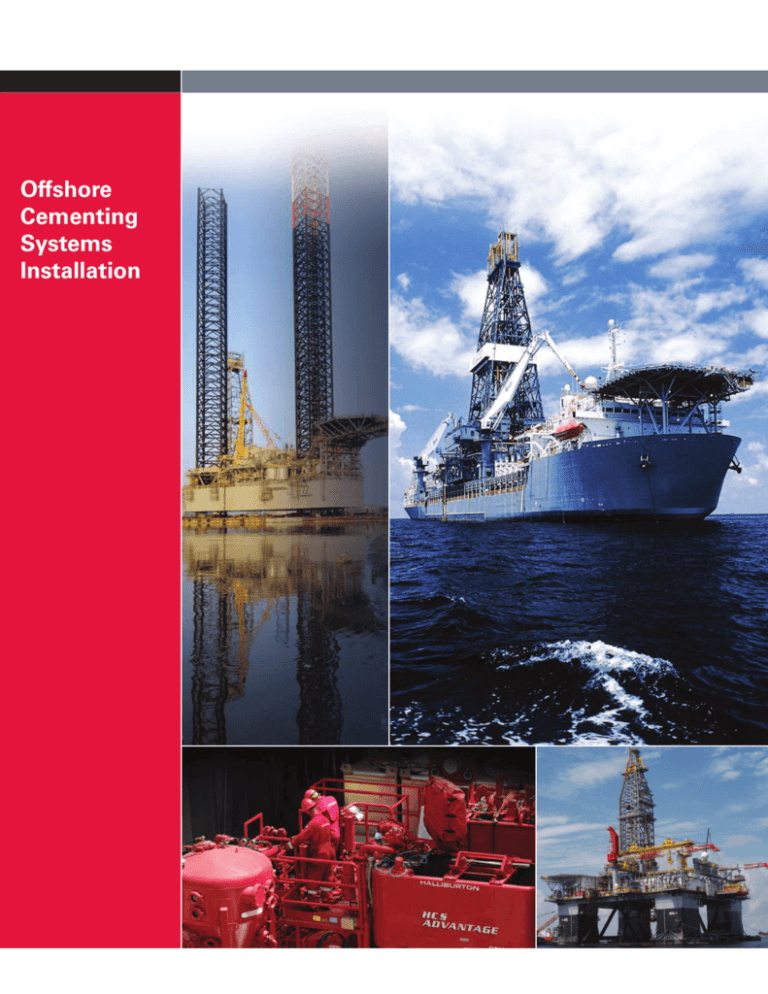

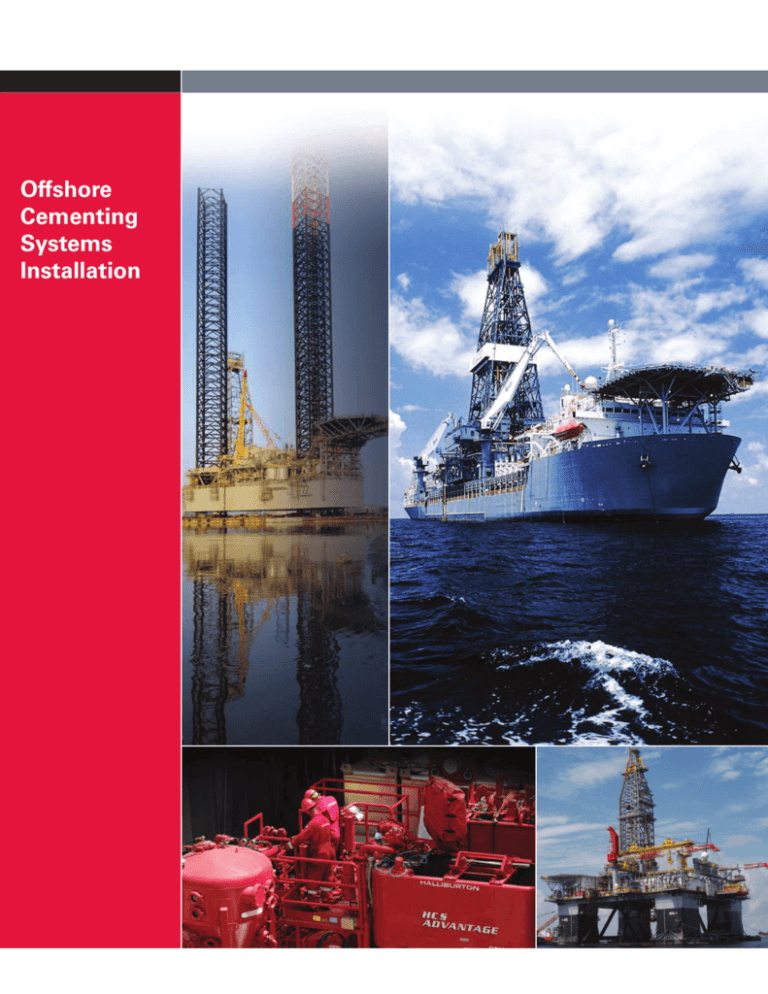

Offshore

Cementing

Systems

Installation

Primary Cementing Services

What is composed of many specially engineered components that

technicians assemble into a functional system that accomplishes

a specific job, often in hostile environments?

That’s right, Halliburton Offshore

Mixing and Pumping Systems

From tidelands to shelf to deepwater — Halliburton first

cemented wells in the Gulf of Mexico tidelands in 1938,

using barge-mounted equipment. In 1947, as drilling

contractors ventured offshore, they did so with skid

units developed by Halliburton. e pattern continues

with Halliburton equipment serving on every type of

offshore rig.

Today, shipyards around the world are building new

rigs and refitting existing ones to meet the growing

demand. Halliburton is building units to meet the

demand.

HAL 30494

2

Standard Yet Modular

From the day an offshore rig is constructed or refitted to the day the well begins producing, everyone is on a clock. Countless components must

come together to create a smoothly functioning drilling rig, whether it is a cantilever jackup for deep-shelf work or a drill ship designed for

ultra-deep water, every assembly and component has a job to do. Regardless of whether it is small and simple, like a water-tight hatch, or large and

complex, like the liing apparatus or the global positioning system, it would not be on the rig if it didn’t have a job to do and it wouldn’t stay if it did

not perform well. When the rig reaches the drilling location, everything, including the cementing equipment, must be ready to start working –

flawlessly, and for as long as needed.

Halliburton designs, manufactures, stages and installs mixing,

pumping and pneumatic bulk-handling equipment with three

purposes constantly in mind:

• Quick and efficient installation

• Safe, reliable and effective operation

• Life-of-the-well zonal isolation

Our install operations group works with the contractors to comply

with their schedules while integrating with the many activities

that are taking place onsite. Halliburton has dedicated installation

teams in China, Korea, Singapore and the United States.

HAL 30495

Staging and Installation

Halliburton cementing equipment must take its place within the larger complexity of the rig itself, and to make sure this happens, Halliburton

preinstalls the several pieces that comprise an offshore cementing system.

Cementing skids are large and complex systems that include several diesel engines or electric motors, powerful pumps, and complex electronic

mixing and control systems. Staging ensures that the actual installation can take place as designed.

We stage the major components in our global

strategically located service centers ...

HAL 30498

HAL 30492

HAL 30497

Halliburton install crews preplan and fabricate fluid and pneumatic lines, sound enclosures and electrical connections to match the actual

installation on the rig. Doing so lessens surprises and subsequent delays during the actual installation.

... and fabricate connections to minimize

delays during the installation on the rig ...

... so that our system is ready when the rig is.

3

Halliburton Offshore

Cementing Skids

Safe, reliable and effective operation depends upon the

dependability of each component. Halliburton’s HCS

Advantage™ cementing skids are powerful units that

comprise six modules joined together to provide

improved mixing, pumping and environmental

performance.

e modular design helps reduce the amount of time and

cost required to install on offshore drilling rigs. e

modular design also provides greater flexibility since it

can be adapted to meet the operator’s exact power-train

configuration. Each module is tested and certified as

built and commissioned as a complete system, as is the

complete system upon installation.

HAL 30488

HAL 30490

HAL 24153

Halliburton skids are certified by ABS and DNV for Safe

Area or Zone II hazardous area classification.

HAL 30487

4

Shown here is a typical installation

of Halliburton’s offshore HCS

Advantage cementing equipment

system. Actual hookups vary

depending upon the rig. e

Halliburton system’s major

components include:

• Mixing/pumping unit

• Continuous metering (liquidadditive) system

• Steady flow separator

• Pneumatic bulk delivery system

HAL 30493

HAL 30500

HAL 30499

5

HCS Advantage™ Cementing System

Today's most intelligent cement mixing system offers more advantages than ever before.

• Enhanced environmental performance including sound

abatement, vibration control and dust control

• RCM® IIIr mixing system is proven worldwide and used by

more operators than any other mixing system

• Conforms to ISO 9001 quality standards and is built under the

Halliburton Equipment and Product Organization's certified

quality management system

• Automatic Density Control® (ADC® ) mixing equipment to

provide consistent, precise density control for the cement slurry

• Unprecedented data acquisition capability using Halliburton's

CompuPacTM system

• Designed for offshore and certifiable for Zone II hazardous

operations

• Modular construction for faster and easier installation, and

adaptability to power train requirements

• Reliability through complete manual backup to help assure job

completion, either electronically or manually.

• e HCS Advantage cementing system is type certified by

ABS-CDS and DNV.

• Designed for hazardous installation, the HCS Advantage system

can be made suitable for Gas Group IIA, Temperature T3.

HAL30882

6

Training and Support

Safe, reliable and effective operation is an

imperative for Halliburton. On offshore drilling

installations, the cementer operating the

equipment is trained to achieve the best

cement placement possible.

Halliburton trains cementers on full-scale

simulators in training centers strategically

located globally.

HAL 30491

HAL 30489

Cementers are trained in the safe and efficient operation of each of the modules

that make up a Halliburton offshore cementing system. Process Logic Control

(PLC) technology assists the cementer in providing accurate and successful

slurry delivery.

HAL 30503

And the ultimate purpose is life-of-the-well zonal isolation.

HAL 30502

Halliburton has engineered solutions to meet every requirement – from time-bound shallow-water flow and gas-migration remedies to

multi-tiered react-and-respond cementing systems that are designed to survive planned and unplanned stresses on the well for years to come.

7

© 2010 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the

terms and conditions contained in the contract between Halliburton and the customer that is applicable to the sale.

H06680 8/10

www.halliburton.com