PHOTOVOLTAIC

DSS™850

Crystalline Growth System

Increased Throughput Improves Productivity by 65 Percent

The GT Advanced Technologies DSS™ 850 is the newest member of the

industry’s leading family of DSS crystallization systems. The DSS850 sets a

new standard for cost-effective, precisely controlled crystalline ingot growth

and helps customers achieve lower cost of ownership and better ingot quality.

The DSS850 can grow significantly larger silicon ingots averaging 800 kg

resulting in 65 percent more output, while reducing consumable costs and

optimizing the wafer- slicing process. The design of the DSS850 will support

MonoCast™ crystal growth that offers a path to higher quality material.

GT Advanced Technologies is committed to delivering sustained value to

customers and the DSS850 delivers on this promise. Customers who operate

DSS™450, DSS™450HP and DSS™650 systems can easily upgrade their

furnaces to take advantage of the improved throughput of the DSS850.

Key Benefits:

•Furnace Output >11.5 MW per year (assumes 17% efficiency from

156 mm cell lines)

•Ingot size: 100 x 100 cm2

•Ingot weight: Typical 800 kg

•Mass ingot yield (MIY) ≥73 percent

•Cycle time ≤76 hours

•Bottom-load process chamber: adds operating convenience

•Automated and guaranteed process

•Patented crucible-coating process

•Lowest cost of ownership

•>3,200 systems of experience ensures trouble-free production ramp

Growth Begins Here™

GT Advanced Technologies’

unmatched expertise in crystal

growth processes, mechanical

design, vacuum and high-pressure

chambers, control system design,

and crystal growth modeling,

provides customers with a

technologically advanced system.

PHOTOVOLTAIC

DSS850 Crystalline Growth System

Service Commitment

Lower the Cost of Wafer Operations

GT Advanced Technologies is

The DSS850 furnace produces the industry’s largest high-volume production ingots

comprised of 36 bricks. PV manufacturers may also be able to lower the cost of

wafer operations because the taller bricks help to optimize and improve the

use of the wafer saw beam to minimize waste and improve the amount of good

wafers produced.

dedicated to delivering the

highest levels of satisfaction

in the implementation of our

processes and equipment.

We respond to the needs of

our customers with proven

solutions, comprehensive

training and support.

About GT Advanced

Technologies

GT Advanced Technologies Inc.

(NASDAQ: GTAT) is a diversified

technology company with

As a leading provider of PV manufacturing technology and services with over 3,200

DSS systems in the field, GT Advanced Technologies ensures a low-risk ramp to

volume production and a high return on investment.

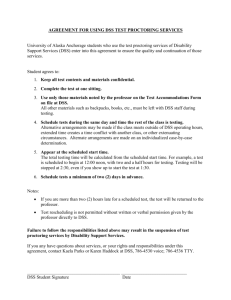

Typical System Dimensions* and Utility Requirements

Dimensions: W x L x H

Ceiling height

Power for entire system

Power factor

Cooling water

Argon

Weight approx.

3823 mm x 4774 mm x 5105 mm (151” x 188” x 201”)

6,000 mm (236”)

200 kVA, 380-480V, 3 Ph, 50/60 Hz

Avg 0.90

125 to 135 liters/min at 3.4 to 3.8 bar

95 m3 per ingot

11,200 kg (24,640 lb)

innovative crystal growth

Required Ceiling Height to Remove Dip Rod

global solar, LED and electronics

Staircase Landing

(detachable)

equipment and solutions for the

5,105 mm

industries. Our products

6,000 mm

4,774 mm

accelerate the adoption of new

advanced materials that improve

Chamber

Closed

3,070 mm

performance and lower the cost

3,823 mm

of manufacturing.

*Dimensions shown are exemplary. Mezzanine can be customized or supplied by customer.

Worldwide Headquarters

20 Trafalgar Square, Nashua, NH 03063 (USA)

Phone: +1 603.883.5200 Fax: +1 603.595.6993

www.gtat.com

PV Equipment Sales & Service

243 Daniel Webster Highway

Merrimack, NH 03054 (USA)

Phone: +1 603.883.5200

Fax: +1 603.595.6993

EquipmentSales@gtat.com

Regional Sales Offices

Hong Kong

Korea

Shanghai

Taiwan

Worldwide Product Support

24/7 Hotline: +1.855.425.4828

ProductSupport@gtat.com

© 2013 GTAT Corporation. All rights reserved. Subject to change without notice. The GT logo, DSS and MonoCast are trademarks of GTAT Corporation.

DS.PHOT.41113