Densel Baltic OÜ Location: Tallinn, Estonia

advertisement

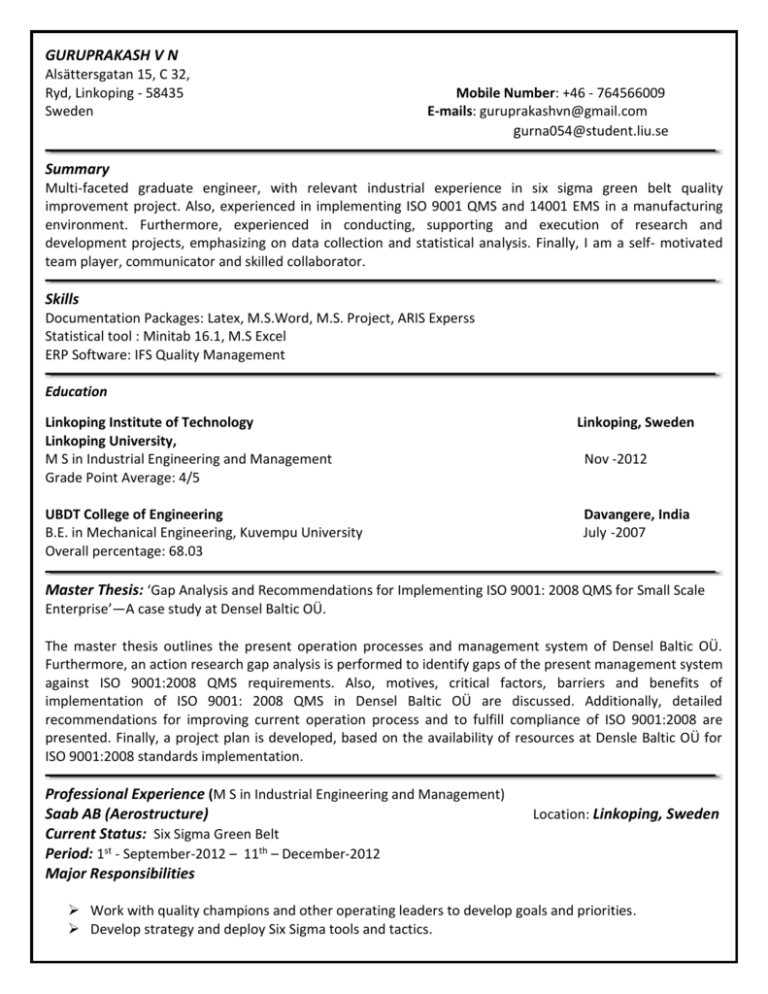

GURUPRAKASH V N Alsättersgatan 15, C 32, Ryd, Linkoping - 58435 Sweden Mobile Number: +46 - 764566009 E-mails: guruprakashvn@gmail.com gurna054@student.liu.se Summary Multi-faceted graduate engineer, with relevant industrial experience in six sigma green belt quality improvement project. Also, experienced in implementing ISO 9001 QMS and 14001 EMS in a manufacturing environment. Furthermore, experienced in conducting, supporting and execution of research and development projects, emphasizing on data collection and statistical analysis. Finally, I am a self- motivated team player, communicator and skilled collaborator. Skills Documentation Packages: Latex, M.S.Word, M.S. Project, ARIS Experss Statistical tool : Minitab 16.1, M.S Excel ERP Software: IFS Quality Management Education Linkoping Institute of Technology Linkoping University, M S in Industrial Engineering and Management Grade Point Average: 4/5 UBDT College of Engineering B.E. in Mechanical Engineering, Kuvempu University Overall percentage: 68.03 Linkoping, Sweden Nov -2012 Davangere, India July -2007 Master Thesis: ‘Gap Analysis and Recommendations for Implementing ISO 9001: 2008 QMS for Small Scale Enterprise’—A case study at Densel Baltic OÜ. The master thesis outlines the present operation processes and management system of Densel Baltic OÜ. Furthermore, an action research gap analysis is performed to identify gaps of the present management system against ISO 9001:2008 QMS requirements. Also, motives, critical factors, barriers and benefits of implementation of ISO 9001: 2008 QMS in Densel Baltic OÜ are discussed. Additionally, detailed recommendations for improving current operation process and to fulfill compliance of ISO 9001:2008 are presented. Finally, a project plan is developed, based on the availability of resources at Densle Baltic OÜ for ISO 9001:2008 standards implementation. Professional Experience (M S in Industrial Engineering and Management) Saab AB (Aerostructure) Current Status: Six Sigma Green Belt Period: 1st - September-2012 – 11th – December-2012 Major Responsibilities Location: Linkoping, Sweden Work with quality champions and other operating leaders to develop goals and priorities. Develop strategy and deploy Six Sigma tools and tactics. Work with operating leaders and teams to assess Six Sigma opportunities for Saab and its suppliers. Work with cross-functional teams to identify and implement process improvements opportunities. Facilitates suppliers in the proper use of statistical process control. Participating lean manufacturing activities and ensure progress while tracking project status. Process mapping of composite box assembly, data collection and statistical analysis. Participation in process and project FMEA of aileron assembly line. Communicate progress, status and issues of Six Sigma project to champions and business leaders. Internship Densel Baltic OÜ Period: 1st - March- 2012 – 20th -August-2012 Position Held: Quality Engineer Major Responsibilities Location: Tallinn, Estonia Supporting implementation of ISO 9001:2008 QMS and ISO 14001: 2004 EMS. Documentation of quality policies, quality manual and operation procedures. Documentation of environmental policies, objectives, aspects and operational control. Perform various process and product quality audits. Development and implementation of CAPA, FMEA and quality control plans. Contribute to the implementation and use of quality tools. Participation in implementation of 5S and visual control work place organization. Developing ‘Lean coaching’ materials and training seminars. Professional Experience (B.E. in Mechanical Engineering) Structure Laboratory, IISc Location: Bangalore, India nd th Position Held: Research Assistant (02 -Feb-2008 – 12 -Aug-2010) Project Title: Denoising of Vibration Signal from Mechanical System using Weighted Recursive Median (WRM) Filters. Major Responsibilities Conducting vibration experiments and collection of data. Statistical analysis of data. Simulation of fixed length WRM filters for denoising vibration signals. Optimization of integer weights for varying length of WRM filters. Supplier development and material purchasing activities. Documentation of results and presentation. Centre for Cryogenic Technology Position Held: Project Assistant (02nd -Aug-2007 – 02nd -Nov-2007) Project Title: Development of smart sensors based on Mixed Metal Oxide Semiconductor (MMOS) for Carbon Monoxide and Hydrogen Detection. Major Responsibilities Preparation and conducting Sputtering experiment. Process capability analysis and testing of thin film substrate. Maintenance of liquid nitrogen plant. Supplier development and material purchasing activities. Knowledge in GD & T symbols and their interpretation. Documentation of results and presentation. Membership: American Society for Quality (ASQ) Student Member. Certification: Certified Six Sigma Green Belt Scholarship: ERASMUS Scholarship, Linköping University, Linköping, Sweden Hobbies: Running, Travelling, Cycling, Swimming, Playing volleyball. 2012 Personal Details Date of Birth: 16/07/1985 Nationality: Indian Sex: Male Language: English, Hindi, Kannada, Swedish (A1). Availability: 15-December-2012 References: Provided on request. I, hereby declare that the information given above is true to the best of my knowledge and belief. Date: 13-December-2012 Place: Linkoping , Sweden Guruprakash Veerana Naikod