work. Daniel Pink, a keynote speaker at ASQ’s

World Conference on Quality and Improvement, talked about this concept at the May

event. (For a brief recap on the conference turn to page 17 or visit http://asq.org/blog.)

By nature, quality professionals are eliciting positive changes within their organizations all the time. Immediate gratification, however, is what’s sometimes lacking. That

is not the case for the organization featured in this month’s cover story, “To All Corners

of Kenya,” p. 18. The organization, Kenya Pharma, delivers much-needed, affordable

HIV/AIDS medication to a network across the African country of Kenya. The work, as is

stated in the article, is truly a matter of life and death.

The ISO 9001-certified Kenya Pharma project is funded by the U.S. Agency for

International Development and implemented by Chemonics International. Its quality

management system (QMS) spans the entire business cycle. The movement toward a

QMS and subsequent certification has allowed the company to make great strides in the

number of customers they serve and how well.

“On a daily basis, ISO 9001 helps ensure problems that do arise in the supply chain

are systematically documented and addressed not only to correct an immediate issue,

but also to gather data on larger trends impacting the project’s ability to serve its customers through the corrective and preventive action process,” according to the article.

Read about how quality really is making a difference in this insightful case study.

Valerie Ellifson

contributing EDITOR

Megan Schmidt

COPY EDITOR

Susan E. Daniels

Art Director

Mary Uttech

Graphic Designer

Sandy Wyss

Production

Cathy Milquet

Advertising production

Barbara Mitrovic

Digital Production specialisTS

Laura Franceschi

Julie Schweitzer

Media sales

Naylor LLC

Lou Brandow

Krys D’Antonio

Norbert Musial

Rob Shafer

Donnie Tuttle (ASQ TV)

Media sales Administrator

Kathy Thomas

Also in this issue, help with handling inconsistency with parts suppliers. If you’ve

Marketing Administrator

ever struggled to get what you want, when you want it, be sure to read “The Power of

Matt Meinholz

Prediction,” p. 26. Finally, in “Getting a Good Read,” p. 40, read about how libraries

Editorial offices

reengineered their processes to better serve customers in the digital age. QP

Phone: 414-272-8575

Fax: 414-272-1734

Advertising offices

Phone: 866-277-5666

ASQ administration

CEO

Paul E. Borawski

Seiche Sanders

Editor

Don’t forget to watch the new episode

Managing Directors

Julie Gabelmann

Brian J. LeHouillier

Michelle Mason

Laurel Nelson-Rowe

To promote discussion of issues in the field of quality and

ensure coverage of all responsible points of view, Quality

Progress publishes articles representing conflicting and minority views. Opinions expressed are those of the authors and not

necessarily of ASQ or Quality Progress. Use of the ASQ logo in

advertisements does not necessarily constitute endorsement of

that particular product or service by ASQ.

June 2013 • QP

5

logon

+Seen&Heard

Statistical ignorance

StayConnected

Find the latest news, quips and targeted

content from QP and its staff

One additional caution to add to

The March 2013 Statistics Roundtable

Anderson-Cook’s article is to avoid the

column by Christine M. Anderson-Cook,

tendency to repeat past plans without

“Let’s Be Realistic,” (pp. 52-54) makes a

adjustment for the current situation. I

number of important points, but misses

specifically mean using past test plans,

QUAlITY PRogRESS | MARCH 2013

P

Putting Best Practices to Work

www.qualityprogress.com | March 2013

5 Takeaways

From the Revised

iSo 19011 p. 38

ISO 22000

QualitY PRoGR

the Right

FooD SAFETY

ingredients

Methods for making

food safer

Quality culture

Risk

management

FDA

Good

manufacturing

practices

Plus:

Closing down the

hidden factory p. 50

HACCP

Food Safety Modernization Act

Creating the perfect

form p. 64

VolUME 46/nUMBER 3

one. I fully agree

sample sizes and measures because

that decision

“that is what we did before.” Each

making is the key

product, production line and situation is

to the value of

different and should have assumptions,

statistical tools.

conditions and analysis checked to be

The intangible

certain the analysis and recommenda-

of slot machine

tions are valid. Sure, it is quicker to

payouts is similar

follow the same steps and repeat past

to the question

analysis rather than think through the

Publisher Seiche Sanders:

@ASQ_Seiche

Associate Editor Mark Edmund:

@ASQ_Mark

Assistant Editor Amanda Hankel:

@ASQ_Amanda

Contributing Editor Megan Schmidt:

@ASQ_Megan

editor@asq.org

www.facebook.com/

groups/43461176682

www.linkedin.com/groups/qualityprogress-magazine-asq-1878386

we hear in business: “What is keeping

problem again. Many would rather avoid

you up at night?“ Many decisions we

opening their statistics books and think-

must make in business have intangible

ing hard about the underlying assump-

qualities. Brand image is one example.

tions. Yet, it is where the value of statisti-

Sorting out what is and is not part of the

cal analysis lies. We owe it to decision

statistical analysis story often helps to

makers to do a proper analysis, check

frame the issue under discussion.

assumptions, apply the right techniques,

QP

popular

state the limitations and encourage an

(All URLs case sensitive)

understanding of statistics.

1.Crunching the Numbers: How

the 2012 Salary Survey data

were compiled. (http://bit.ly/

crunchnumbers)

One of the key issues I see facing those of us active with statistical

thinking is the ignorance of most of

The current climate is prime for

our colleagues. While ASQ provides

expanding the use and understanding

a lot of information, the content may

of statistical methods. We (statisti-

need to focus more on the value of

cally thinking folks) have the skills that

proper statistical thinking to encourage

are in demand. We can add value with

application. The Wall Street Journal ran

our knowledge. I encourage all to read

an article titled, “Data Crunchers Now

Anderson-Cook’s article again, then look

the Cool Kids on Campus,” extolling the

for opportunities to apply your statistical

value businesses are finding in statisti-

knowledge to improve decision making.

Fred Schenkelberg

Los Gatos, CA

cians. The American Statistical Asso1

ciation and others have declared 2013

as the International Year of Statistics.

Consider an online basic statistics class

I’m currently taking though edX that

has 47,000 students enrolled.2 It seems

that we (the business world at large)

are finding statistics of value.

6

Executive Editor & Associate

QP • www.qualityprogress.com

Reference and note

1.Carl Bialik, “Data Crunchers Now the Cool Kids on

Campus,” Wall Street Journal, March 1, 2013, http://bit.

ly/datacrunchers.

2.edX is a nonprofit enterprise of its founding partners

Harvard University and the Massachusetts Institute of

Technology that features learning designed specifically

for interactive study via the web.

’s Most

articles

2.Corrective vs. Preventive

Action: Do you know the difference between corrective and

preventive action? (http://bit.

ly/correctvsprevent)

3.Learning to Fish: The fishbone

diagram can help you achieve

career growth. (http://bit.ly/

learningtofish)

4.Paving the Way: Seven data

collection strategies to enhance

your quality analyses. (http://

bit.ly/pavingtheway)

QP

QP

Online

Extras@

QUALITY PROGRESS

www.qualityprogress.com

PAST CHAIR

• Life-saving improvements

Listen to Tiffany Darabi, author of “To All Corners of Kenya,” p. 18, talk more about the project that helped deliver HIV/AIDS drugs in Kenya more efficiently by improving

supply chain activities in this month’s Author Audio interview.

James J. Rooney, ABS Consulting, Global

Government Division

CHAIR

John C. Timmerman, Gallup Inc.

CHAIR-ELECT

• Volviendo a los Fundamentos

Stephen K. Hacker, Transformation Systems

International

Read this month’s Back to Basics column translated in Spanish.

TREASURER

Chava Scher, RAFAEL—Advanced Defense Systems

(retired)

Quick Poll RESULTS

Each month at www.qualityprogress.com, visitors can take an informal survey. Here are

the numbers from last month’s Quick Poll:

What poses the greatest risk to today’s organizations?

• Market uncertainty. • Data management.

• Technology.

PARLIAMENTARIAN

Karla Riesinger, ASQ

DIRECTORS

44.4%

36.1%

19.4%

Visit www.qualityprogress.com for the latest question:

Are you on Twitter?

• Yes, I actively tweet.

•No, but I’d be open to trying it.

• I plan to set up an account soon.

• I’ll never tweet.

QualityNewsToday

Recent headlines from ASQ’s global news service

(All URLs case sensitive)

Behind the Scenes: Boeing’s Dreamliner Battery Fix

It was a logistical effort Boeing had never faced before: simultaneously moving a small

army of technicians to 13 international locations, transporting 15 tons of tools per

repair kit and installing newly designed equipment in the field, taking five days per

airplane and working around the clock in two 12-hour shifts. (http://bit.ly/boeingbehind

scenes)

London to Create Airport of the Future

London City Airport wants to eradicate the nuisances associated with flying by creating

a streamlined experience with the help of a technology known as the Internet of Things.

Essentially, it is an overarching platform that allows a variety of devices or machines to

communicate with one another. (http://bit.ly/airportoffuture)

Heather L. Crawford, Apollo Endosurgery

Raymond R. Crawford, Parsons Brinckerhoff

Ha Dao, Emerson Climate Technologies Inc.

Gary N. Gehring, Saskatchewan Ministry of

Governmental Relations

Kathleen Jennison Goonan, M.D., Goonan

Performance Strategies

Eric A. Hayler, BMW Manufacturing Co.

James M. Loseke, Sargento Foods Inc.

Joanne D. Mayo

Elías Monréal, Industrial Tool Die and Engineering

Richard A. Perlman, Bayer HealthCare

Steven J. Schuelka, Calumet College

Daniel E. Sniezek, Lockheed Martin (retired)

G. Geoffrey Vining, Virginia Tech Department of

Statistics

Alejandra Vicenttin, Alejandra Vicenttin Advisors

Bharat Wakhlu, Tata Services Ltd., a division of Tata Sons

J. Eric Whichard, JE Whichard and Associates

QP EDITORIAL REVIEW BOARD

Randy Brull, chair

Administrative Committee

Brady Boggs, Randy Brull, Jane Campanizzi, Larry

Haugh, Jim Jaquess, Gary MacLean,

R. Dan Reid, Richard Stump

Technical reviewers

Andy Barnett, David Bonyuet, David Burger, Bernie

Carpenter, L.N. Prabhu Chandrasekaran, Ken Cogan,

Linda Cubalchini-Travis, Ahmad Elshennawy, Mark

Gavoor, Kunita Gear, Daniel Gold, T. Gourishankar,

Roberto Guzman, Ellen Hardy, Lynne Hare, Ray

Klotz, Tom Kubiak, William LaFollette, Pradip Mehta,

Larry Picciano, Gene Placzkowski, Tony Polito, Peter

Pylipow, John Richards, James Rooney, Brian Scullin,

Amitava Sengupta, A.V. Srinivas, Joe Tunner, Manu

Vora, Keith Wagoner, Jack Westfall, Doron Zilbershtein

Want the latest quality-related news and analysis?

The QNT Weekly e-newsletter delivers it every Friday.

Subscribe now at http://email.asq.org/subscribe/qntwk.

June 2013 • QP

7

expertanswe

Doing the right thing

Q: During an audit closeout meeting, what

ing a finding on behalf of their function.

• The finding is wordy, poorly written or

is the right thing to do if the auditee refuses

unclear about what to address or im-

of those involved in the audit. However, with

to accept a correct nonconformance report

prove, so the auditee cannot understand

awareness of the most common root causes,

(NCR) by the lead auditor? Should the lead

what the real gap is.

an auditor will be equipped to avoid most

auditor submit his or her report with or

without the disputed NCR regardless? What if

the auditee—such as a director or CEO—interprets the case according to his or her opinion

and sees there isn’t an NCR?

Ayad Mosab Al-Ani

Salalah Free Zone, Oman

• NC statements appear to be opinionbased rather than fact, failing to provide

sufficient evidence and references.

disagreements over NCs.

Obviously, an auditor’s soft skills, including

tact, reasoning and persuasion, are important.

• An opportunity for improvement is mis-

Having management commitment from the

classified as an NC. Inconsistent use of

auditing and auditee organizations, following

audit terminology and definitions is often a

auditing protocol, adequately planning and

rookie mistake.

preparing for the audits, offering solid value-

• The same finding is unnecessarily

added feedback, promptly verifying corrective

A: If your nonconformance (NC) is factual, has

repeated. An auditor who identifies a

actions, linking audit action effectiveness to

business impact and appropriately references

document control issue and counts sepa-

the organizational bottom line, and presenting

a standard or specification, you should not

rate NCs for the multiple areas in which it

the audit’s effectiveness to management will

drop the finding.

appears, for instance, will be perceived as

also help ensure a healthy audit management

It appears from the question that the

being interested in generating a number

process.

auditee may not have been aware of the NC

of findings rather than providing valuable

until the closing meeting. Don’t keep an NC a

surprise until the closing meeting. If the audit

feedback.

• Issues unrelated to the audit are

Even if the auditee is a high-profile individual, such as a director or CEO, the auditor

should stick to the task. During my audits, if I

is a multi-day event, you should discuss any

bundled with the findings. More often

am convinced of the importance of a finding, I

NCs with the auditee as you find them, ideally

than you would expect, auditors incorpo-

explain it to the auditee, outlining the benefits

during daily caucus meetings with the auditee.

rate known issues for the audit area into

of addressing the gaps and the risks of not

Discussing NCs before the closing meeting

the current audit report, using the audit as

addressing the gaps, and provide references

will provide the auditee an opportunity to

leverage to get things done. There is noth-

to support the NC. I also give the auditee the

clarify the situation or produce evidence.

ing wrong with verifying through samples

opportunity to explain any disagreement. If

Why would an auditee refuse to accept an

whether past issues are still potent and

the reason for objection is not supported by

NCR? The most common root causes are:

reporting them with evidence. Bundling

facts and evidence, I will let the finding remain,

• The audit finding is outside the scope

past issues without verification, however,

and the auditee will have to respond to it.

may cause auditee refusal.

Management should be counted on to respect

of the contract or audit. In the case of

supplier audits, the finding goes beyond

• There is no sign of continued or future

the agreed-on purchasing requirements.1 In

business. A particularly difficult supplier

the case of internal audits, the finding may

audit scenario can occur when an existing

be beyond the responsibility of the auditee

contract is near expiration and there has

function.

been no word on extension while the

• Addressing the NC would not add value, such as recreating missing paperwork

that has no value for the business.

• The auditee is not empowered to ac-

8

Other reasons will likely be as varied as the

personalities, character traits and capabilities

customer is auditing and issuing findings.

• Hostility between the auditor and auditee creates a strained, “gotcha” mentality.

• The auditor bullied the auditee into ac-

cept the findings. Auditees who are too

cepting a finding rather than convincing

junior in the organization’s hierarchy may

the auditee through careful and thorough

worry about the consequences for accept-

reasoning.

QP • www.qualityprogress.com

the integrity and value of the audit process,

upholding findings that are genuinely offered.

Govind Ramu

Director, quality assurance

SunPower Corp., San Jose, CA

reference

1.Govind Ramu, “Expert Answers: Information Collection,”

Quality Progress, March 2013, pp. 8-9.

Bibliography

Russell, J.P., “Exit Meeting,” chapter in The ASQ Auditing Handbook, third edition, ASQ Quality Press, 2005.

Russell, J.P. and Terry Regel, “Chapter 1: Reporting Problems,”

After the Quality Audit: Closing the Loop on the Audit Process,

second edition, ASQ Quality Press, 2000.

rs

Keeping customers happy

determined, they can be translated—using

by changes, running pilots, selecting team

Q: I’m developing a customer-oriented

tools such as critical-to-quality analysis—into

members who will participate, ensuring the

system for updating a service operation that

appropriate customer satisfaction metrics for

project has a sponsor and communicating to

allows managers to gather information, make

each category or segment.

all stakeholders.

changes in service delivery and assess the

More than likely, your customer satisfac-

Your organization may have a preferred

effects of these changes. How do I imple-

tion metrics will involve performance around

implementation approach that is already set

ment that in banking? What is the best way

on-time delivery, quality and subjective mea-

up with software and a database. It would be

to measure customer satisfaction based on

sures of performance, such as friendliness,

wise to make a few inquiries at the outset.

this approach? Which quality system should

product knowledge and helpfulness.

Which quality system?

I use? How do I develop a system framework

for updating these services?

Mahmoud Madgy

Dubai, United Arab Emirates

A: You have asked quite a few questions that

Achieving satisfaction levels

Again, without knowledge of your organiza-

Next, you must determine if your internal

tion, it is difficult to recommend a specific

processes help you meet all of the require-

quality system. Actually, a more basic ques-

ments and how capable they are of achieving

tion is, “Why do you feel the need to operate

the required levels of customer satisfaction.

within a quality system?”

will be difficult to answer in the short space

Where there are deficiencies in meet-

If your organization has already imple-

allotted. Perhaps I can, at least, point you in

ing requirements, processes must be either

mented a quality system, perhaps there is a

the right direction.

modified or new processes put in place.

natural fit for your service delivery system

Where processes are not capable, improve-

within that quality system. If so, I suggest you

ments must be made.

explore that avenue.

The framing of your questions indicates

the focus of your thinking is on the customer

and you are intent on building a closed-

Don’t be surprised to find gaps in require-

Otherwise, if no such system exists, you

loop system. This approach will provide a

ments and processes not capable. In my

might want to complete your service delivery

solid foundation for whatever method you

experience, many organizations never origi-

project before addressing a quality system

develop.

nally designed and built their service delivery

project. That way, you’ll be able to complete

processes with the intent of supporting cus-

your project in the event the organization

Measuring satisfaction

tomer satisfaction. Now that service delivery

does not have an appetite for taking on a

Several important considerations should be

is recognized as an important component of

quality system project. More specifically, if

addressed before you can begin to measure

customer satisfaction and a key differentia-

you must expand the scope of your service

customer satisfaction. These include:

tor—particularly in high transaction environ-

delivery project to include the building of a

• Categorizing and segmenting your cus-

ments—these processes are now receiving

quality system, you may never complete the

the attention they are due.

service delivery project. Keep the project

tomer base to better identify and align

customer requirements.

• Establishing a set of independent listening

scopes distinct and manageable.

Implementation approach

T. M. Kubiak

posts for each customer category or seg-

Without knowledge of your organization, it is

President

ment.

difficult to recommend a specific implemen-

Performance Improvement Systems

• Analyzing customer data obtained

through the listening posts to determine

tation approach.

However, there are basic elements of

customer requirements.

most implementations that I suggest you

After the customer requirements are

consider, such as: involving those affected

Asked and Answered

Submit your question at www.qualityprogress.com, or send it to editor@asq.org,

and our subject matter experts will help you find a solution.

Weddington, NC

Bibliography

Kubiak, T. M., The Certified Six Sigma Master Black Belt Handbook, ASQ Quality Press, 2012, pp. 148-156.

Kubiak, T. M. and Donald W. Benbow, The Certified Six Sigma

Black Belt Handbook, second edition, ASQ Quality Press,

2009, pp. 66-65.

Shipley, David, Carl W. Keller, James Bossert, Steven S. Prevette,

Duke Okes, Dale Crownover and T. M. Kubiak, “Multiple

Choice—What’s the Best Quality System?” Quality Progress,

July 2003, pp. 25-45.

June 2013 • QP

9

QUALITY COUNCIL OF INDIANA

CQIA

PRIMER

C

CSSBB

PRIMER

C

CQE

PRIMER

C

CQT

PRIMER

C

PRIMERS

CSQE

PRIMER

C

CMQ

PRIMER

C

CRE

PRIMER

C

LSS

PRIMER

C

CQI

PRIMER

CCT

PRIMER

C

C

CQA

PRIMER

CSSGB

PRIMER

C

CQPA

PRIMER

C

C

Our Primers contain study material for the current ASQ bodies of

knowledge plus sample questions and answers. The Primers may be

taken into the exam. The completeness of our materials makes them the most widely used texts for Certification Training.

SOLUTION TEXTS

Quality Council of Indiana offers detailed solutions to all

questions presented in the corresponding Primer.

CD-ROMS

QCI offers user-friendly interactive software to assist students preparing

for ASQ examinations. Each CD contains 1000 total questions.

Examinations are timed and summarized graphically. A help file provides

explanations and references. The CDs run on Windows XP and newer.

CQE

CSSGB

CQA

Mail Orders

Information

Fax Orders

Quality Council

812-533-4215

812-533-4216

of Indiana

Telephone Orders

Order Department

800-660-4215

602 W. Paris Ave.

Internet Orders

W. Terre Haute, IN 47885-1124

www.qualitycouncil.com

Juran’s

Quality

Handbook

Implementing

Six

Sigma

The Quality

Technician’s

Handbook

6th Edition

2nd Edition

6th Edition

The essential quality reference

for most ASQ exams

A great CSSBB reference

Great for CQT and CQI exams.

by Forrest W. Breyfogle, III

by Juran & De Feo

En Español

CSSGB

PRIMER

by Gary K. Griffith

Spanish

Green Belt

Quality

Dictionary

The Spanish version of the

CSSGB Primer.

by Tracy Omdahl

LSS Primer

RAM

Dictionary

More than 2500 definitions.

Great for any ASQ certification.

The Lean Six Sigma Primer is

written to a QCI BoK. There are

more case studies and lean content

than in any other QCI products. 400

questions are included. A solution

text is also available.

by Tracy Omdahl

Contains 2800 definitions.

Helpful for Reliability and

Quality Engineers.

ISO 9001 Internal

Auditing Primer

ISO Primer

by Bensley & Wortman

by Greg Wies & Bert Scali

A convenient book for training internal

auditors to the ISO 9001 expectations.

An instructor CD is available.

Reliability & Maintenance

Analyst CD

by Bryan Dodson

Solve your Weibull, reliability, warranty, Bayesian &

Maintenance, prediction & estimation problems.

Measurement Analyst CD

Performs all measurements required in the AIAG manual.

Contains ANOVA methods and excellent graphs.

Site and global license available!!!

Used by Chrysler, ITT, FedEx, Ford,

TRW, GM, HP, U.S. Postal Service

ISO

Presents a thorough treatment

of the ISO implementation and

documentation process.

There are generic manuals on

the CD.

Quality System

Handbook

by Edenborough

QSH

Details the selection,

organization, and writing

of quality documents.

The disk contains

procedures and work

instructions.

PERSPECTIVES

BY Andrew Kumiega, Michael Davis

and Ben Van Vliet

Bank on It

Ethics and quality will strengthen automated trading and finance

AUTOMATED TRADING, including high-

ers, mathematicians (usually called quants)

ness implies irresponsibility or imprudence.

frequency trading, now accounts for more

and computer engineers. Each specialty

But what constitutes prudence, or good

than 70% of daily trading volume.1 Though

has well-defined ethical standards. How-

faith, in automated trading system research

not everyone agrees, most academic studies

ever, like most new industries, the ethics at

and development? This is where ordinary

support the claim that automation benefits

the intersections or interfaces among these

regulation ends and the creation of new ethi-

the overall functioning of society and mar-

groups is still evolving. The intersection of

cal codes for automated trading begins.

kets.2-5 Automated trading tends to mitigate

the three professions gives rise to new ethi-

volatility, add liquidity and reduce transac-

cal issues at the organizational level.

Overregulation may stifle competition,

forcing a one-size-fits-all solution to such

problems. Because self-regulation is gener-

tion costs for all market participants.

A matter of ethics

ally thought to be more cost-effective than

occur every day without mistakes. The

In the age of automation, financial innova-

governmental regulation, the financial in-

proportion of incorrect trades is small.

tions—new strategies, methods of analysis,

dustry long ago established self-regulatory

However, automated trading systems oc-

execution venues, instruments, technolo-

organizations, such as exchanges and the

casionally do have quality problems due to

gies and data sources—are the ultimate

Financial Industry Regulatory Authority, as

various types of errors. These occasions

source of competitive advantage. How is

proxy regulators of their markets and mem-

have forced the industry to take stock of its

this innovation to be kept as socially useful

bers. Yet, even exchange regulations cannot

responsibilities to its shareholders, other

as possible? Given innovation’s rapid pace,

cross national borders without significant

market participants and society.

neither governmental nor exchange regula-

international coordination. Only ethics can

Consider what happened to Knight Capi-

tion can keep up. One of the problems—as

provide general principles and specific rules

tal last August. The firm lost $440 million in

John Boatright, professor at Loyola Univer-

that cross national borders, market cultures

less than 45 minutes when its new trading

sity in Chicago, points out— is that “people

and even professional disciplines.

software flooded the market with orders,

(in finance) believe that the task of creating

almost bankrupting the firm.6 Even such

and enforcing ethical rules and standards

exchanges (for example, NASDAQ, New

rare events may reduce investors’ appetite

is the job of legislatures and regulators,

York Stock Exchange and CME Group

Millions of computer-generated trades

As enablers of automated trading, the

not themselves.”7

Inc.) and even the off-exchange execution

No code, public or

venues, consider their ethical responsibili-

private, addresses

ties to include constructing fair markets,

overall ethical

helping to sustain confidence in them.

responsibilities in

As a starting point for fixing this problem,

automated trading

many authors point to the basic premise of

of the professional

Isaac Asimov’s Three Laws of Robotics: “a

groups that create

robot may not harm humanity, or, by inac-

and operate these

tion, allow humanity to come to harm.”8

automated systems.

Regulators are

beginning to address

One problem for ethics in automated

trading and finance is that market outcomes (as with all outcomes) are uncertain

for risk and thereby may cause the average

these ethical issues. For example, while the

and ambiguous. Yet, the best way to pro-

investor to not invest in the stock or futures

Securities and Exchange Commission and

duce the social benefits of free markets is

market. These rare events also invite the

the Commodity Futures Trading Commission

to foster market agents with a robust ethi-

public to view financial markets as casinos,

have long prohibited market manipulation,

cal framework that combines the ethics of

not capital allocation mechanisms.

they have recently lowered the bar to prov-

the various groups. An industrywide ethical

ing it from intent to recklessness. Reckless-

climate can determine how organizations

Automated finance brings together trad-

12 QP • www.qualityprogress.com

and professionals perceive problems,

has been prudent and that its automated

obligations to external stakeholders, and

trading systems function properly, are op-

techniques can provide a structure for un-

formal standards of right and wrong.

erationally safe, and are robust enough to

derstanding and solving the interdisciplin-

behave acceptably during extreme events.

ary ethical problems. Quality techniques

Quality and standards

Of course, the ability of automated

As a starting point, quality management

then can be employed to find solutions

To improve the ethical interface between

trading and finance firms to prove the

for root causes rather than (the industry’s

professions, other industries have turned

stability of their systems depends on the

current mode) containment of individual

to quality management standards. Quality

availability of execution-venue-simulation

outcomes.

is not only a software testing or statistical

facilities to fully test those systems. Such

framework, but also an ethical one (inso-

simulation facilities should provide testing

tures for organizational responsibility,

far as the standards in question are ones

against all manner of extreme market and

regulators can assess the rigor of research,

everyone in the relevant disciplines—at

infrastructure events.

development, operations and control with-

their rational best—want everyone else

Following ISO 9000-style standards tes-

Given formal decision-making struc-

out infringing on the secrecy of propri-

in those disciplines to follow, even if that

tifies to an automated trading firm having

etary trading strategies and their sources

would mean having to do the same).

satisfied its obligations to prove and docu-

of competitive advantage. QP

To be sure, many trading firms, execution venues and third-party vendors of

trading system components perform

ment trading strategies and technologies

that operate safely, reliably and profitably.

Such standards would mean the finan-

rigorous quality control over their pro-

cial industry is taking the lead in improv-

cesses—not strictly out of ethics, but from

ing its own management systems. The fed-

an understanding that a quality approach

eral government then should be less likely

to innovation is, in the end, the source of

to issue prescriptive regulations, allowing

competitive advantage. However, even

it to concentrate its surveillance efforts on

these systems can fail at the interfaces

the integrity of the trading organization as

because methodology has not been coordi-

opposed to the details of individual trad-

nated across professions.

ing systems. (That is how regulators have

Quality processes operationalize (in

responded to the aerospace industry’s

part, at least) an organization’s ethics. In

AS9100 standard.) Likewise, global indus-

the automated trading and finance indus-

try standards should present significant

try today, discussion of quality typically

opportunities for regulatory harmoniza-

focuses on specific guidance for improve-

tion across national boundaries.

ment of trading systems within the professional silos. But beyond simple software

Framing ethical problems

testing, quality in finance can include

To mitigate the possibility of a breakdown

all professionals—computer engineers,

in the global trading mechanism, the

quants and traders alike. automated finance-trading industry needs

The ISO 9000 family of standards—and

a global ethical framework. Properly fram-

its industry-specific derivatives—are the

ing the ethical problems will enable root

most widely recognized standards for a

cause analysis and long-term fixes, rather

quality management system (QMS). In

than short-term regulatory containments

other industries (where public safety must

of undesirable outcomes. A QMS standard,

be ensured), ISO standards define how

such as the (ISO 9000-style) AT 9000 proj-

firms ought to do business in, for example,

ect we are working on, should enable the

aerospace, chemicals, medical devices and

industry to address professional, organi-

food safety.

zational and industrywide responsibilities.

A similar standard for automated trad-

A broad ethical framework must ensure

ing and finance should include software

prudence without infringing on the neces-

and hardware testing that proves the firm

sary independence of trading firms.

REFERENCES

1.Jonathan A. Brogaard, “High Frequency Trading and Its

Impact on Market Quality,” Northwestern University, 2010,

www.futuresindustry.org/ptg/downloads/hft_trading.pdf.

2.Boyan Jovanovic and Albert Menkveld, “Middlemen in

Limit-Order Markets,” New York University, 2011, http://

papers.ssrn.com/sol3/papers.cfm?abstract_id=1624329.

3.Terrence Hendershott, Charles Jones and Albert Menkveld,

“Does Algorithmic Trading Improve Liquidity?” Journal of

Finance, 2011, Vol. 66, No. 1, pp. 1-33.

4.Terrence Hendershott and Ryan Riordan, “Algorithmic

Trading and Information,” NET Institute Working Paper

No. 09-08, 2011, www.im.uni-karlsruhe.de/upload/

publications/218bfa37-798e-44df-8ad3-8289af8a0920.pdf.

5.Frank Fabozzi, Sergio M.Focardi and Caroline Jonas, “HighFrequency Trading: Methodologies and Market Impact,”

Review of Futures Markets, special issue, Vol. 9, 2011, pp.

7-38, www.conatum.com/presscites/hftmmi.pdf.

6.Jenny Strasburg and Jacob Bunge, “Loss Swamps Trading

Firm,” Wall Street Journal, Aug. 2, 2012, http://online.wsj.

com/article/SB100008723963904438664045775647720839

61412.html.

7.John Boatright, ed., “Ethics in Finance,” Finance Ethics,

John Wiley & Sons, 2010.

8. Isaac Asimov, “Runaround,” Astounding Science Fiction,

March 1942.

ANDREW KUMIEGA is the director at a proprietary trading

firm. He is also an adjunct professor at the Illinois Institute of

Technology (IIT) in Chicago. He holds a doctorate in industrial

engineering from the University of Illinois in Chicago. An ASQ

member, Kumiega is a certified quality engineer, a quality

auditor and a software quality engineer. He is the co-author

of Quality Money Management (Academic Press, 2008).

MICHAEL DAVIS is senior fellow at the Center for the Study

of Ethics in the Professions and professor of philosophy at

IIT. He earned a doctorate in philosophy from the University

of Michigan in Ann Arbor. Davis has published more than

200 articles and chapters and authored seven books. His

most recent book is Code Writing: How Software Engineering

Became a Profession (Center for the Study of Ethics in the

Professions, 2009).

BEN VAN VLIET is an assistant professor at IIT’s Stuart School

of Business in Chicago. He holds a doctorate in management

science from IIT. He is an author or co-author of Quality

Money Management (Academic Press, 2008), Building Automated Trading Systems (Academic Press, 2006) and Modeling

Financial Markets (McGraw-Hill, 2004), and has published

several articles in the areas of finance and technology.

June 2013 • QP 13

keepingcurre

automotive

A New Path Forward

A

Toyota details strategy to improve design and production approach

After battling four years of setbacks—including global financial crisis, worldwide recalls,

an earthquake and a tsunami—Toyota Motor

Corp. in Japan, the company that brought

us the Toyota Production System and the

concept of lean manufacturing, is once again

introducing a new approach.

In late April, the organization’s president,

Akio Toyoda, provided details to Automotive

News about an overhauled R&D strategy he

hopes will help lift the automaker to sustained

growth and improve product development

efficiencies by 20 to 30%. Since taking over

as CEO in 2009, Toyoda’s focus has been to

make the organization less susceptible to the

external risks that have plagued the carmaker

during the past few years.

The new method is called the Toyota New

Global Architecture (TNGA), and it focuses

on simultaneous development of multiple

models and massive use of common parts.

The ultimate goal is to boost global sales to 10

million vehicles per year—a feat no carmaker

has accomplished to date.

“If you compare it to soccer, it’s like changing the field formation,” Toyoda said. “As the

head coach, I have changed us from a defen-

Mr. Pareto Head

By Mike Crossen

14 QP • www.qualityprogress.com

sive formation to an offensive one.”

While Toyota announced it was undertaking a new product development strategy last

year, this was the first time details had been

discussed. The first cars built using TNGA will

debut in 2015.

By increasing product development

efficiency, time and money savings will be

reinvested into new technology and designs,

better manufacturing processes and enhanced quality, said Mitsuhisa Kato, executive

vice president and global R&D chief.

Toyota will use more components made

to global standards rather than to proprietary

specifications, which should help in worldwide procurement from large suppliers and

reduce costs. Initially, cars under the same

platform will share 20 to 30% of their parts,

but Kato said the eventual goal is to commonize 70 to 80% of parts.

“Commonization is not new,” Kato said.

“But we are trying to push it to a higher level.”

Additional efforts to maximize efficiencies

include grouping future vehicles by launch

timing and engineering them simultaneously

to take advantage of commonalities. Before,

according to the Automotive News article,

planning was based on individual model without considering the big picture.

To speed R&D processes, in April the

company reorganized into four parts—Lexus,

Toyota-brand vehicles for mature markets,

Toyota-brand vehicles for emerging markets

and the Unit Center, which conducts R&D on

shared core technologies, such as engines

and transmissions.

Also in April, Toyota established new R&D

facilities at its Toyota City headquarters. The

facilities are designed to enhance collaboration among powertrain, prototyping and

production engineers. The facilities are also

equipped with a new aerodynamics lab and

a wind tunnel with a maximum speed of 155

mph. The wind tunnel uses a moving belt

under the cars that better simulates airflow

around a moving vehicle than if it were sitting

on a stationary platform.

With these improvements underway,

Toyoda is confident his organization can get

back on its feet, achieve its goals and sustain

its tradition of continuous improvement.

BIBLIOGRAPHY

Automotive News, “Toyota’s 10 Million Plan,” May

3, 2013, http://asq.org/qualitynews/qnt/execute/

displaySetup?newsID=15926.

nt

manufacturing

asq joins coalition focused on manufacturing

ASQ has joined the Smart Manufacturing Leadership

Coalition (SMLC), a public-private partnership developing platforms for experimentation of large development projects, or testbeds, and training for nextgeneration manufacturing technology platforms.

The SMLC was launched last July to drive improved

manufacturing efficiencies, reduce waste and integrate manufacturing intelligence in real time across an

entire production operation.

ASQ, which has been indirectly involved in SMLC initiatives for

months, recognized that SMLC efforts aligned well with ASQ’s longstanding role in manufacturing. ASQ said it hopes its subject matter

experts can help the coalition develop workforce training, tools and

innovations to implement breakthrough smart manufacturing technologies.

“The Smart Manufacturing Leadership Coalition has

its goals rooted in quality, which is helping companies

perform more efficiently with higher quality outcomes,” said ASQ CEO Paul Borawski. “We are excited

for the opportunity to share our resources with the

SMLC, accentuating quality through the development

and growth of the organization.”

“ASQ’s extensive knowledge in helping organizations increase efficiencies will be an asset to the

Smart Manufacturing Leadership Coalition as we continue to improve

manufacturing productivity,” said SMLC Chairman Dean Bartles. “We

are pleased to have ASQ as part of the SMLC, as both organizations

share the passion for improvement.”

As a member of the SMLC, ASQ joins companies such as Alcoa,

General Motors, Honeywell, Pfizer and Rockwell Automation.

asqnews

CALL FOR PRESENTATIONS ASQ

has issued a call for presentations

for the 2014 World Conference on

Quality and Improvement, which

will be held May 6-7 in Dallas. The

submission deadline is Aug. 2. For

more information, visit http://wcqi.

asq.org/2014/call-for-presentations/

index.html.

TEAM AWARD APPLICATIONS ASQ

is looking for teams to participate in

next year’s International Team Excellence Award process. The deadline

for intent to submit forms is July 1.

For more information, visit http://

wcqi.asq.org/team-competition/

timeline.html.

ASQ TO HOST TC 69 MEETING ASQ

will host the International Organization for Standardization (ISO) annual

meeting for members of Technical

Committee (TC) 69 on applications of

statistical methods June 3-7 in Mil-

waukee. Created in 1948, TC 69 has

representatives from 48 countries

and focuses on standardization in

the application of statistical methods, including generation, collection

(planning and design), analysis, and

the presentation and interpretation

of data. For information about ASQ

standards involvement, visit www.

asq.org/standards.

ASQ QUALITY INSTITUTE ASQ is offering a series of introductory quality

courses July 15-17 at its headquarters

in Milwaukee. The ASQ Quality Institute will feature training not normally available in classroom settings.

Courses include quality basics, integrated quality management, auditing

for improvement, failure mode and

effects analysis, and corrective and

preventive action. Visit www.asq.org/

promotional/milwaukee for details on

the courses, instructors and special

registration offers.

ASQ Journal

spotlight

Every month, QP

highlights an openaccess article from

one of ASQ’s seven

other journals. This

month, make sure you

read “Quantile-based

Optimization of Noisy

Computer Experiments

With Tunable Precision,” which appeared in

February’s edition of Technometrics. ASQ

co-publishes Technometrics four times a

year with the American Statistical Association.

The article, written by Victor Picheny,

David Ginsbourger, Yann Richet and Gregory

Caplin, addresses kriging-based optimization of stochastic simulators.

To access the article, click on the “Current Issue” link on Technometrics’ website:

http://asq.org/pub/techno. From there, you

also can find a link to information about

subscribing to the quarterly publication.

June 2013 • QP 15

keepingcurrent

Q

Who’s Who in

NAME: Timothy J.

Robinson.

RESIDENCE: Laramie, WY.

EDUCATION: Doctorate in statistics from

Virginia Tech in Blacksburg.

CURRENT JOB: Professor of statistics at the

University of Wyoming (UW) in Laramie.

INTRODUCTION TO QUALITY: A response surface methods

course taught by Raymond H. Myers at Virginia Tech and assisting

Myers with a short course on experimental design that Robinson

delivered at the Ethyl Corp.

PREVIOUS EXPERIENCE: Robinson worked as a high school

mathematics teacher in vastly different settings—inner city and

private school environments—before he decided to attend graduate school.

ASQ ACTIVITIES: Robinson is the Statistics Division’s chair for

student and early career grants for the Statistics Division’s Fall

Technical Conference.

OTHER ACTIVITIES: Robinson and his wife, Dawn, operate a small

statistical consulting company with contracts with the U.S. Fish

and Wildlife Service and the National Park Service. Previous clients

have included Merck, Southwest Airlines, Ethyl Corp., the New

Zealand Department of Conservation, and the American Samoa

Government’s Department of Marine and Wildlife Resources.

PUBLICATIONS: Robinson has had more than 40 peer-reviewed

manuscripts published. He is also the co-author of Generalized

Linear Models With Applications in Engineering and the Sciences

on a Generalized Linear Models, second edition (Wiley, 2010).

RECENT AWARDS: Robinson was included in the 2012 class

of ASQ fellows. He and his colleagues who presented “Multiple

Objective Pareto Frontier Optimization for Split-Plot Experiments”

received the Shewell Award for the best presentation at last

year’s Statistics Division Fall Technical Conference. Last spring,

he also won a UW Promoting Intellectual Engagement Award for

Classroom Teaching. In 2007, he received the John P. Ellbogen

Award for Meritorious Classroom Teaching, UW’s highest award

for classroom teaching.

PERSONAL: He and Dawn have four children, ages 2 to 12.

FAVORITE WAYS TO RELAX: Spending time with family, hunting

big game in Wyoming and hiking in the wilderness areas outside

of Laramie.

16 QP • www.qualityprogress.com

dateinqualityhistory

QP occasionally looks back on a person or event that made

a difference in the history of quality.

June 18, 1926

Philip B. “Phil” Crosby was born in

Wheeling, WV.

Crosby was a businessman and

author who contributed to management theory and quality management practices. He is widely recognized for promoting the concept of

zero defects and for defining quality

as conformance to requirements.

Crosby is credited with reinforcing the message to do things right the first time. He also

became well-known for acquainting quality professionals

with the following theories: The price of nonconformance is

a measure of poor quality; prevention is a means to eliminate quality problems; leadership is a requirement to make

progress, teamwork is the principle for work; and customer

requirements define the standard of quality performance.

Crosby’s first book, Quality is Free, has been credited in

part with igniting the quality revolution in the United States

and Europe. He wrote 13 books, including The Absolutes of

Leadership in 1996 and Quality and Me, an autobiography

published in 1999.

Crosby was diagnosed with and treated for esophageal

cancer in early 2001. A few months later, he developed adult

respiratory distress syndrome. His condition worsened, and

he died in August 2001.

WordtotheWise

To educate newcomers and refresh practitioners and

professionals, QP occasionally features a quality term

and definition:

Supermarket

A lean term meaning the storage locations of parts

before they go on to the next operation. Supermarkets are managed by predetermined maximum and

minimum inventory levels. Each item in the plant is at

a designated location.

SOURCE:

“Quality Glossary,” Quality Progress, June 2007, p. 57.

ASQ World conference

speaker: money isn’t always

the only motivator for workers

Indianapolis served as the backdrop to

ASQ’s 2013 World Conference on Quality

and Improvement, held in May. Thousands

of quality professionals from nearly 50

countries flocked to the Indiana Convention Center for a jam-packed schedule of

educational and networking opportunities,

keynote speakers and a bustling trade

show floor.

Highlights included opening keynote,

author Daniel Pink, who explained what

motivates people to act, and to do their

best work. Guess what? It’s not money.

He discussed the findings of a study

where results showed that tasks requiring

mechanical skills got better results where

there was greater monetary incentive

offered, but surprisingly, the results were

the opposite for tasks requiring “even

rudimentary cognitive skill.” Results, in

fact, were poorer the more reward that

was offered.

Pink referenced W. Edwards Deming’s

early teachings which addressed this subject: Deming said reward as a motivator

squeezes out a person’s intrinsic motivation over the course of their lifetime.

Money still motivates, of course. But

it’s not the core motivator. “Pay people

enough to take the issue of money off the

table,” Pink said.

“Management is a technology from the

1850s that was designed to get compliance,” he said. “We need some measure

of that in the workplace today, but what

we need is engagement. If you really want

engagement, you can’t manage into it.”

Examples of organizations finding ways

to create engagement included Facebook,

which allows new engineers to choose

which team they want to work with, and

FedEx, where employees are given a short

period of time each week where they can

work on whatever they want. It has led to

great innovation.

Finally, Pink discussed what the great-

est motivator is: each day, making progress

on meaningful work.

Karen Martin, Jamais Cascio, James

Melton and Sally Hogshead also gave

keynote or featured speaker presentations

during the three-day conference.

Awards and events

Other highlights of the conference included

the release of ASQ’s Global State of Quality

research and an accompanying panel discussion, with representatives from India,

Finland, Germany and the United States.

“The ASQ Global State of Quality

Research: Discoveries 2013” is the first

of three reports that will be released this

year. “Discoveries 2013” provides a first

view of the data, collected from nearly

2,000 organizations in 22 countries.

Future reports—due out in July and in

November during World Quality Month—

will provide deeper insights and greater

context to the findings.

Key findings? “There are significant gaps

in the governance and management models of quality, and the availability and use

of metrics in manufacturing and servicebased organizations worldwide,” according

to a press release.

“The ASQ Global State of Quality

Research: Discoveries 2013” report also

shows disparities between manufacturing and services in quality management

frameworks and training.

Also of note at the conference was the

always-engaging ASQ International Team

Excellence Awards. Argentina’s Telefonica

de Argentina and Thailand’s Pruksa Real

Estate Public Company Limited-QCI Team

were awarded silver-level status for increasing quality and financial savings.

In its 28th year, 32 teams from 10 countries competed for gold, silver and bronze

status.

No teams in this year’s awards process

earned gold-level status.

shortruns

THE QUALITY FUNCTION DEPLOYMENT

(QFD) Institute has issued a call for

papers for its 19th International Symposium on QFD, which will be held Sept. 6-7

in Santa Fe, NM. For more information,

visit www.qfdi.org/call_for_papers.html.

THE INTERNATIONAL ASSOCIATION for

Food Protection will hold its 2013 conference July 28-31 in Charlotte, NC. Registration and housing information is now

available at: www.foodprotection.org.

NOMINATIONS ARE BEING sought for

the 2013 National Institute of Statistical Sciences’ Jerome Sacks Award for

Outstanding Cross-Disciplinary Research.

For more information about the award,

visit www.niss.org/news/awards/

jerome-sacks-award-outstanding-crossdisciplinary-research.

WORLD ACCREDITATION DAY 2013 will

be celebrated around the globe on June

9. This year’s theme—Accreditation:

Facilitating World Trade—was selected

because it is relevant in developed

and developing economies. For more

information about the day and ways to

join the celebration activities, visit www.

ilac.org.

CORRECTIONs

In an article about his death, the state in which

Donald Feigenbaum resided was incorrectly

reported in the April 2013 edition of QP (“Donald

Feigenbaum Passes Away,” p. 17). Feigenbaum

resided in Pittsfield, MA, until he died of heart

failure in March. QP regrets the error.

In the May 2013 edition of QP, Huawei Technologies Co. Ltd. was inadvertently omitted from

the special section devoted to ASQ Enterprise

and Site Members (pp. 50-52). Huawei Technologies Co. Ltd. is currently one of ASQ’s Site

Members. ASQ apologizes for this oversight.

June 2013 • QP 17

To All

Corners

of Kenya

Project ensures a reliable

supply chain provides

medicines to people

with HIV/AIDS

In 50 Words

Or Less

• Kenya Pharma is a $550

million USAID-funded

project implemented by

Chemonics International, which delivers drugs

to people with HIV/AIDS

throughout the African

country of Kenya.

• The project uses an

ISO 9001 approach to

improve and solidify

supply chain activities

and ensure medicines

are provided to Kenyans

affected by the disease.

by Tiffany Darabi

case study

EFFECTIVE SUPPLY CHAINS deliver products on schedule and within budget to customers. Those customers shouldn’t have to think about the behindthe-scenes process or worry about whether the goods will be delivered on time.

The ISO 9001 requirements for building a quality management system (QMS) provide a framework for business operations that capture the intricacies of supply chain

processes while simultaneously providing a method for improving operations.

A prime example of using an ISO 9001 approach to supply chain management can

be seen in the ISO 9001-certified Kenya Pharma project,

funded by the U.S. Agency for International Development

(USAID) and implemented by Chemonics International,

a development company based in Washington, D.C.

THE SKIPPER OF a taxi boat, along with his young helper, navigate

the waters of Lake Victoria to reach Mfangano Island to deliver

supplies to the Sena Health Center.

(All photos courtesy of Chemonics International)

June 2013 • QP 19

Kenya Pharma ensures a reliable supply of high-qual-

Setting the stage

ity, low-priced pharmaceutical commodities for people

Kenya Pharma operates a demand-driven (pull) distribu-

with HIV/AIDS in Kenya. The project’s customers are

tion system with 169 facilities submitting orders to the

children and adults, including pregnant women, from

central warehouse. In partnership with DHL-Kenya for

some of the poorest and most remote regions in the

distribution and with Phillips Healthcare Services Ltd.

country. The ability of the project to operate a success-

for warehousing, Kenya Pharma effectively engages the

ful supply chain is fundamentally about serving people—

private sector in the developing world to deliver results.

much more than just being a business proposition—because it is quite literally a matter of life or death.

Through a hub-and-spoke distribution network, the

169 ordering points supply 626 antiretroviral therapy

The decision to implement an ISO 9001-certified

(ART) dispensing points, which generally provide a full

QMS was driven by the desire to create a systematic ap-

range of HIV/AIDS prevention, treatment and care ser-

proach for supply chain practices to ensure continual

vices. The ordering points also supply an additional 654

improvement of services to the Kenyans served across

dispensing points that provide only prevention of moth-

the 225,000-square-mile country.

er-to-child transmission (PMTCT) services.

ISO 9001 certification process

/ figure 1

Chief of party

Participates in meetings with the registrar

and ensures that project staff are also

available to meet with registrar as needed.

Launch

(April 5, 2012)

Get ISO 9001

certified

(July 2012)

Management representative

Manages schedule of auditor and staff.

Process leaders

Speak knowledgeably about role

as reflected in quality management system

(QMS).

All staff

Speak knowledgeably about role

as reflected in QMS.

Internal

audits

(May 21-24,

2012 and at

least annually

after that)

Follow processes.

Keep records.

Suggest improvements.

Chief of party

Oversees selection of internal auditors. Oversees

audits to ensure they are done according to

ISO 9001 requirements.

Management representative

Ensures training of internal auditors. Schedules

and oversees internal audits.

Process leaders

Make available at least one member of each

team to participate in internal audits.

Internal auditors

Conduct and report audit results and identify improvements.

All staff

Prepare for and participate in audits.

20 QP • www.qualityprogress.com

Management

review

(June 11-14,

2012, and at least

annually after that)

Certification

assessment/

periodic

reviews

(Certification

assessment

occurs every

three years; periodic

review occurs

annually)

Chief of party and senior staff

Meet at least annually to review data, quality policy

and quality objectives. Identify corrective and

preventive actions to ensure effectiveness of QMS.

Management representative

Aggregates continual improvement and internal audit

data for analysis and facilitates management reviews.

Process leaders